Mechanical bearing fault diagnosis technology based on wide residual network learning model

A fault diagnosis and network learning technology, applied in the field of mechanical vibration, can solve problems such as increasing depth, and achieve the effect of high accuracy and feasible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

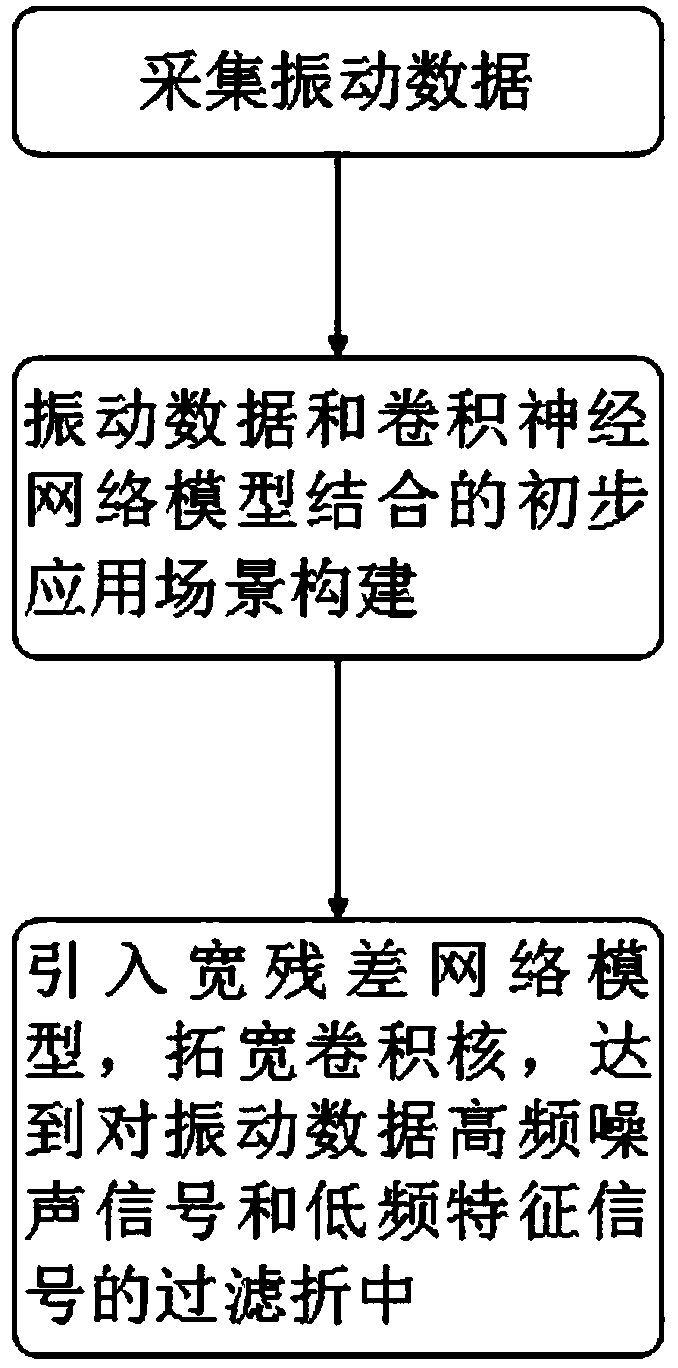

[0055] A mechanical bearing fault diagnosis technology based on wide residual network learning model, the specific process is as follows:

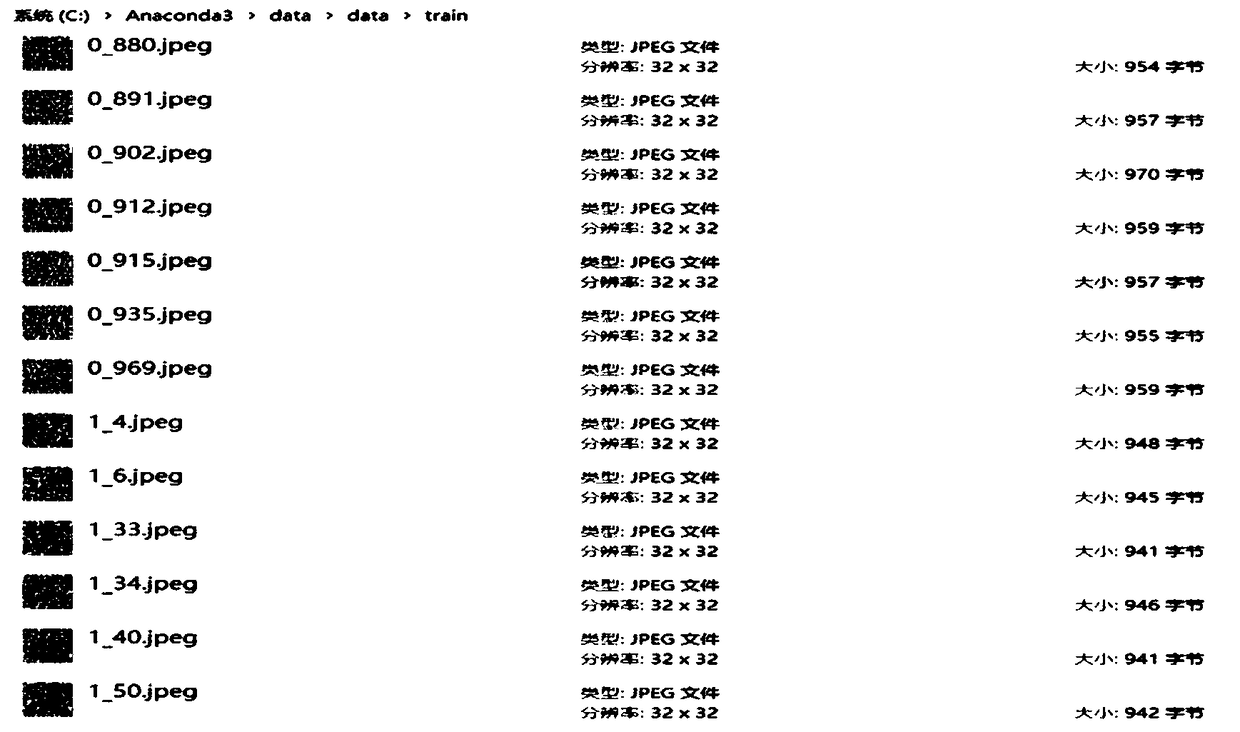

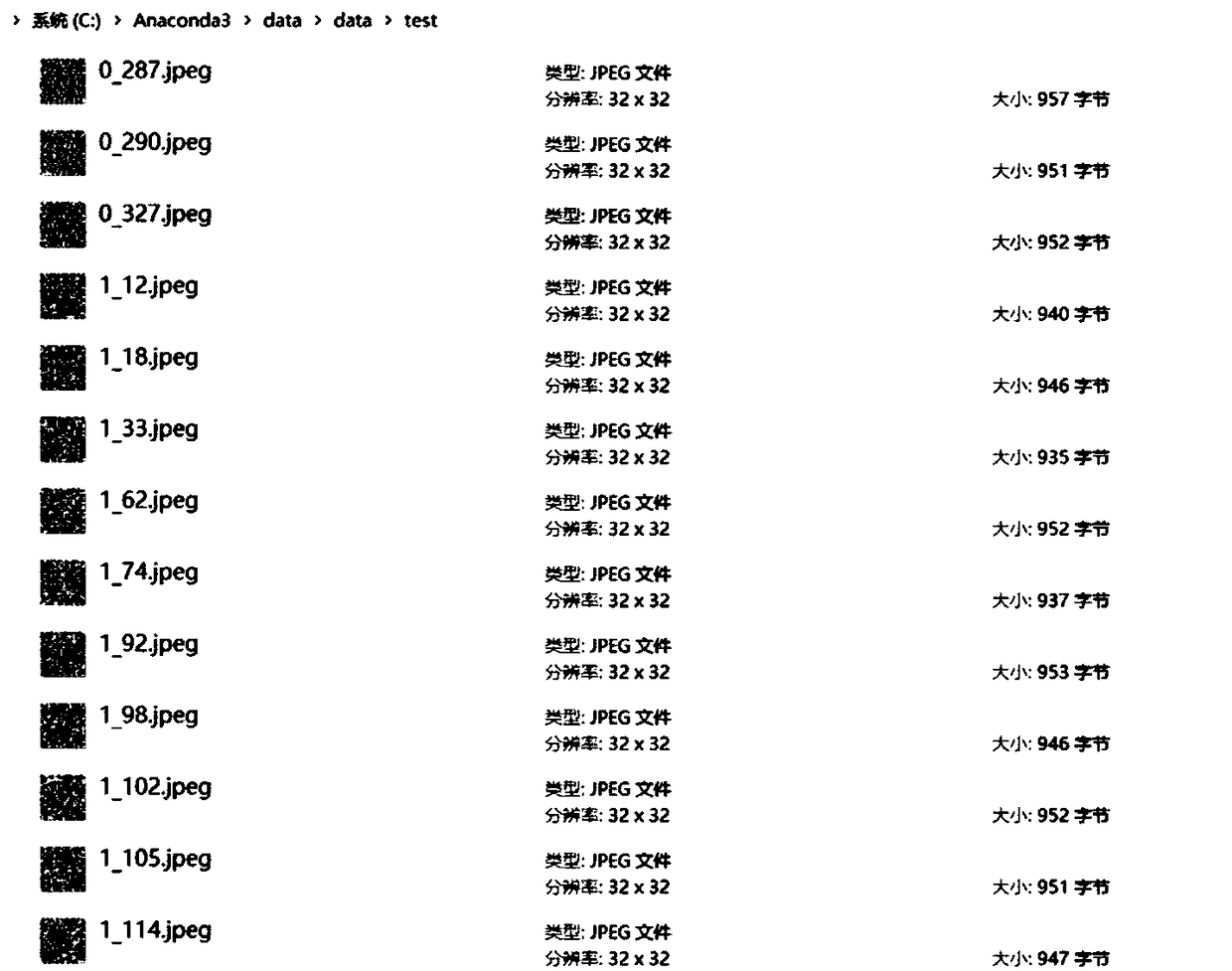

[0056] 1. Collect vibration data. According to the sampling theorem, the sampling frequency is greater than twice the signal frequency. Taking the rolling element fault as an example, 1024 sampling points are selected for sampling per unit time, that is, the sampling frequency is 1024Hz>2*137.48Hz, and this sampling frequency is also consistent with other faults. In order to effectively retain the fault characteristics of the original vibration signal, a single learning sample is set to a size of 32*32 (1024 sampling points), and the vibration data is converted into a data set format of 32*32 grayscale image, through a bit depth of 8 The size of the gray value of the bit grayscale image represents the vibration amplitude of the vibration data, and then the data set is divided into a training set and a test set according to a certain ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com