Microelectromechanical microphone

A microphone and micro-electromechanical technology, applied in the field of micro-electro-mechanical microphones, can solve the relative positioning of difficult micro-electro-mechanical microphone components and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The detailed description hereinafter refers to the accompanying drawings that, for purposes of illustration, show specific details and implementations in which various embodiments can be practiced.

[0013] The concept "exemplary" is used herein to mean "serving as an example, as an illustration, or for illustration." Each implementation or configuration described herein as "exemplary" is not necessarily to be construed as preferred or advantageous over other implementations or configurations.

[0014] In the drawings, the same reference numerals refer to the same parts in different views. The drawings serve primarily to illustrate principles of the various embodiments and are therefore not necessarily to scale.

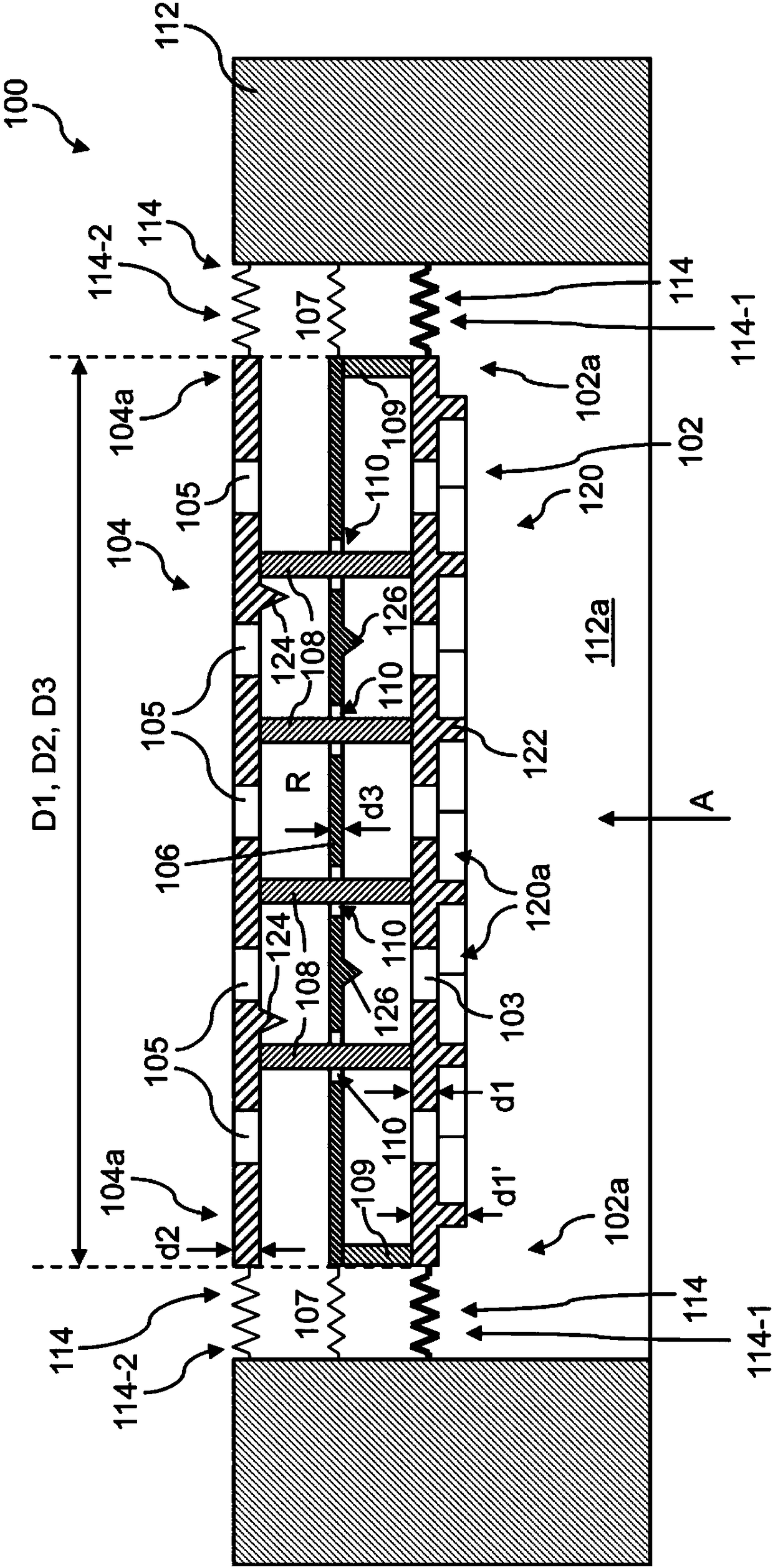

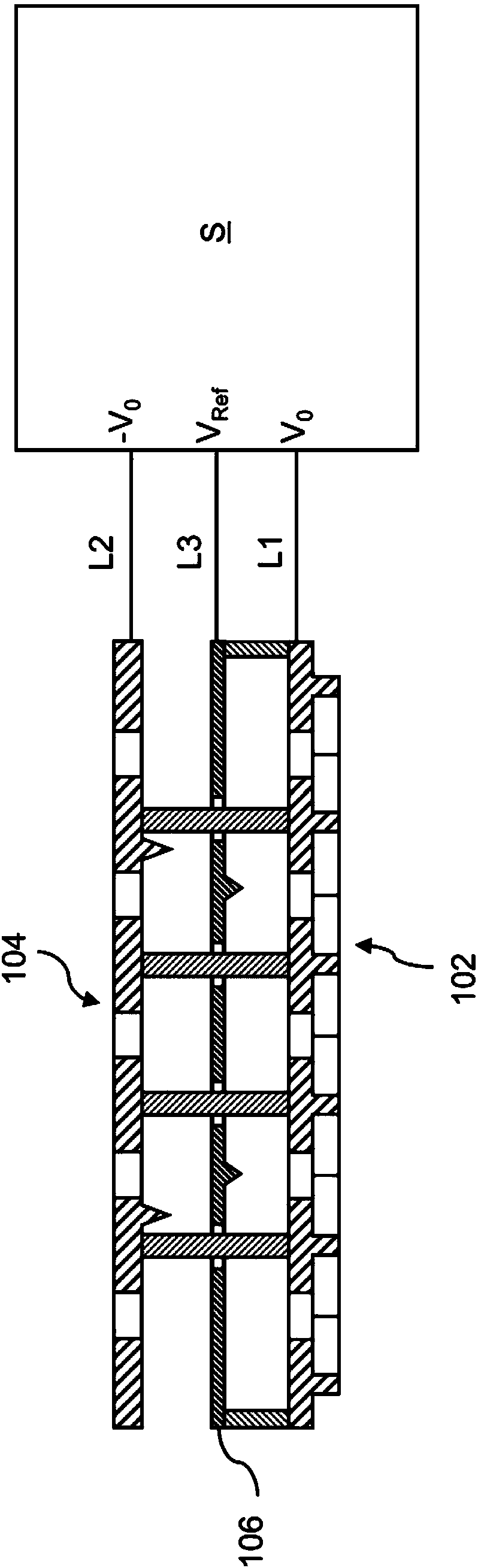

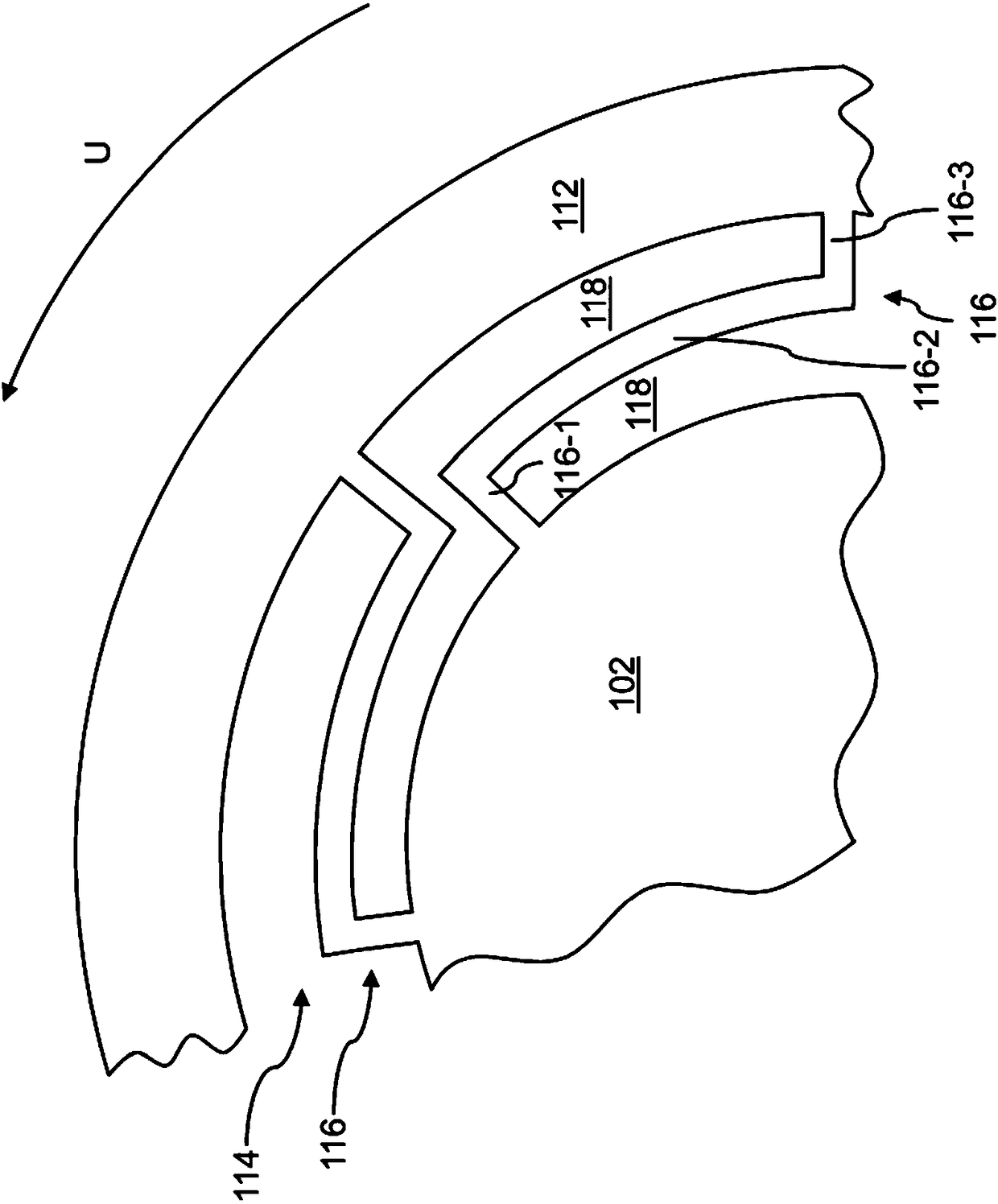

[0015] exist figure 1 An exemplary microelectromechanical microphone 100 is shown in . The MEMS microphone 100 has a flat first electrode 102 and a flat second electrode 104 , and the second electrode is spaced apart from the first electrode 102 .

[0016]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com