Metal mesh processing device

A processing device and metal mesh technology, applied in the field of mechanical processing, can solve the problems of complex structure, easy to be torn apart, high processing cost of metal mesh, etc., achieve good use effect and simplify the weaving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is further described:

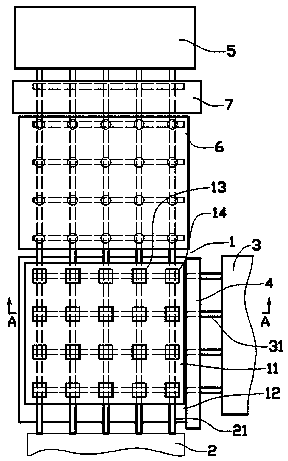

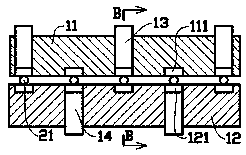

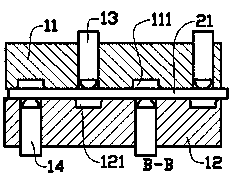

[0017] Such as Figure 1 to Figure 5 As shown in the embodiment, the metal mesh processing device includes a weaving module 1, the rear of the weaving module 1 is equipped with a warp feeding module 2, and the side of the weaving module 1 is equipped with a weft feeding module 3 , the warp feeding module 2 supplies more than three parallel warp filaments 21 moving forward to the weaving module 1 , and the weft feeding module 3 supplies weft filaments 31 moving laterally to the weaving module 1 . Both the warp threads 21 and the weft threads 31 are made of metal materials. In this embodiment, the metal threads as the weft threads 31 have a certain rigidity, so that they can be threaded forward directly from the rear. In specific design, the weaving module 1 includes an upper block 11 and a lower block 12 that are assembled parallel to each other up and down. A working interval is designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com