Edge pressure-controlled perforator

A perforator and edge-edge technology, which is applied in metal processing and other directions, can solve the problems of incomplete hole opening, inflexible use, and short force arm, and achieve good promotion and use value, simple structure, and powerful perforation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

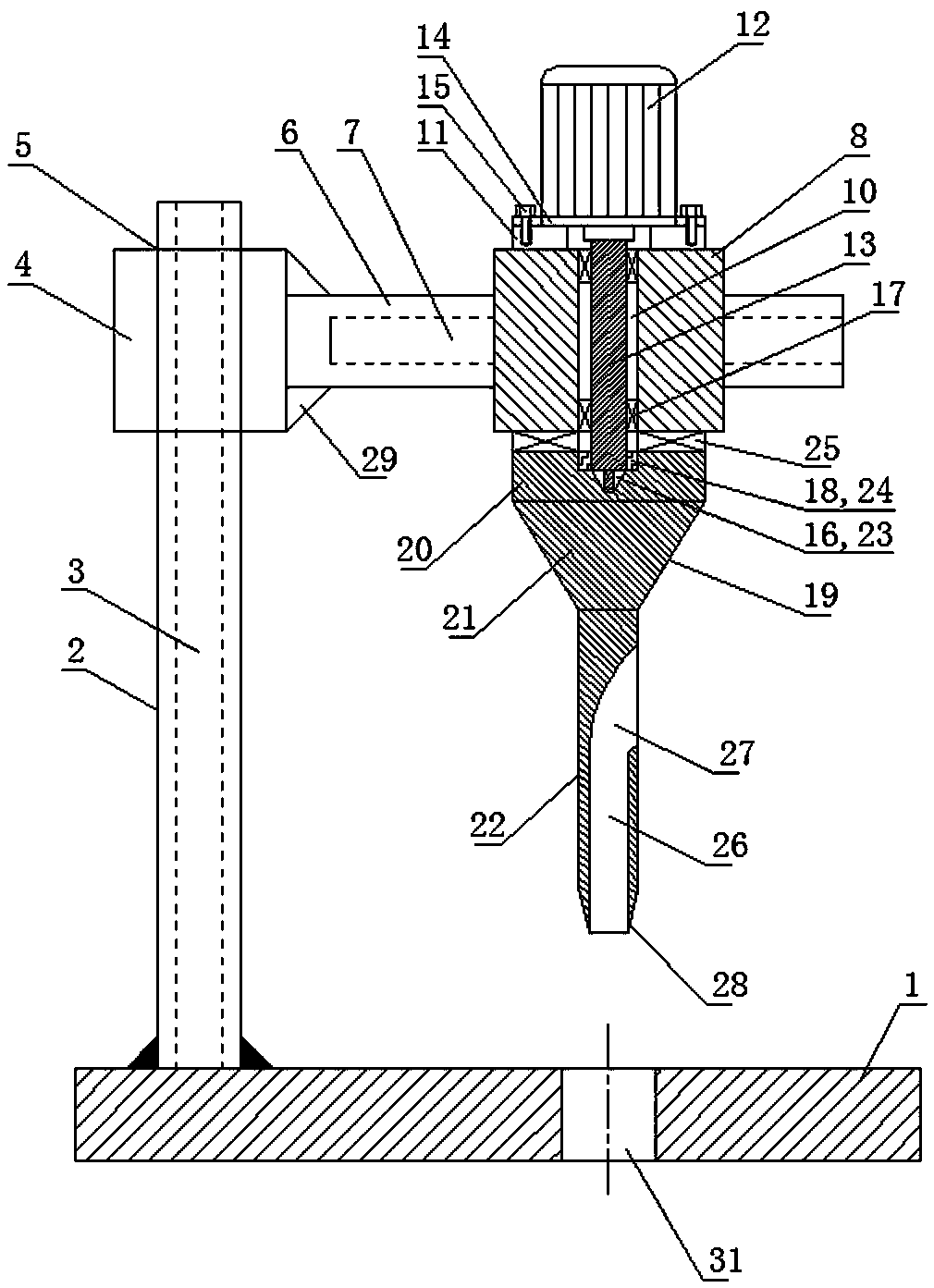

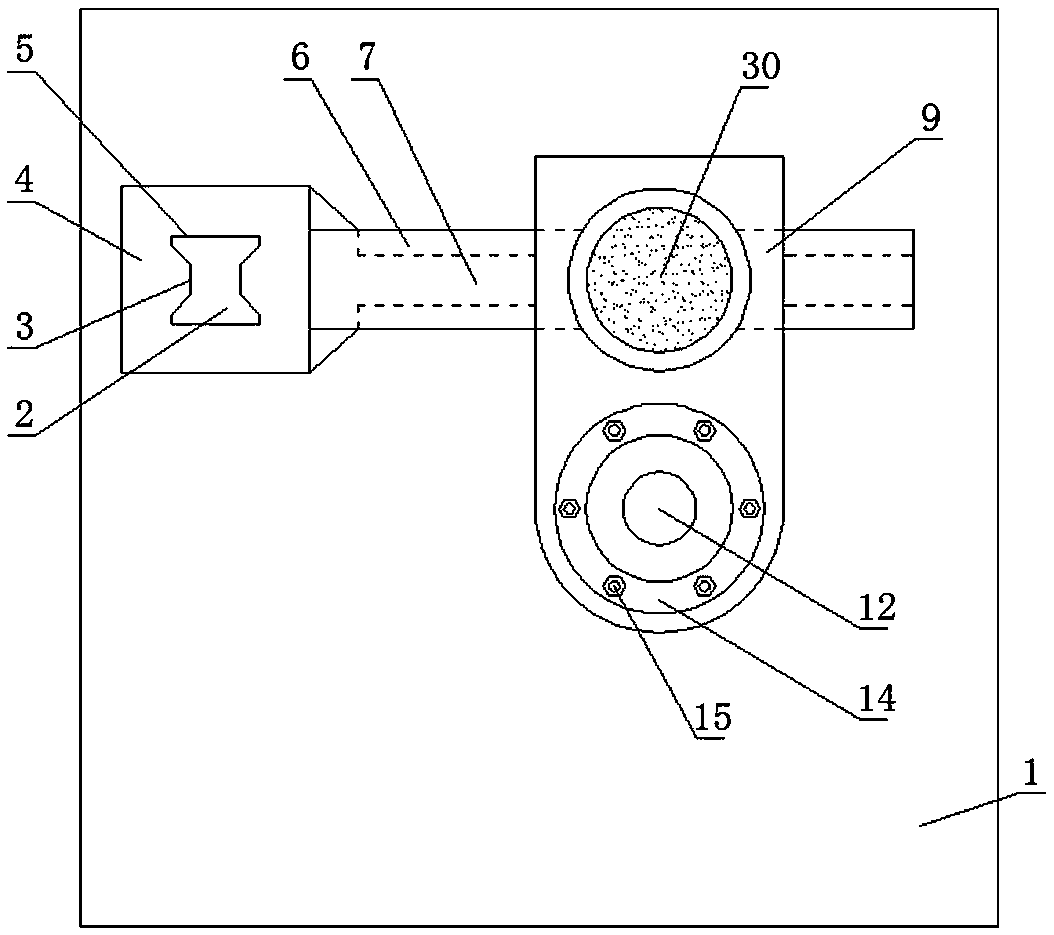

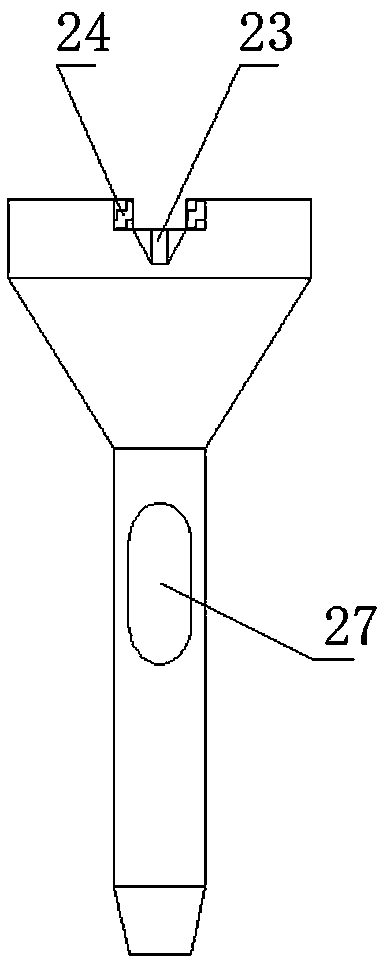

[0043] The edge-type pressure-controlled perforator of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] As shown in the accompanying drawings, the structure of the edge-type pressure-controlled perforator of the present invention includes a base, a longitudinal beam, a horizontal beam and a sliding block,

[0045] The base 1 is arranged horizontally, and a longitudinal beam 2 is fixedly connected to a corner of the base 1 plane.

[0046] A longitudinal beam rail groove 3 is provided on the beam body along the vertical height span of the longitudinal beam, and a slider 4 is sleeved on the longitudinal beam 2, and the slider 4 is provided with a slider rail hole that runs through the slider longitudinally and coincides with the longitudinal beam 5. The rail hole 5 of the slider and the longitudinal beam are fitted together to form a slide rail connection;

[0047] One side of the slider 4 is provided with a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com