Repairing device of traction roller boss

A technology of traction rollers and bosses, which is applied in the field of repairing devices for traction roller bosses, can solve problems such as leaving potholes, long-term shutdown, and affecting the production progress of glass substrates, so as to prolong the service life and reduce production loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0062] In this disclosure, unless stated otherwise, the orientation words "up" and "down" used refer to the up and down of the repair device of the traction roller boss in the working state, "front" and "rear" It is defined according to usage habits. The direction close to the boss of the traction roller is the front, and the direction away from the boss of the traction roller is the rear. "Inner" and "outer" refer to the contours of the corresponding parts. The terms "first", "second", etc. used in , are to distinguish one element from another, and do not have order or importance.

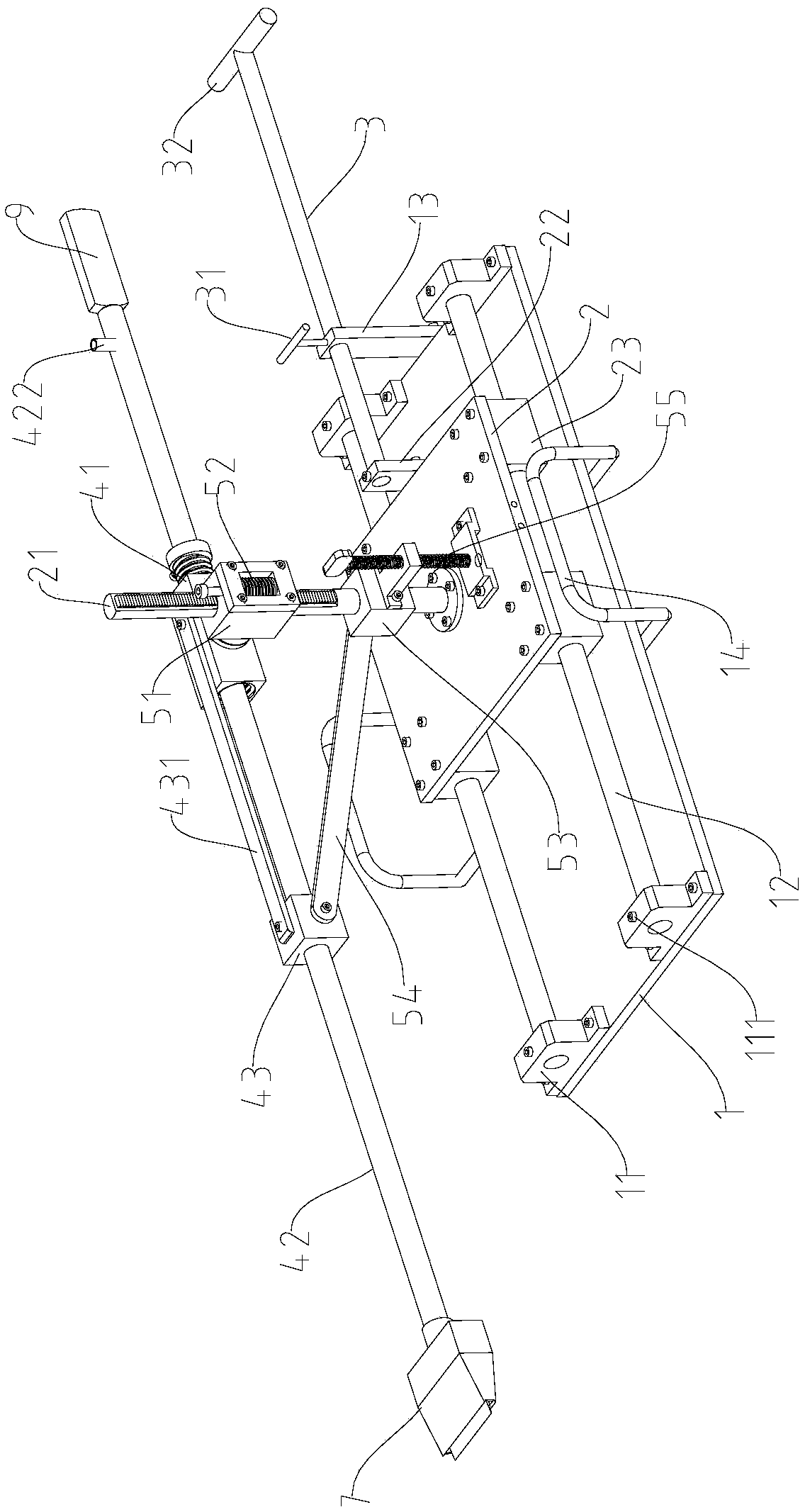

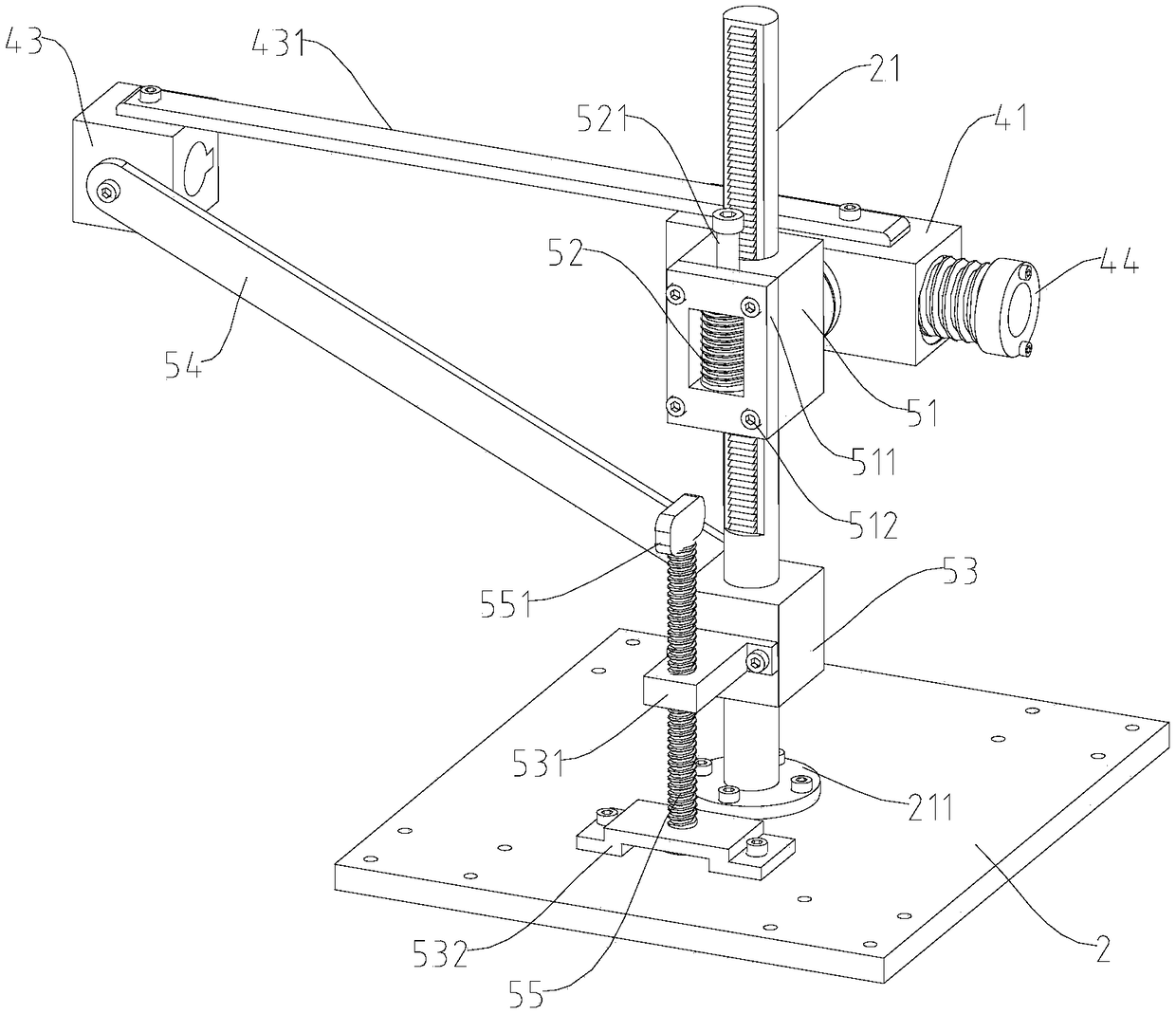

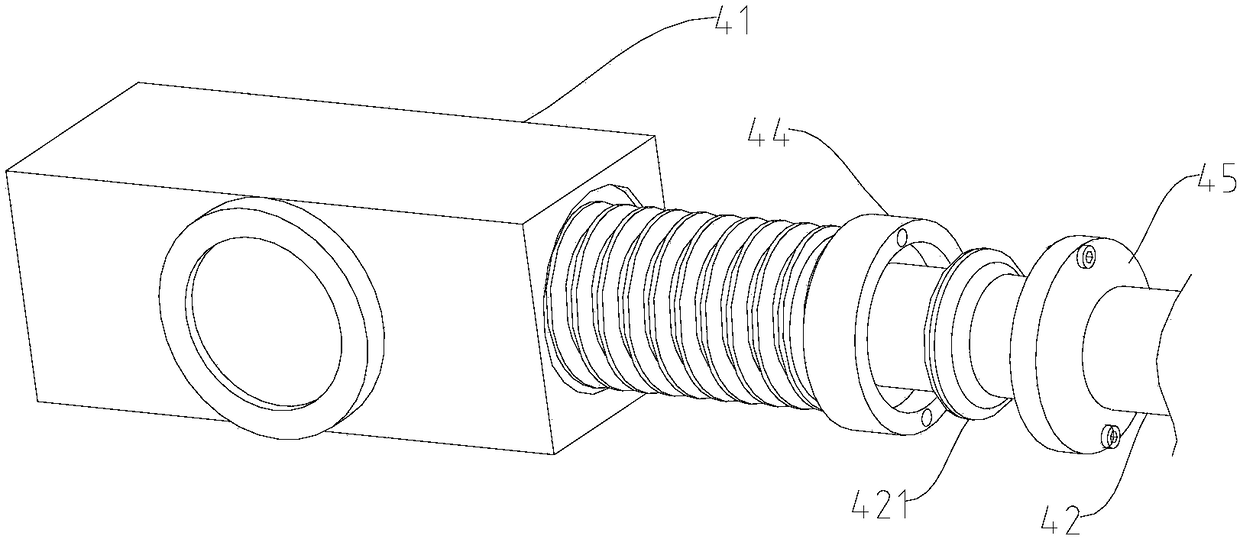

[0063] Such as figure 1 As shown, the present disclosure provides a repair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com