Connecting structure of small flue and waste-gas opening and closing device

A technology of exhaust gas switch and connection structure, which is applied in the petroleum industry, coke oven, charging device, etc., can solve the problems of inability to meet the requirements of use, and achieve the effect of simple structure, convenient installation and use, and changing air flow speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

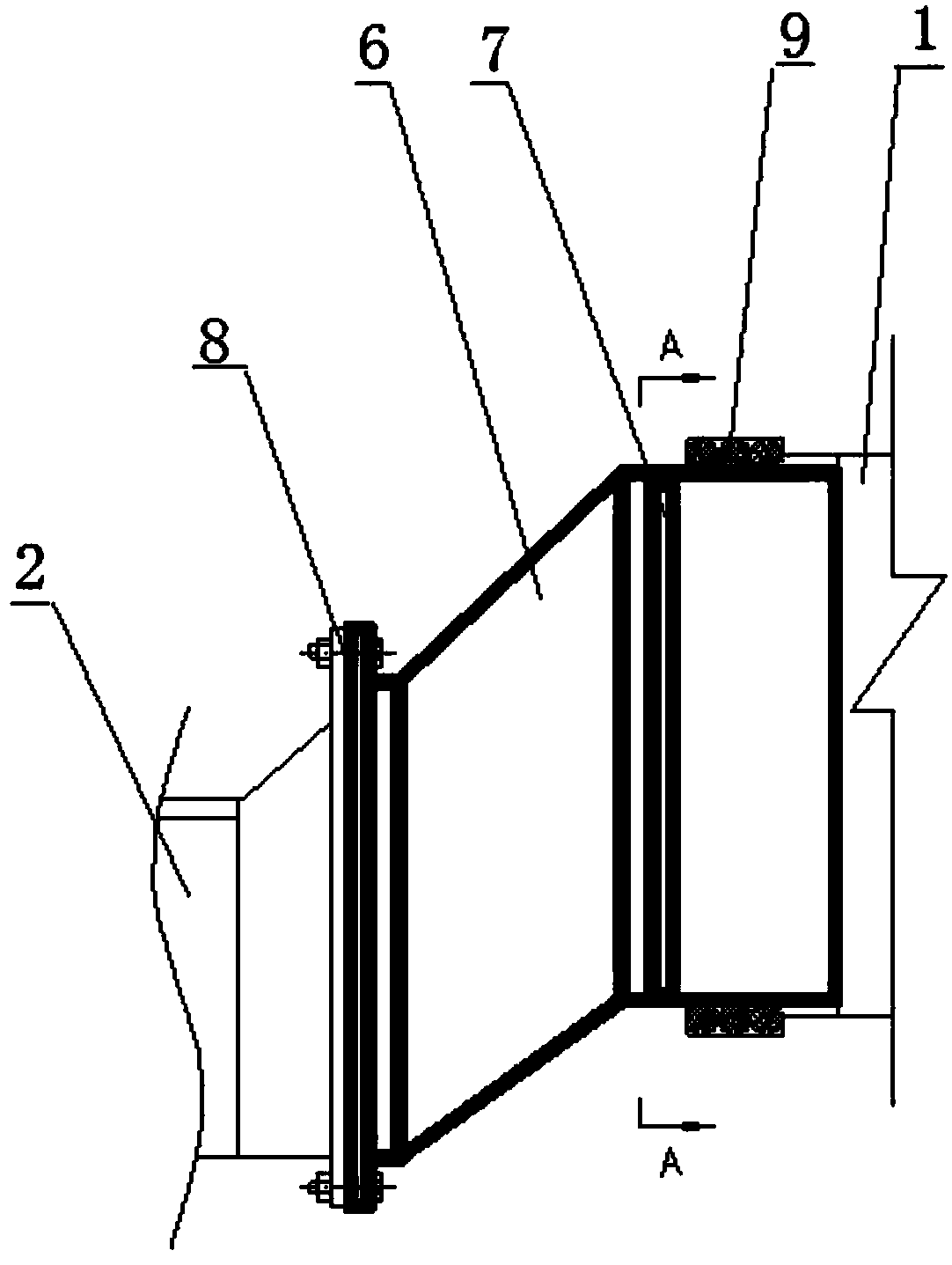

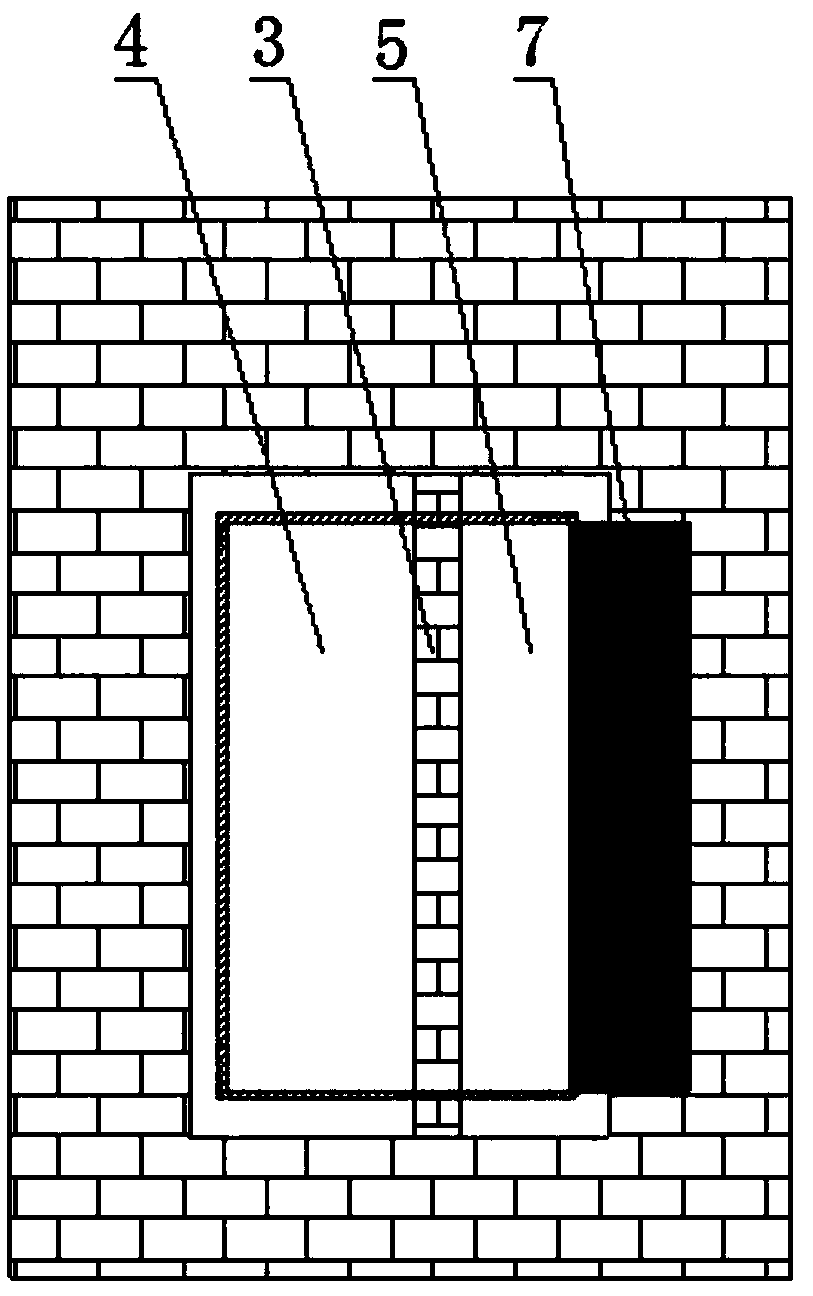

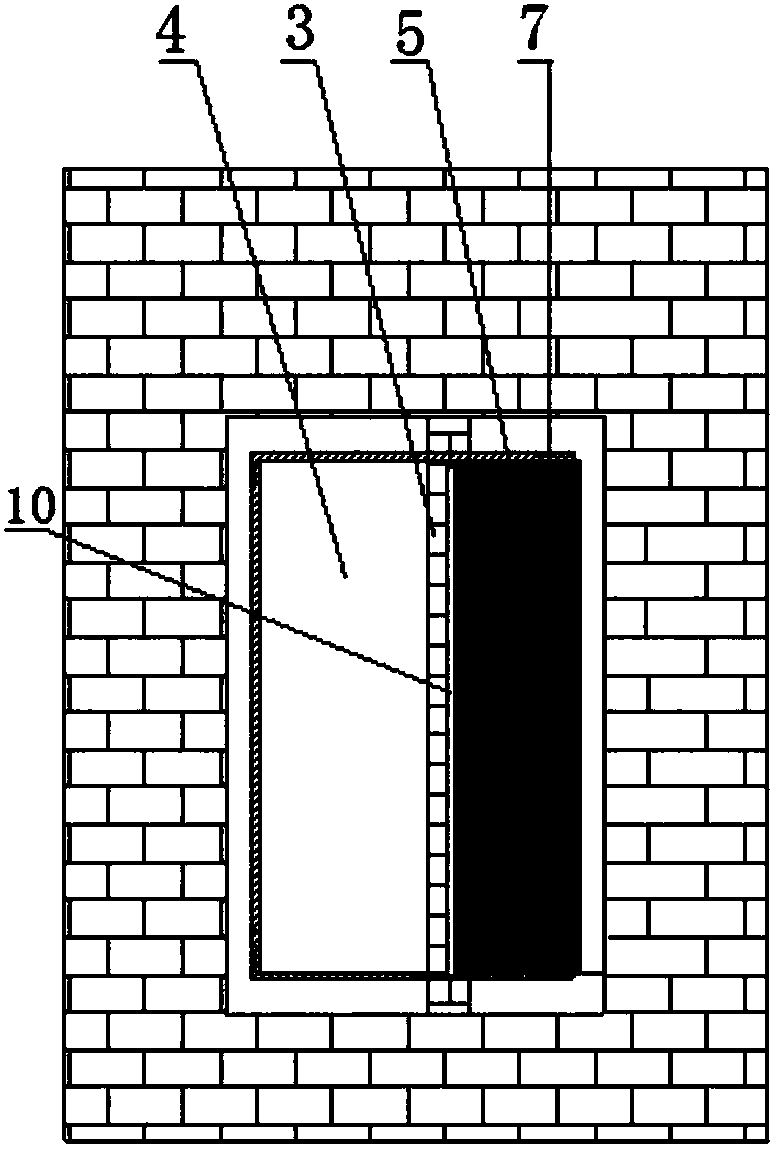

[0016] Such as Figure 1-Figure 3 As shown in the present invention, a connection structure between a small flue and an exhaust gas switch, the small flue 1 is provided with a partition wall 3, and the partition wall 3 is set between the machine side and the coke side, and the small flue The flue 1 is divided into two independent sub-flues 4 and 5; the connection structure includes a small flue connecting pipe 6, a partition plate 10 and an insert plate 7; one end of the small flue connecting pipe 6 is connected to the small flue 1 The other end is connected with the exhaust gas switch 2, and the side of the small flue connecting pipe 6 close to the small flue 1 is longitudinally provided with a partition plate 10, and one end of the partition plate 10 is connected to the partition wall 3 in the small flue 1 Connected, the small flue connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com