Method for manufacturing COB light source

A manufacturing method and light source technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of inability to achieve high-density integration, large spacing between LED chips, etc., and achieve high-density integration, simple manufacturing process, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

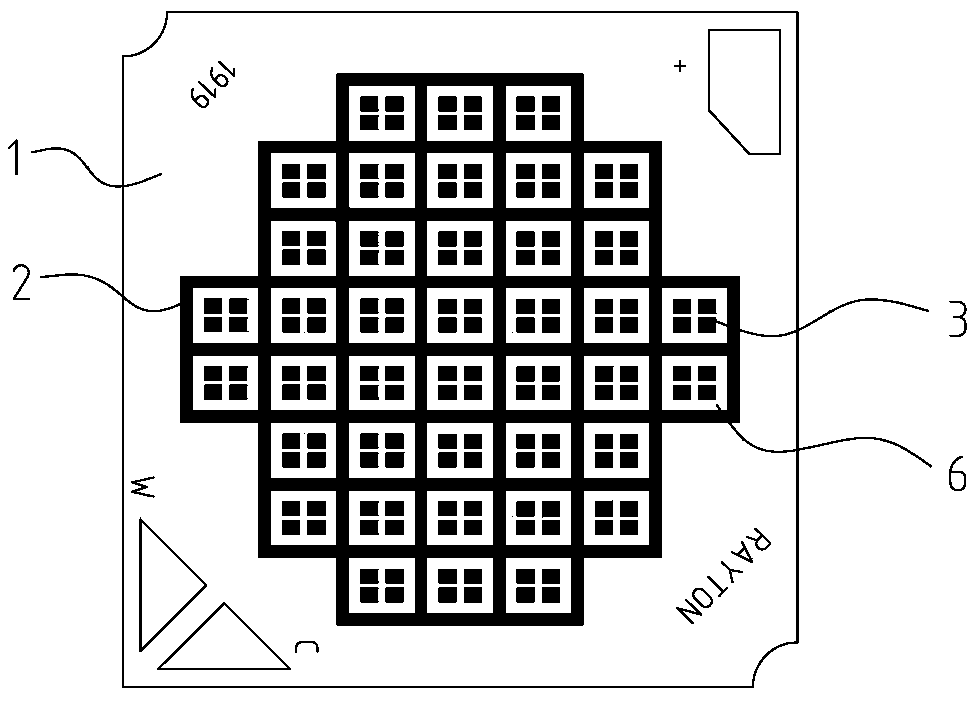

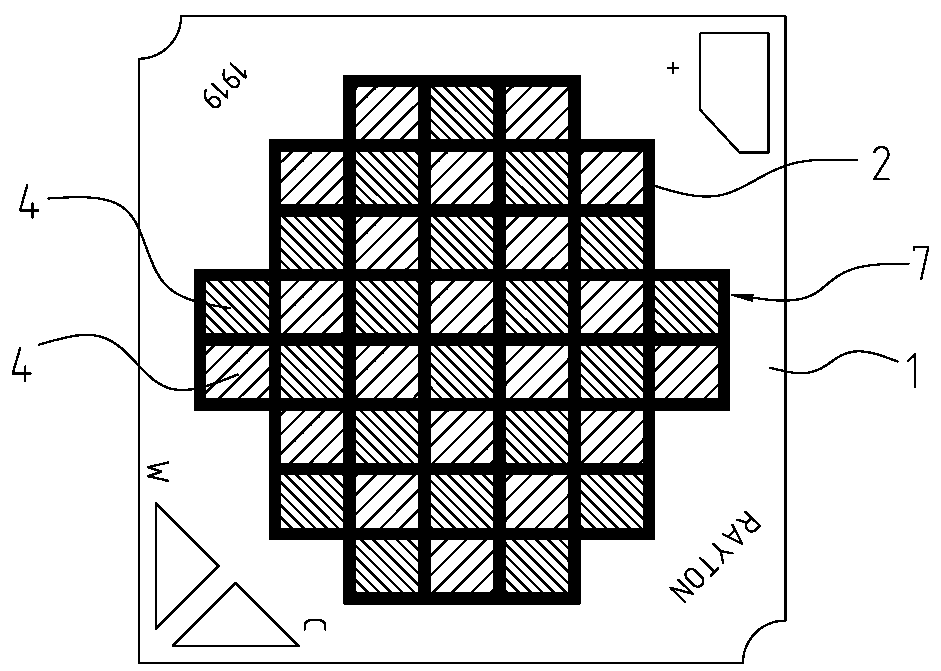

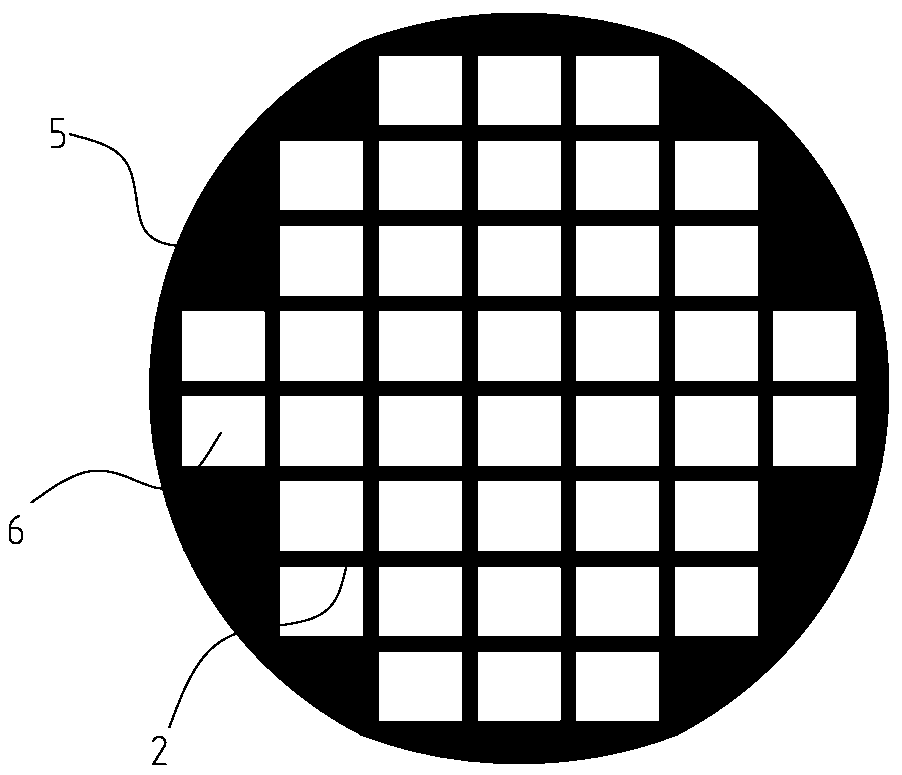

[0044] Such as figure 1 , 2 , 5, a COB light source includes a substrate 1, a number of LED chips 3 distributed on the substrate 1 and a fluorescent film 7 for light distribution. The fluorescent film 7 includes a grid 2, the grid 2 is fixed on the substrate 1, a number of filling regions 6 are formed in the grid 2, and the shape of the grid 2 is the same as that of the crystal-bonding region on the substrate 1 , the filling area 6 is in one-to-one correspondence with the LED chips 3 , that is, each LED chip 3 is located in the filling area 6 . The filling area 6 is provided with a fluorescent glue 4. The fluorescent glue 4 in this embodiment includes a positive white fluorescent glue and a warm white fluorescent glue. The warm white fluorescent glue and the positive white fluorescent glue are distributed at intervals. Thus, white light with different color temperatures is produced.

[0045] The manufacturing method of the COB light source comprises the following steps:

...

Embodiment 2

[0052] Such as Figures 3 to 6 As shown, a COB light source includes a substrate 1, several LED chips 3 distributed on the substrate 1, and a fluorescent film 7 for light distribution. The fluorescent film 7 includes a grid 2, the grid 2 is fixed on the substrate 1, a number of filling regions 6 are formed in the grid 2, and the shape of the grid 2 is the same as that of the crystal-bonding region on the substrate 1 , the filling area 6 is in one-to-one correspondence with the LED chips 3 , that is, each LED chip 3 is located in the filling area 6 . The filling area 6 is provided with a fluorescent glue 4. The fluorescent glue 4 in this embodiment includes a positive white fluorescent glue and a warm white fluorescent glue. The warm white fluorescent glue and the positive white fluorescent glue are distributed at intervals. Thus, white light with different color temperatures is produced.

[0053] The manufacturing method of the COB light source comprises the following steps:...

Embodiment 3

[0061] Such as Figures 3 to 6 As shown, a COB light source includes a substrate 1, several LED chips 3 distributed on the substrate 1, and a fluorescent film 7 for light distribution. The fluorescent film 7 includes a grid 2, the grid 2 is fixed on the substrate 1, a number of filling regions 6 are formed in the grid 2, and the shape of the grid 2 is the same as that of the crystal-bonding region on the substrate 1 , the filling area 6 is in one-to-one correspondence with the LED chips 3 , that is, each LED chip 3 is located in the filling area 6 . The filling area 6 is provided with a fluorescent glue 4. The fluorescent glue 4 in this embodiment includes a positive white fluorescent glue and a warm white fluorescent glue. The warm white fluorescent glue and the positive white fluorescent glue are distributed at intervals. Thus, white light with different color temperatures is produced.

[0062] The manufacturing method of the COB light source comprises the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com