Method and device for measuring diaphragm closed pore temperature and broken film temperature of lithium ion battery

A lithium-ion battery, closed-cell temperature technology, used in measuring devices, electrical devices, thermometers, etc., can solve problems such as safety hazards, diaphragm suppliers have not provided the diaphragm temperature range, testing, etc., to achieve the effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

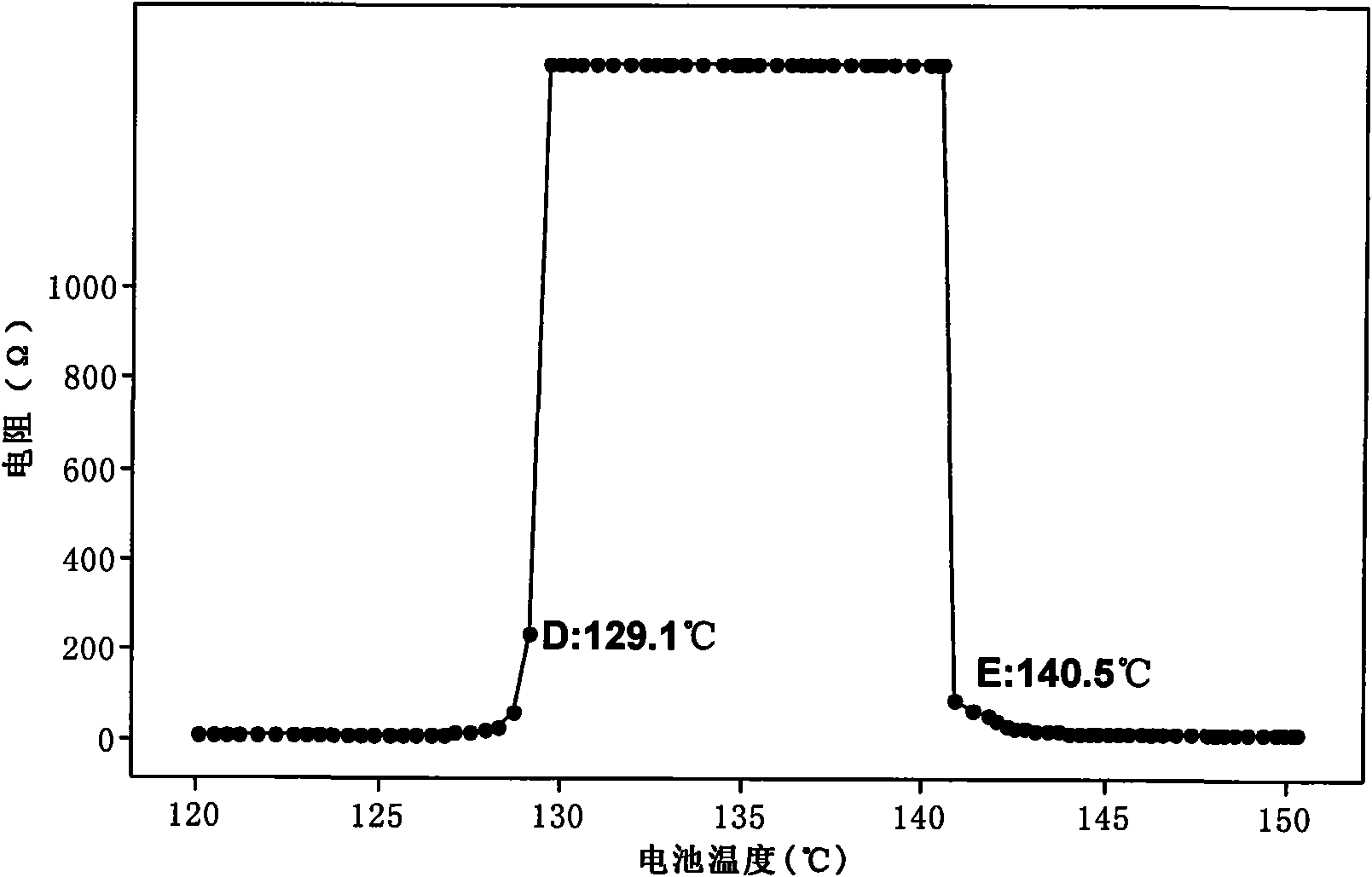

[0021] The invention provides a kind of test method of lithium-ion battery diaphragm closed-cell temperature and rupture temperature, in this example, the diaphragm sample of manufacturer A of commercially available PE (polyethylene) material is tested, and it is characterized in that comprising the following steps:

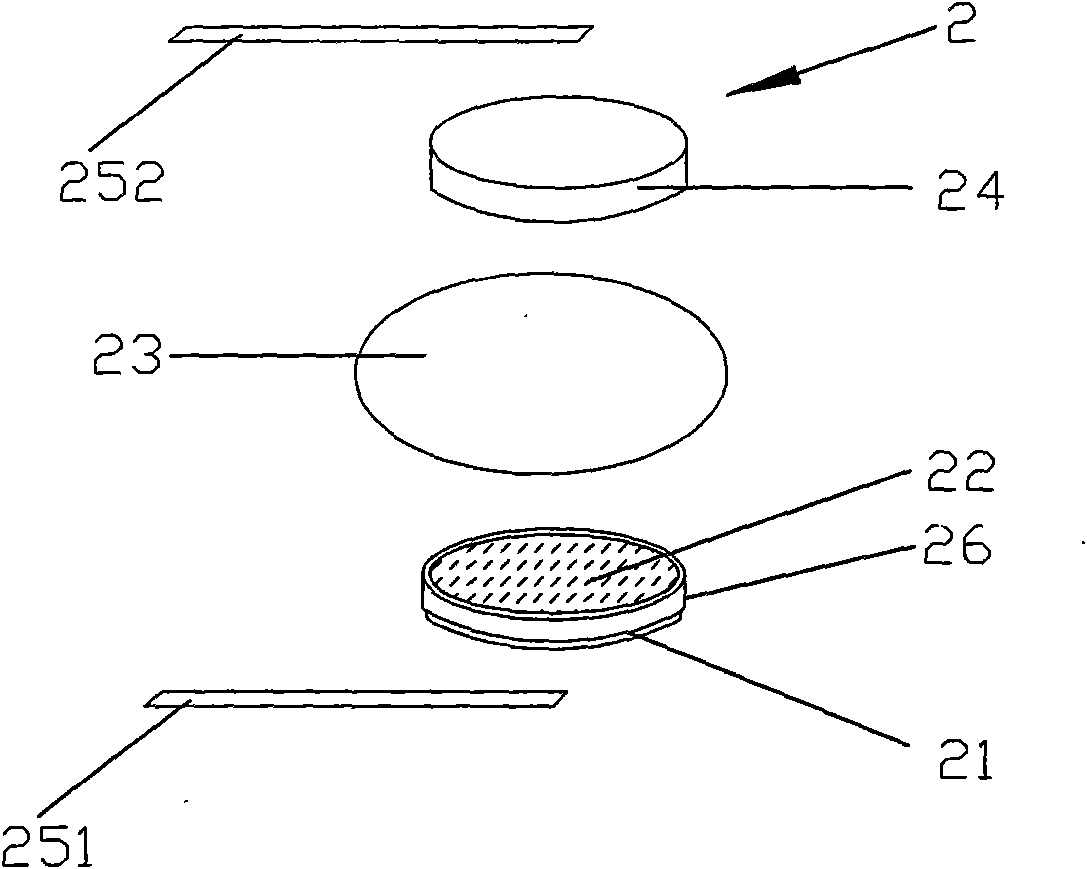

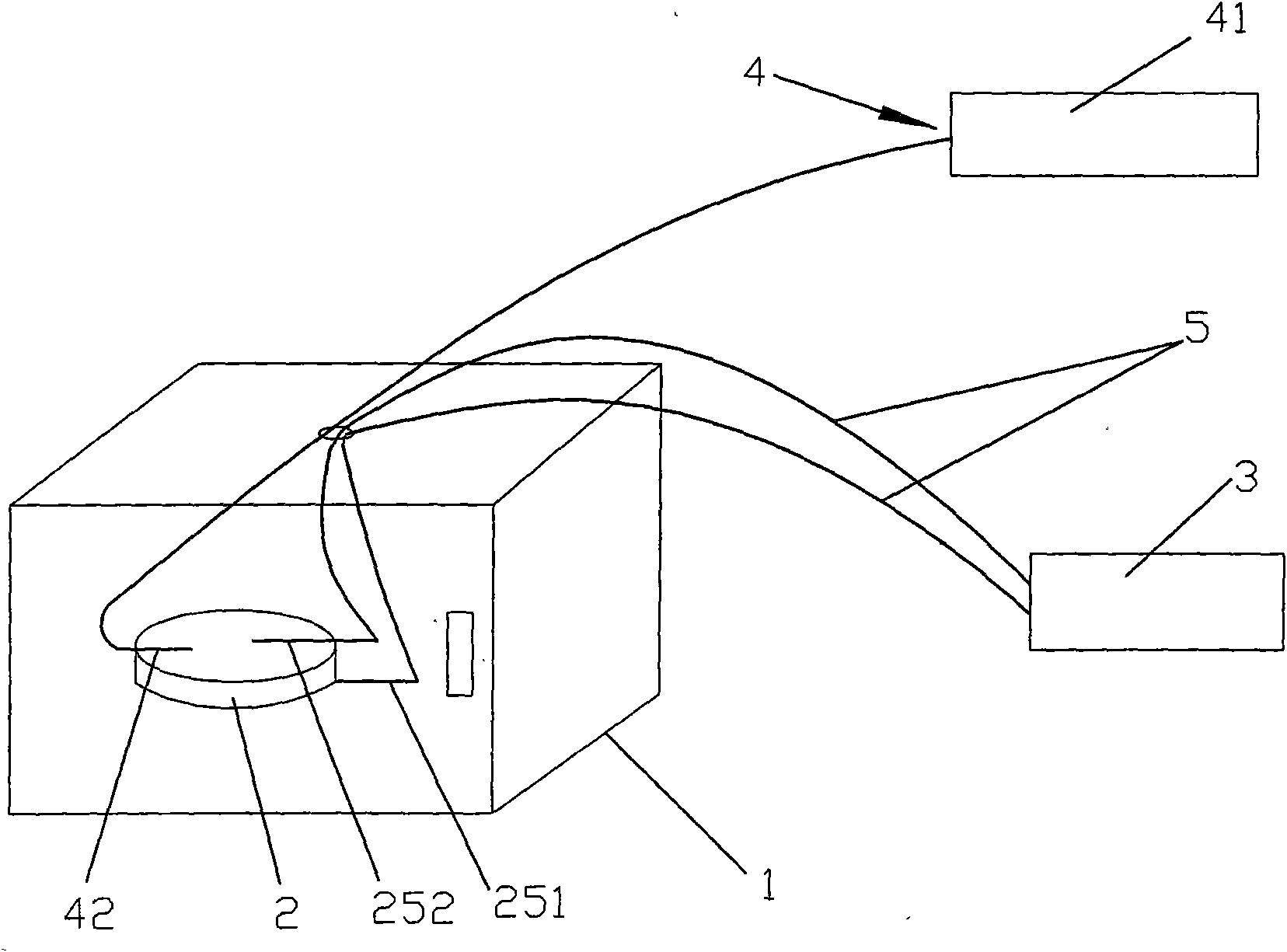

[0022] (1) Make a test battery: such as figure 1 As shown, the existing model is selected as CR2430 button battery to make test battery 2, such as figure 1 As shown, cut the test diaphragm 23 with the diaphragm sample of manufacturer A. First, the test diaphragm 23 whose diameter is larger than the test diaphragm 23 at the end mask with an insulating layer of the battery case 21 injected with the electrolyte 22 is larger than the port of the battery case, and then the battery cover 24 is fastened and used. The battery sealing machine is sealed to ensure that the test diaphragm 23 separates the battery case 21 and the battery cover 24 into two independent chambers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com