Casting blank arc angle forming device

A forming device and arc angle technology, applied in the field of billet arc angle forming device, can solve problems such as low cleaning efficiency, extremely high requirements for workers' operating skills and judgment experience, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

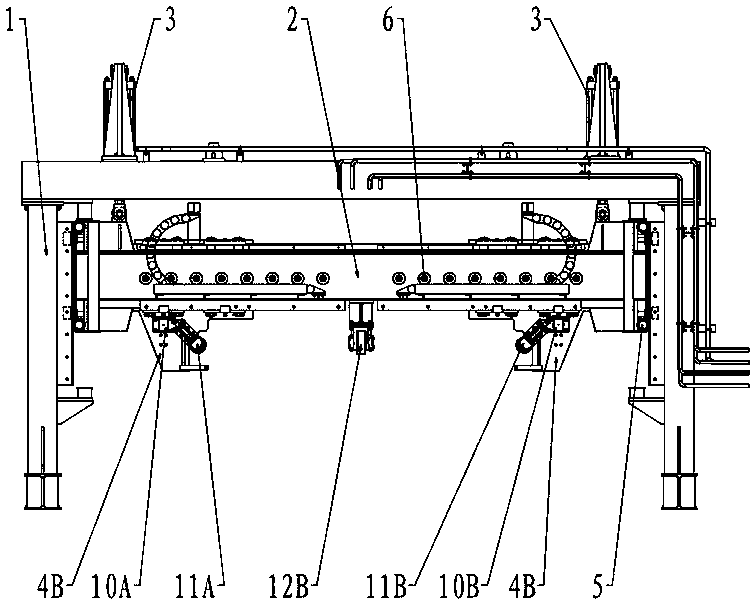

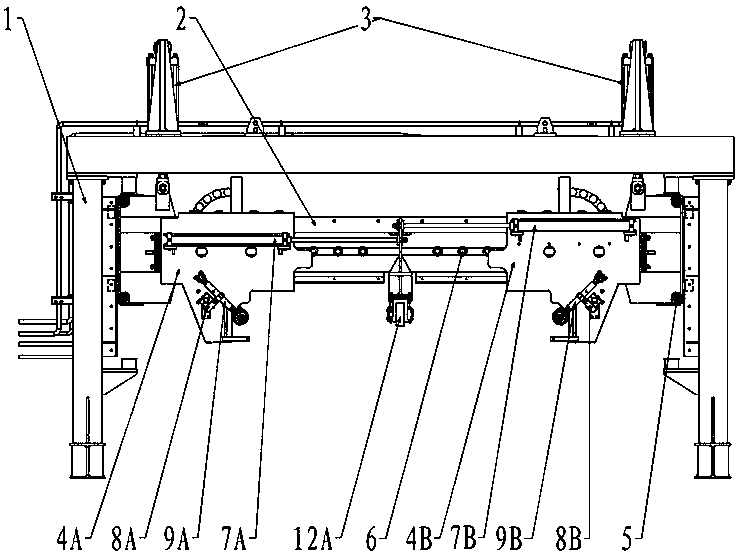

[0016] Such as figure 1 , figure 2 As shown, the device consists of gantry 1, vertical floating beam 2, floating beam lifting cylinder 3, No. 1 horizontal moving slider 4A, No. 2 horizontal moving slider 4B, eccentric wheel 5, horizontal guide wheel 6, No. 1 moving slider Block translation cylinder 7A, No. 2 moving slider translation cylinder 7B, No. 1 heating burner support 8A, No. 2 heating burner support 8B, No. 1 heating burner 9A, No. 2 heating burner 9B, No. 1 arc angle forming Composed of burner bracket 10A, No. 2 arc angle forming burner bracket 10B, No. 1 arc angle forming burner 11A, No. 2 arc angle forming burner 11B, No. 1 wheel assembly 12A, and No. 2 wheel assembly 12B. Among them, the gantry 1 is installed on the foundation surface, and the vertical floating beam 2 is assembled on the gantry through eight eccentric wheels 5 and the floating beam lifting cylinder 3, distributed at both ends of the vertical floating beam 2, and the vertical floating beam 2 can p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com