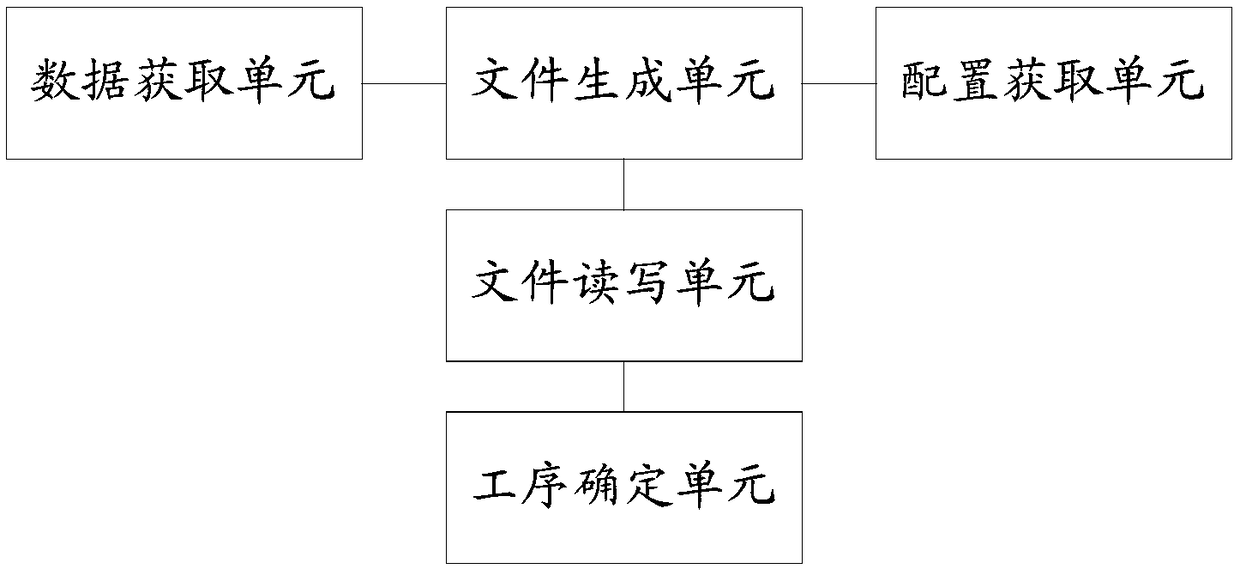

Parameter configuration method and system for coating equipment as well as coating equipment

A technology of coating equipment and configuration method, which is applied in the direction of program control design, program control device, electrical digital data processing, etc., can solve problems such as long time consumption, and achieve the effect of improving efficiency and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

[0049] In view of the current preparation process of thin-film solar cells, in the process of coating equipment, the start-up of the coating equipment needs to go through processes such as heating up and vacuuming, which takes several hours. However, the preparation parameter setting of the existing coating equipment is often read in at startup. If the preparation parameters are to be readjusted, the system software of the coating equipment needs to be restarted to take effect, which will cause the equipment to enter the process of shutting down and then restarting. Make the production line pause for a long time and affect normal production. The invention provides a method and system for parameter configuration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com