Automatic control system and control method of metallurgical projectile robot

A technology of automatic control system and control method, applied in general control system, control/regulation system, program control in sequence/logic controller, etc. problem, to achieve the effect of short time required, easy operation and little stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

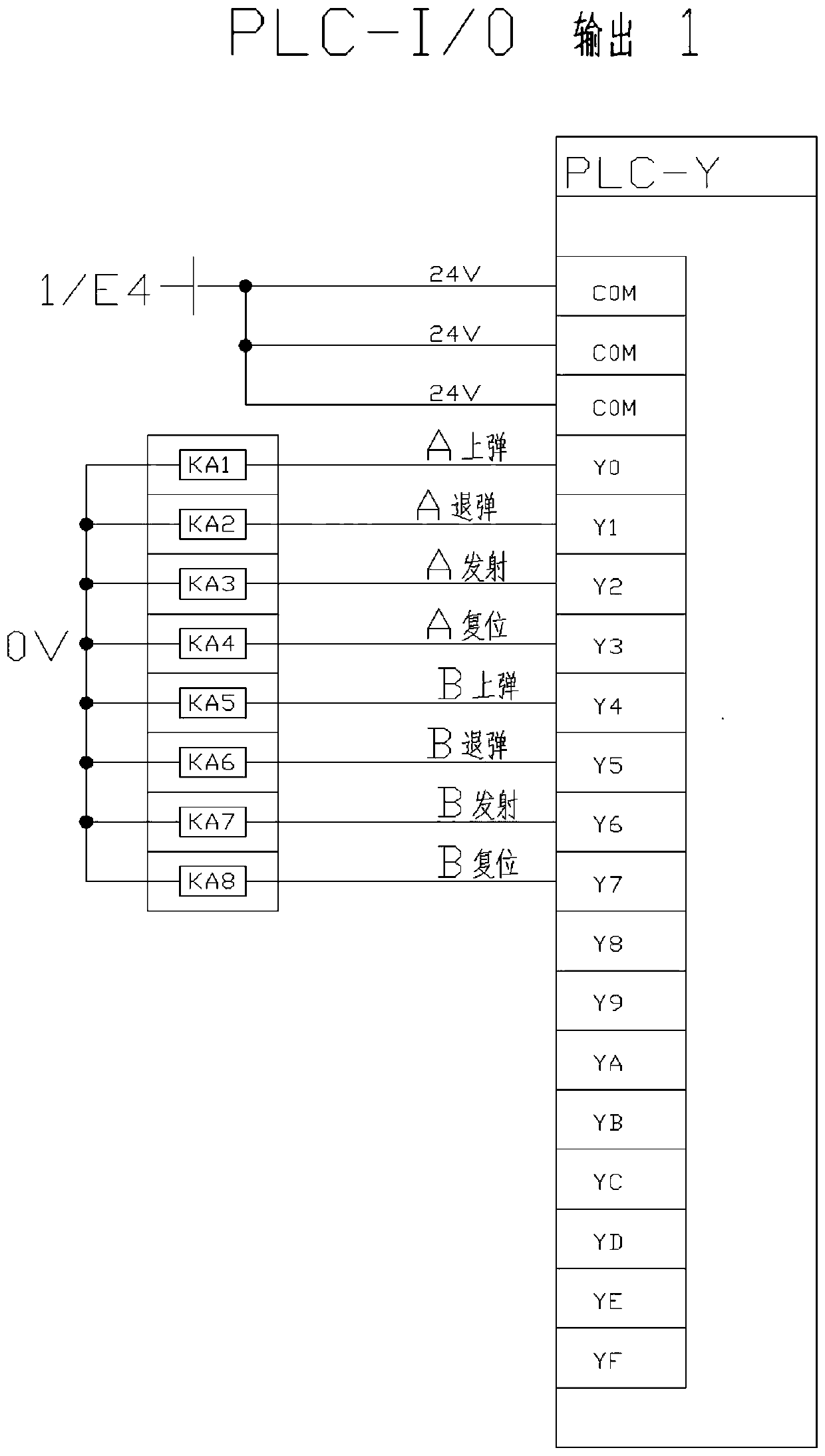

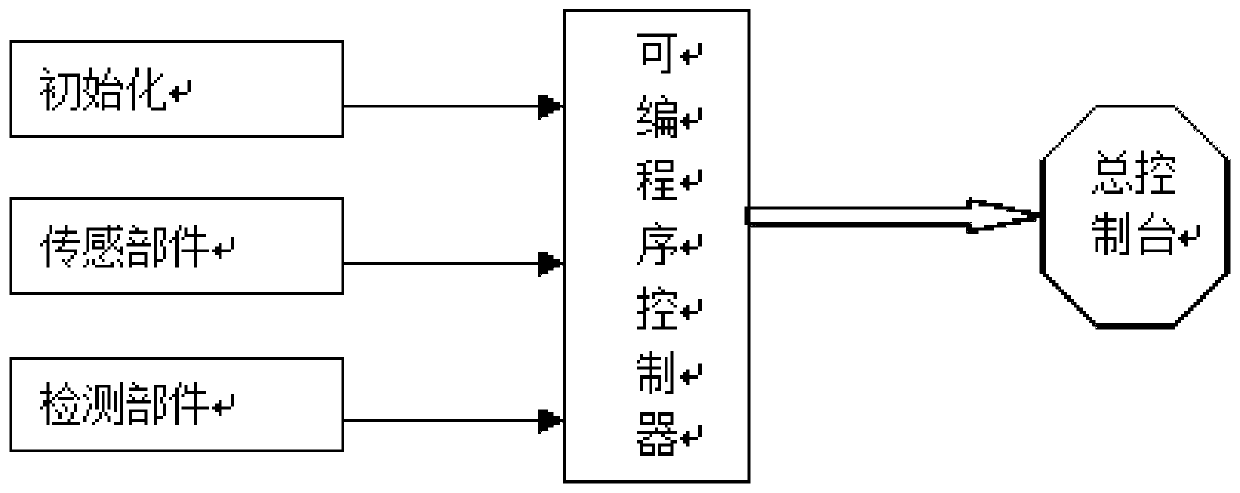

[0028] A special projectile robot automatic control system for metallurgy, its composition comprises: contactor switch, described contactor switch comprises contactor switch KA1, contactor switch KA2, contactor switch KA3, contactor switch KA4, contactor switch KA5 , contactor switch KA6, contactor switch KA7, contactor switch KA8, the contactor switch KA1 controls the ejection of the projectile mechanism A, the contactor switch KA2 controls the ejection of the projectile mechanism A, and the contact The contactor switch KA3 controls the launch of the projectile mechanism A, the contactor switch KA4 controls the reset of the projectile mechanism A, the contactor switch KA5 controls the loading of the projectile mechanism B, and the contactor switch KA6 controls the projectile mechanism B ejects, the contactor switch KA7 controls the launch of the projectile mechanism B, the contactor switch KA8 controls the reset of the projectile mechanism B, the projectile mechanism A is conn...

Embodiment 2

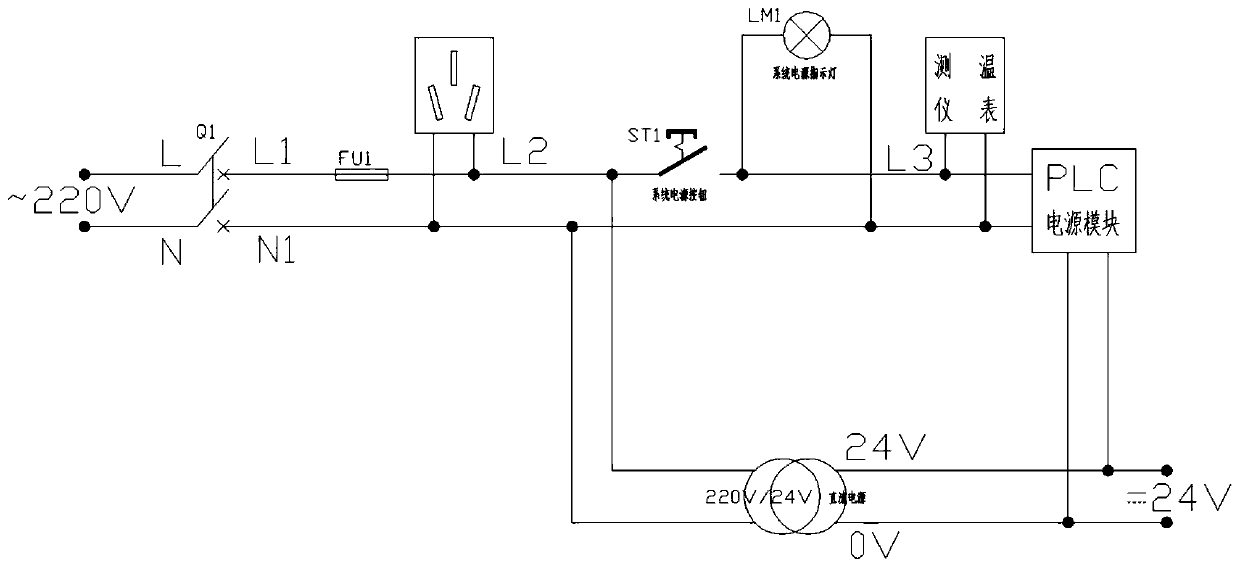

[0030] In the metallurgical projectile robot automatic control system described in Embodiment 1, the power module PLC-Y is connected to a DC power supply of 220V / 24V, the power module PLC-Y is connected to a temperature measuring instrument L3, and the temperature measuring instrument L3 is connected to the system power indicator LM1, the system power indicator LM1 is connected to the system power button ST1, the system power button ST1 is connected to the inductor L2, the inductor L2 is connected to the fuse FU1, and the fuse FU1 is connected to The contactor Q1 is connected to the 220V power supply.

Embodiment 3

[0032] In the metallurgical special-purpose projectile robot automatic control system described in Embodiment 1, the crystal oscillator Y series also includes crystal oscillator Y8, crystal oscillator Y9, crystal oscillator YA, crystal oscillator YB, crystal oscillator YC, crystal oscillator YD, crystal oscillator YE, and crystal oscillator YF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com