Full-automatic marking machine for bearing

A fully automatic, bearing technology, applied in the field of marking machines, can solve the problems of insufficient dust removal, affecting the marking effect, and poor dust removal effect, so as to improve the accuracy and automation, improve the marking effect, and improve the dust removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

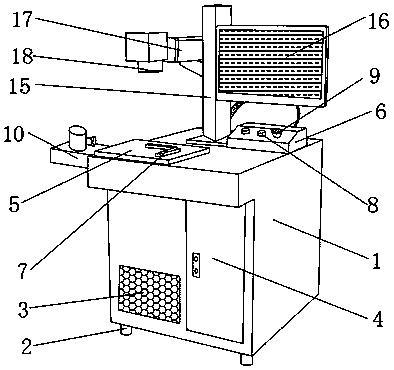

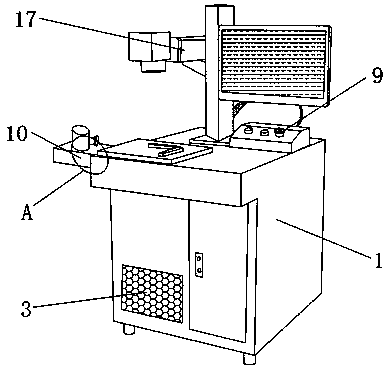

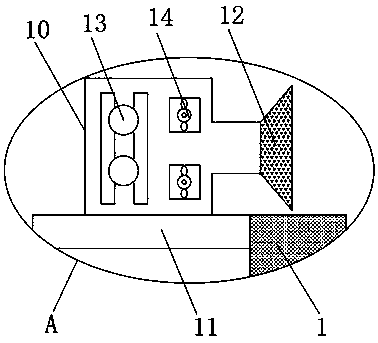

[0018] like Figure 1-4 As shown in the figure, a bearing automatic marking machine includes a frame 1 and a column 15, a support foot 2 is fixedly installed on the outer side of the lower end of the frame 1, and a ventilation hole 3 and a motor box door are arranged on the outer surface of one side of the frame 1. 4, and the motor box door 4 is movably installed on the horizontal side of the ventilation hole 3, the outer side of the upper end of the rack 1 is fixedly installed with the stage 5 and the control panel 6, and the outer side of the upper end of the stage 5 is provided with a positioning block 7, control The upper end of the oblique side of the panel 6 is provided with an indicator light 8 and a start button 9, the start ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap