On-site waterproof membrane attaching machine

A waterproof membrane and attachment technology, which is applied in the field of construction machinery and equipment, can solve the problems of waste of materials, repeated attachment of waterproof membranes, and loose attachment of waterproof membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

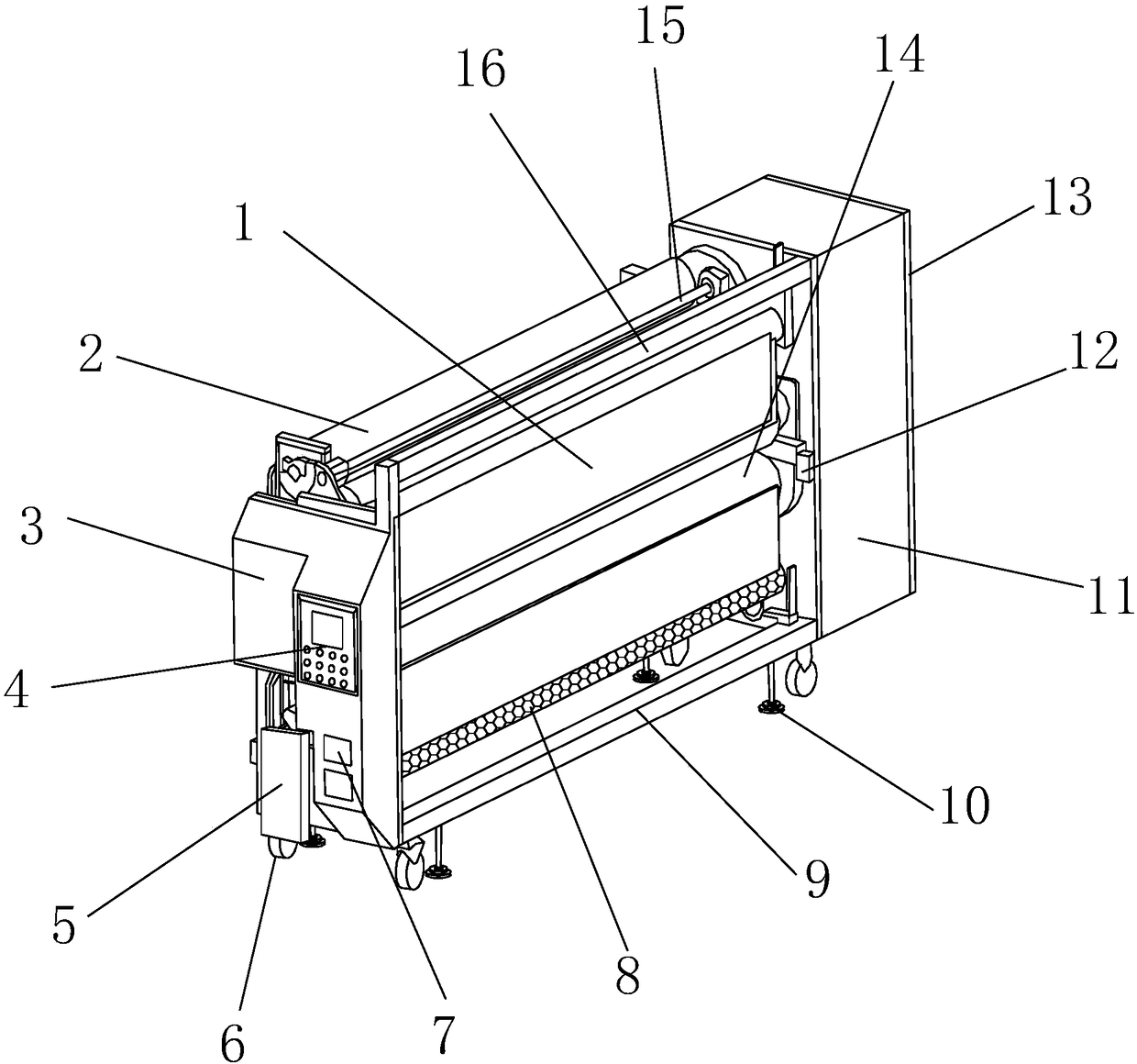

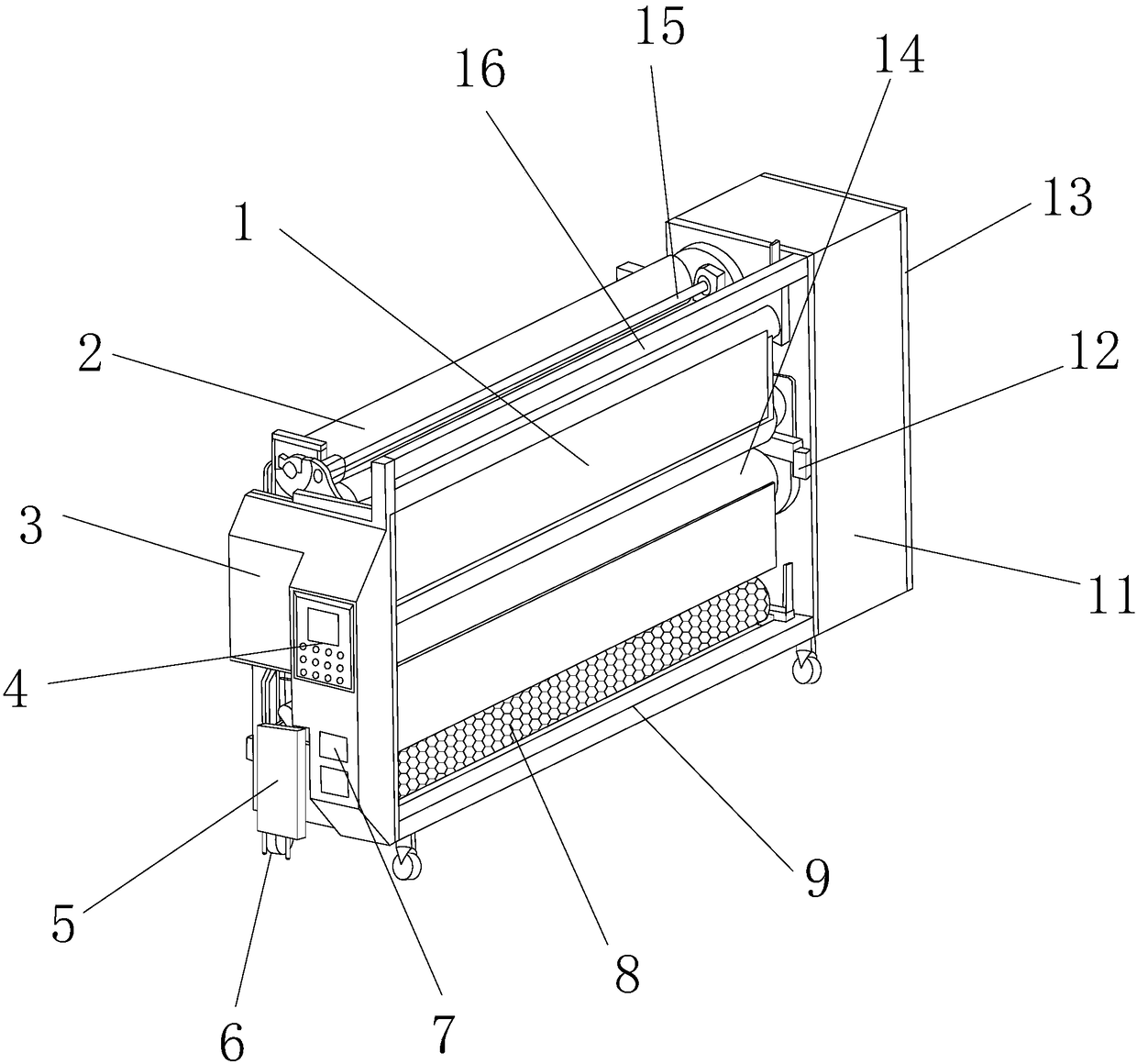

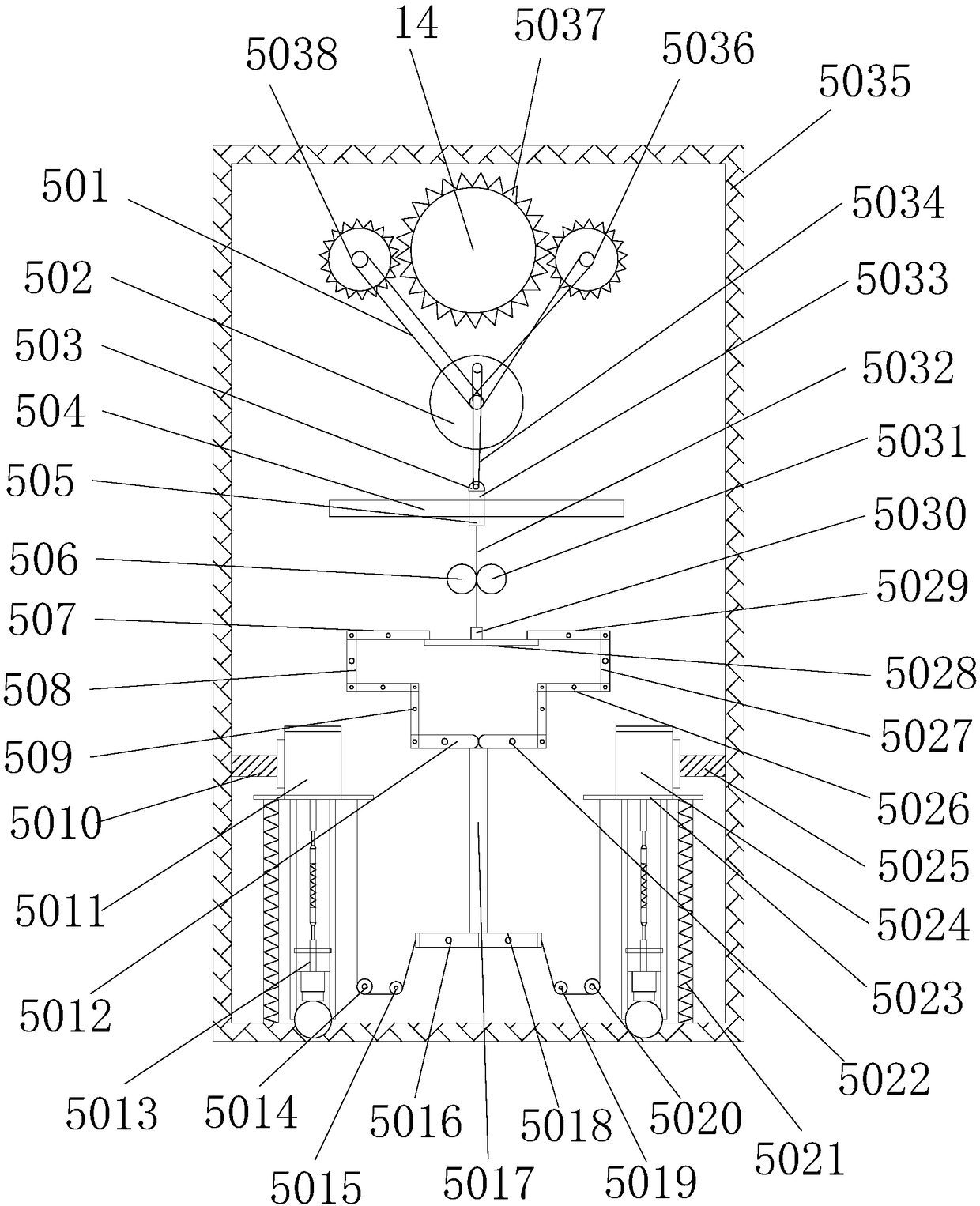

[0023] see Figure 1 to Figure 5, the present invention provides a waterproof membrane on-site attachment machine: its structure includes a limit isolation baffle 1, a waterproof membrane placement shaft 2, an operation panel 3, a control platform 4, a linear positioner 5, a universal wheel 6, a switch control Device 7, attachment finale 8, lower limit support bar 9, support foot cup 10, gear box 11, regulator 12, side protective cover 13, film pulling shaft 14, auxiliary positioning shaft 15, upper limit support bar 16. The left end of the side protective cover 13 is screwed to the right end of the gear box 11, and the lower side of the left end of the gear box 11 is welded to the right end of the lower limit support bar 9, and the lower limit su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap