Multifunctional brush type sealing experiment system

A technology of brush seal and experimental system, applied in the direction of using liquid/vacuum to measure liquid tightness, using electromagnetic means, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

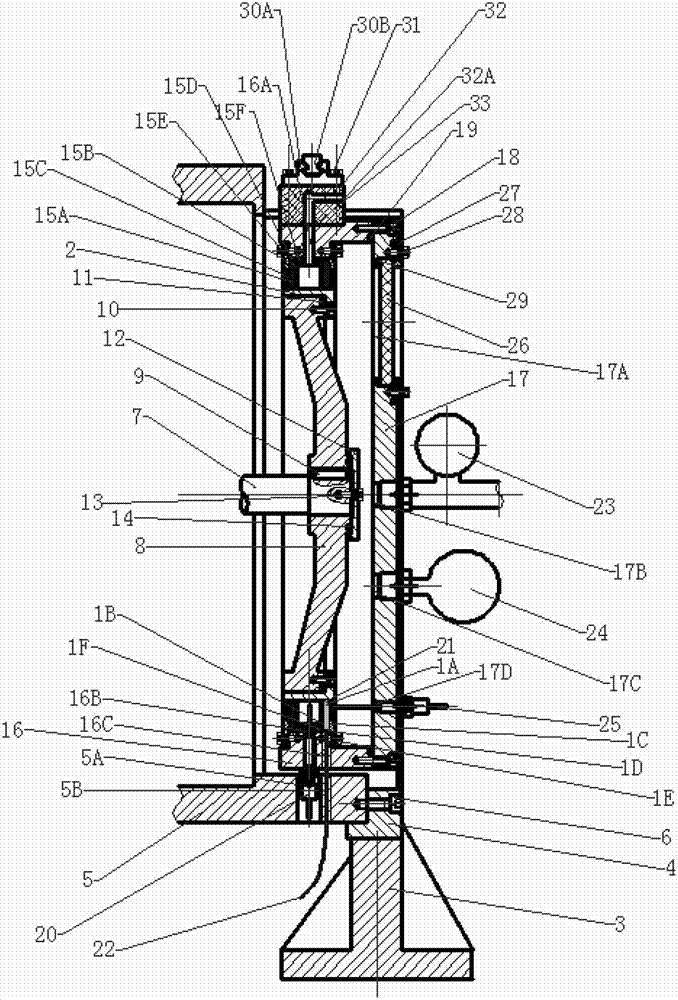

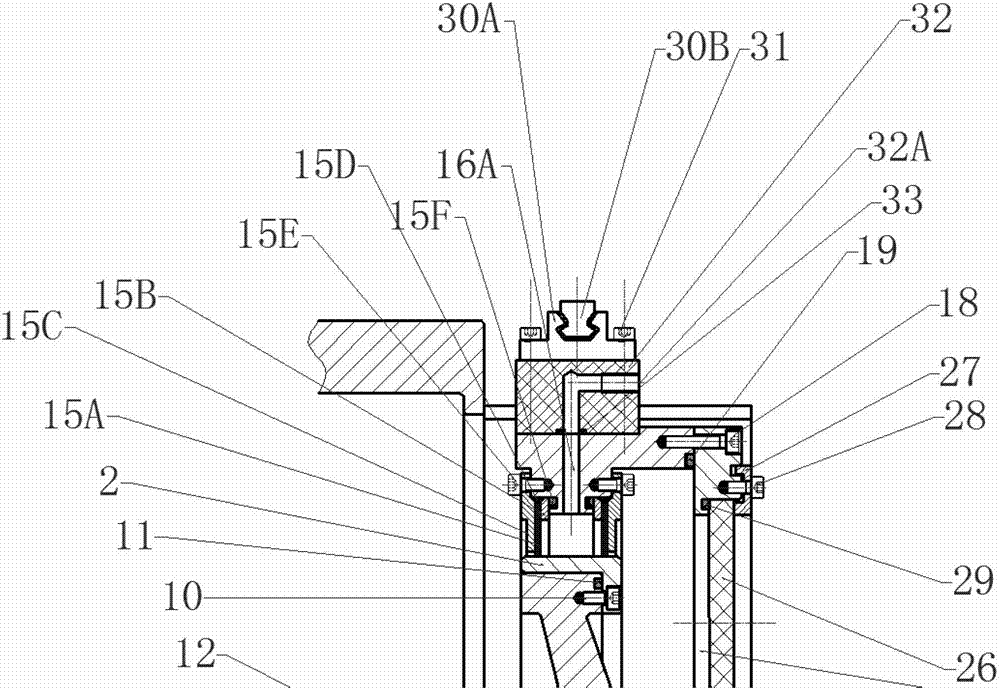

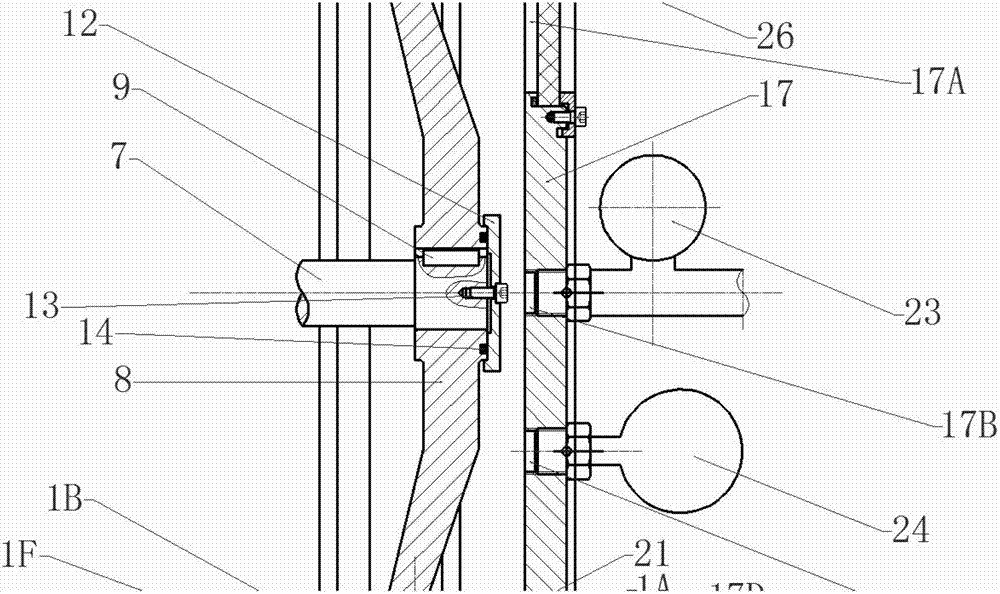

[0048] Such as figure 1 , Figure 1A , Figure 1B , Figure 1C , figure 2 , Figure 2A , Figure 2B , Figure 2C As shown, a multifunctional brush seal experiment system of the present invention includes an external support part, a rotating part, a brush ring part, a test chamber part, an observation window part, a radial moving part and a measuring part, wherein:

[0049] The external support part includes a base 3, a seat ring 4, a shell 5, and shell fastening screws 6, wherein: the base 3 is fixed on a stationary reference plane to support the entire experimental system; the seat ring The outer peripheral surface of 4 is matched with the inner peripheral surface of the base 3, and the groove on the left side of the outer circumference of the seat ring 4 is matched with the shell 5 to play a supporting and positioning role; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com