Laser measuring device and measuring method

A technology of laser measurement and laser head, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as large errors in measurement results, and achieve the effects of ensuring constant accuracy, improving work efficiency, and reducing rotation angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

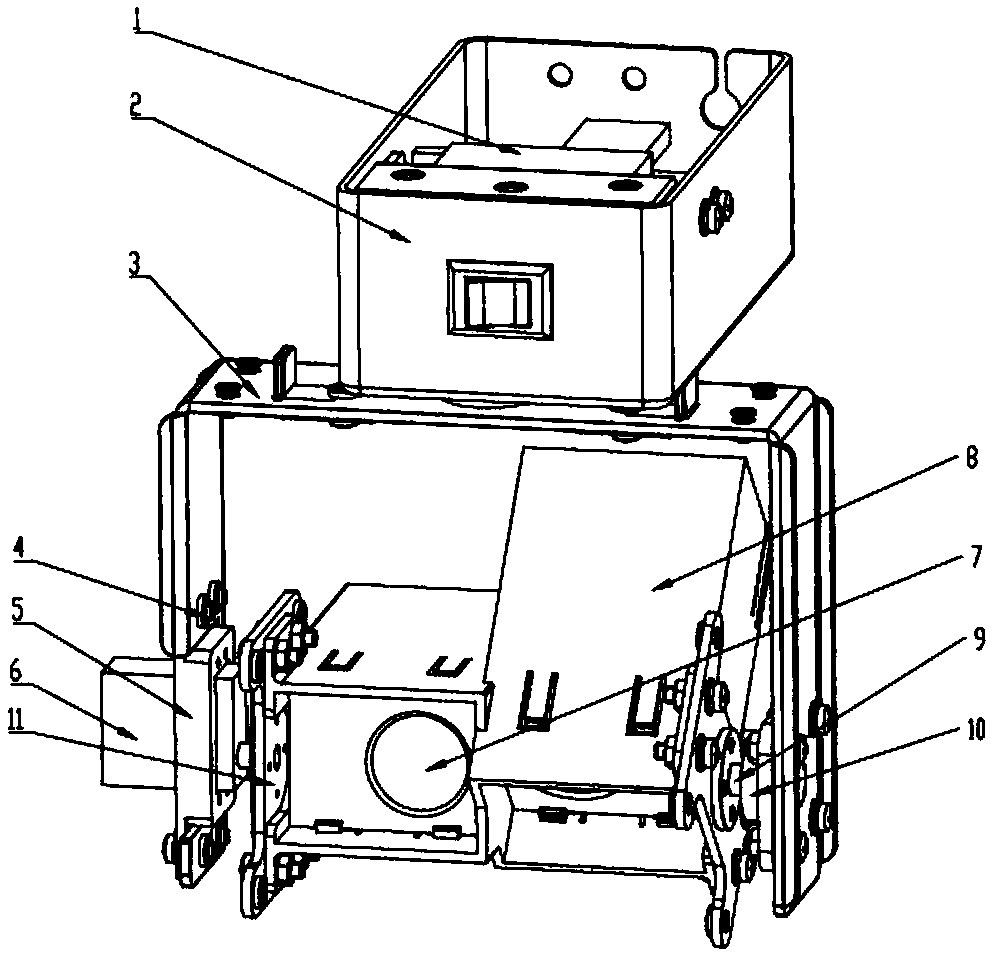

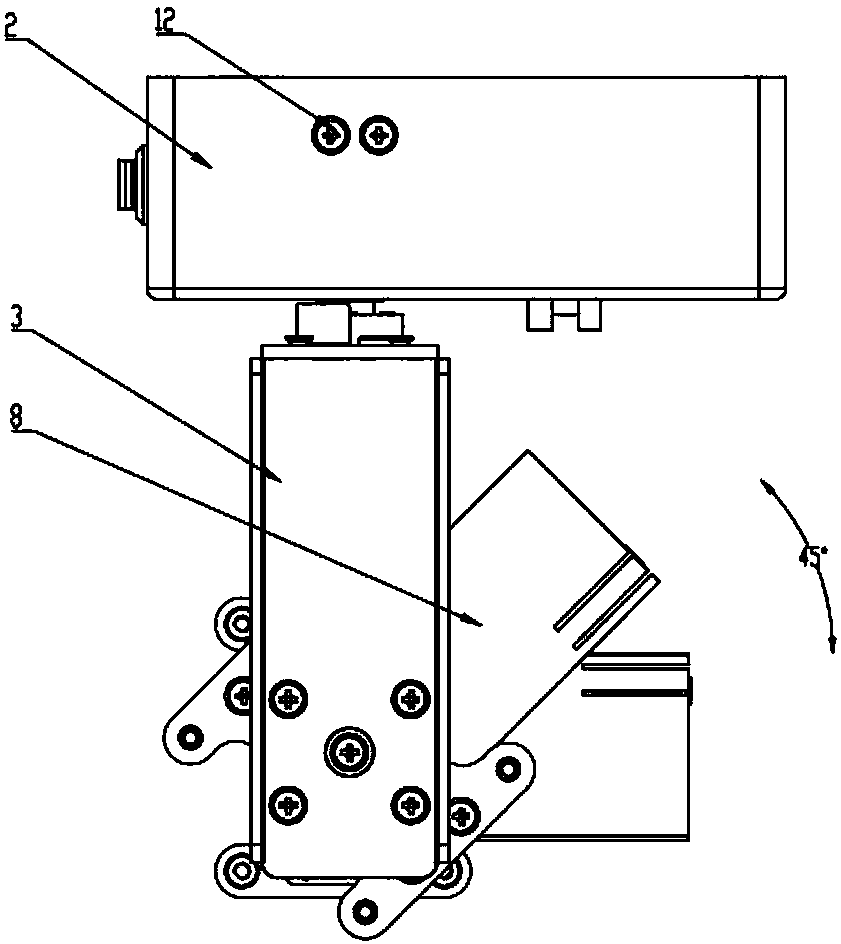

[0059] Such as Figure 1-Figure 3 As shown, the present embodiment provides a kind of laser measuring device, wherein, comprise laser emission mechanism, vertical rotation mechanism, horizontal rotation mechanism and support 3, vertical rotation mechanism, horizontal rotation mechanism and laser emission mechanism are installed on the support 3, vertical The rotating mechanism is connected with the laser emitting mechanism and drives the laser emitting mechanism to rotate, and the horizontal rotating mechanism is connected with the bracket 3 and drives the bracket 3 to rotate,

[0060] Whenever the horizontal rotation mechanism drives the bracket 3 to rotate from the horizontal initial position to the horizontal end position, the vertical rotation mechanism drives the laser emitting mechanism to rotate a predetermined angle from the current position in the vertical direction.

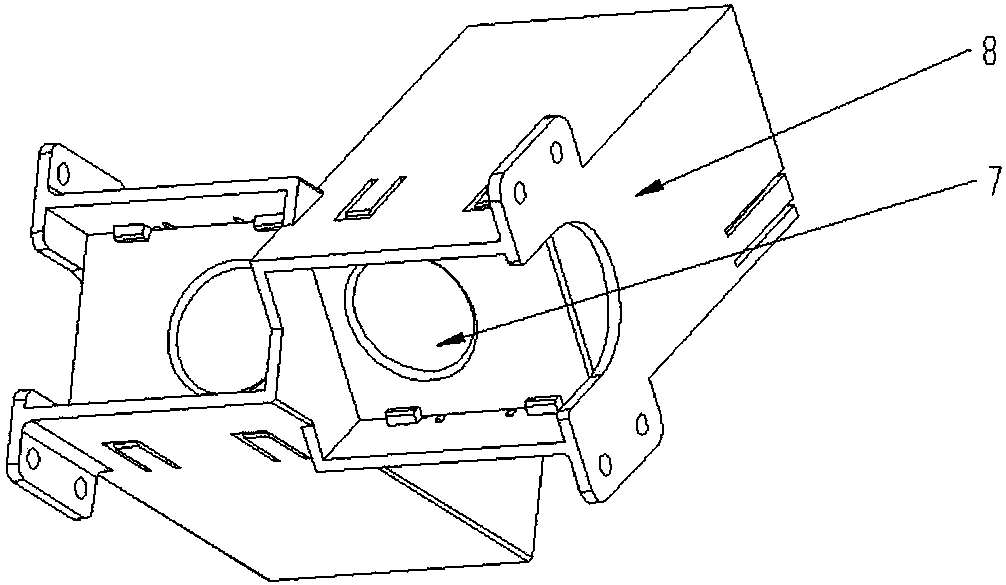

[0061] The laser emitting mechanism includes two laser heads 7, the laser heads 7 are installed in t...

Embodiment 2

[0099] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0100] The laser emitting mechanism includes three laser heads 7, the laser heads 7 are installed in the laser head bracket 8, the included angle between the three laser heads 7 is 30°, and the sum of the included angles of the three laser heads 7 is 90°.

[0101] The laser measuring device of the example of the second embodiment is installed on the top of the measured space through the control box 2, and after the suspension of the laser measuring device is completed, the horizontal rotation mechanism drives the bracket 3 to rotate on the horizontal plane, and the vertical rotation mechanism drives the laser emitting mechanism to The scanning measurement work on a vertical plane can be completed by turning down 30°.

[0102] Compared with the prior art that requires a laser head to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com