Testing device for quantizing volume of gas produced in battery and testing method

A technology for testing devices and battery casings, applied in the direction of volume measuring instruments/methods, measuring devices, measuring capacity, etc., which can solve problems such as poor sealing and invalid test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

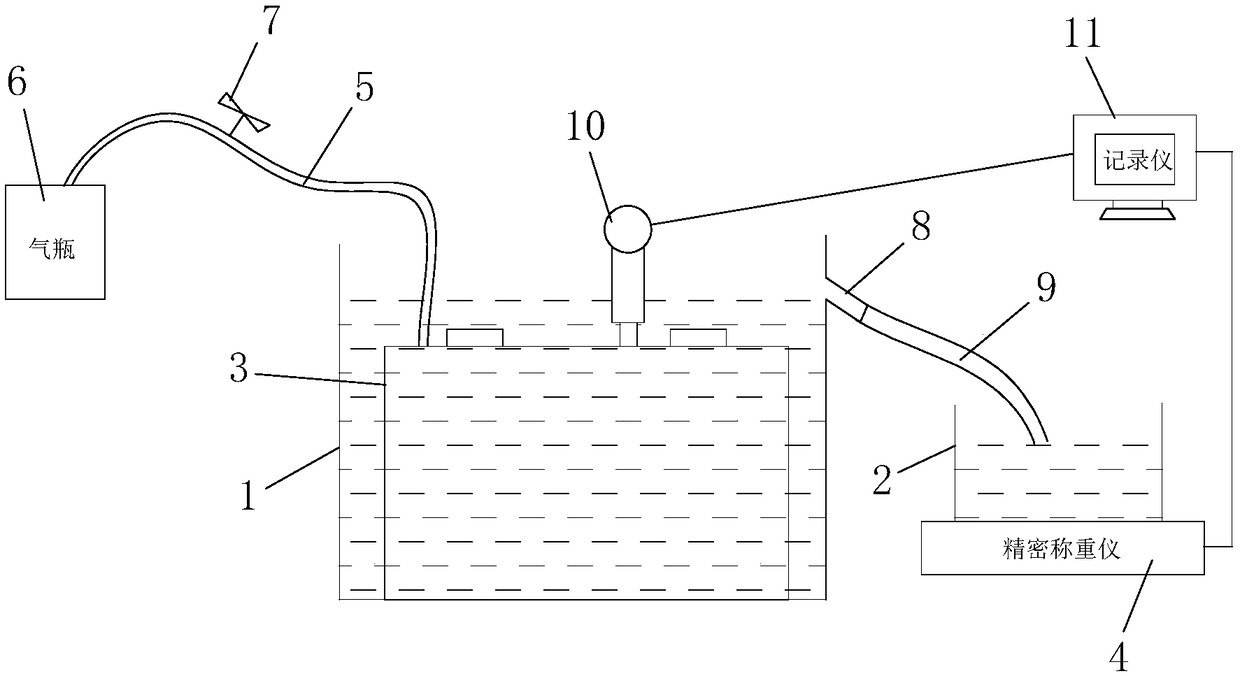

[0034] Such as figure 1 A test device for quantifying the volume of gas produced inside a battery is shown, including a first water tank 1 and a second water tank 2 respectively filled with deionized water. The deionized water can avoid short circuit when the battery is put in; the first water tank 1 A square test battery 3 is placed, the second water tank 2 is placed on the precision weighing instrument 4, the liquid injection hole of the test battery 3 is connected to the gas cylinder 6 through the gas pipe 5, and the gas flow meter 7 is arranged on the gas pipe 5, and the test The battery 3 is provided with an internal pressure sensor 10 communicating with it, and the internal pressure sensor 10 and the precision weighing instrument 4 are both connected to a data recorder 11 .

[0035] The side wall of the first water tank 1 is provided with a glass protruding head 8 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com