Patents

Literature

44results about How to "Reduced productivity loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

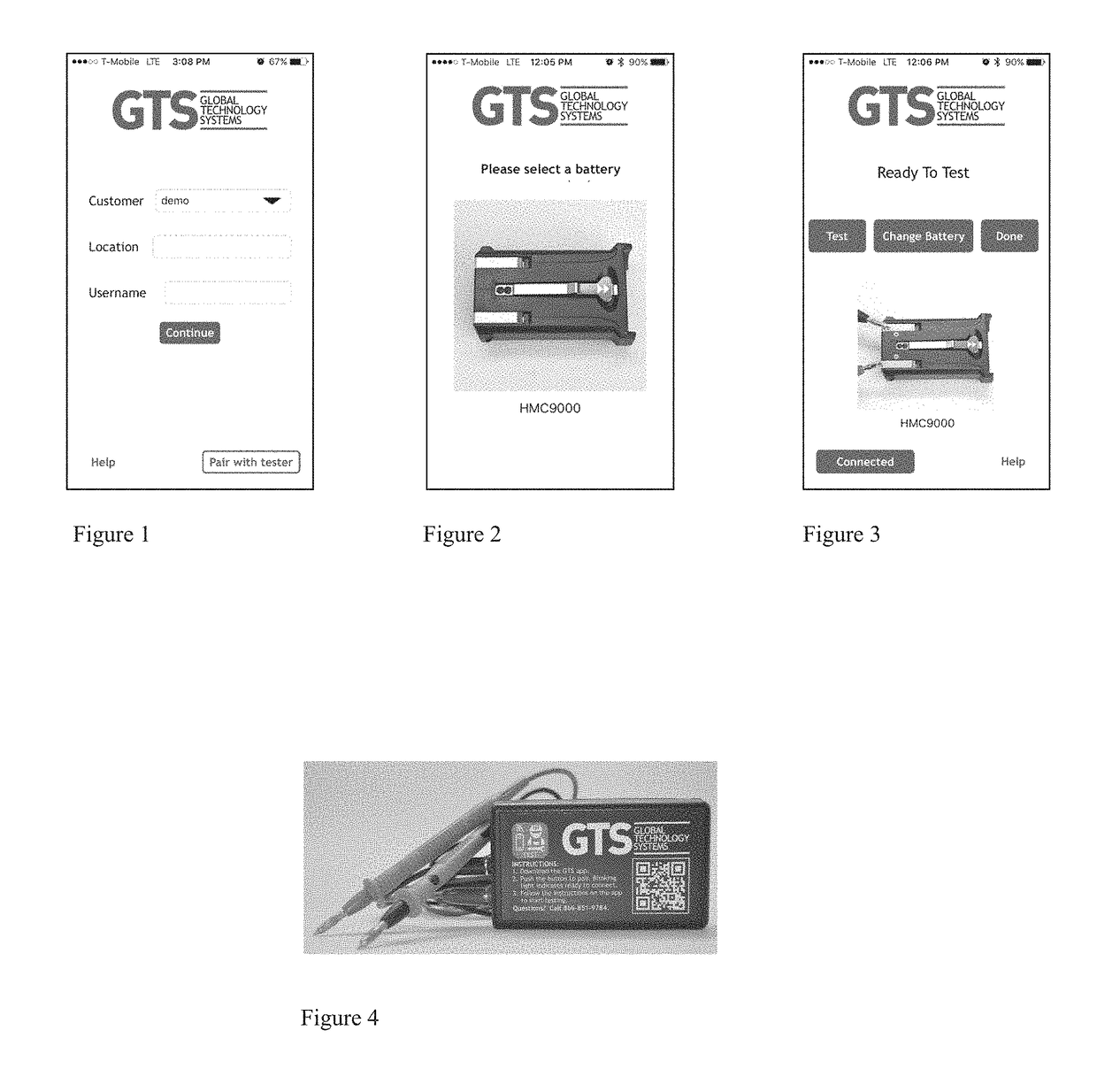

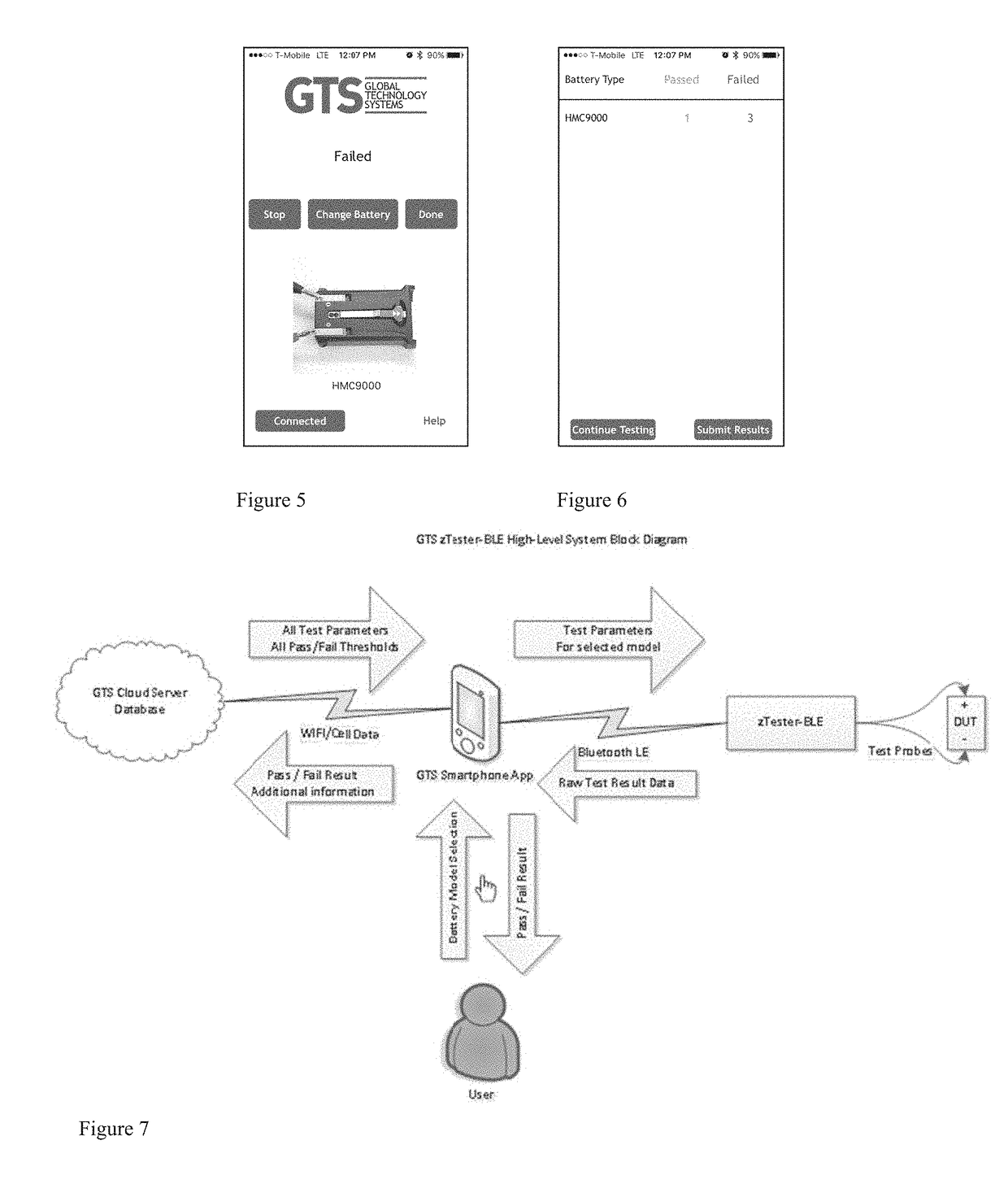

Battery pack tester and connected app for bluetooth connected smart device

InactiveUS20170315183A1Avoid Equipment FailureReduced productivity lossElectrical testingBluetoothEmbedded system

Disclosed is a system for managing and replacing batteries. In particular, a rapid field tester that pairs via Bluetooth with a smart device, such as a mobile phone. The smart device containing an APP that further interfaces with a remote server to provide management of the battery. A user can test their battery and receive a visual indication if the battery passes or fails predetermined conditions. If the battery fails the test, a replacement battery will be automatically sent to the user. All of the test data is logged through the server and provided to the user in order to facilitate effective battery management.

Owner:GLOBAL TECH SYST

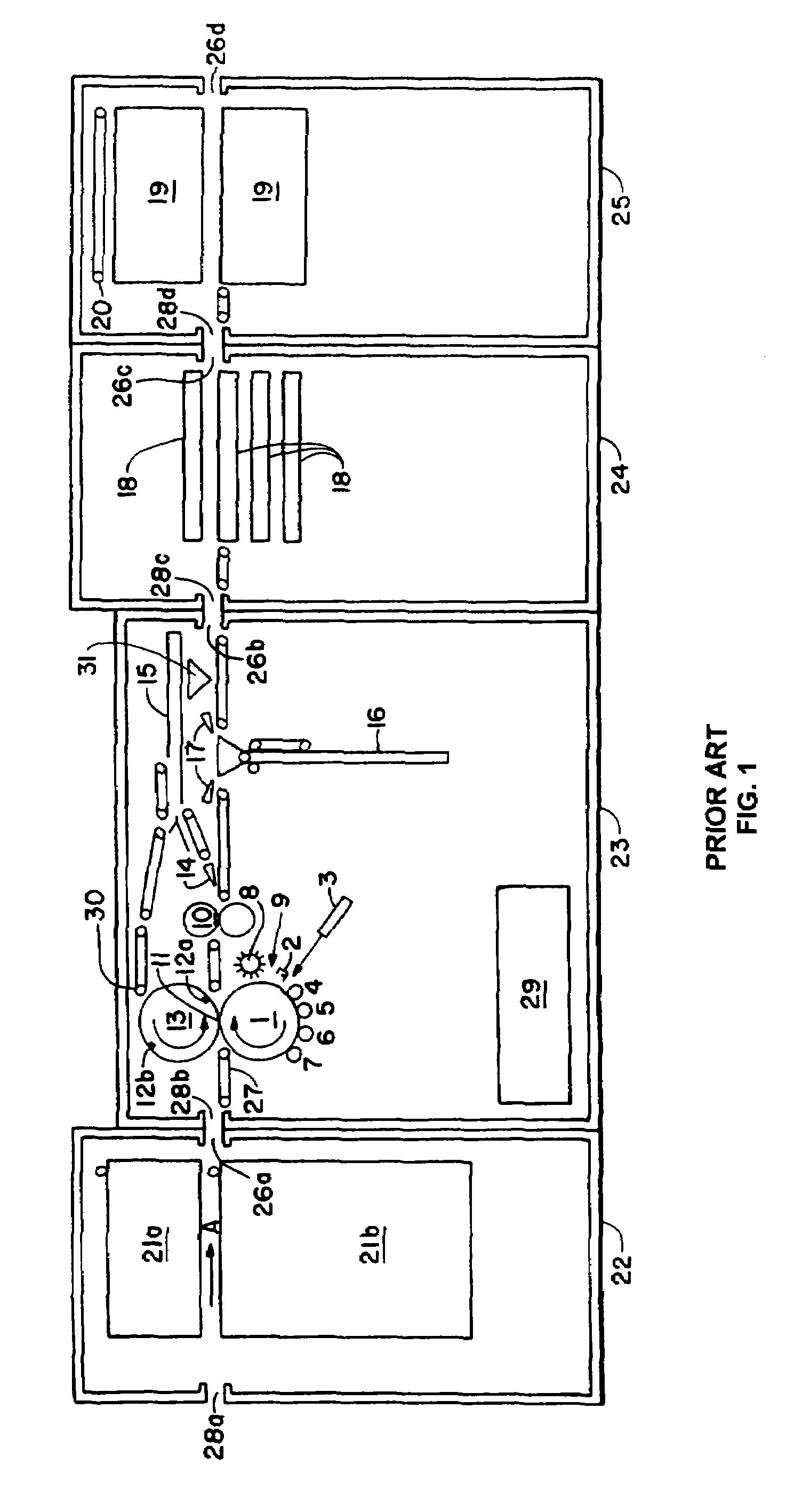

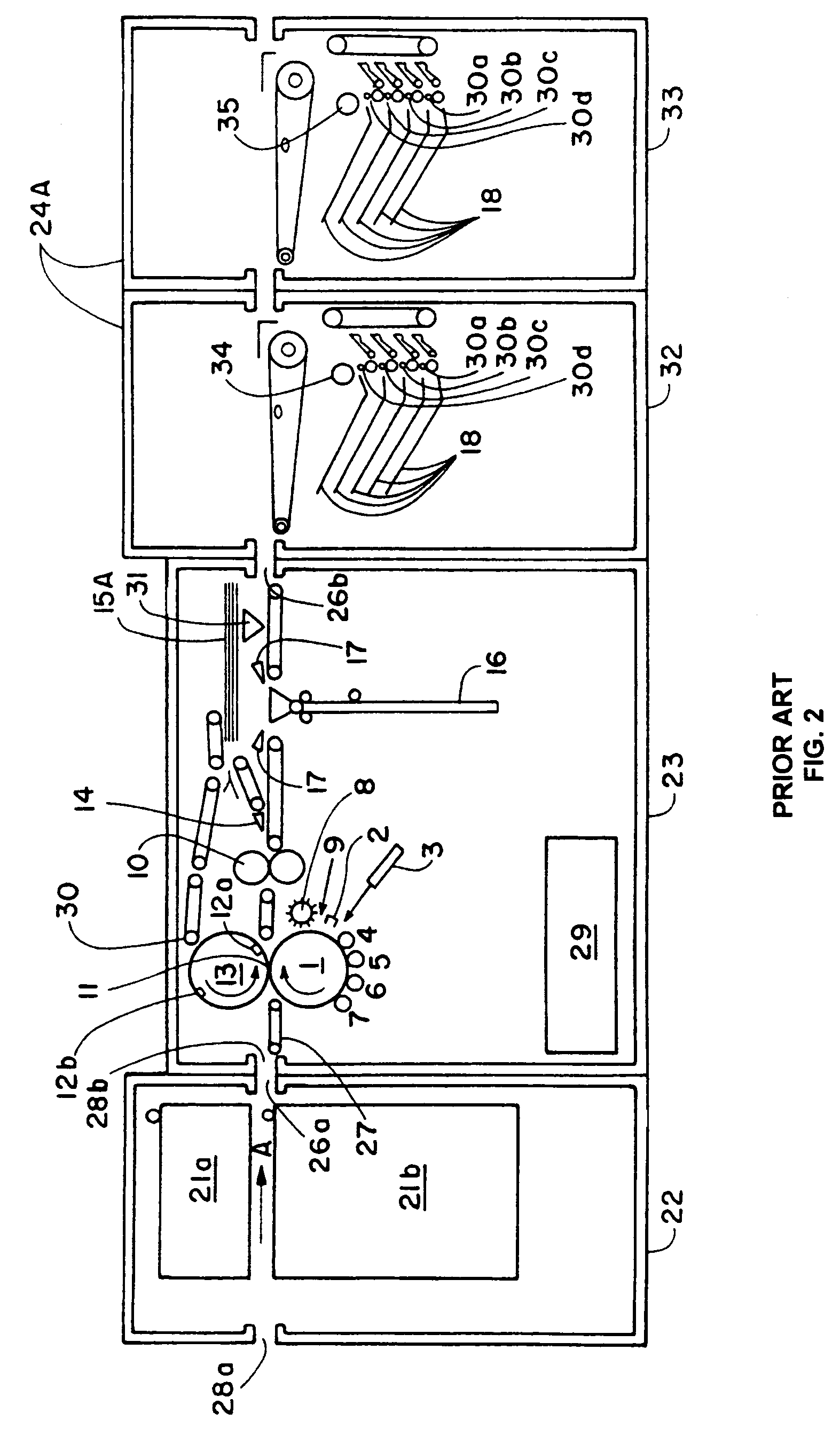

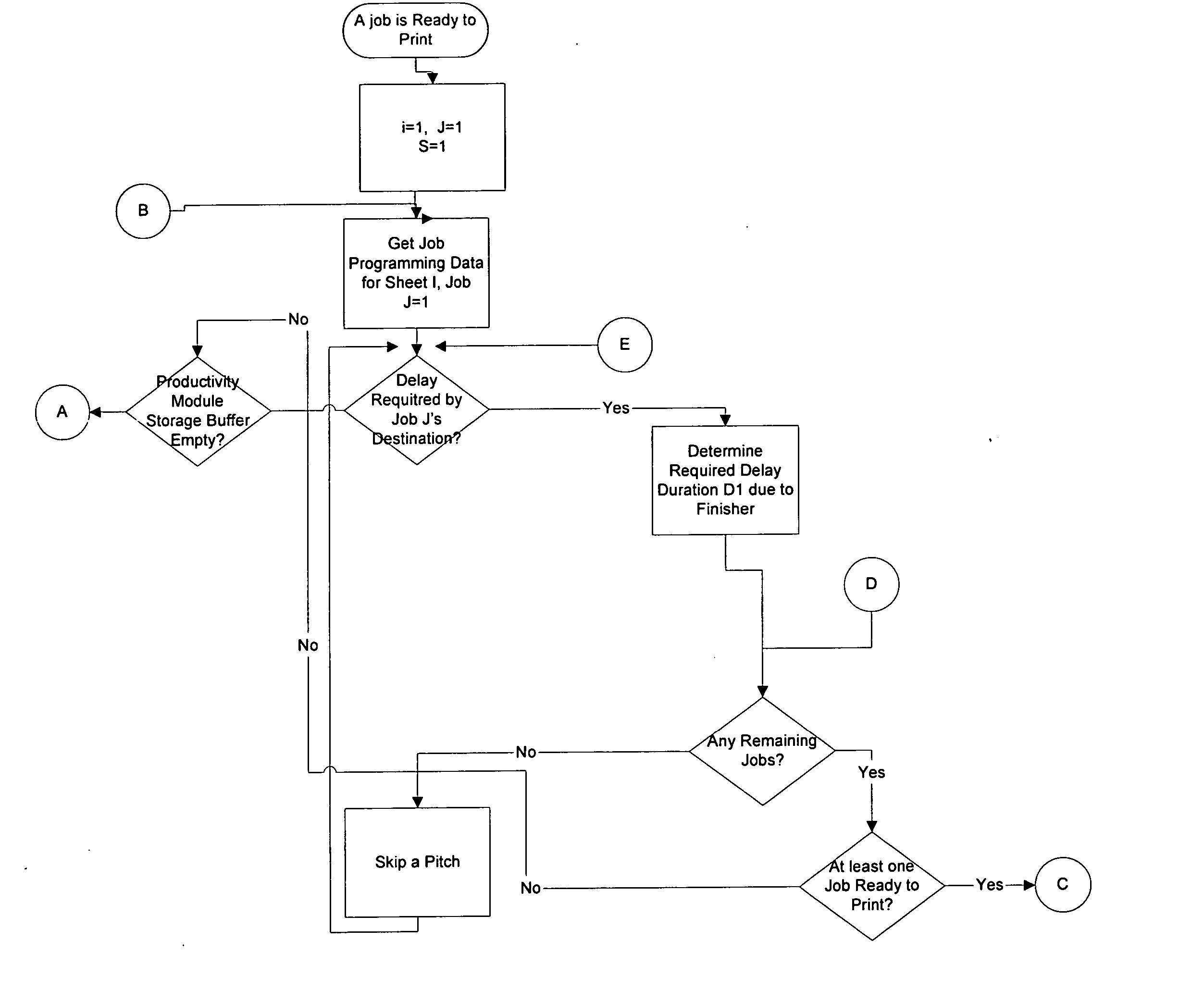

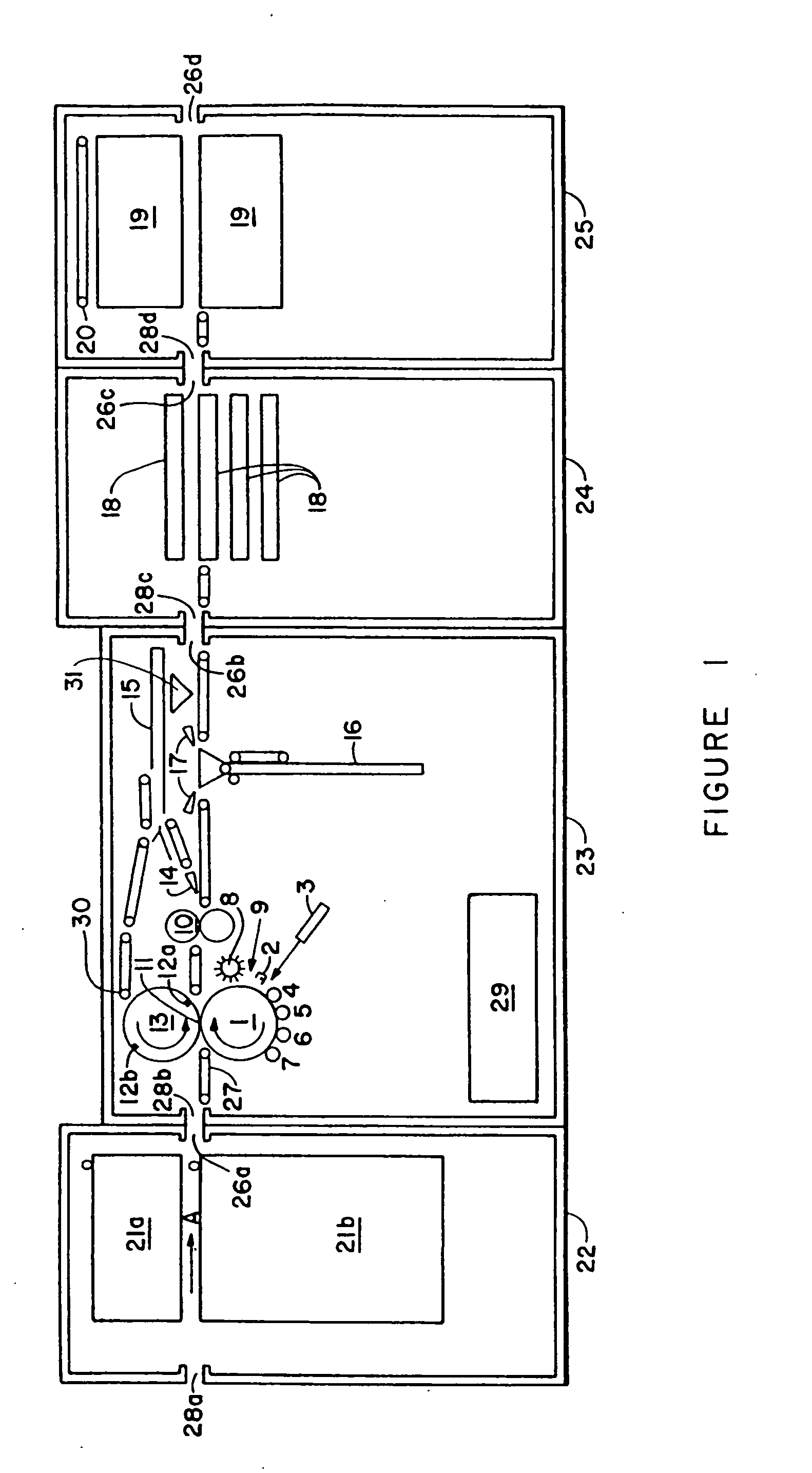

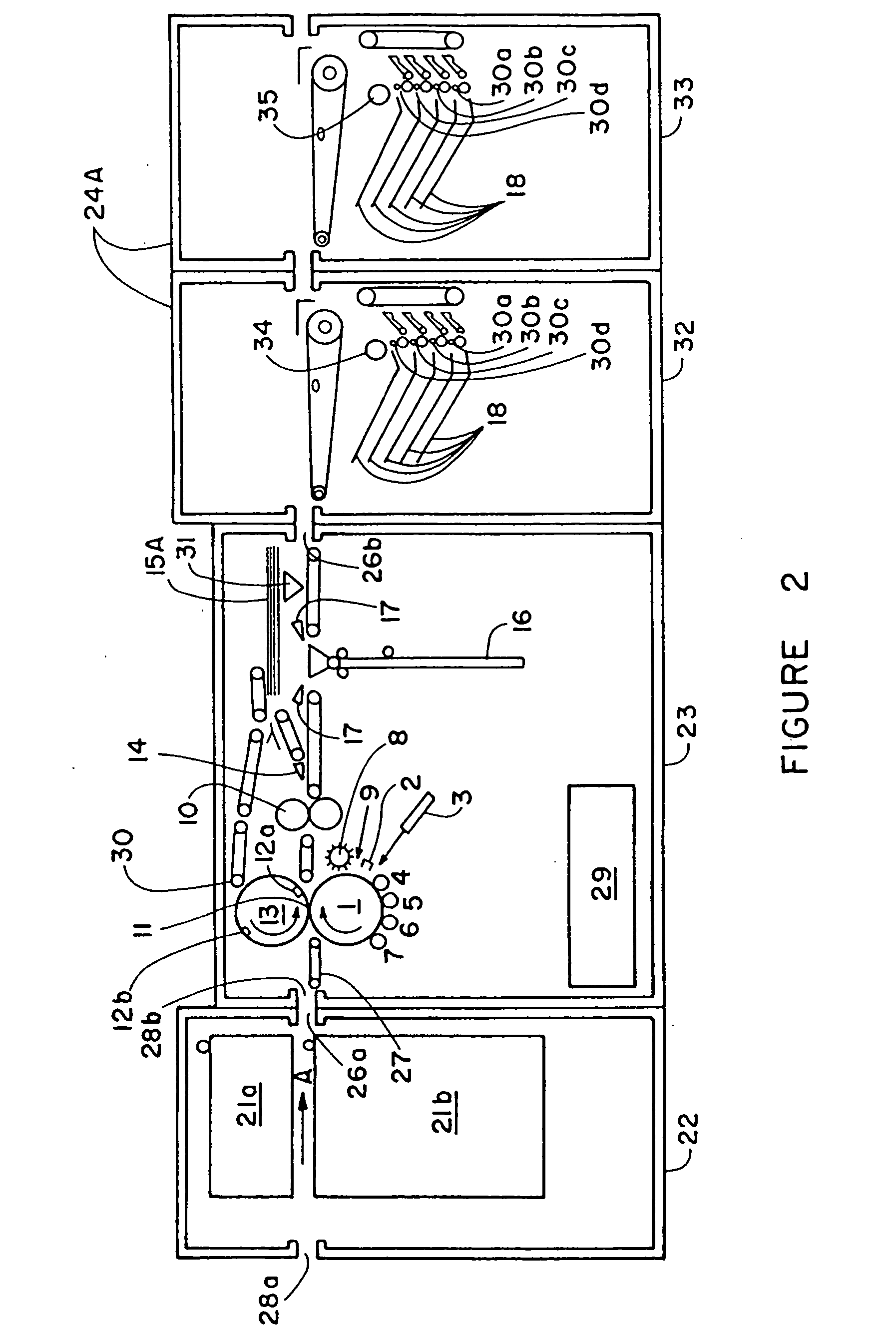

Apparatus and method to improve printer productivity

InactiveUS7254355B2Reduced productivity lossElectrographic process apparatusProduction rateIndustrial engineering

Owner:SAHAY RAVI B

Apparatus and method to improve printer productivity

InactiveUS20060263110A1Increase flexibilityImprove integrityElectrographic process apparatusProduction rateIndustrial engineering

Owner:SAHAY RAVI B

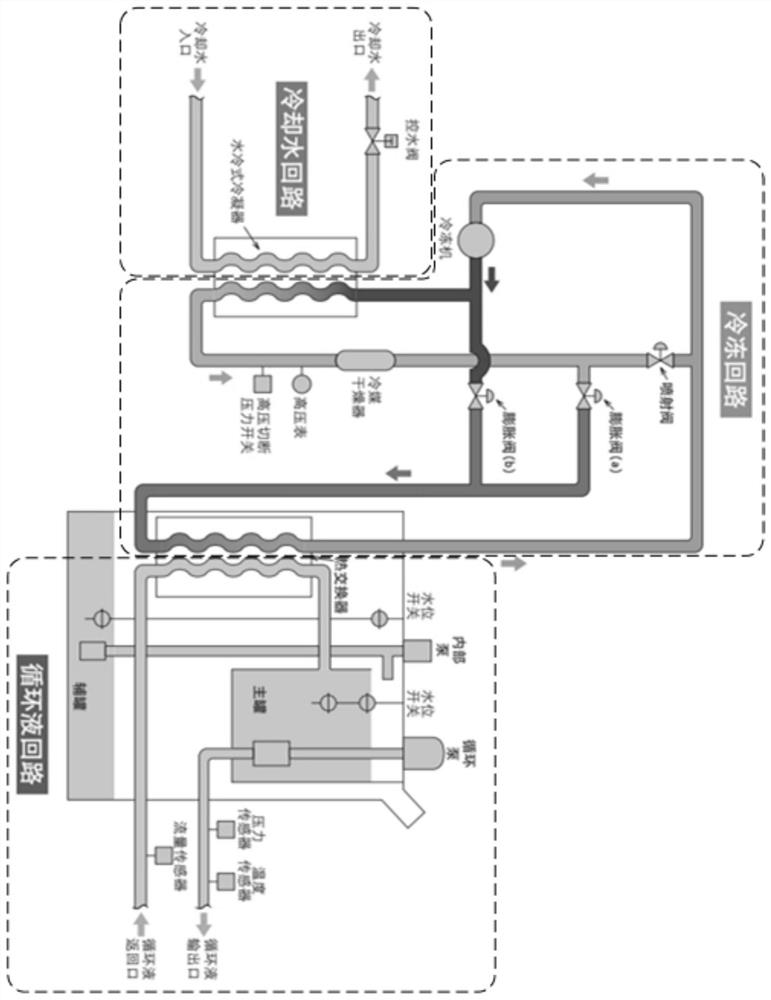

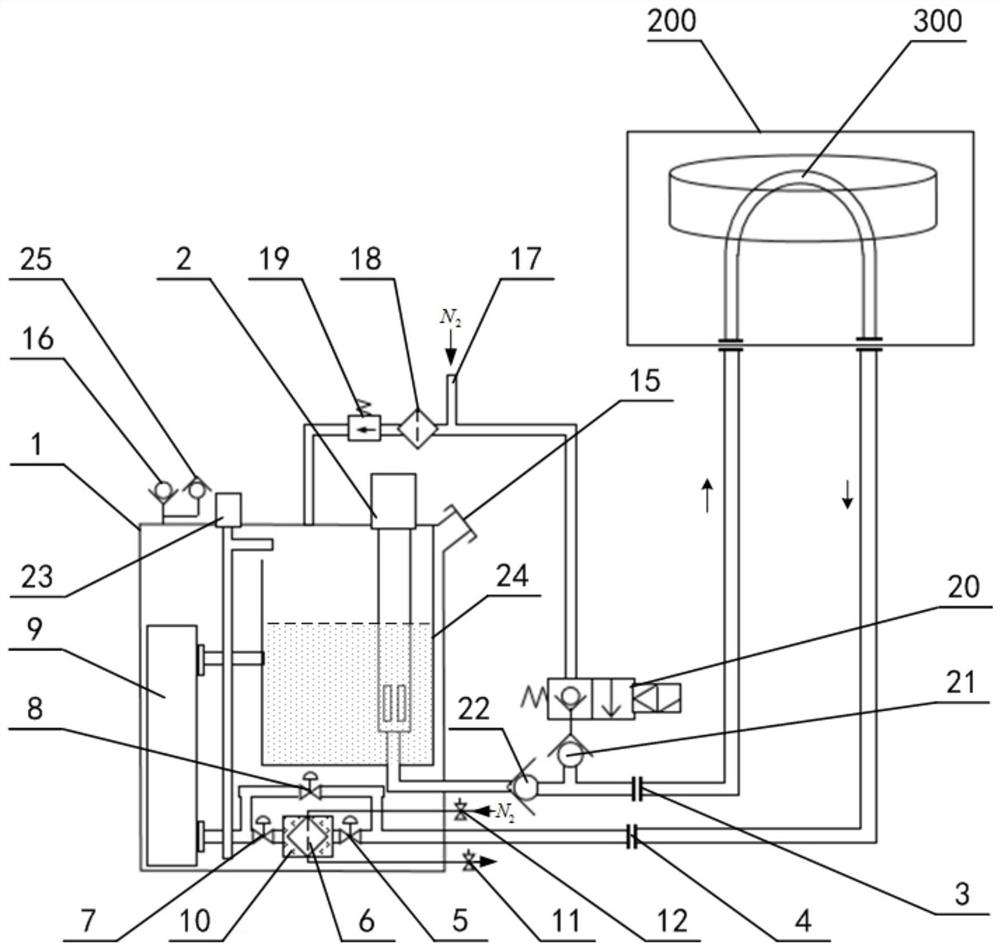

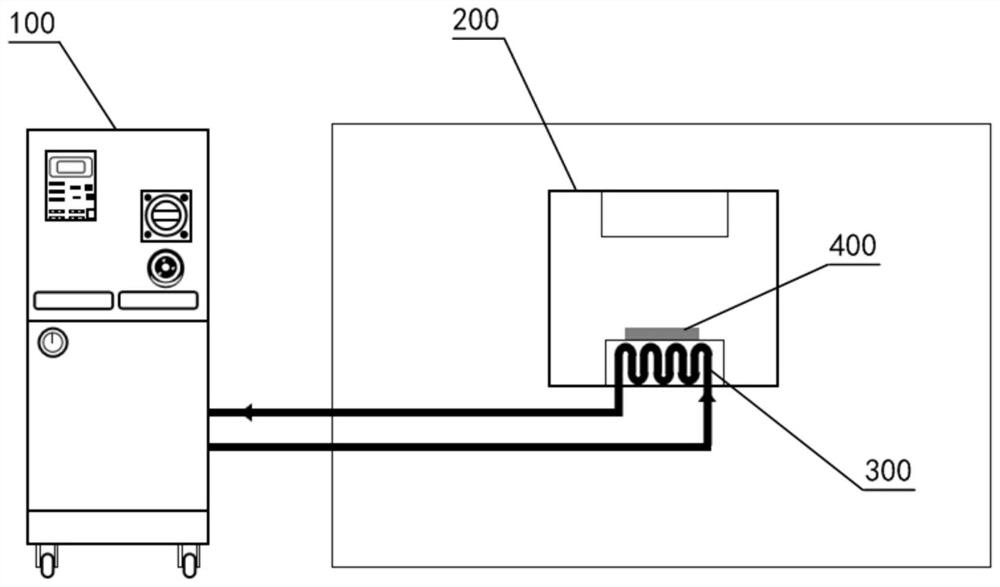

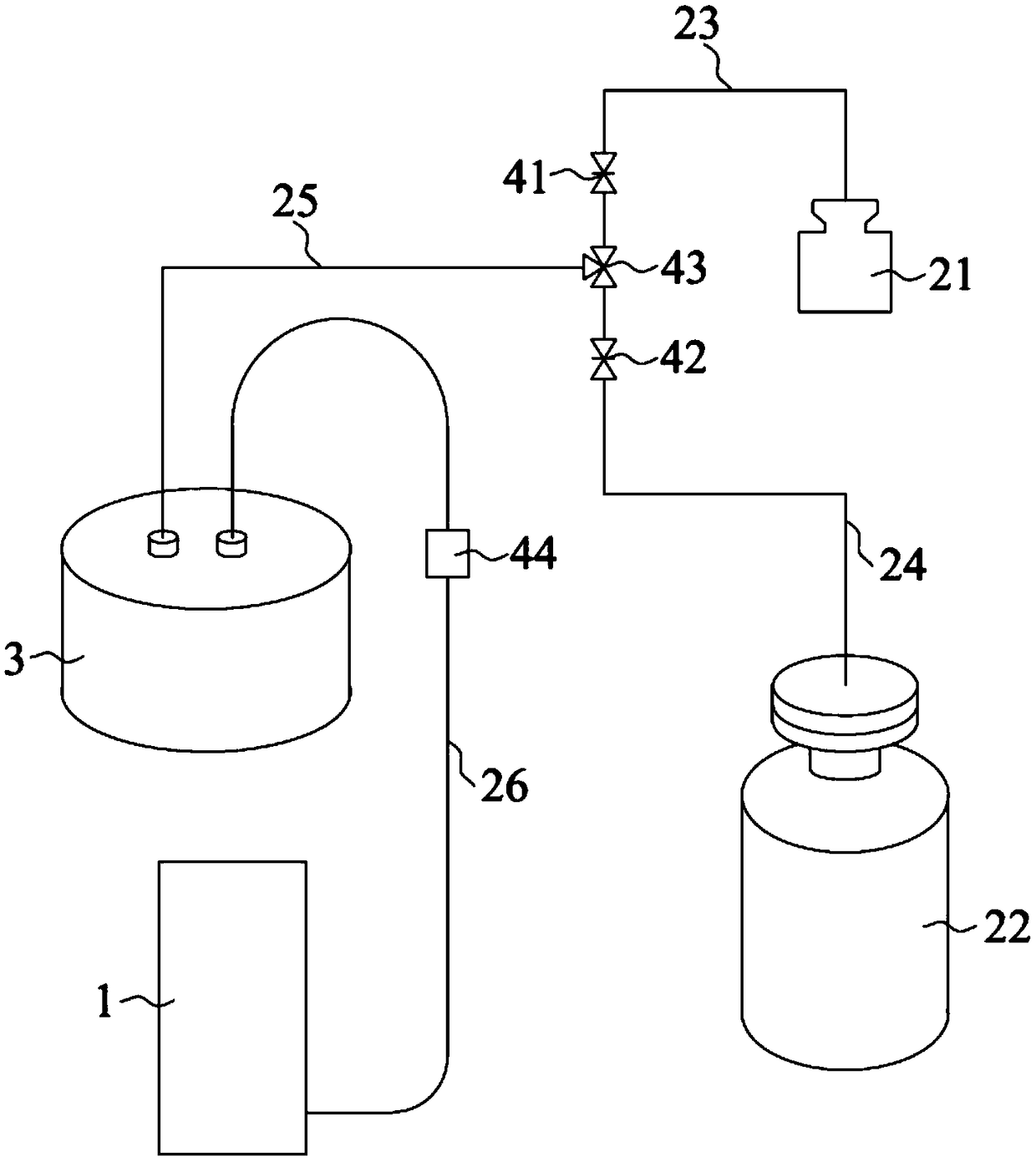

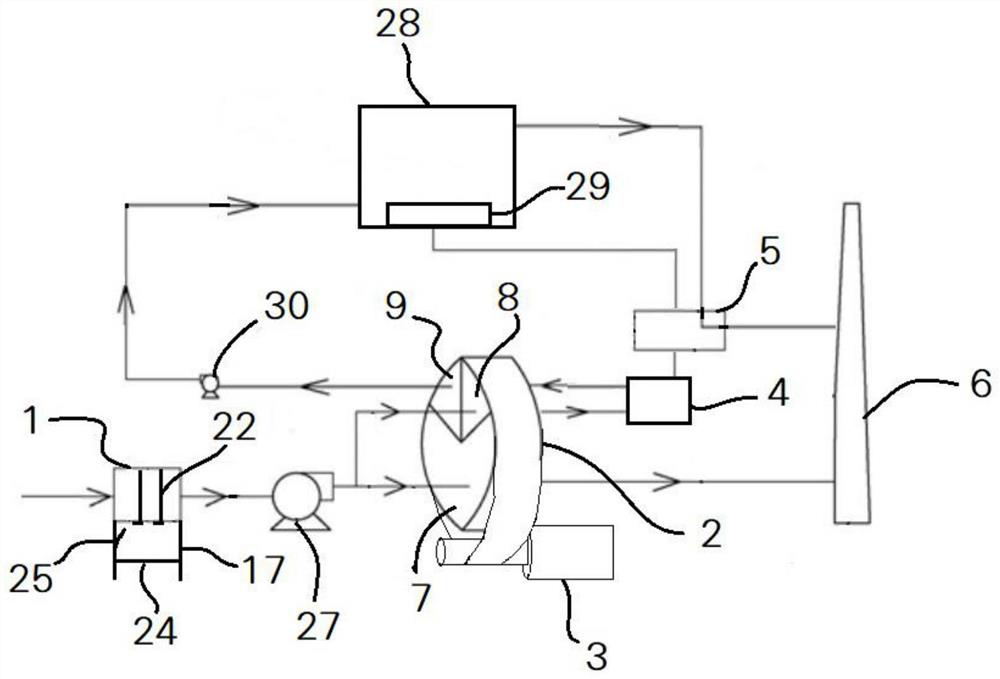

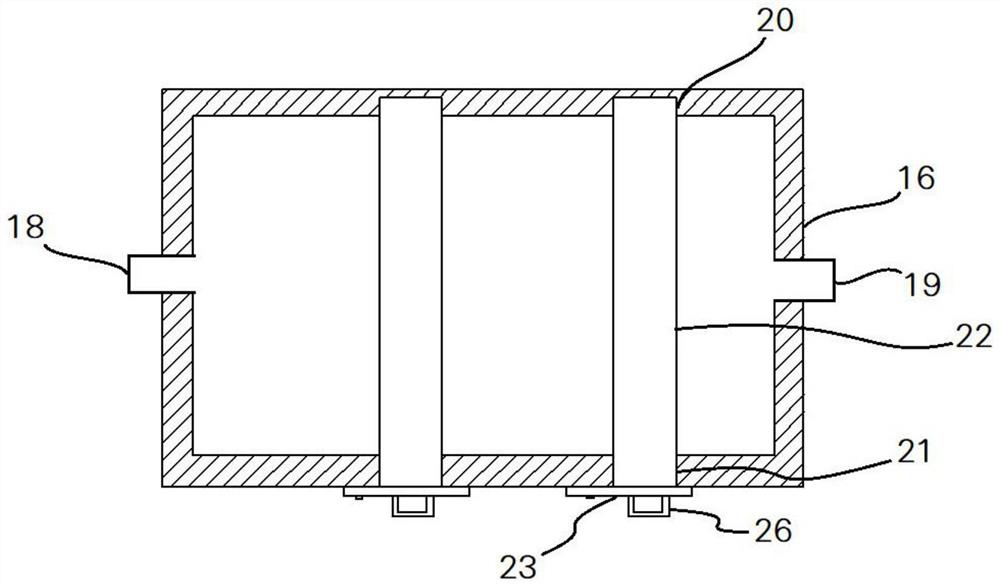

Low-temperature and constant-temperature liquid circulating device and dewatering method thereof

InactiveCN112629125AAvoid cloggingAvoid Cooling FailuresDrying gas arrangementsCooling fluid circulationTemperature controlCapillary Tubing

The invention relates to the technical field of low temperature and constant temperature, and discloses a low-temperature and constant-temperature liquid circulating device and a dewatering method thereof. According to the low-temperature and constant-temperature liquid circulating device and the dewatering method thereof, on one hand, an ice crystal filter and a plurality of stop valves are additionally arranged in a circulating liquid loop, so that a pair of parallel standby branch and common branch can be formed, when circulating liquid flows through the common branch where the ice crystal filter is located, mixed water can be effectively intercepted and collected due to the fact that the water is frozen into ice cubes, the phenomena that a capillary pipeline in a temperature control liquid pipeline is blocked in the follow-up circulating process, and component cooling faults are caused can be solved, the temperature control stability is guaranteed, on the other hand, a heater, an exhaust connector, a nitrogen connector and a plurality of valves are continuously and additionally arranged for the ice crystal filter, when the standby branch is switched to replace the common branch to keep the circulating liquid loop to be connected, water in the ice crystal filter can be heated and purged in an isolated mode, and therefore on the premise that the circulating liquid loop is not interrupted, the maintenance time can be shortened, the maintenance operation can be reduced, and the equipment productivity loss can be reduced.

Owner:上海谙邦半导体设备有限公司

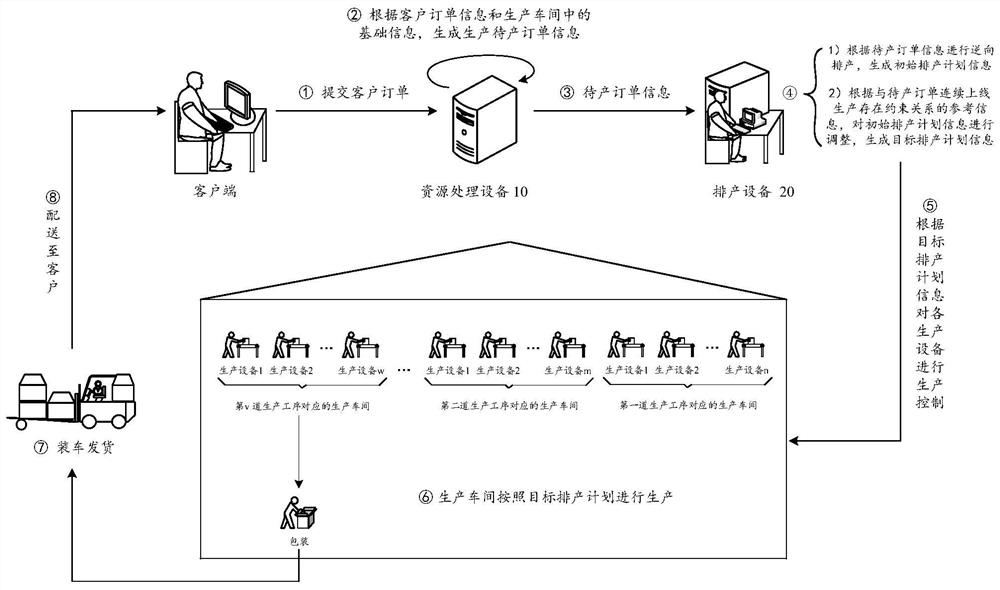

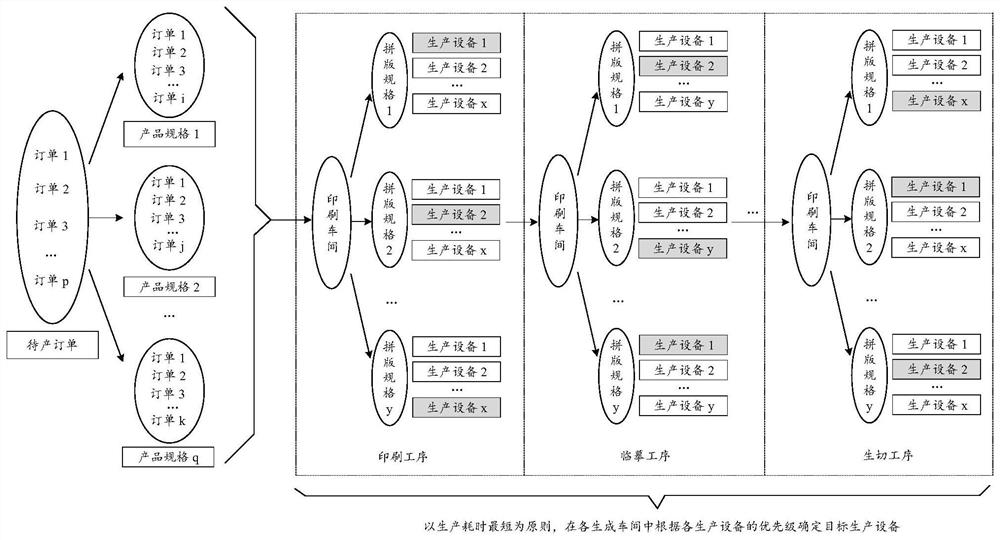

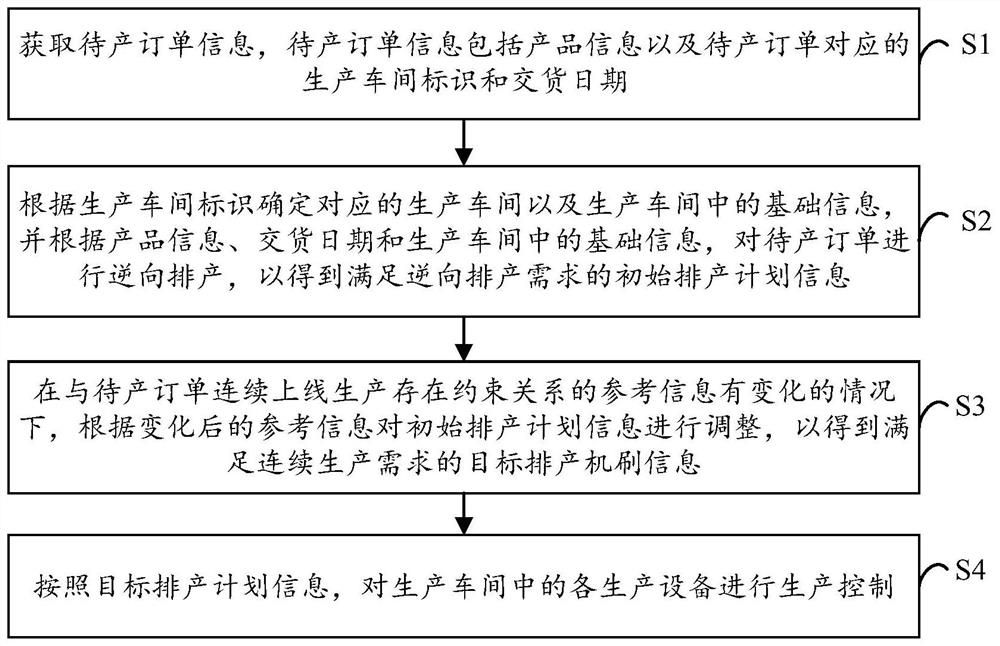

Production scheduling method, equipment, device and storage medium

ActiveCN113393092AWaste less timeReduced productivity lossResourcesManufacturing computing systemsProcess engineeringIndustrial engineering

The embodiment of the invention provides a production scheduling method, equipment and device and a storage medium. In the embodiment of the invention, the corresponding production workshop and the basic information in the production workshop can be determined according to the production workshop identifier corresponding to the to-be-produced order, and targeted production scheduling is carried out on the production workshop by taking continuous online production of the to-be-produced order as a target based on the basic information and the product information in the production workshop and the delivery date of the to-be-produced order, therefore, the most time-saving production scheduling plan information is obtained. And on the basis of the production scheduling plan information, production control is performed on the production equipment, so that time waste and capacity loss can be reduced, and the production efficiency is improved. Moreover, under the condition that the reference information having the constraint relationship with the continuous on-line production of the to-be-produced order changes, the scheduling plan information can be adjusted according to the changed reference information, so that the adjusted scheduling plan information still meets the requirement of the continuous on-line production of the to-be-produced order.

Owner:青岛奥利普奇智智能工业技术有限公司

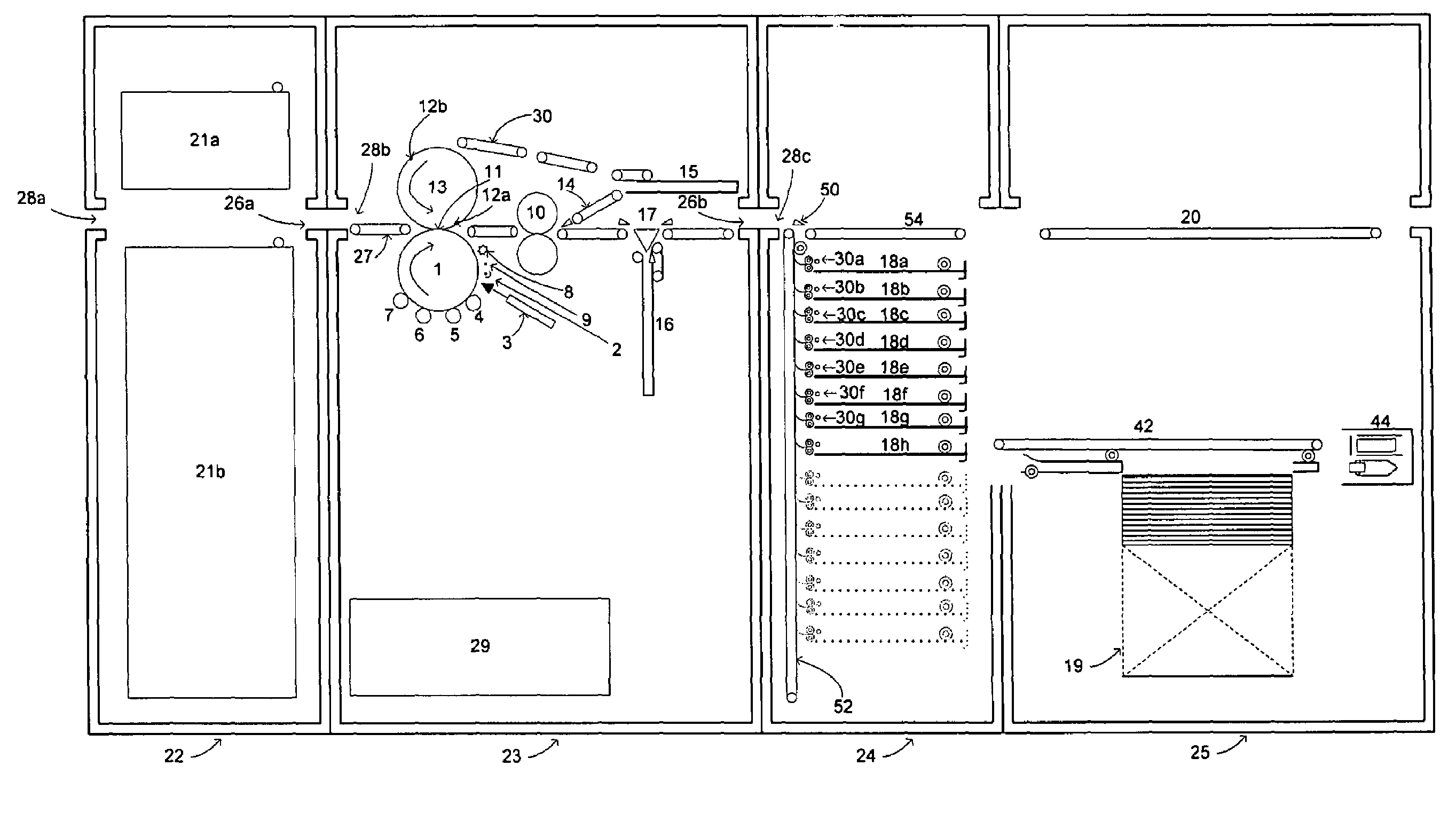

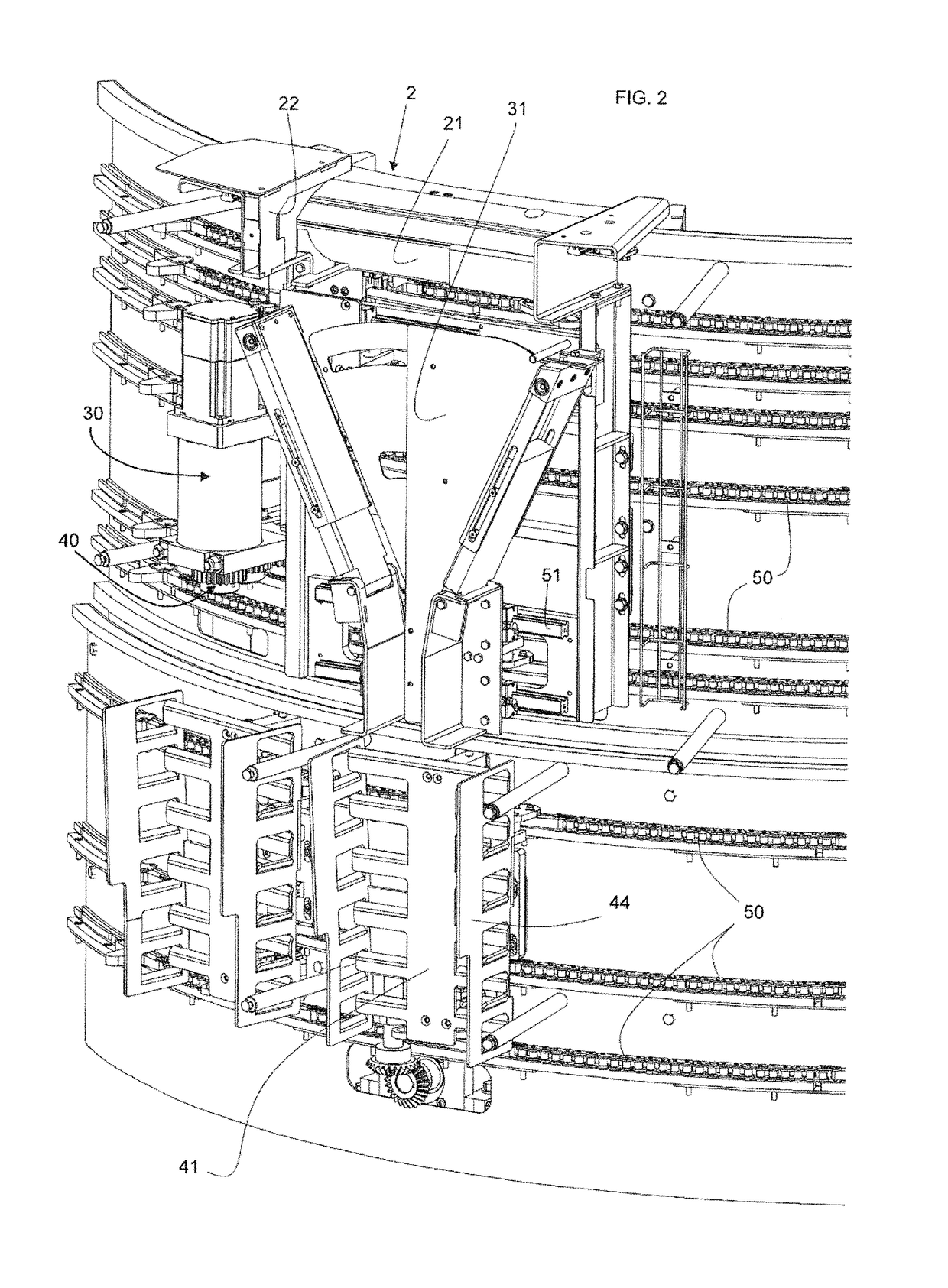

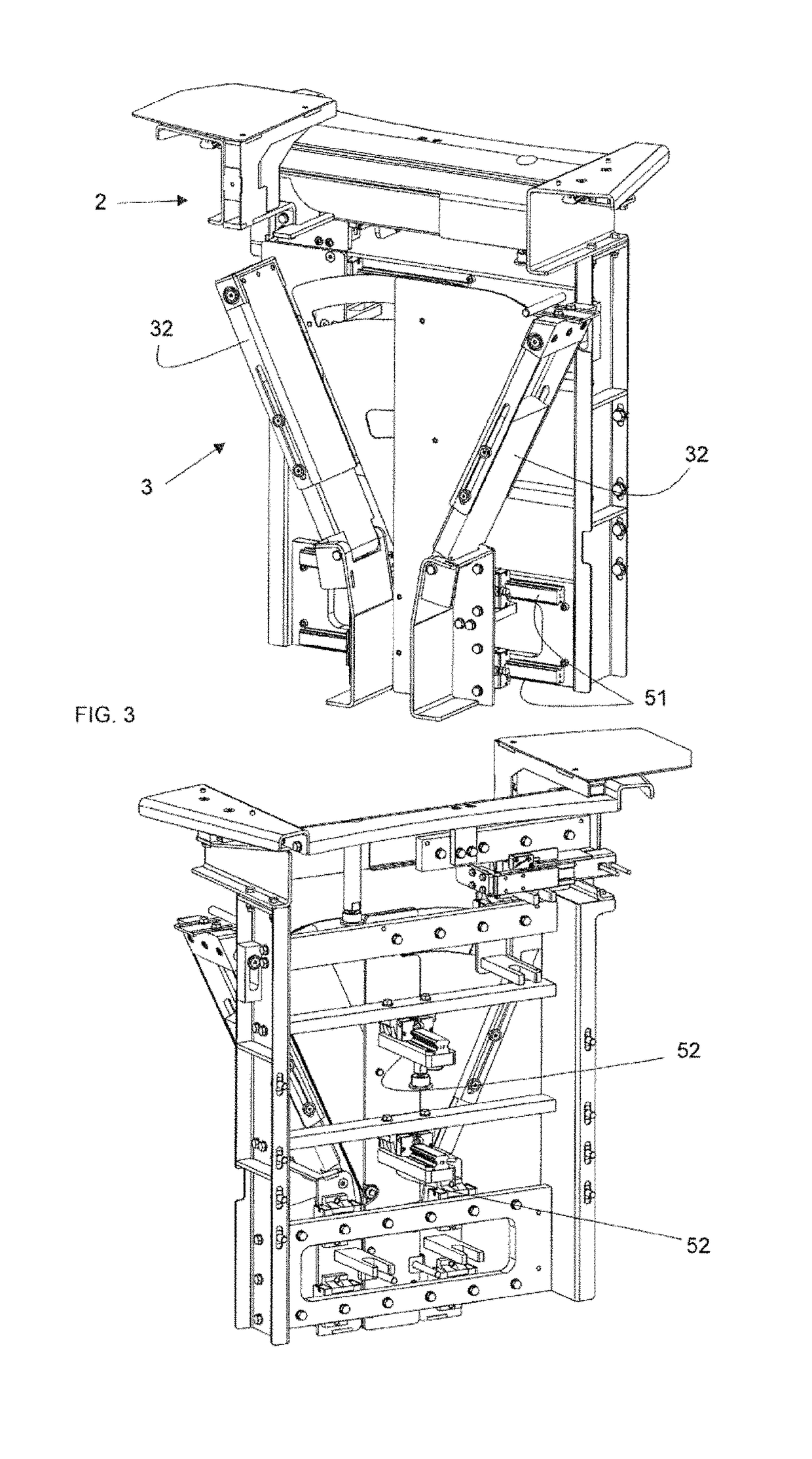

Sorting device of bulk containers with automatic size change

InactiveUS20190071256A1Reduced productivity lossIncrease in sizeConveyorsConveyor partsSize changeDischarger

A sorting machine, or unscrambler of bulk containers, including a first carousel and a second carousel on which a series of cradles are mounted which are adapted to receive the containers in a horizontal position, a series of straightening dischargers, a series of separation frames, more generally separators, having the function of receiving the container discharged by the overhead discharge channels; and wherein at least one of the series of cradles and / or dischargers and / or separators has at least one element or wall movable in width or in depth. The machine includes automatic actuation devices configured to move the movable element or wall, wherein the devices are arranged outside the first and second carousels.

Owner:LANFRANCHI SRL

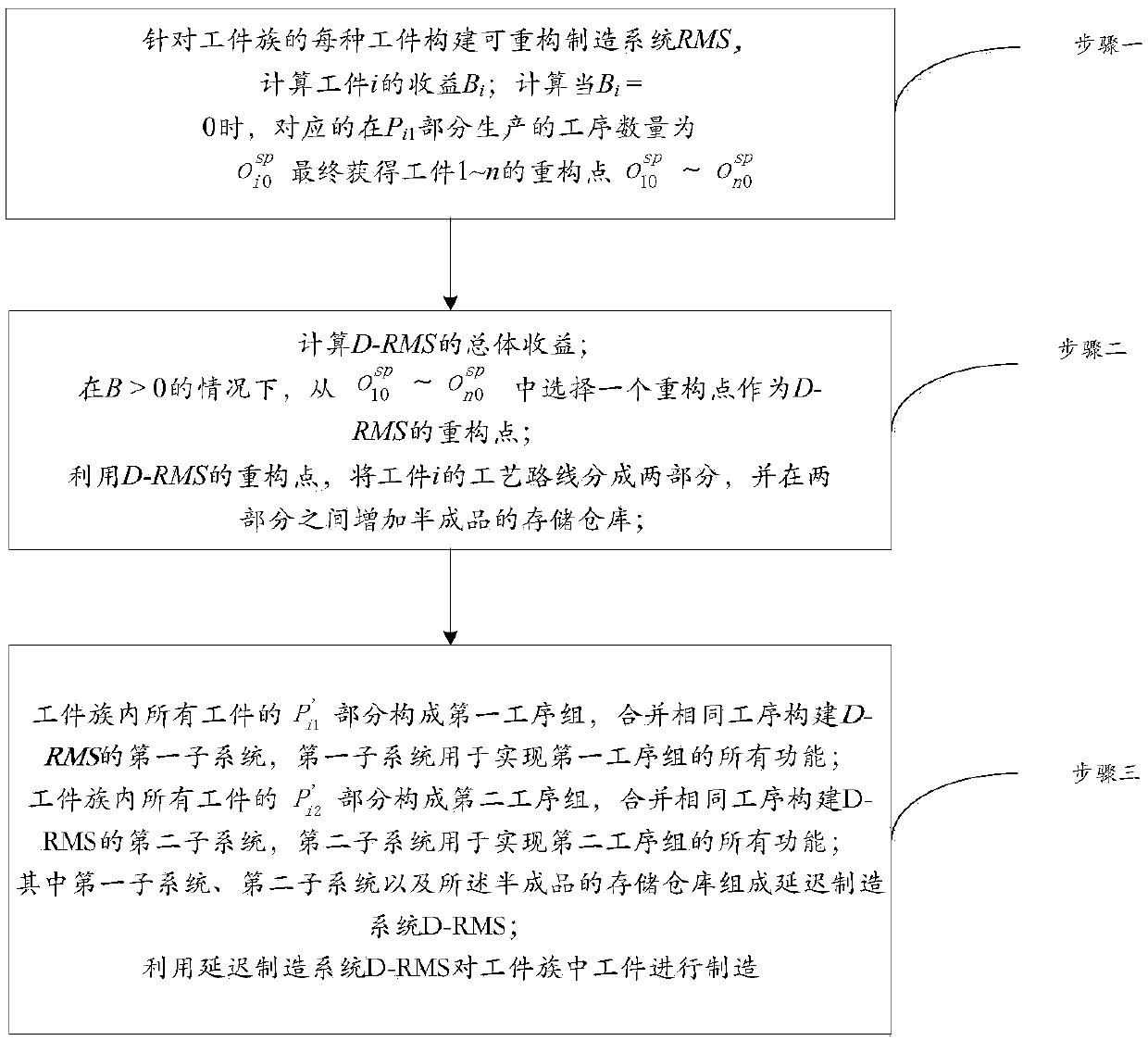

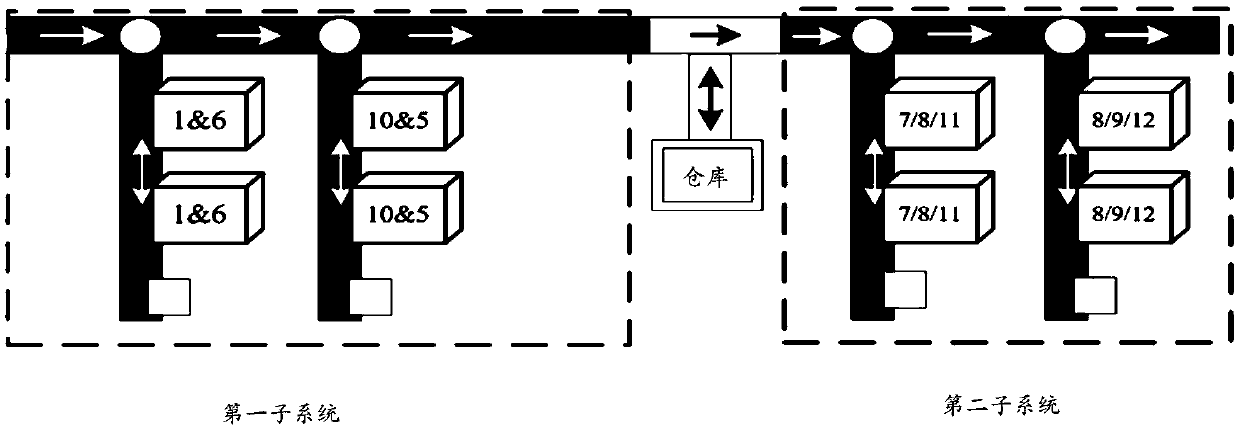

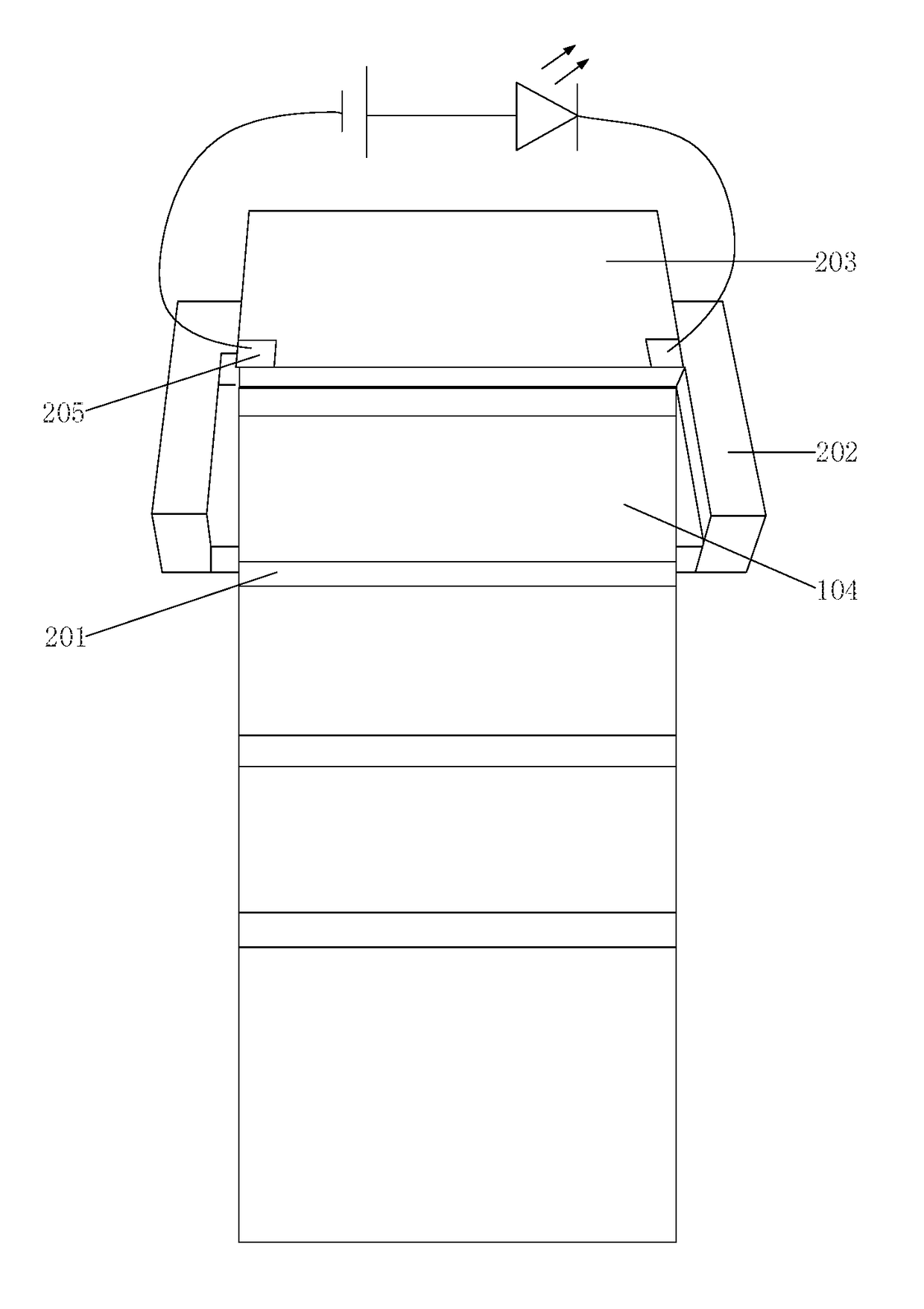

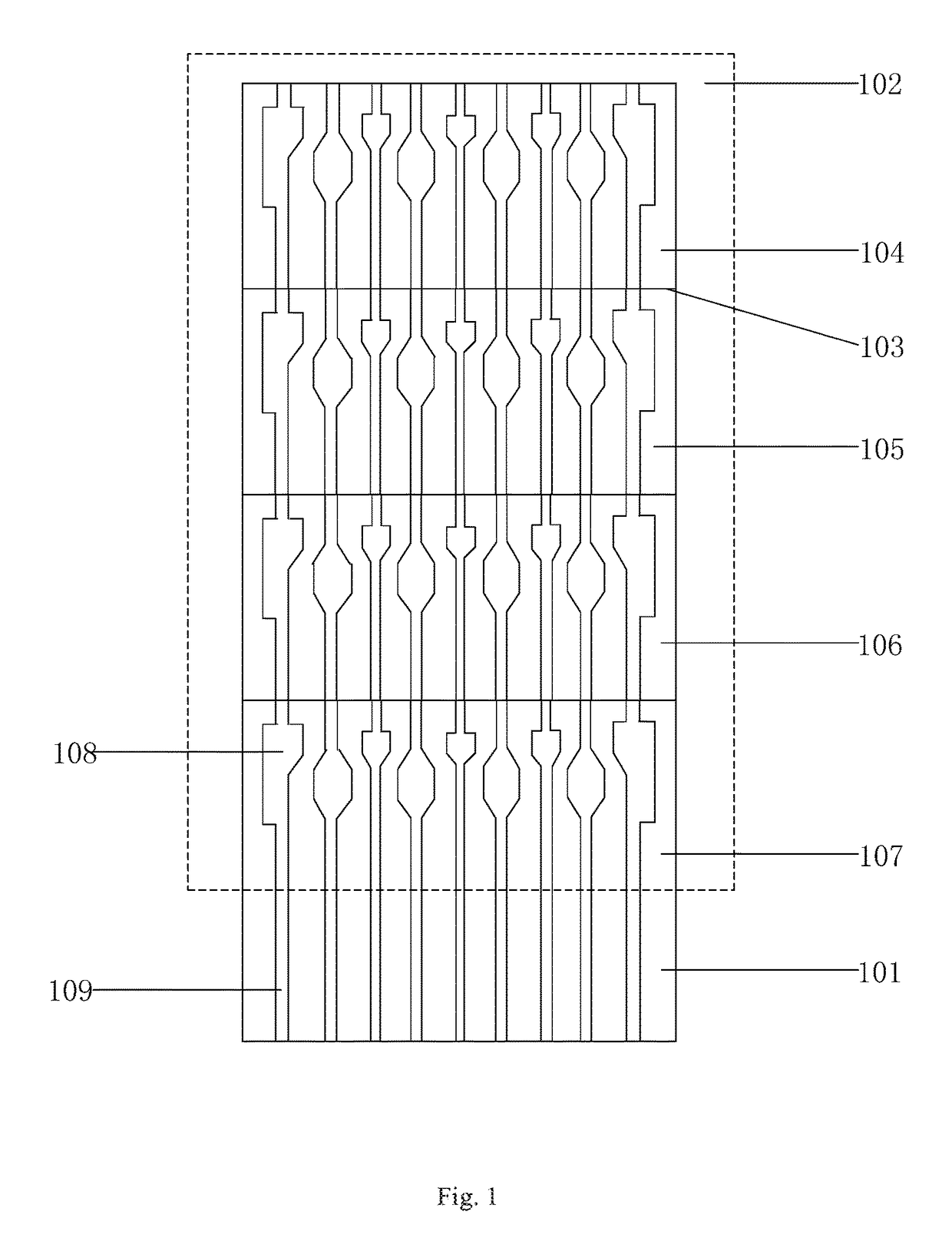

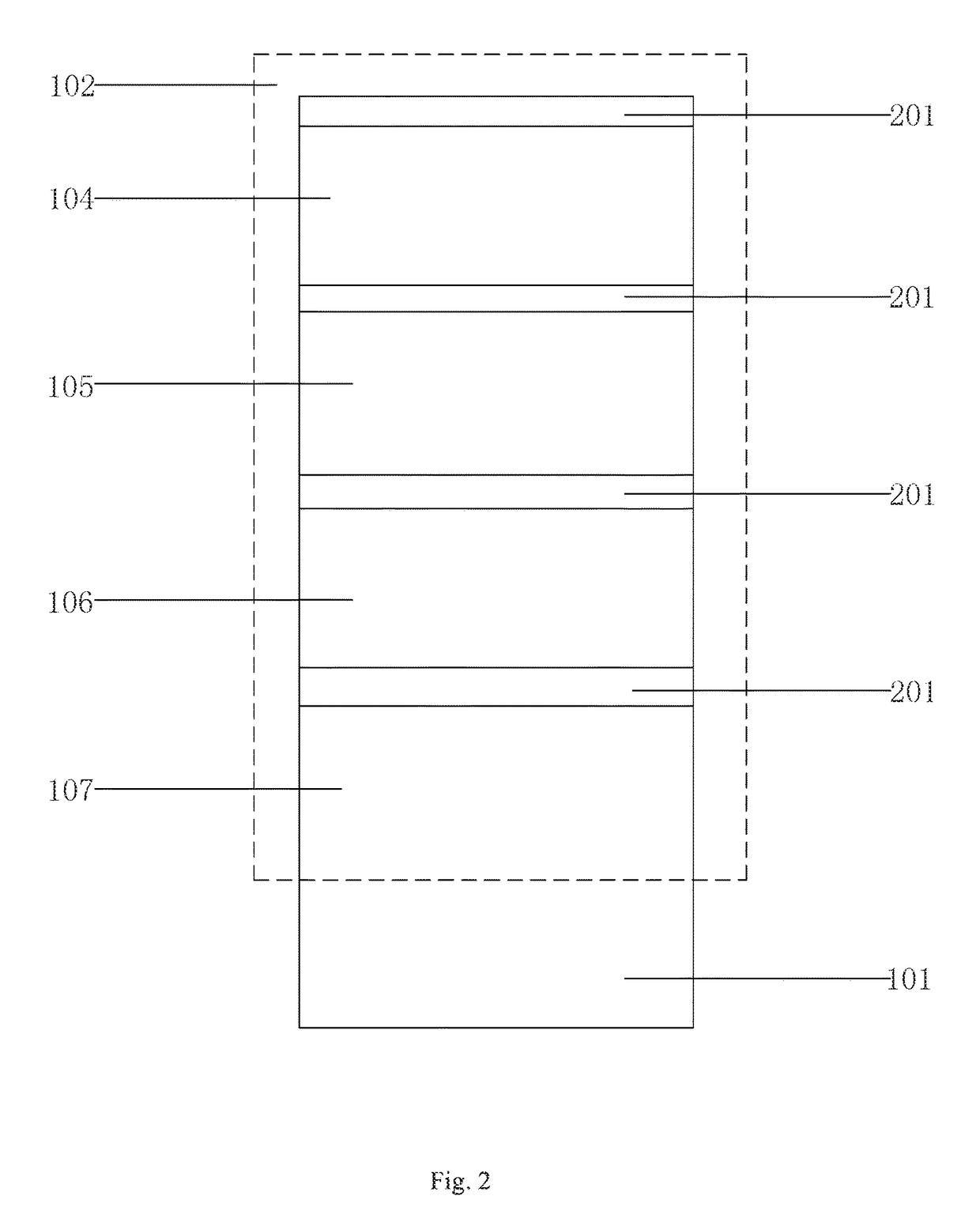

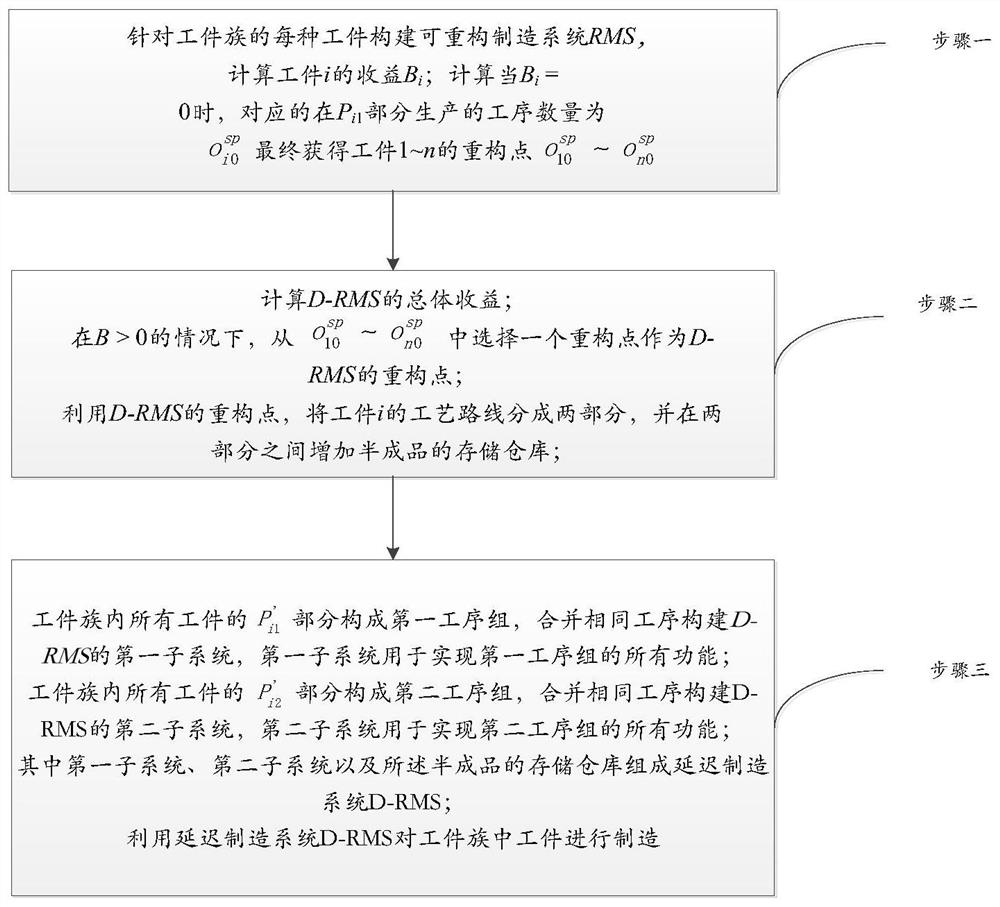

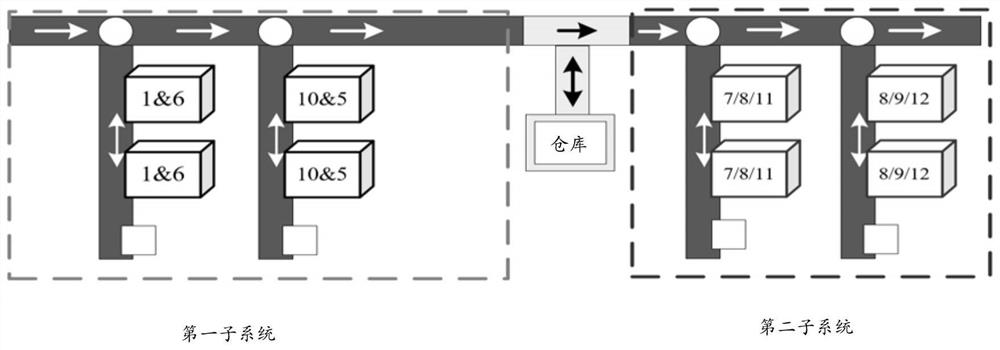

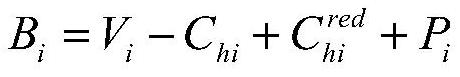

Partial reconfiguration method of reconfigurable manufacturing system

ActiveCN108681829AImprove practicalityShorten the timeResourcesManufacturing computing systemsWork in processReconfigurable computing

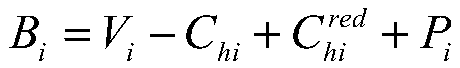

The invention discloses a partial reconfiguration method of a reconfigurable manufacturing system. The method comprises the following steps of constructing the reconfigurable manufacturing system (RMS) for workpieces of a workpiece family; for the workpiece i, dividing a process route of the workpiece i into a Pi1 part and a Pi2 part; calculating an income Bi of the wrokpiece i; when Bi=0, calculating a value, defined in the specification, of corresponding Oi<sp>, wherein the value is used for dividing the process route of the workpiece i into the Pi1 part and the Pi2 part, namely, reconfiguration points of the workpiece i, and reconfiguration points of the workpieces 1-n are defined in the specification; calculating a total income, defined in the specification, of a D-RMS; under the condition that B>0, selecting a reconfiguration point from the reconfiguration points of the workpieces 1-n as a reconfiguration point O1<sp> of the D-RMS; by utilizing the O1<sp>, dividing the process route of the workpiece i into a P'i1 part and a P'i2 part; by utilizing the P'i1 parts of all the workpieces in the workpiece family, constructing a first subsystem of the DRMS; by utilizing the P'i2 parts of all the workpieces in the workpiece family, constructing a second subsystem of the D-RMS, and adding a storage warehouse of semi-finished products between the two subsystems to construct the D-RMS; and by utilizing the D-RMS, manufacturing the workpieces in the workpiece family.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

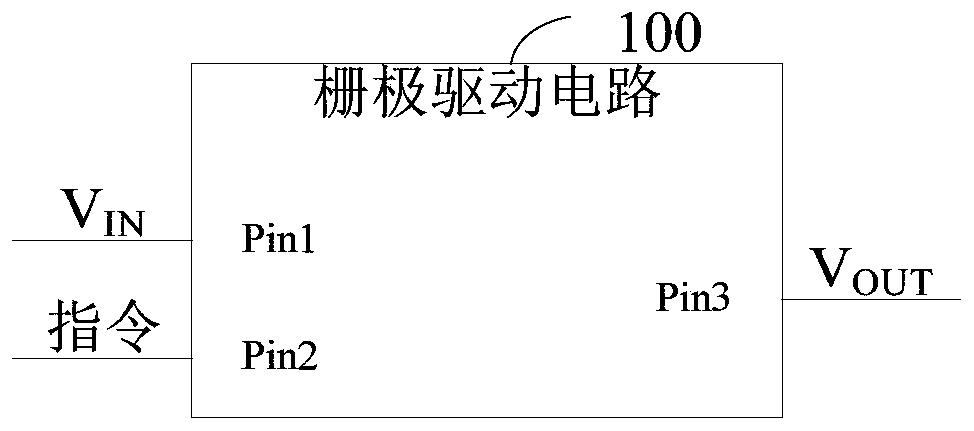

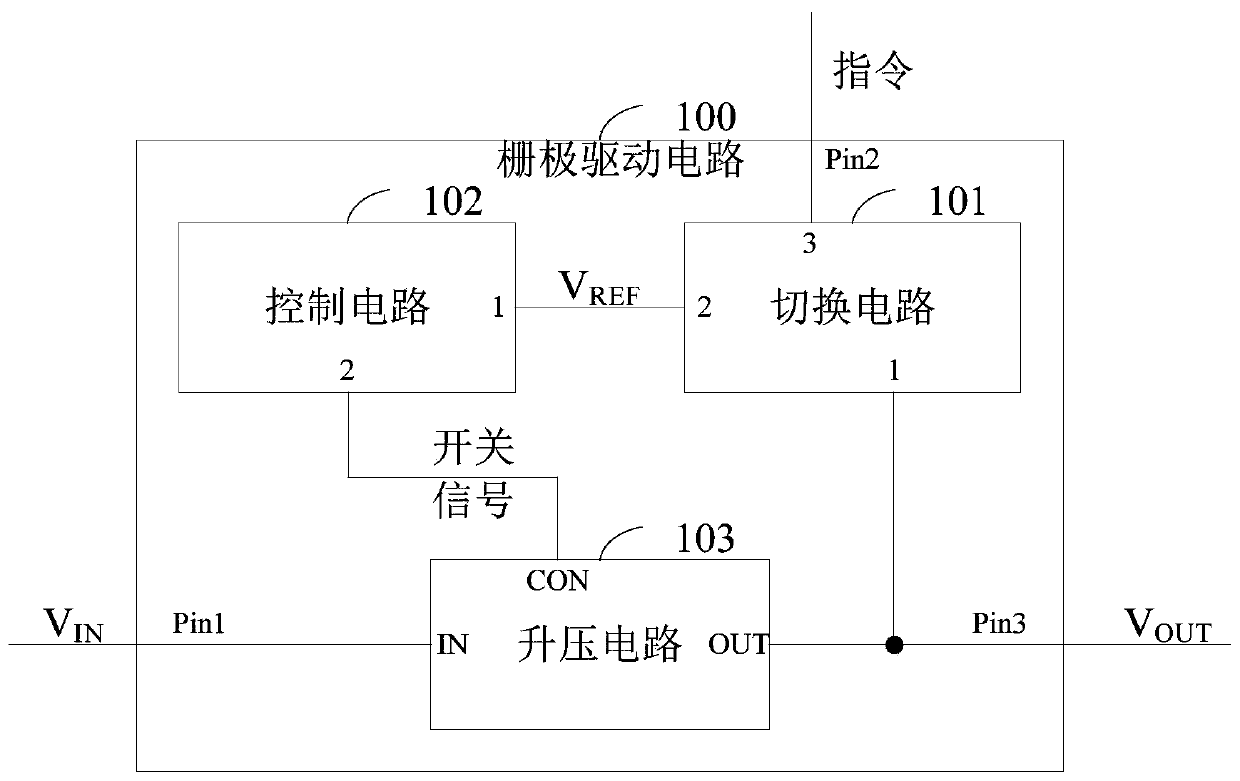

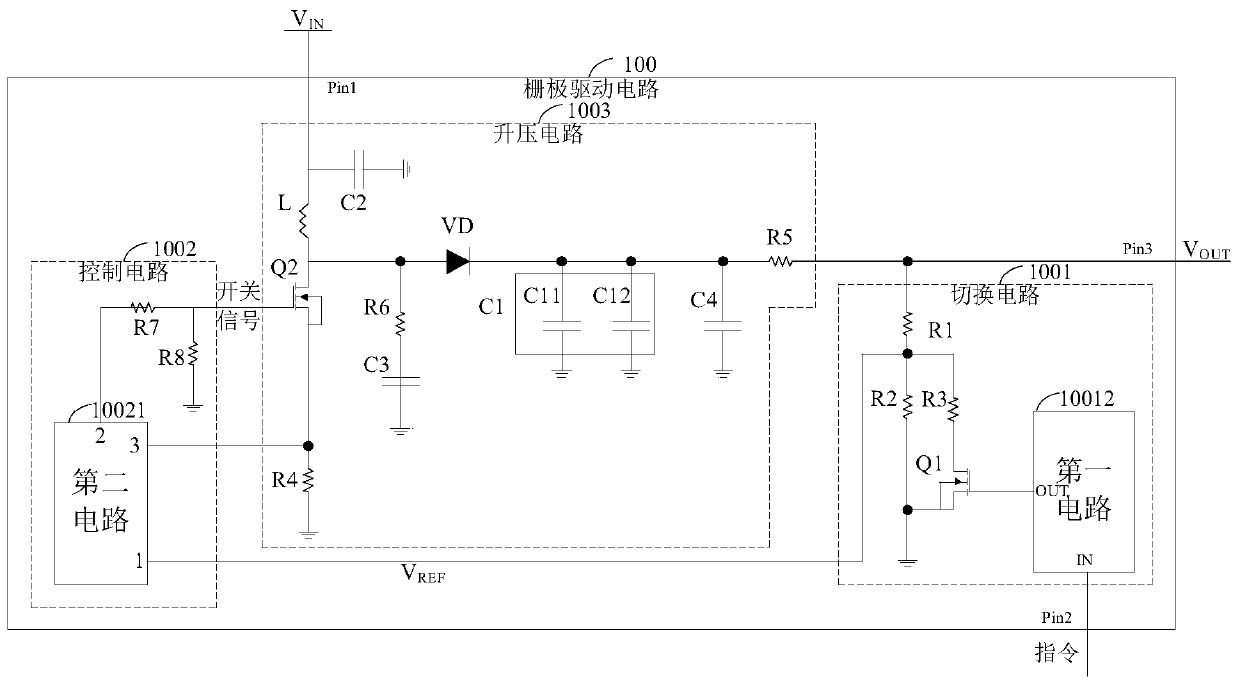

Gate drive circuit, liquid crystal panel, display device and aging method

The invention provides a gate drive circuit, a liquid crystal panel, a display device and an aging method. According to the circuit, a first pin of the gate drive circuit configured to receive an input voltage, and a second pin of the gate drive circuit is configured to adjust the resistance value of a target resistor to be greater than a preset resistance value when receiving an instruction indicating that the aging of the display device is started, and adjust the resistance value of the target resistor to be equal to a preset threshold value after a preset period of time. A third pin of thegate drive circuit is configured to output an output voltage corresponding to the target resistor through the input voltage based on the reference voltage with the amplitude kept unchanged. When the resistance value of the target resistor is greater than the preset resistance value, the amplitude of the output voltage is greater than the amplitude of the turn-on voltage of a thin film transistor TFT in the display device; when the resistance value of the target resistor is equal to the preset resistance value, the amplitude of the output voltage is equal to the amplitude of the turn-on voltageof a thin film transistor TFT in the display device. Therefore, automatic aging of the display device is realized.

Owner:CHENGDU ZHONGDIAN PANDA DISPLAY TECH CO LTD

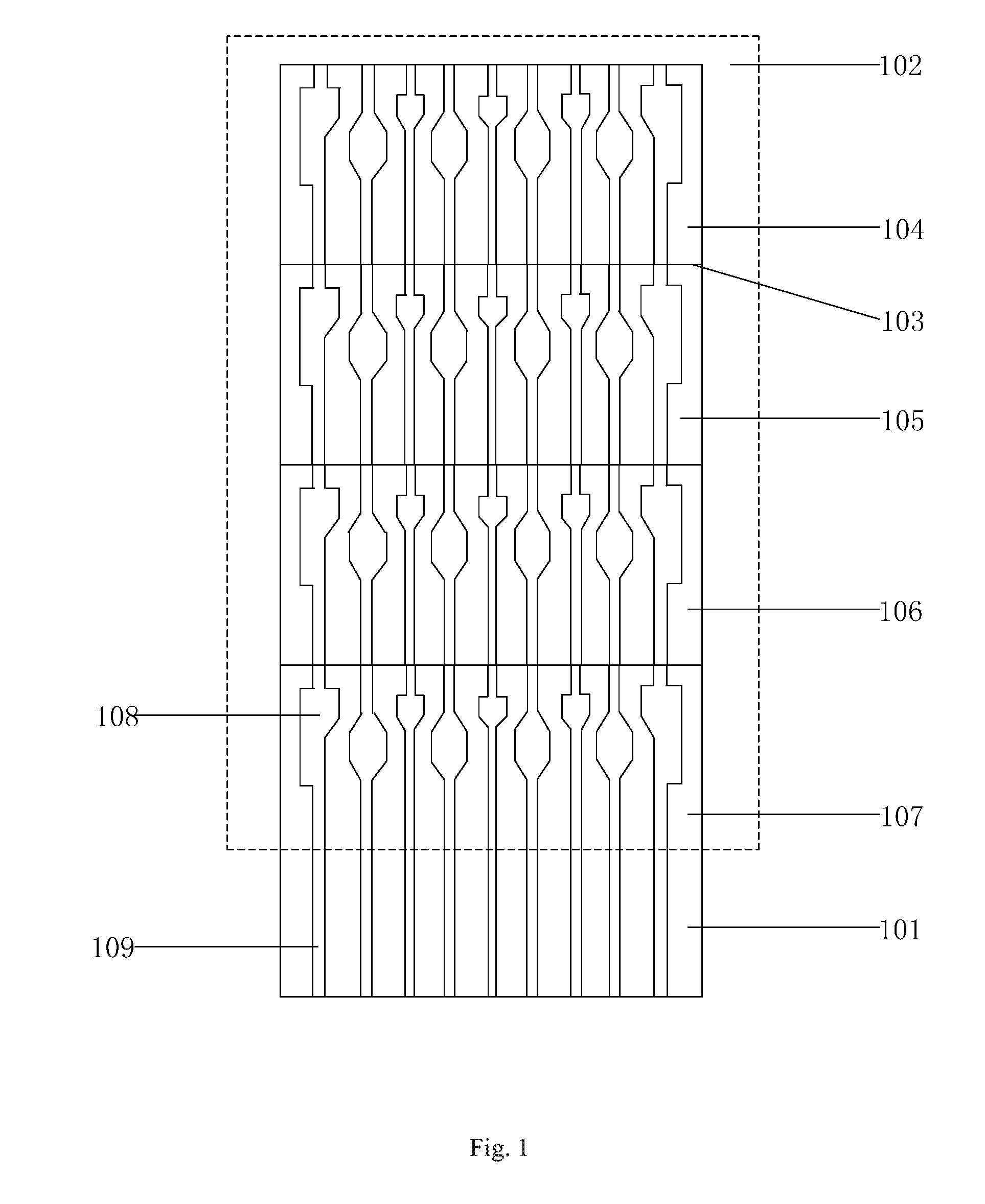

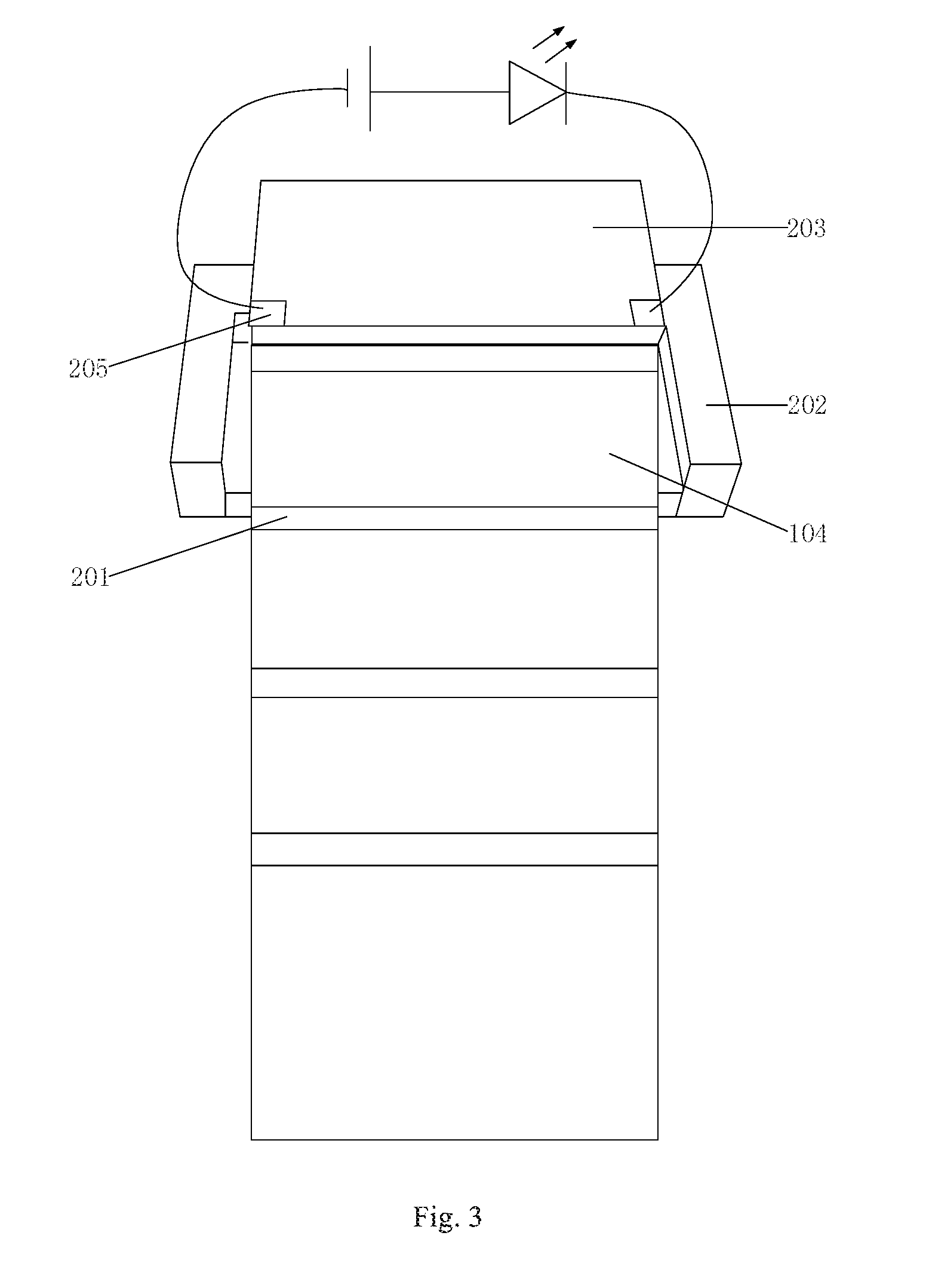

Flexible Printed Circuit and Detecting Device, Detecting Method and Display Device Thereof

ActiveUS20160356840A1Avoid misjudgmentAccurately determineElectronic circuit testingPrinted circuit aspectsDisplay deviceEngineering

Disclosed are a flexible printed circuit and a detecting device, a detecting method and a display device thereof. The flexible printed circuit comprises a body and an interface structure that is connected with the body, wherein the interface structure is provided with a plurality of mark lines dividing the interface structure into a plurality of interfaces with the same structure. When a front end interface of the flexible printed circuit of the disclosure is damaged, the front end interface can be removed along the mark line, and then an exposed rear end interface can be used successively, thus preventing a situation where the flexible printed circuit cannot be used because the only interface is damaged, thereby extending the life span of the flexible printed circuit, reducing productivity loss due to frequent replacements of the flexible printed circuit and reducing production cost.

Owner:BOE TECH GRP CO LTD +1

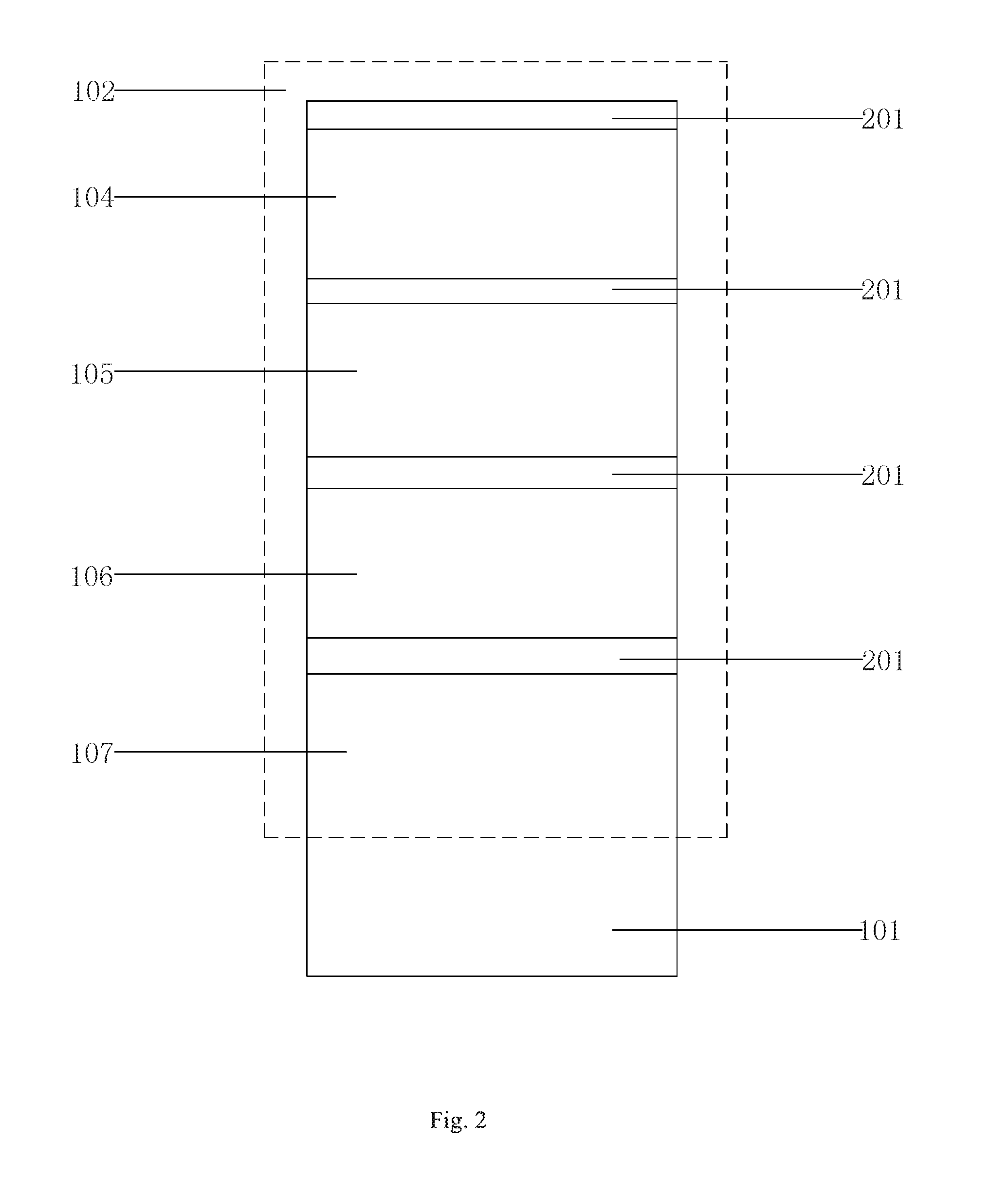

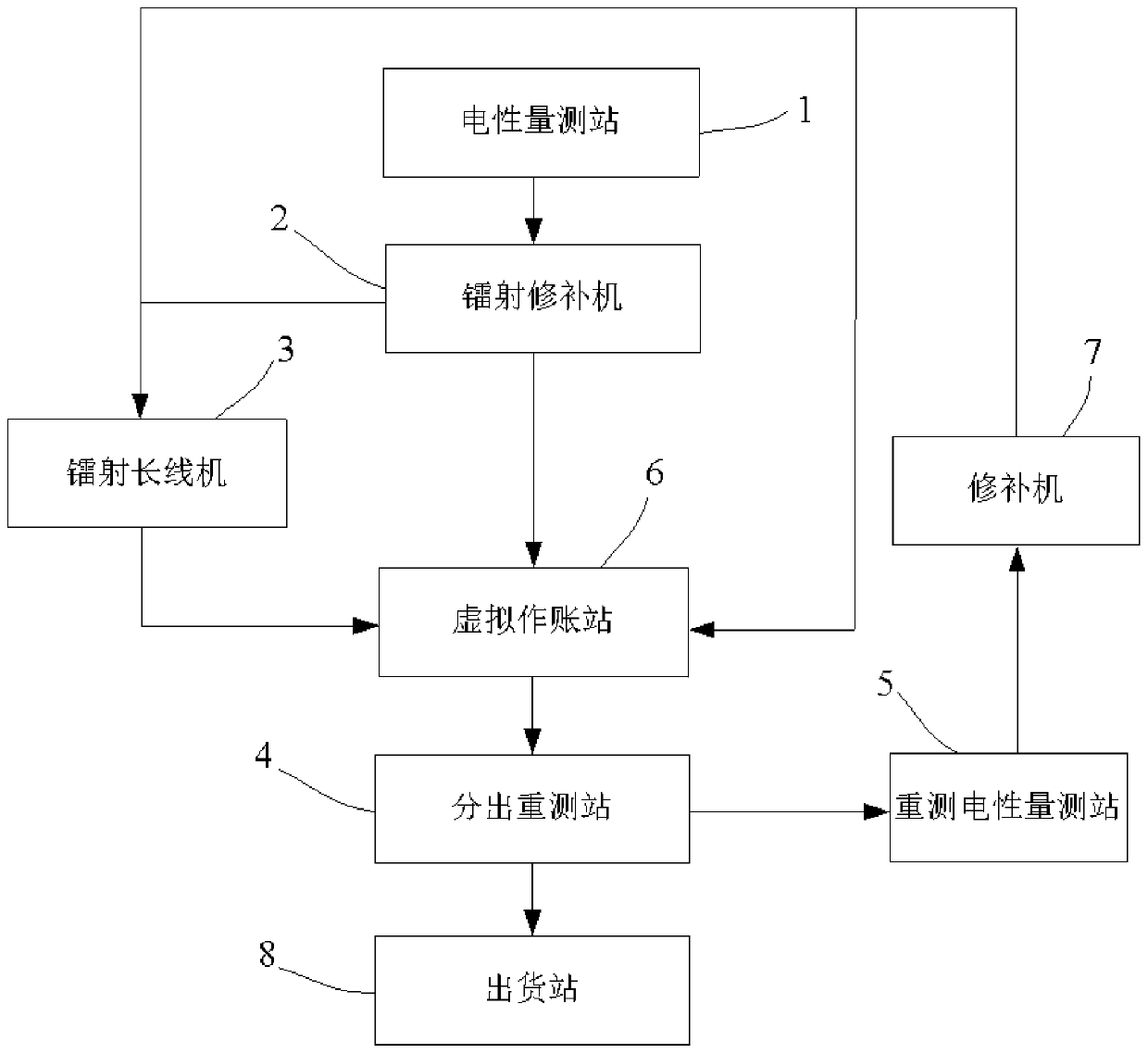

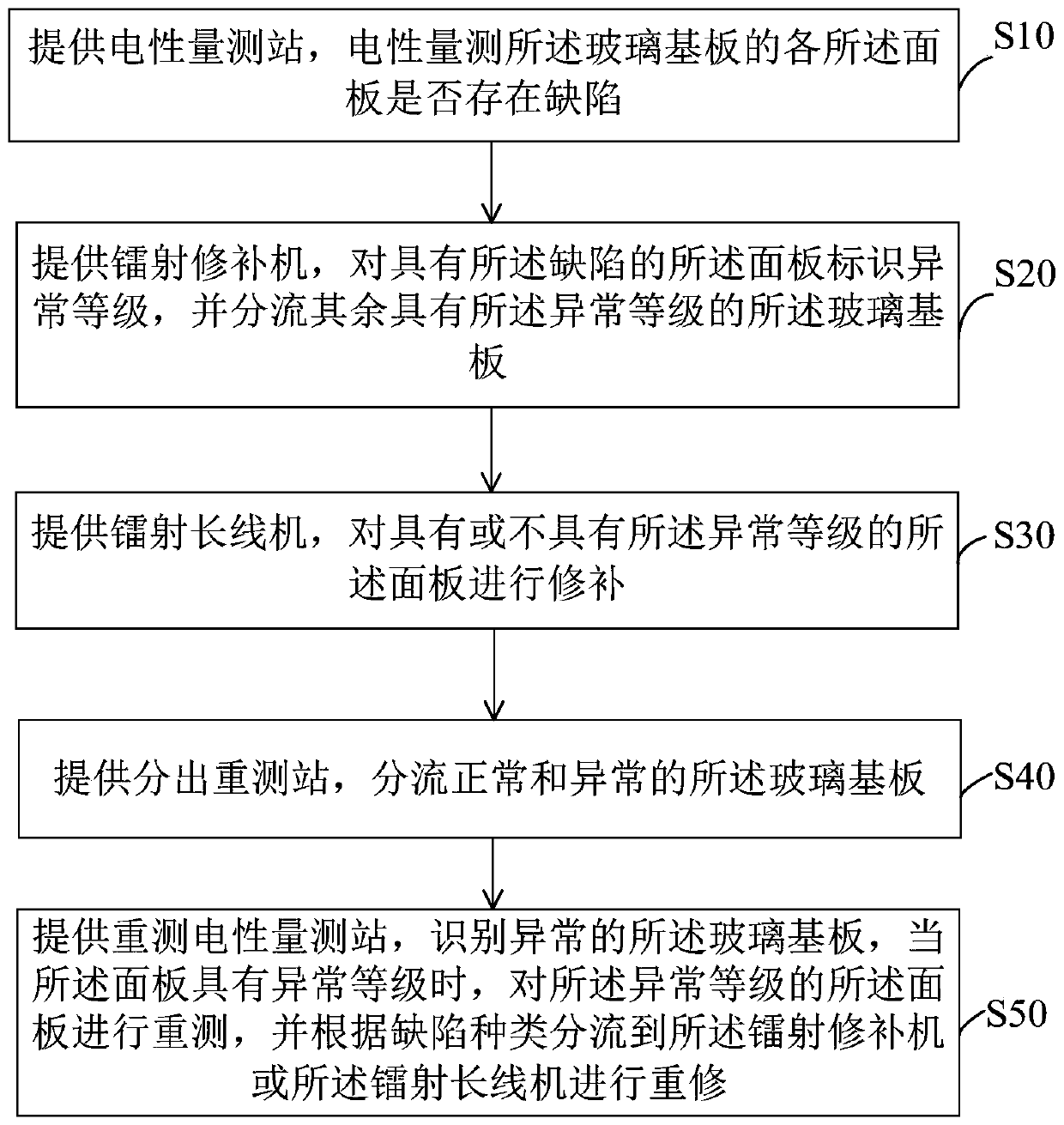

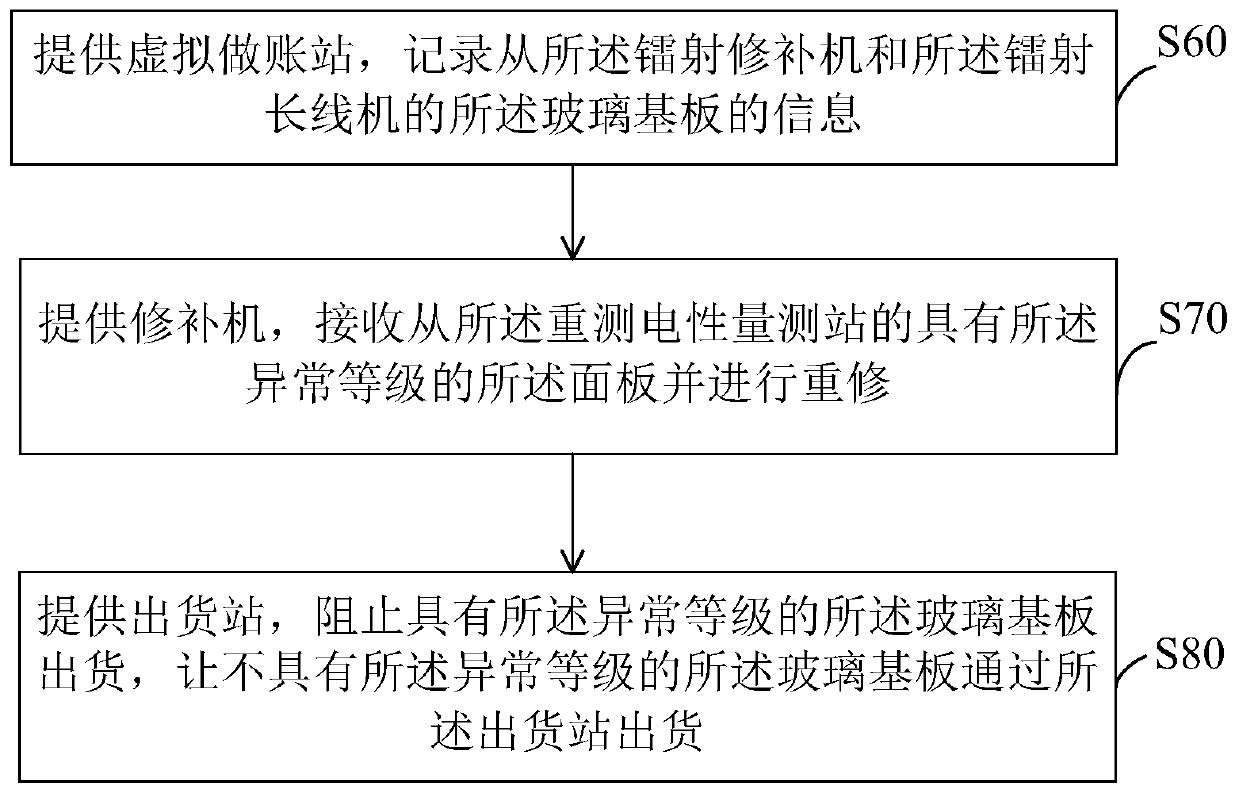

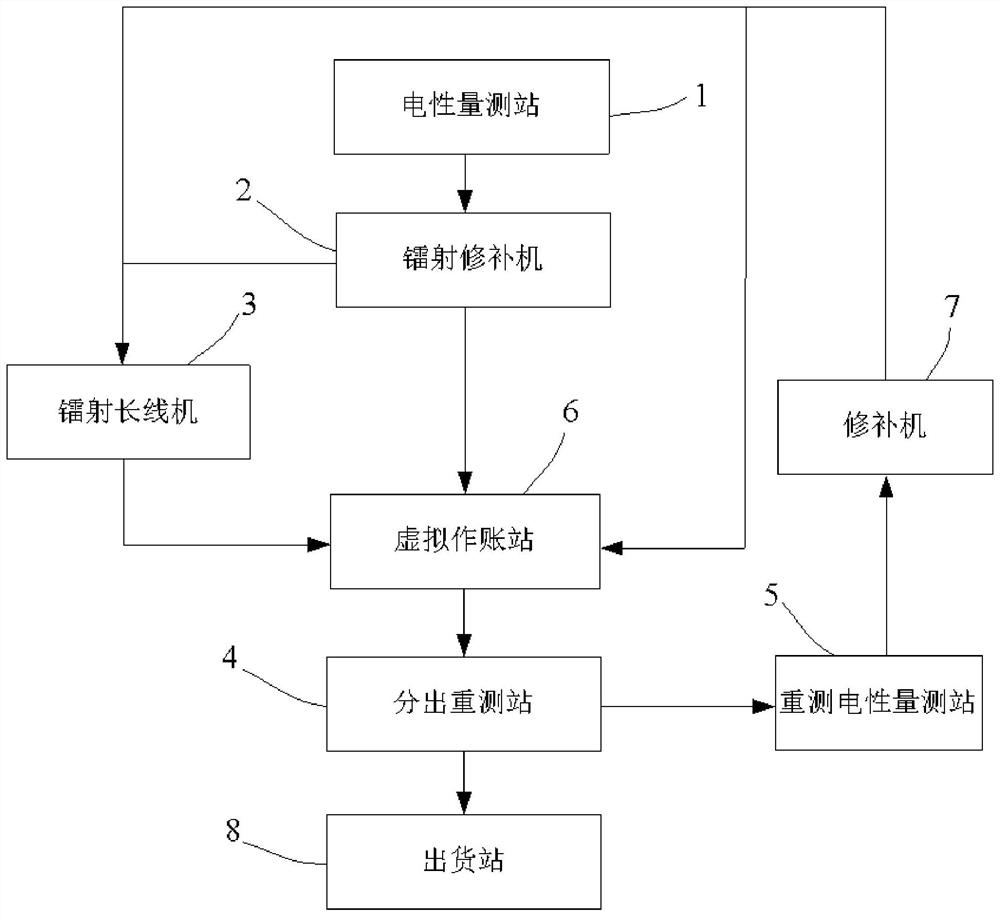

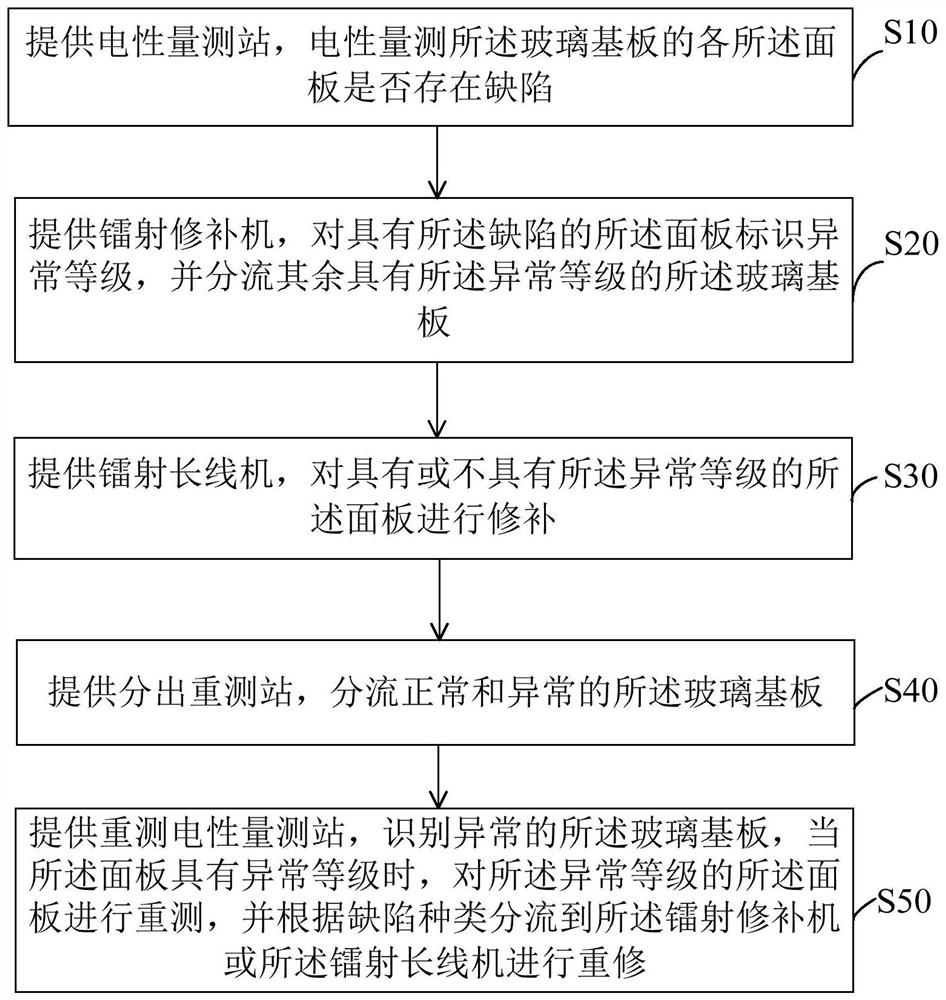

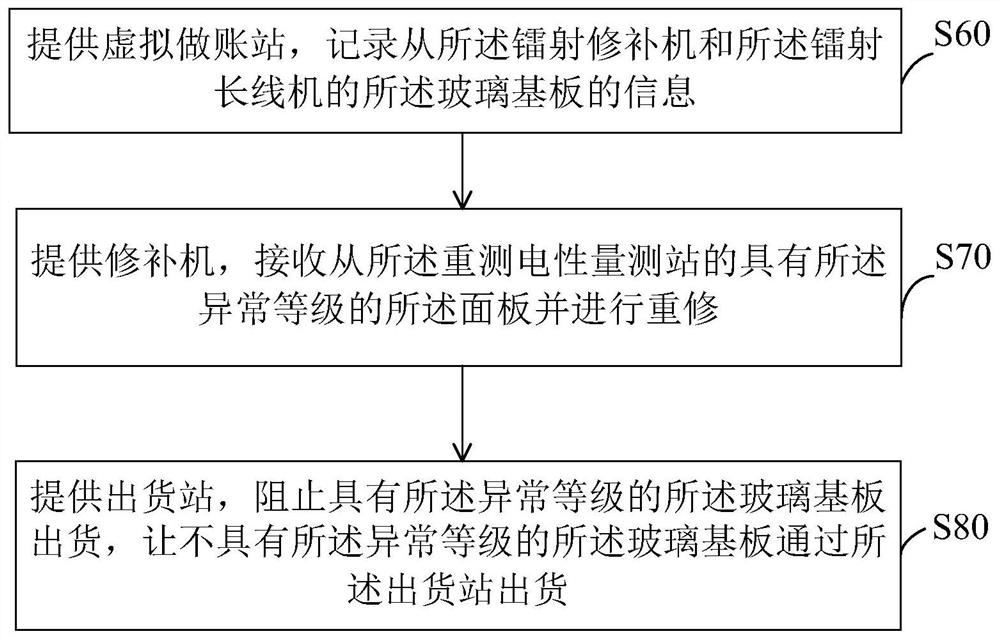

Glass substrate retest and reconditioning system and method

A glass substrate retest and reconditioning system and method are provided, wherein the glass substrate retest and reconditioning system comprises an electrical test station, a laser repair machine, alaser long line machine, a branch retest station and a retest electrical test station. The electrical test station tests whether panels of a glass substrate have defects. The laser repair machine marks abnormality levels for the panels having the defects and diverts other glass substrates with the abnormality levels. The laser long line machine repairs the panels with the abnormality levels. Thebranch retest station divides the normal and abnormal glass substrates. The retest electrical test station recognizes the abnormal glass substrates. When the panels have the abnormality levels, the panels with the abnormality levels are retested; the panels are diverted to the laser repair machine or the laser long line machine for reconditioning according to defect types; therefore, the loss in productivity and in time cost due to retesting and reconditioning is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

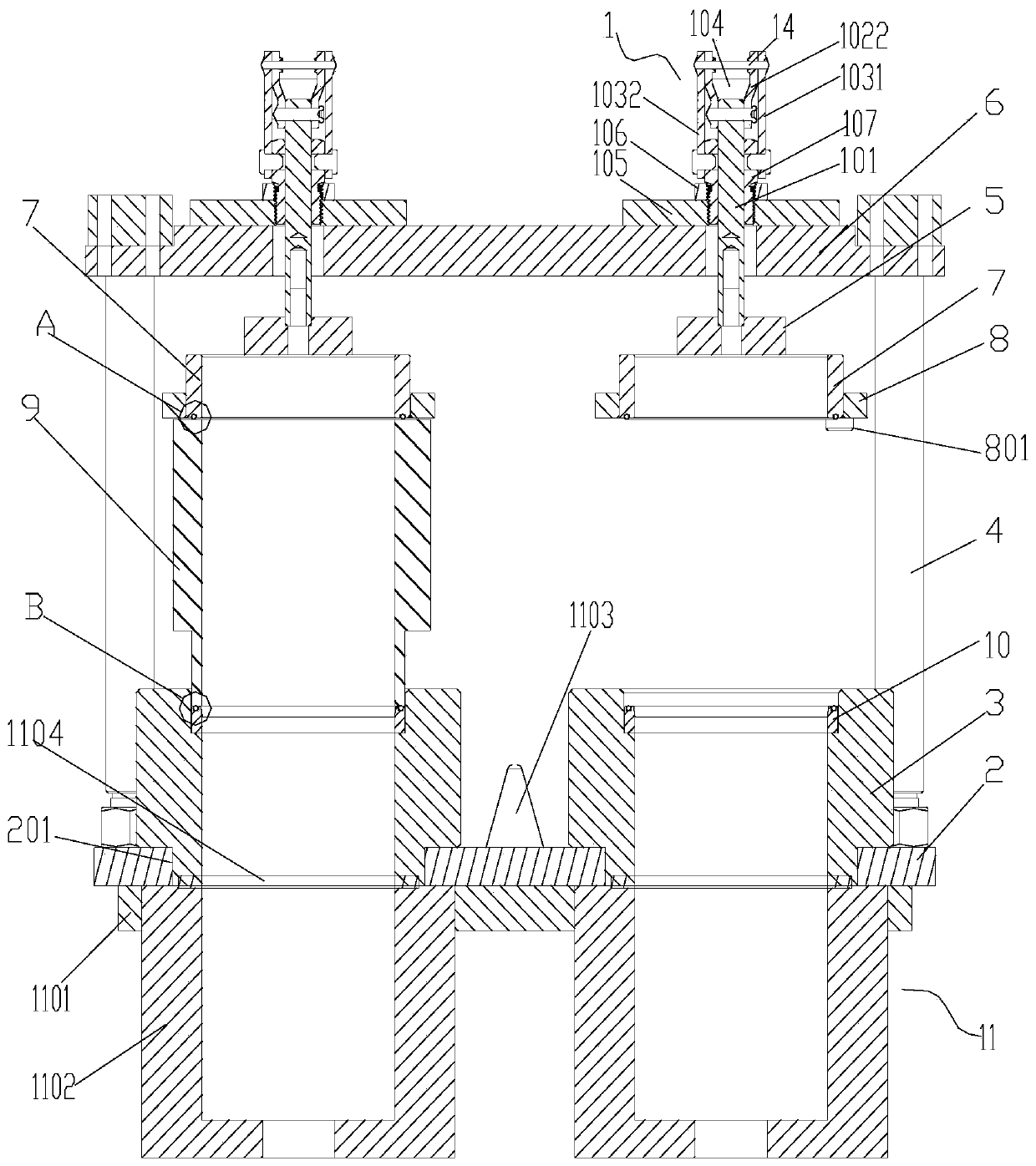

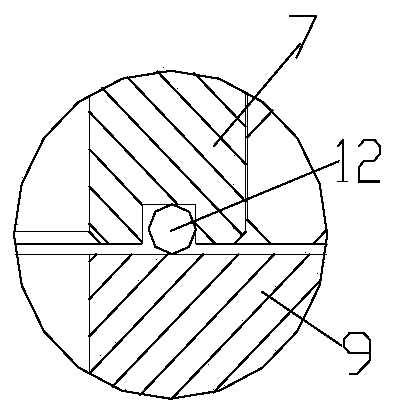

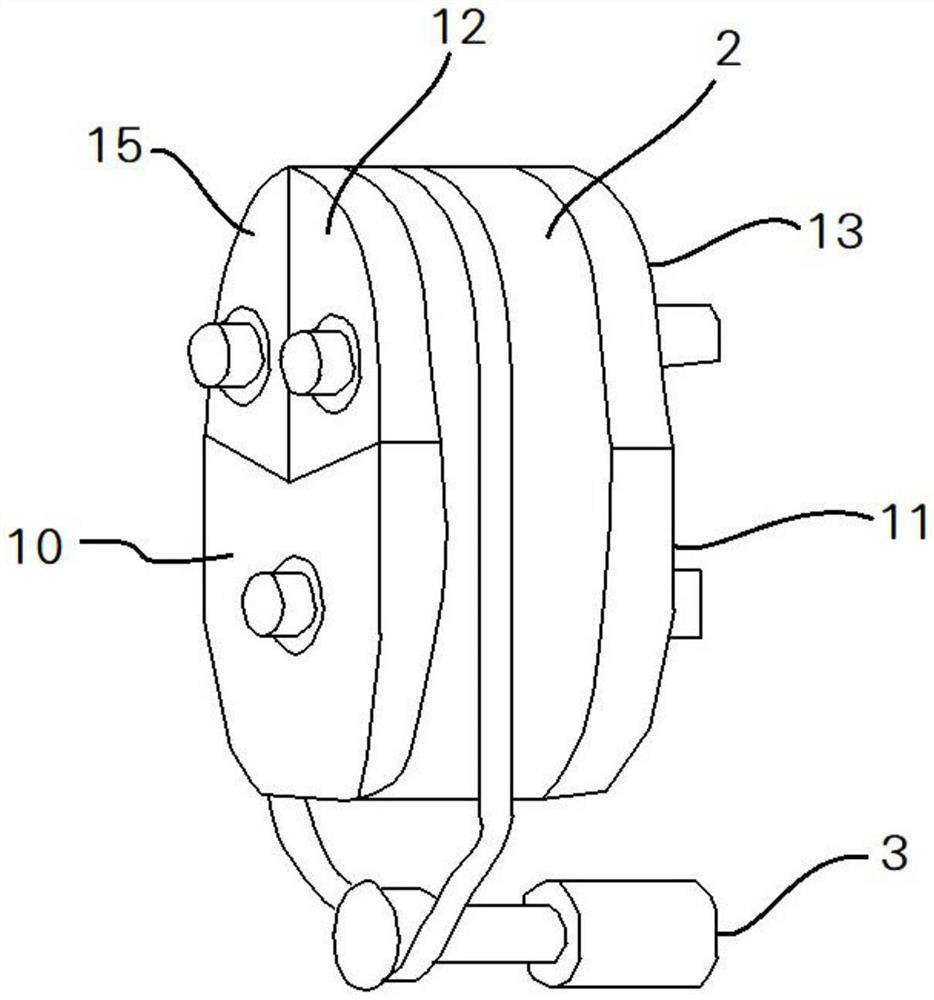

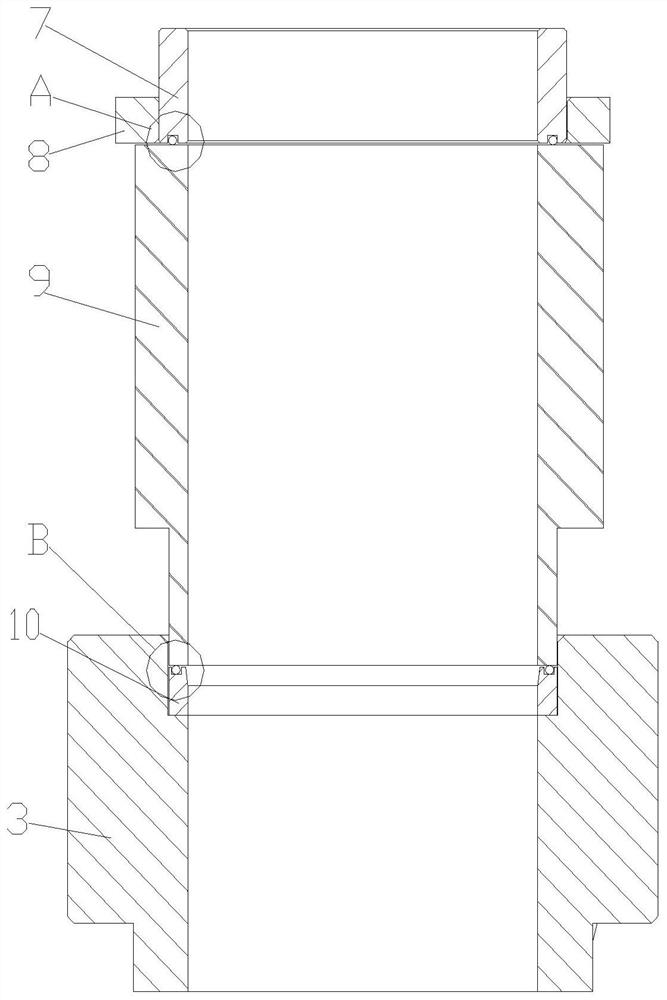

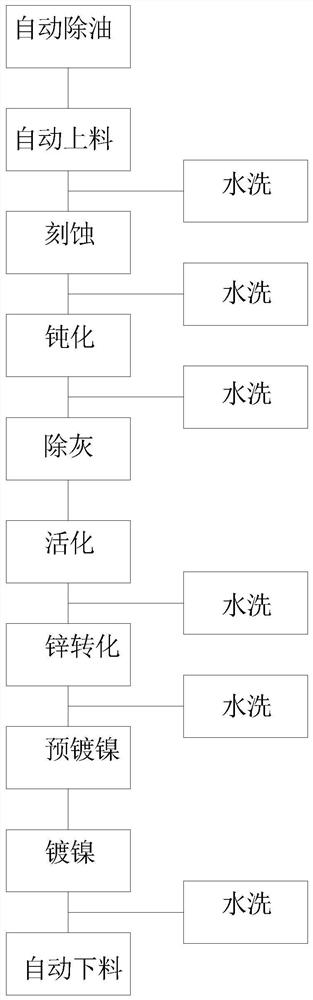

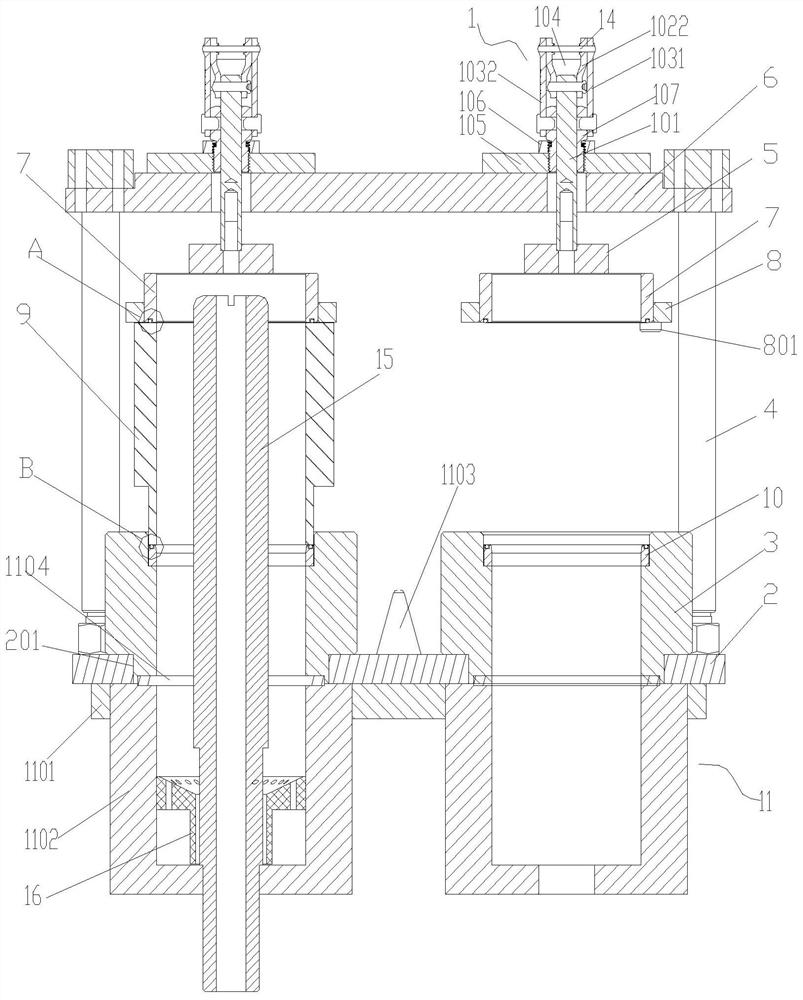

Electroplating environment treatment device for cylinder body out-of-groove electroplating

The invention discloses an electroplating environment treatment device for cylinder body out-of-groove electroplating. The electroplating environment treatment device comprises a mounting frame assembly, a mounting auxiliary assembly and a flow guide mounting assembly, wherein the mounting frame assembly comprises a fixing frame and a pressing assembly; the fixing frame comprises a bottom plate and a frame fixed on the bottom plate; the mounting auxiliary assembly is used for mounting a workpiece, is mounted on the bottom plate after being compensated in height and diameter, and is pressed bythe pressing assembly; the mounting auxiliary assembly is further used for guiding electroplating liquid into a cylinder body and is used for enabling an electroplating environment to be formed between an anode and the workpiece through the anode; and the flow guide mounting assembly is used for mounting the anode and guiding the electroplating liquid to the electroplating environment. According to the electroplating environment treatment device, the unique and simple electroplating environment is formed, the mounting and positioning are convenient, the universality is achieved when the electroplating environment treatment device is used for cylinder body out-of-groove electroplating, the electroplating environment treatment device is suitable for workpieces with various sizes, seamless switching of products is realized, the capacity loss caused by line stopping is avoided, the delivery requirement is rapidly met, the switching time of mature products is reduced to the minimum, and thecapacity loss is reduced to the minimum.

Owner:LONCIN MOTOR

Coating device

InactiveCN108897154AReduce wasteAvoid replacementNon-linear opticsManufacturing technologyLiquid-crystal display

The invention discloses a coating device and relates to the technical field of liquid crystal display device manufacturing. The coating device includes a coating head and a supply portion for supplying a raw material to the coating head. The supply portion includes a first container and a second container which have different capacities, and the first container and the second container are connected with the coating head and selectively supply raw materials to the coating head. The first container in the coating device can be a small-capacity glass bottle, and the second container may be a large-capacity stainless steel tank. In the actual production process, if the small-volume production is performed, a small amount of raw materials are required, the glass bottle may be selected to supply the raw materials to the coating head, a large number of safety residual quantity is avoided, and thus raw material waste is reduced; if large-volume production is performed, a large amount of raw materials are required, the stainless steel tank can be selected to supply the raw materials to the coating head, frequent replacement of the glass bottle is avoided, and defoaming operation time is saved, thereby reducing the loss of productivity and increasing the rate of equipment utilization.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

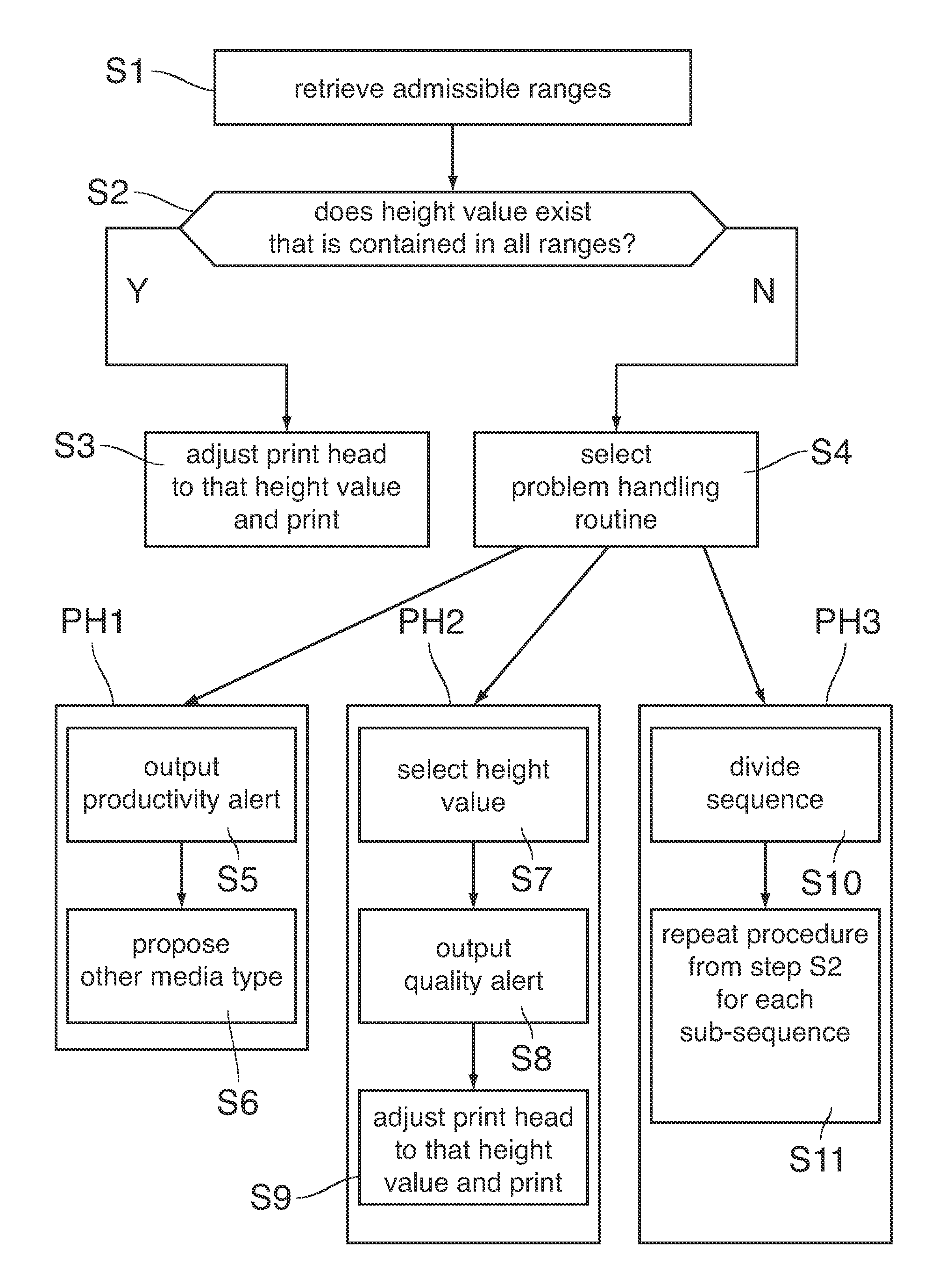

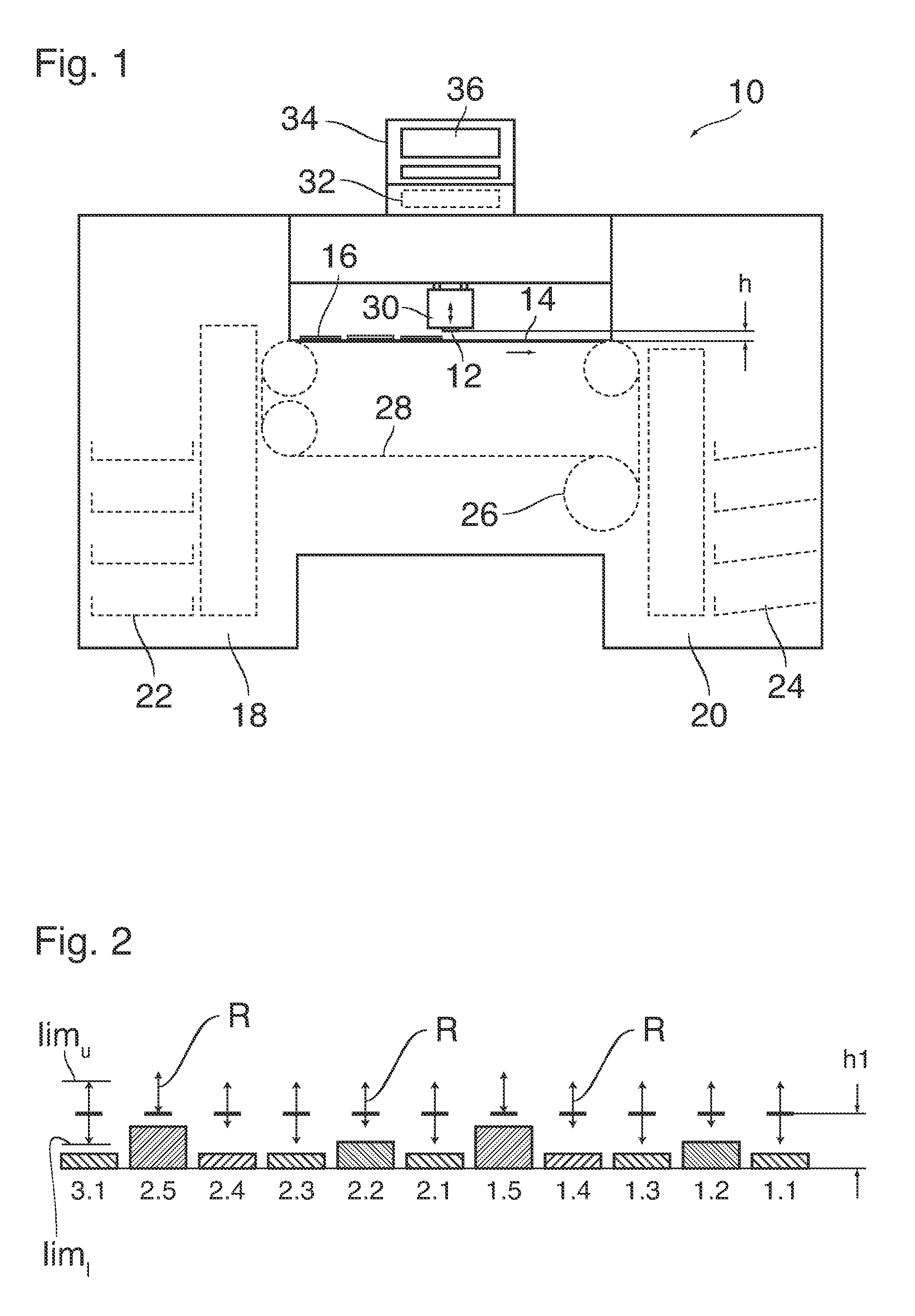

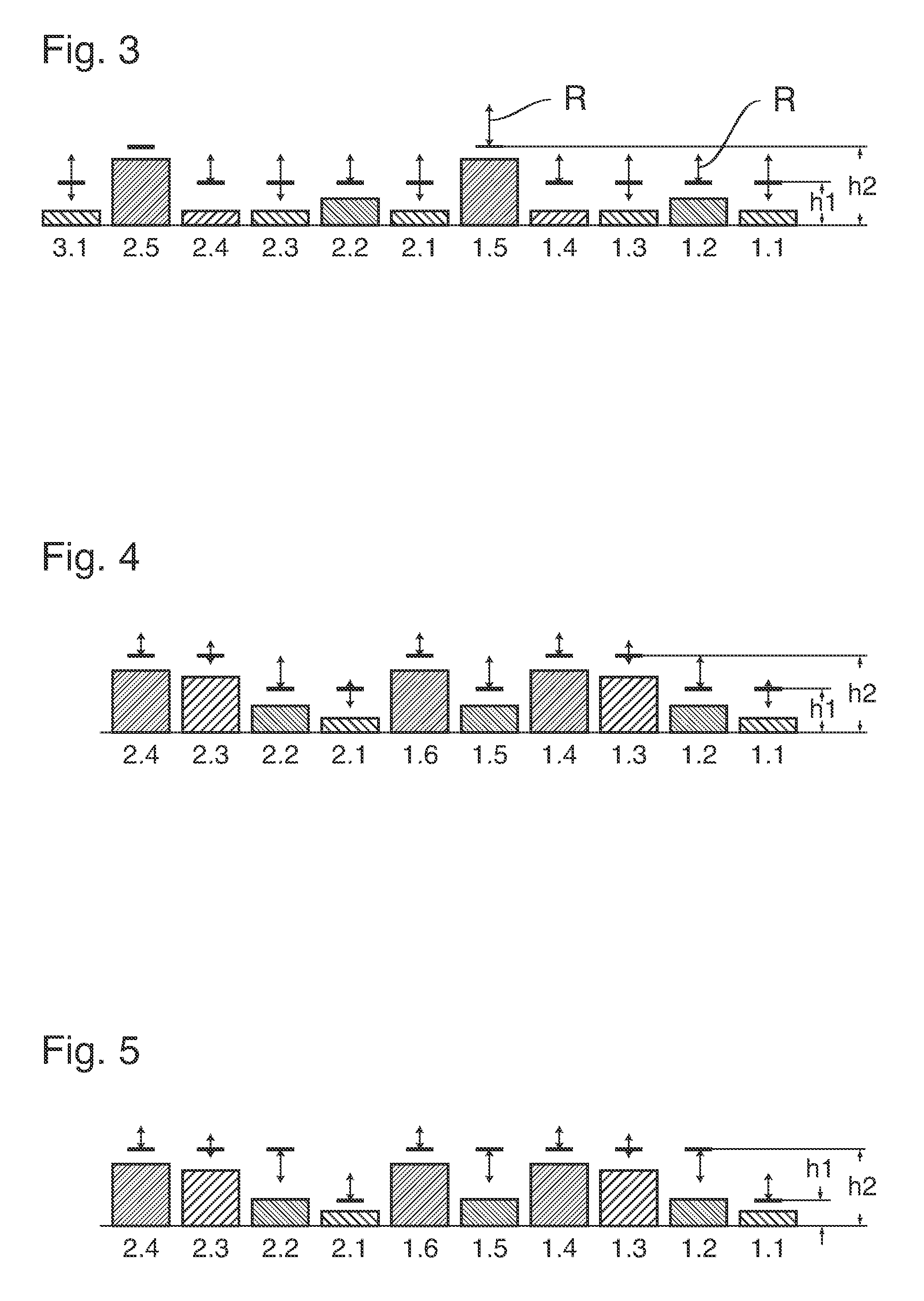

Method of printing with height adjustable print head

ActiveUS9533520B2Reduced productivity lossImprove productivityPower drive mechanismsOther printing apparatusEngineeringHead parts

Owner:OCE TECH

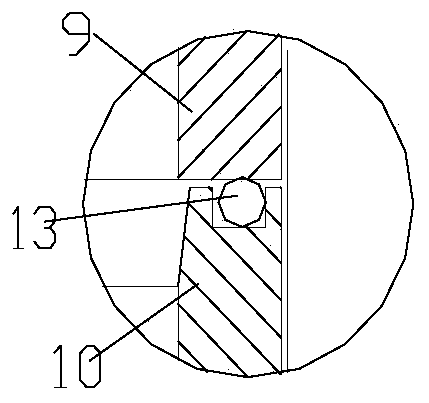

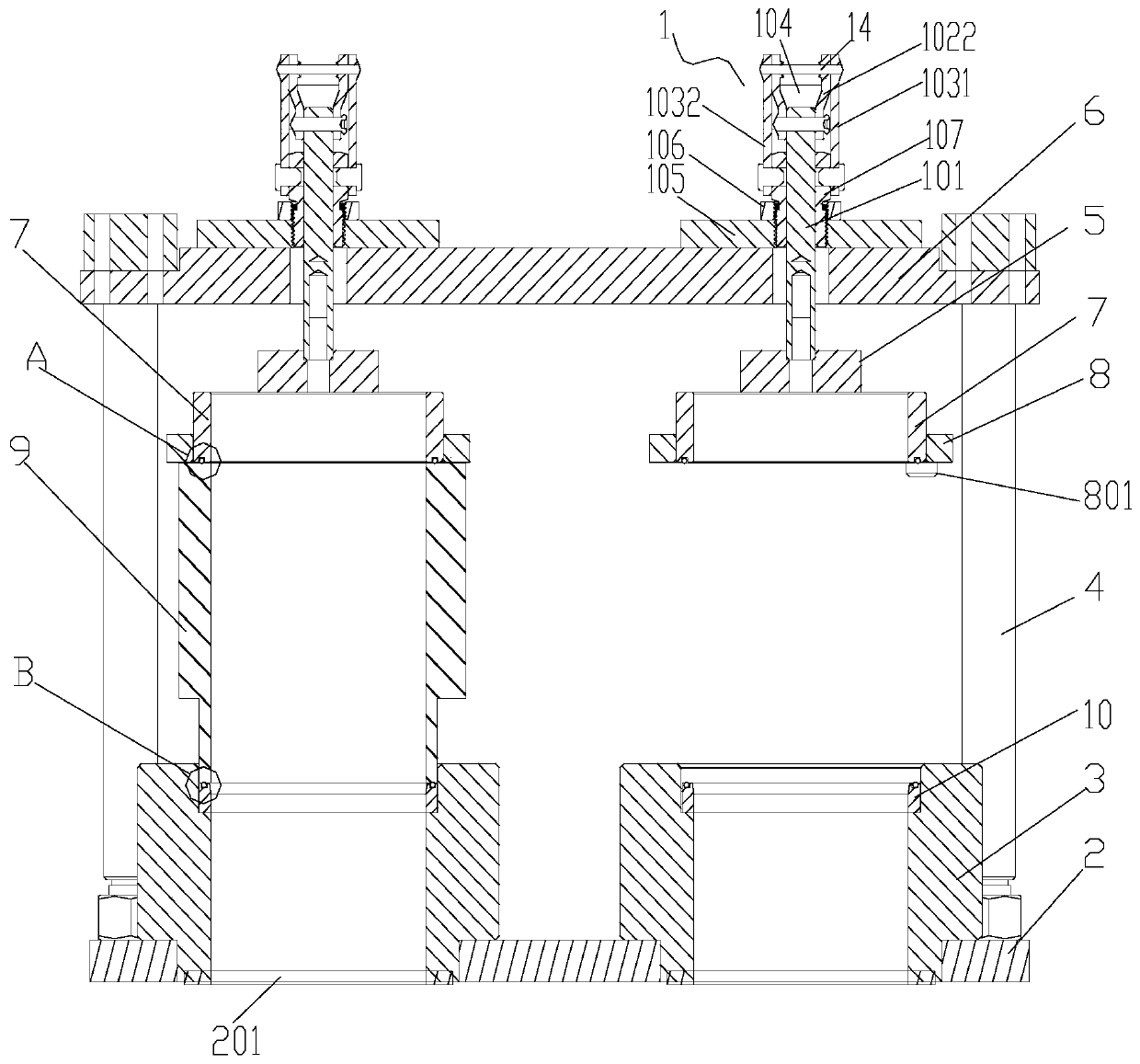

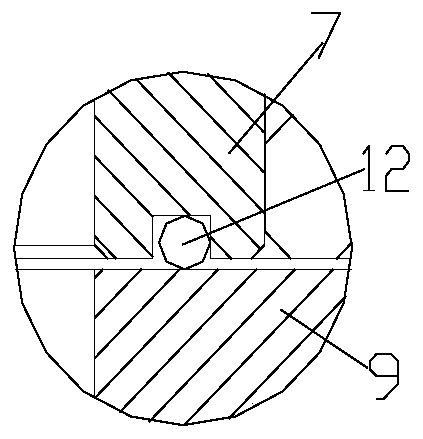

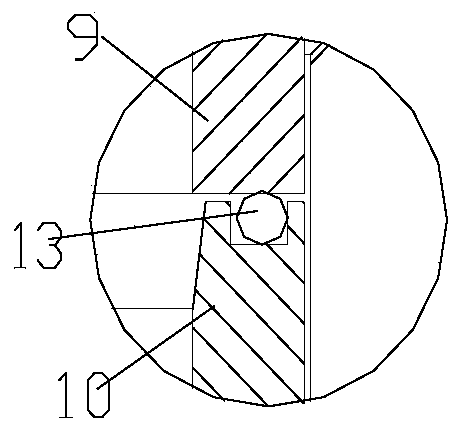

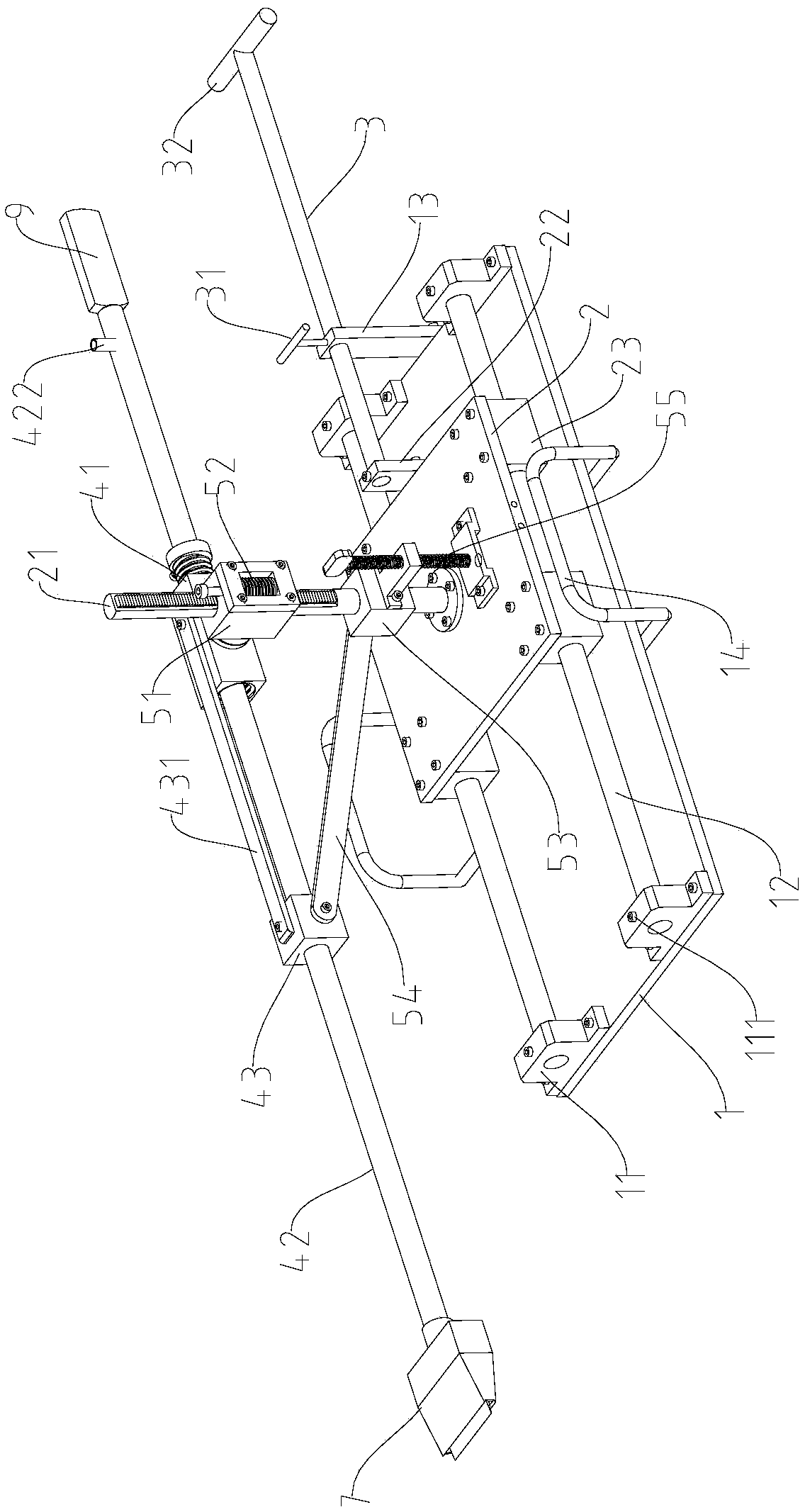

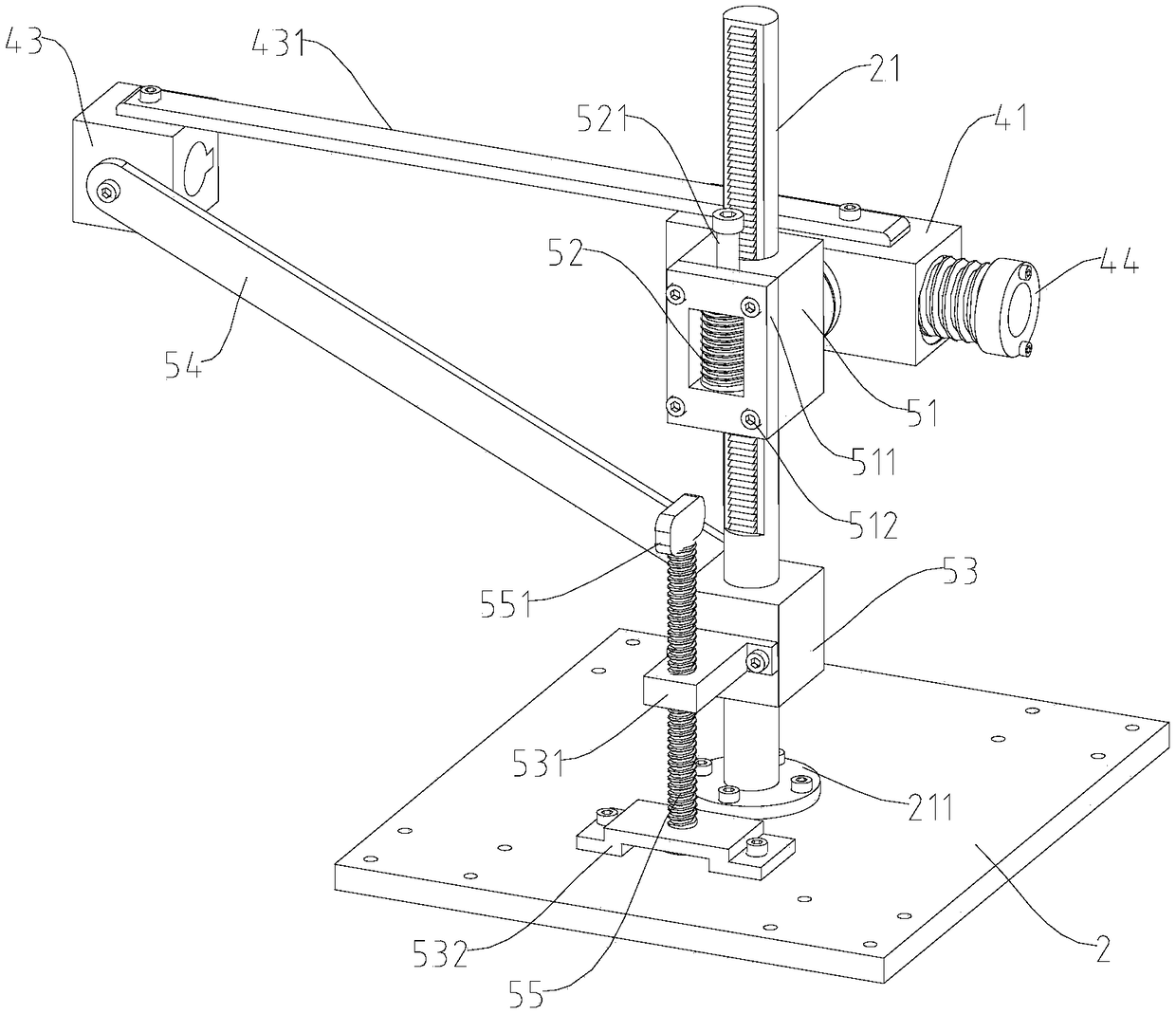

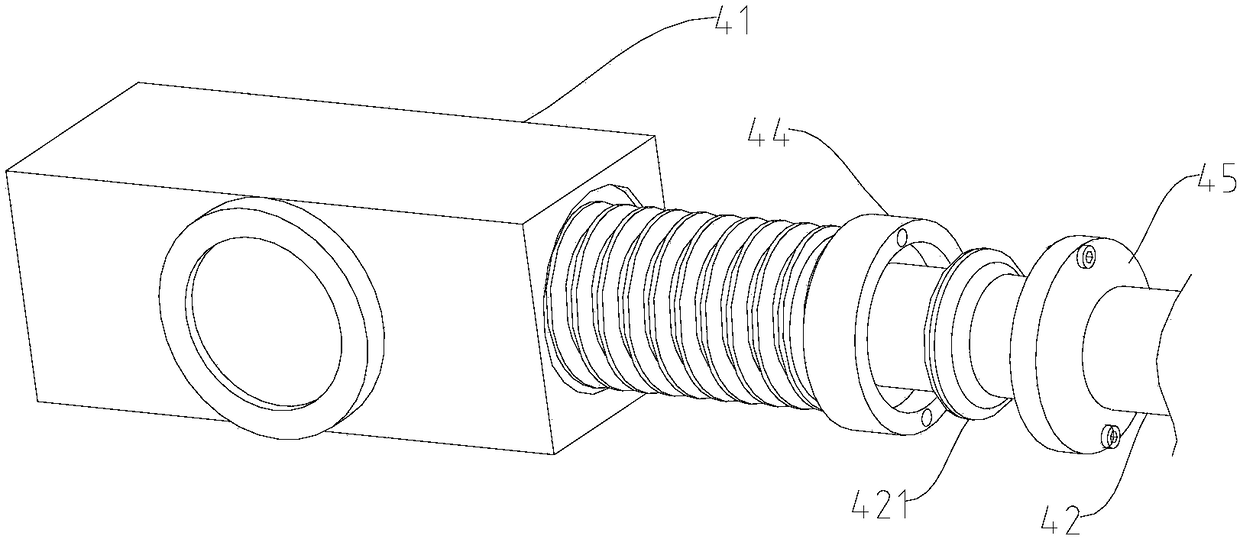

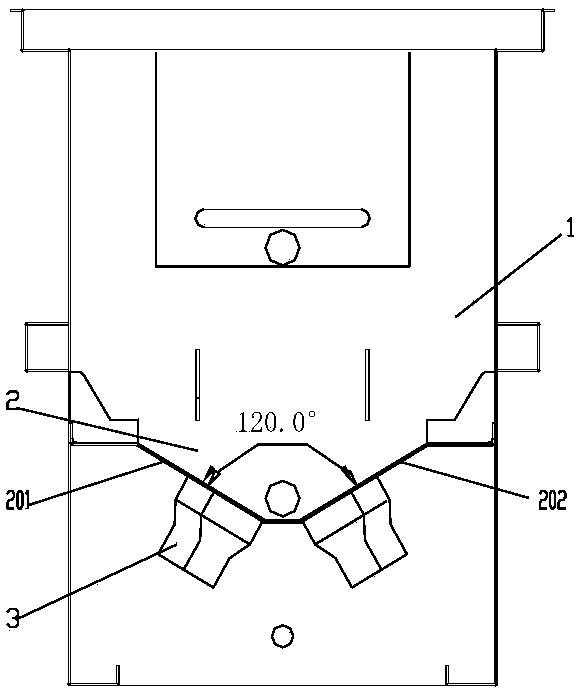

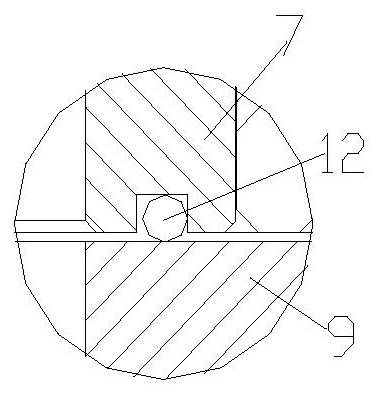

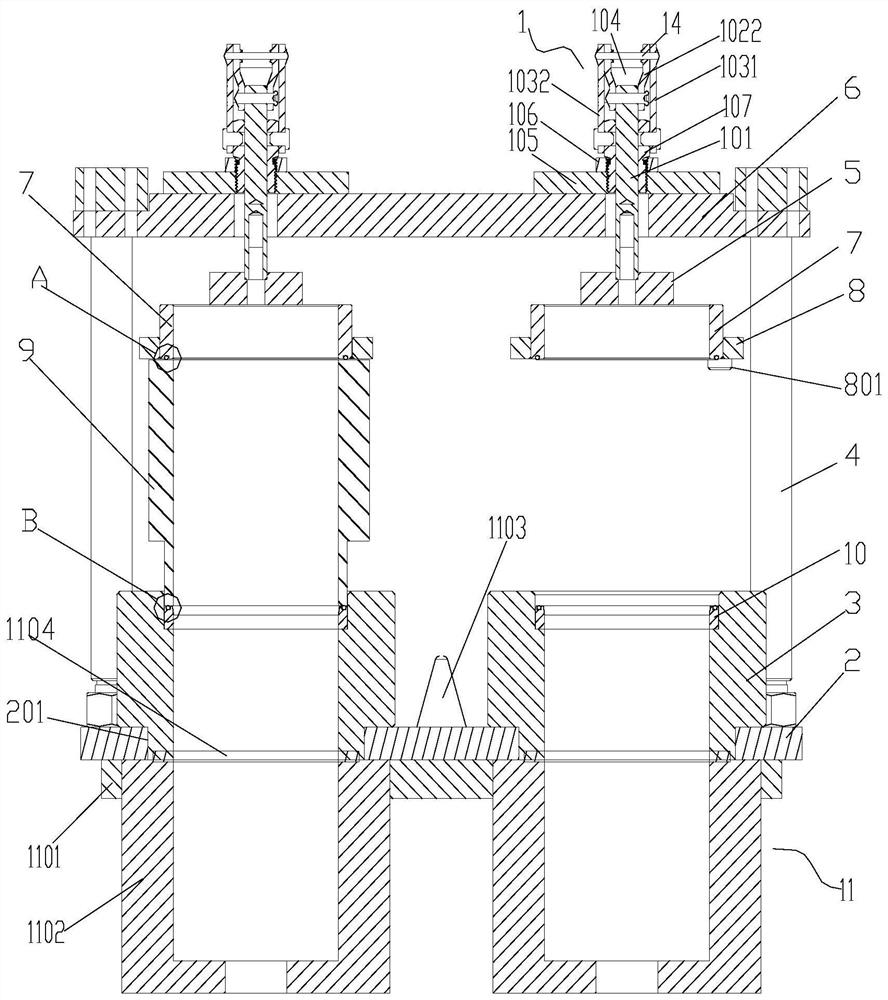

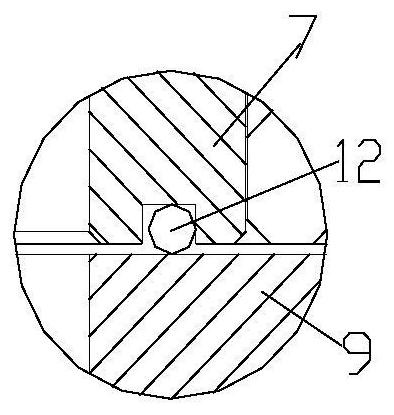

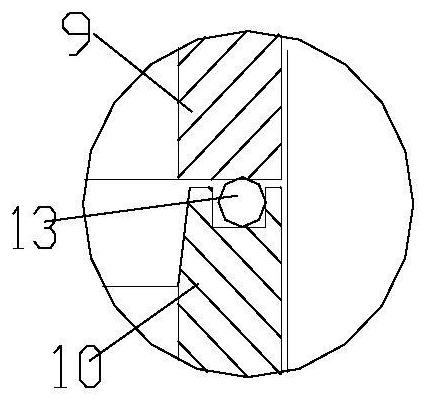

Universal-type tool for outside-groove electroplating of cylinders

ActiveCN110760909ASwitching times are minimizedShort switching timeElectrolysis componentsProduction lineStructural engineering

The invention discloses a universal-type tool for outside-groove electroplating of cylinders. The universal-type tool comprises a mounting frame assembly and an auxiliary mounting assembly. The mounting frame assembly comprises a fixed frame and a pressing assembly; the fixed frame comprises a bottom plate and a framework fixed to the bottom plate; the auxiliary mounting assembly is used for mounting the workpieces, mounting the workpieces on the bottom plate after compensation is made in the height and diameter and tightly pressing the workpieces with the pressing assembly, and besides, the auxiliary mounting assembly is used for guiding electroplating liquid into the cylinders and passing through anodes. When the universal-type tool is in use, there is no need to replace the anodes for different workpieces, therefore, the production line does not need to be stopped either, the universal-type tool is suitable for workpieces of various sizes, seamless switching of the products is achieved, capacity loss caused by line stopping is avoided, the delivery demand is quickly satisfied, the switching time of finished products is shortened to the minimum, and the capacity loss is lowered to the lowest.

Owner:LONCIN MOTOR

Method for sectional treatment of ammonia-containing waste gas

PendingCN114100268AAvoid cloggingClean up thoroughlyGas treatmentDispersed particle filtrationExhaust fumesEnvironmental engineering

The invention discloses a method for sectional treatment of ammonia-containing waste gas. The method comprises the following steps: A, pre-filtering treatment: pre-filtering the ammonia-containing waste gas; b, adsorption and desorption treatment: dividing the pre-filtered ammonia gas into a large part and a small part, performing ammonia adsorption concentration on the large part, and discharging the large part into the atmosphere; heating the small stream of gas through clean gas after ammonia adsorption, and then desorbing the adsorbed ammonia; c, catalytic combustion: introducing the desorbed concentrated ammonia-containing waste gas into a catalytic combustion device for catalytic combustion, stopping heating after combustion is started, and maintaining combustion of ammonia gas under heat generated by combustion; and D, heat recovery, wherein heat generated by catalytic combustion is recovered through a heat recovery device, and tail gas obtained after heat recovery is discharged into the atmosphere through a chimney. The ammonia-containing waste gas is treated by adopting a sectional treatment method, and the purpose of thoroughly removing pollutants in the ammonia-containing waste gas can be achieved.

Owner:LIUZHOU HAIDA NEW MATERIAL TECH

Compensating auxiliary tooling for electroplating outside the cylinder tank

ActiveCN110923790BShort switching timeRealize seamless switchingElectrodesProduction lineProcess engineering

The invention discloses a compensating auxiliary tooling for electroplating outside a tank of a cylinder body. The compensating auxiliary tooling is used to install a workpiece and is installed and pressed after being compensated in height and diameter. The compensating auxiliary tooling also uses The electroplating solution is introduced into the cylinder and used to pass through the anode; through the adjustment of the overall height of the invention matched with the workpiece to form a match with the anode, different workpieces do not need to replace the anode, so there is no need to stop the production line, and the replacement of different workpieces is directly installed on this The tooling can only be installed in the electroplating device, and the supporting compensating auxiliary tooling can also compensate the installation difference between the different inner diameters of different workpieces and the bottom plate, forming the versatility in height and diameter; therefore, the present invention is used for cylinders The electroplating outside the tank is versatile, suitable for workpieces of various sizes, realizes "seamless switching" of products, avoids production loss due to line stop, quickly meets delivery requirements, minimizes switching time of mature products, and minimizes production loss drop to lowest.

Owner:LONCIN MOTOR

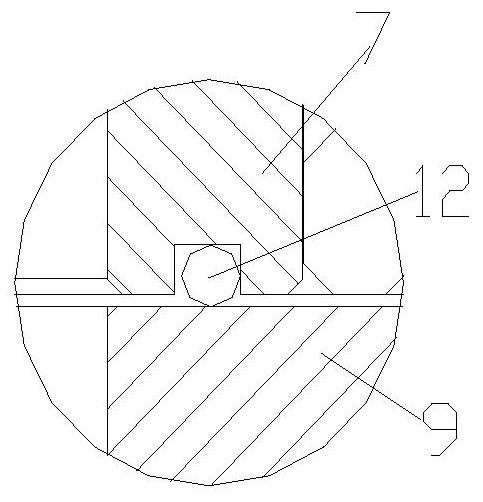

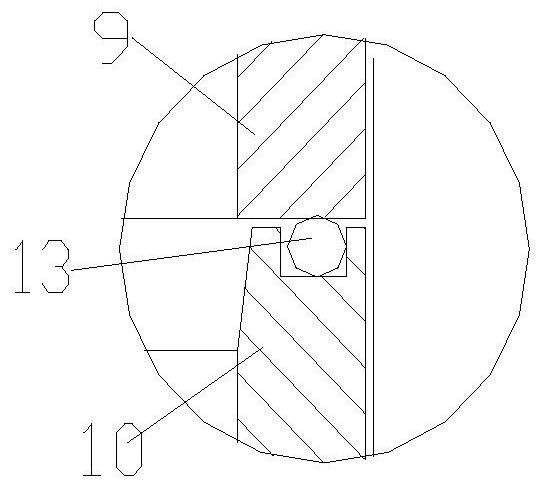

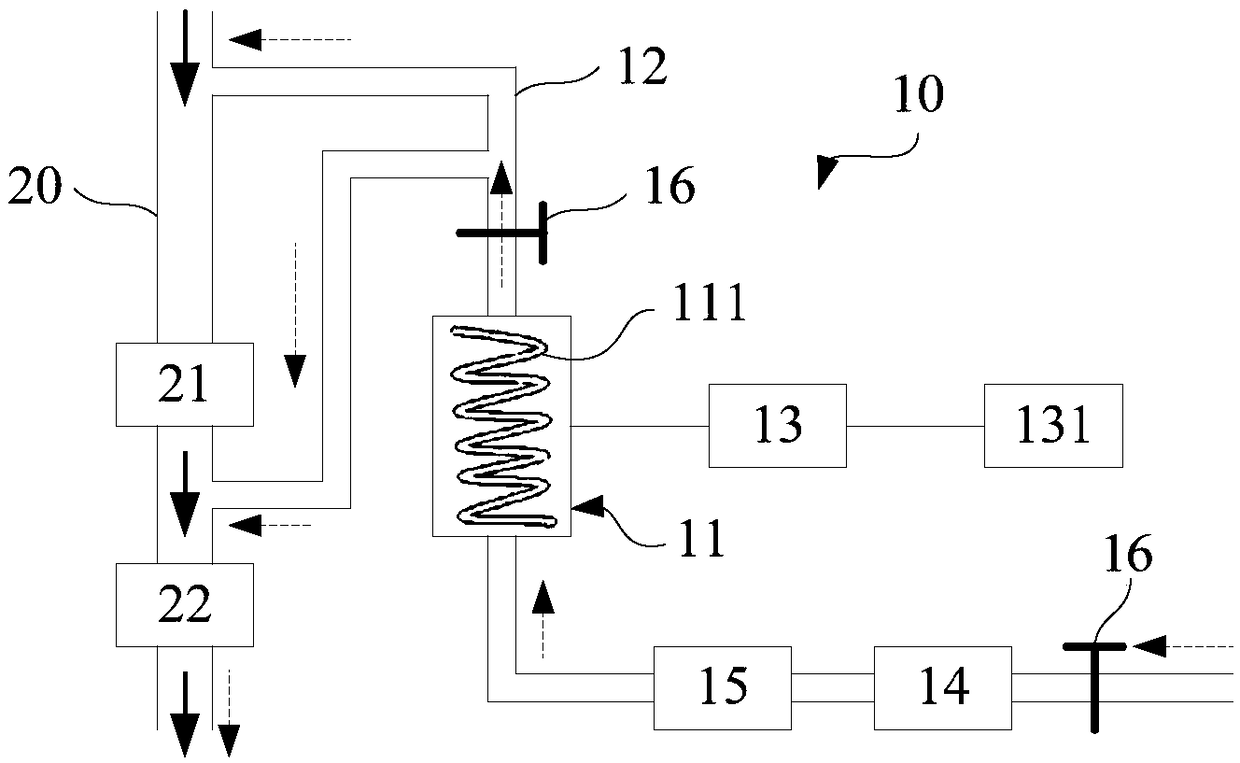

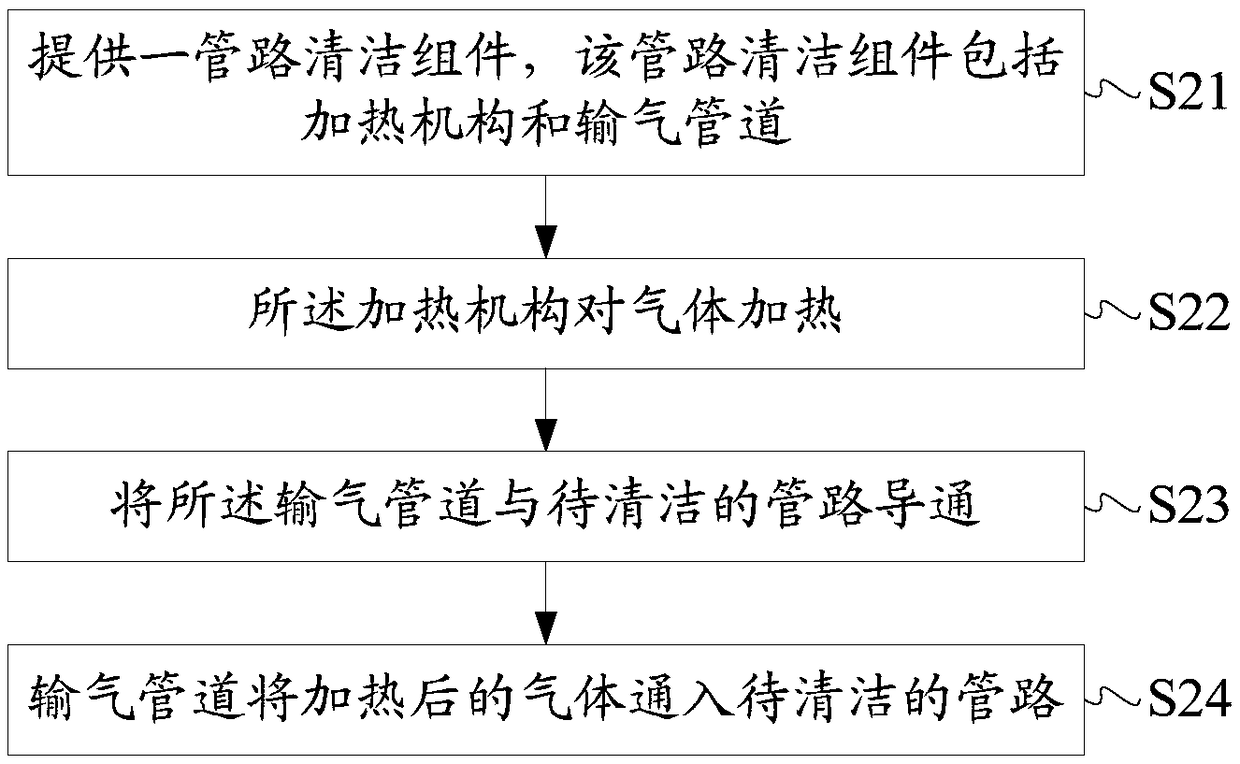

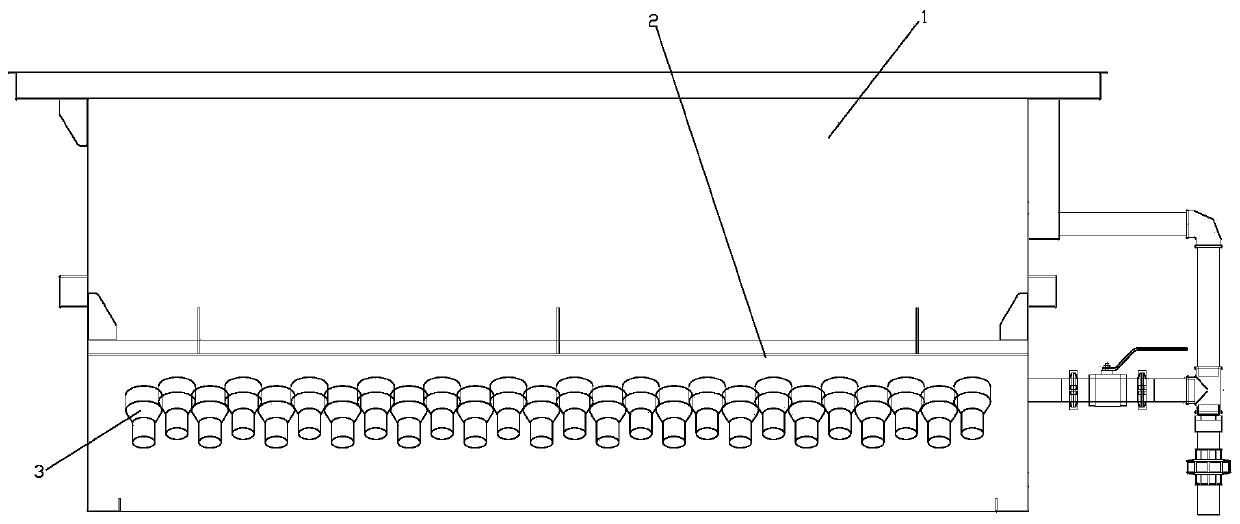

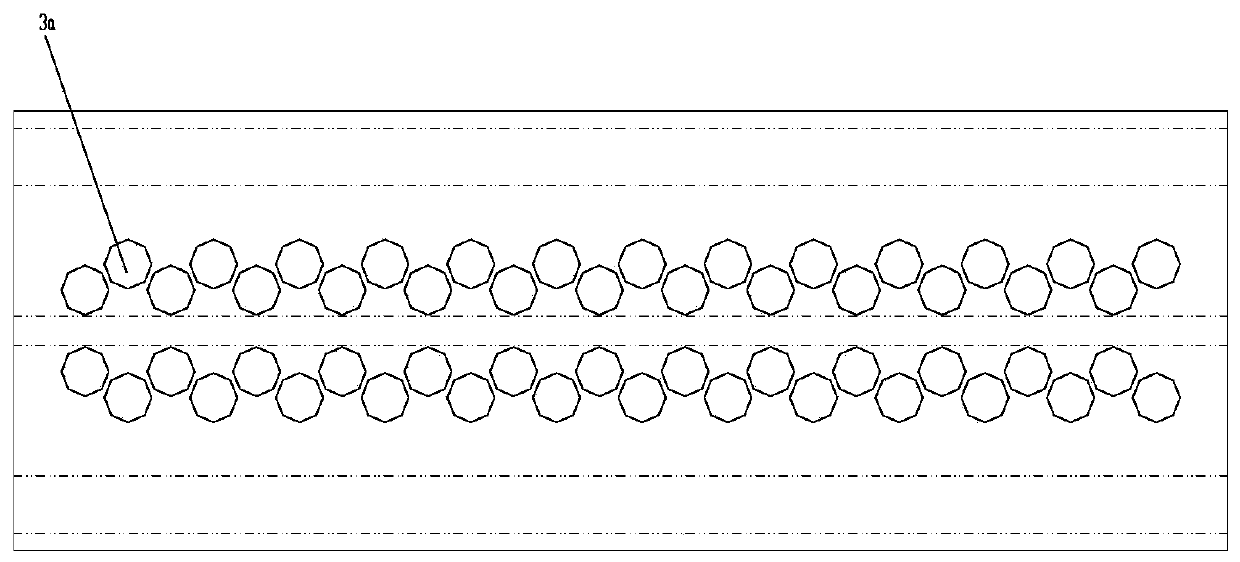

Tube cleaning assembly and tube cleaning method

InactiveCN108787645ANot easy to condenseEasy to prevent blockingHollow article cleaningCleaning methodsTube cleaning

The application discloses a tube cleaning assembly and a tube cleaning method. The tube cleaning assembly comprises a heating mechanism and a gas transportation tube, wherein the heating mechanism isused for heating gas; and the gas transportation tube is communicated with a tube to be cleaned and introducing heated gas into the tube. Based on this, the tube cleaning assembly disclosed by the invention facilitates prolonging the running time of the tube and reducing the loss of the production capacity while cleaning the tube.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

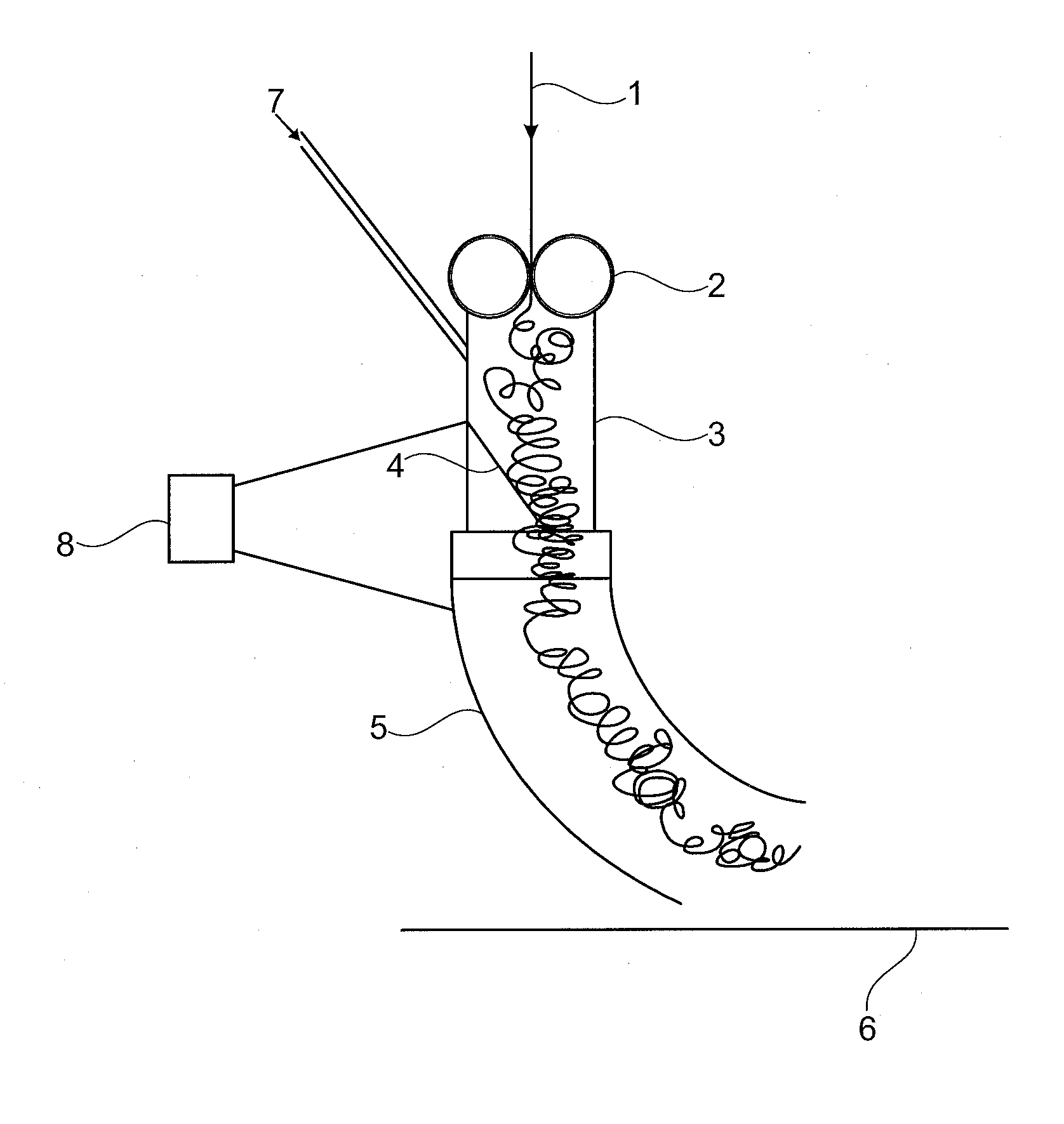

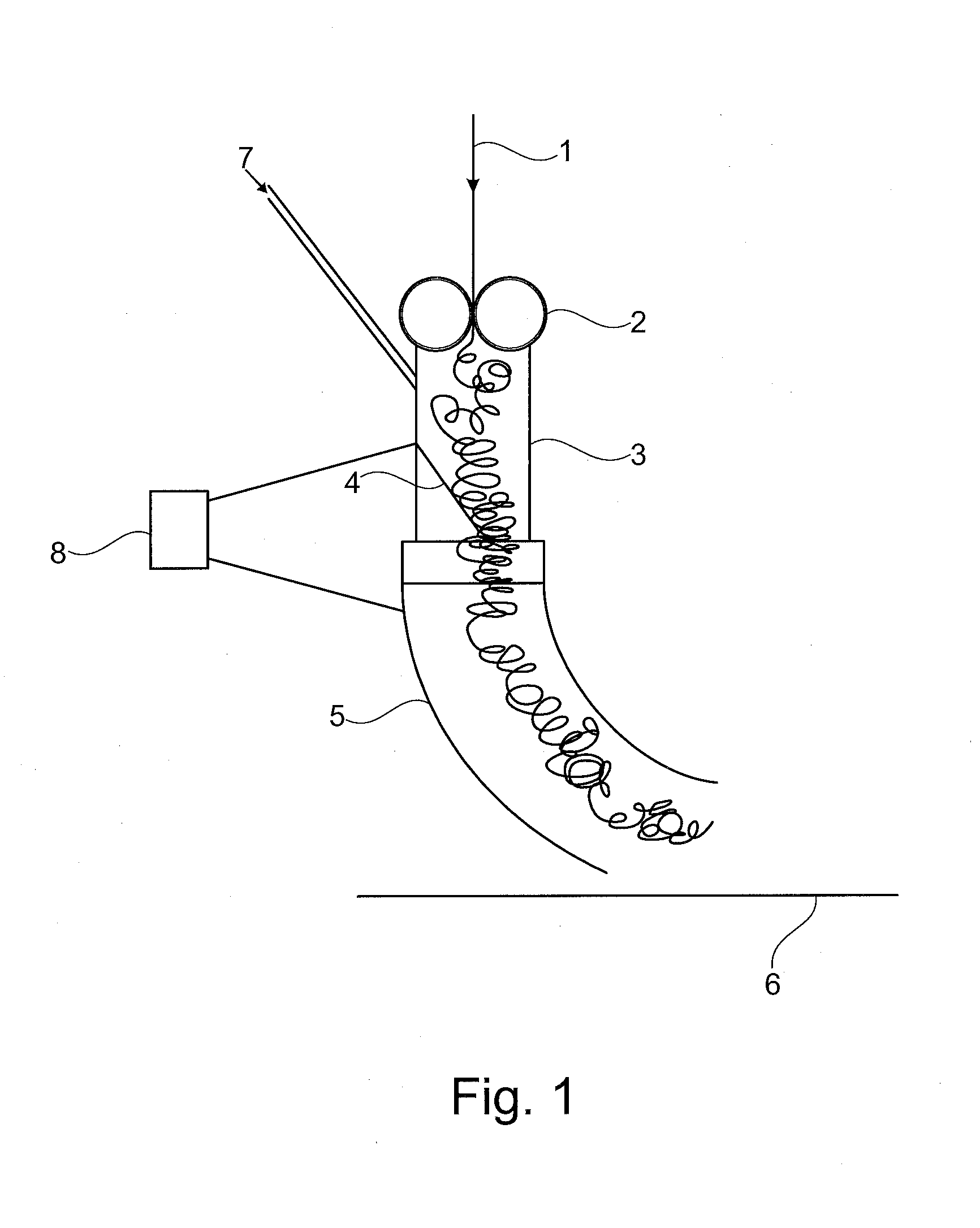

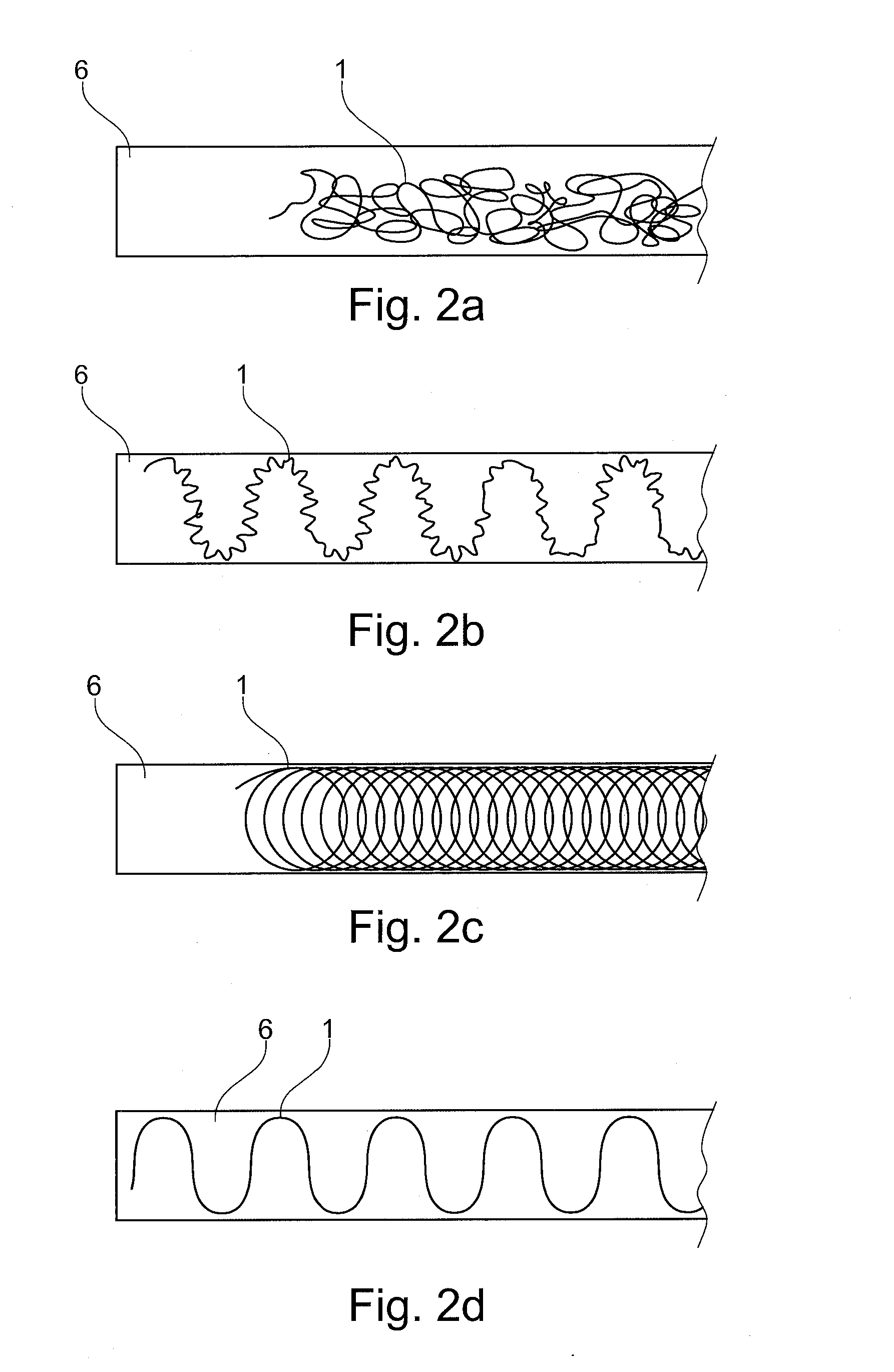

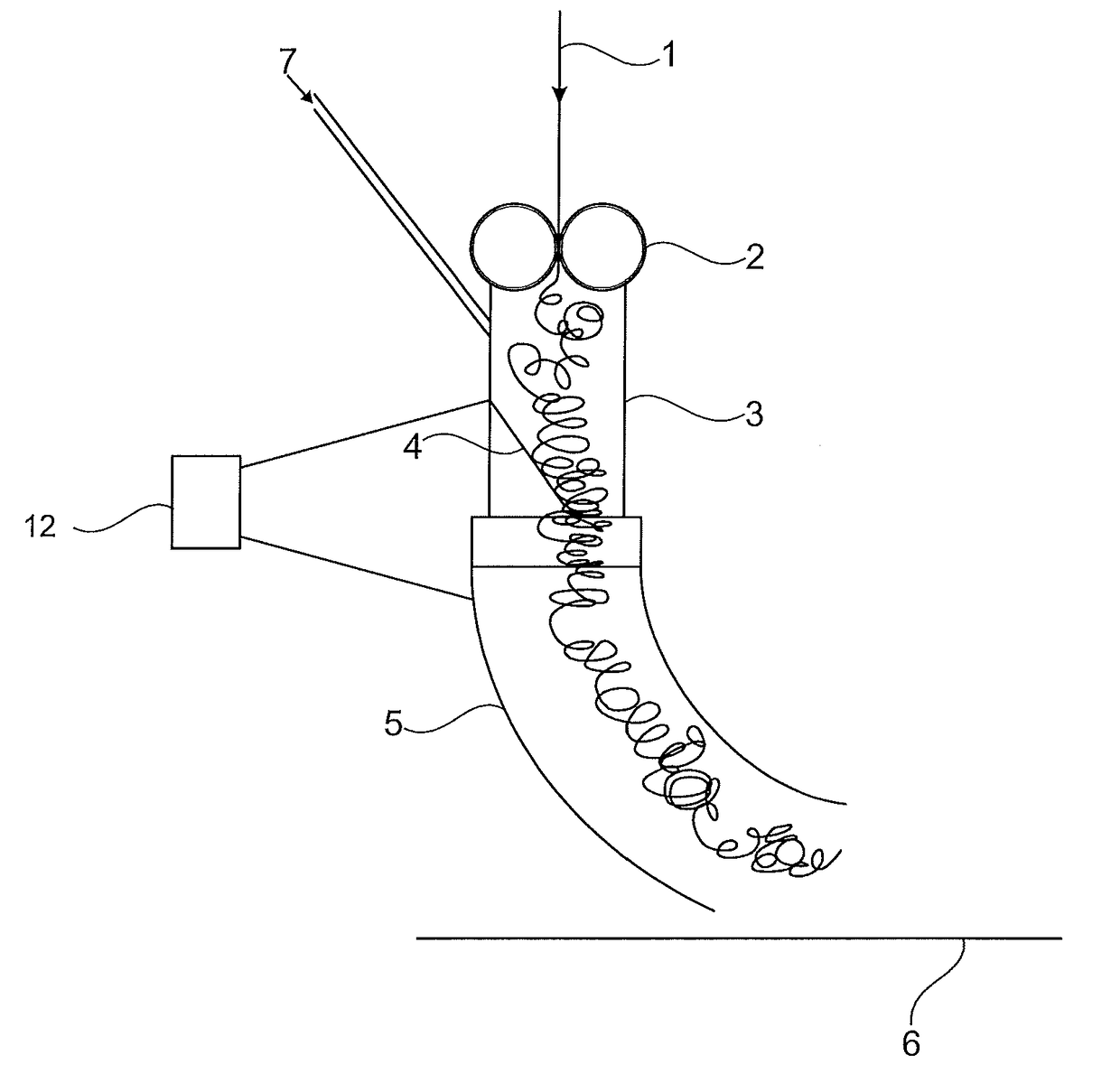

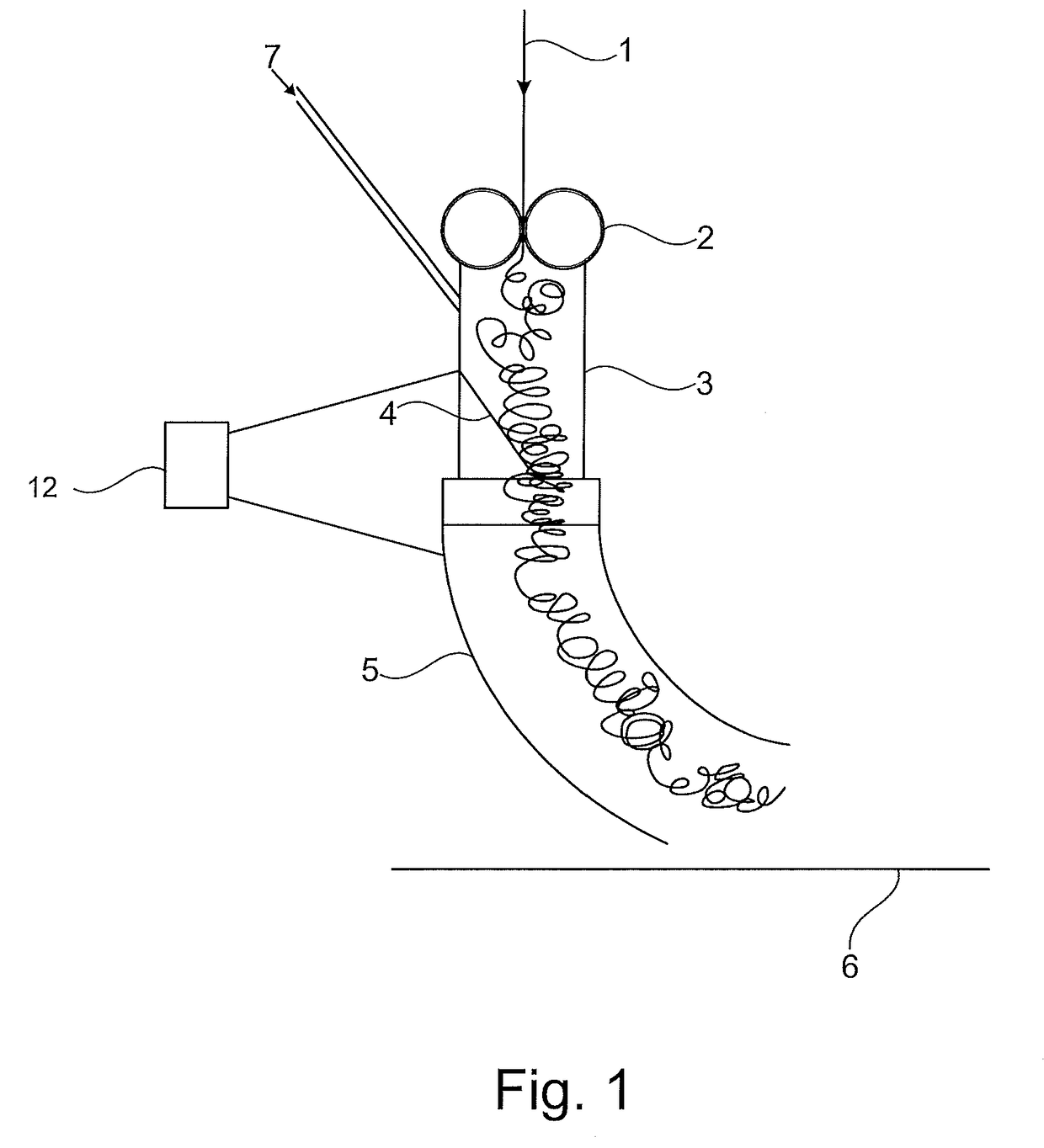

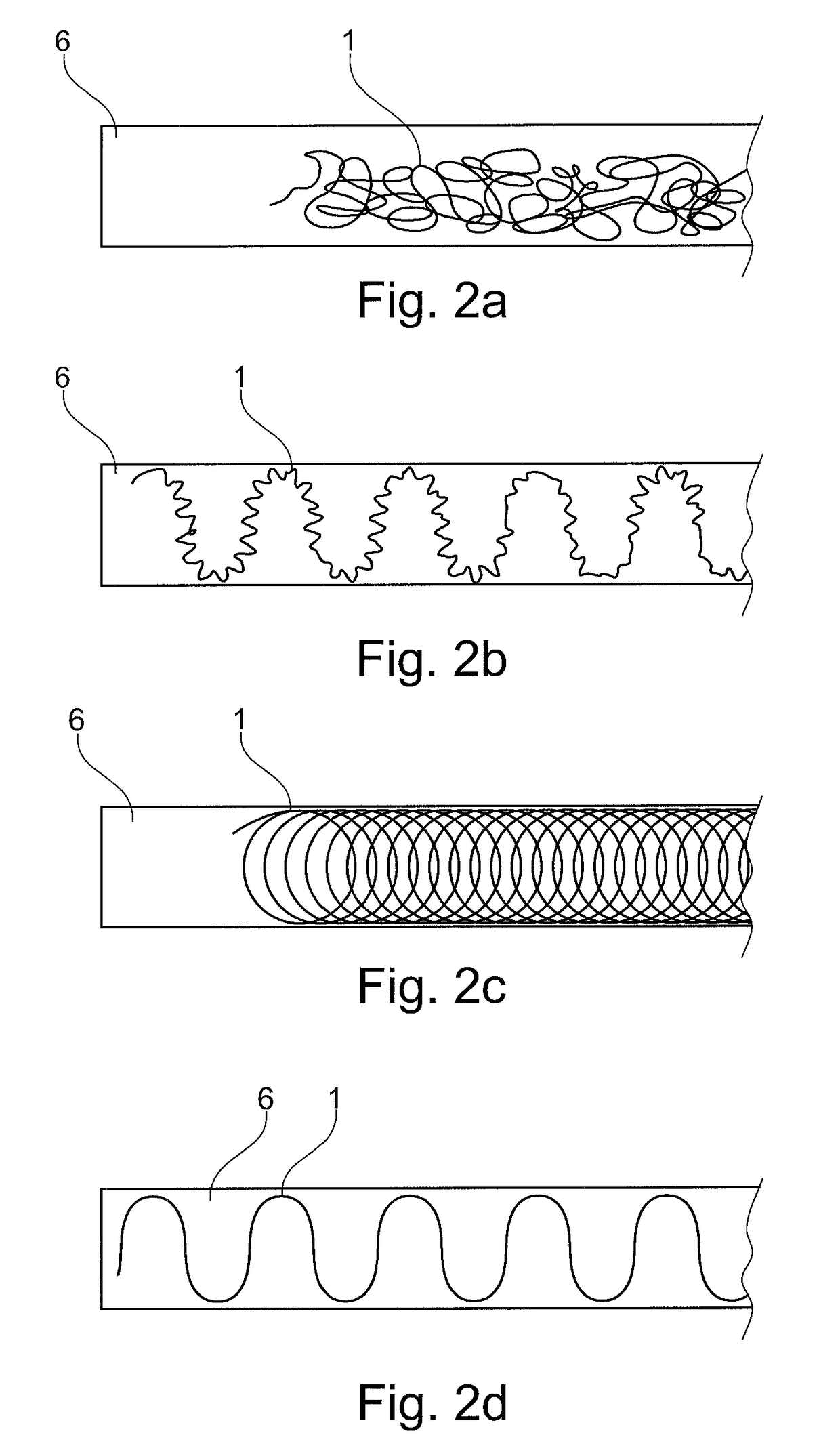

Device for shaping a thread-like material

ActiveUS20150152576A1Easy to operateReduced productivity lossKnotting netsYarnEngineeringMechanical engineering

Owner:SAURER TECH GMBH & CO KG

Glass substrate retesting and repairing system and method thereof

A glass substrate remeasurement and rework system and method thereof, wherein the glass substrate remeasurement and rework system comprises an electrical measuring station, a laser repairing machine, a laser long-line machine, a branching re-measurement station and a re-measurement electrical measuring station. The electrical measuring station electrically measures whether each of the panels of the glass substrate has defects. The laser repairing machine marks an abnormal level for the panel with the defect, and diverts the remaining glass substrates with the abnormal level. The laser line machine repairs the panel having the abnormal level. The separating and retesting station separates the normal and abnormal glass substrates. The re-measurement electrical measuring station identifies the abnormal glass substrate. When the panel has an abnormal level, the panel with the abnormal level is re-measured, and is diverted to the laser repairing machine or the laser long-line machine for re-repair according to the type of defect, so as to reduce the damage caused by re-measurement and re-repair. Loss of capacity and time cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Device for shaping a thread-like material

ActiveUS9670603B2Reduced productivity lossYarnLiquid/gas/vapor yarns/filaments treatmentMechanical engineeringTHREAD-LIKE

Owner:SAURER TECH GMBH & CO KG

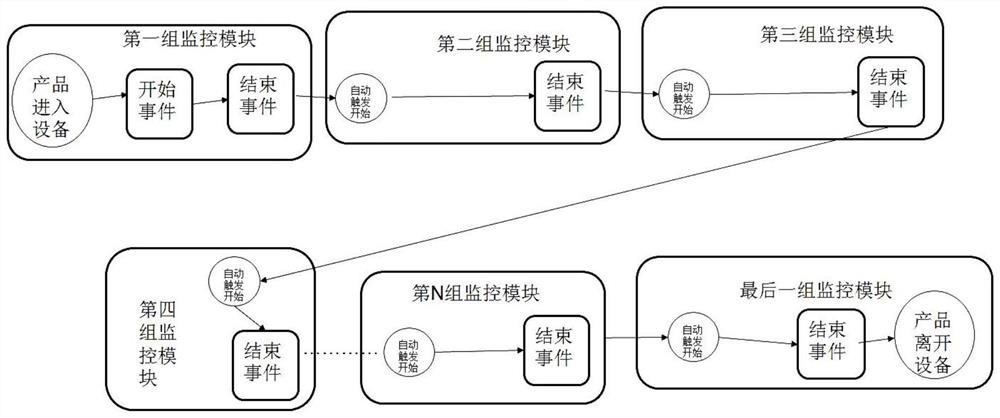

Time monitoring and management method and system for manufacturing process of equipment based on chain type triggering

PendingCN112418816AImprove accuracyReduced productivity lossOffice automationAlarmsChain typeComputer science

The invention relates to a time monitoring and management method and system for the manufacturing process of equipment based on chain type triggering. The time monitoring and management method comprises the steps of carrying out the manufacturing process according to the sequence of all action events in a processing process after a product enters the equipment, and if the previous set of time monitoring module receives the end event of the corresponding action event and does not trigger the monitoring alarm, taking the end event received by the previous set of time monitoring module as the start event of the next set of time monitoring module; and performing the subsequent monitoring process according to the chain type triggering mode until the last set of monitoring module receives an endevent, and indicating that the time monitoring of the whole complete manufacturing process of the current product is completed. The time monitoring and management is performed on each action event inthe manufacturing process of the product, and no matter what mechanism of the equipment has the abnormal condition of pausing execution, the abnormal condition can be found immediately and the alarmcan be triggered, so that the accuracy of monitoring and management in the manufacturing process of the equipment is greatly improved, and the product rejection rate and the productivity loss of a factory are reduced.

Owner:中电九天智能科技有限公司

Repairing device of traction roller boss

The invention relates to a repairing device of a traction roller boss. The repairing device comprises a base, a sliding table, a tool installation mechanism and a tool assembly, wherein the sliding table can be mounted on the base in a front-back moving mode, and a guide column extending upwards is vertically connected to the sliding table; the tool installation mechanism is arranged on the guidecolumn in an up-and-down movement manner, and the tool assembly is installed on the tool installing mechanism; and the tool assembly comprises a blade which can be attached to the traction roller boss. According to the technical scheme, the cutting effect of the repairing device is formed with the blade after the blade makes contact with the traction roller boss, the position of the blade can be adjusted through the sliding table and the tool installation mechanism, so that the blade and the traction roller boss are well attached to repair the traction roller boss; the repairing device is simple and easy to operate, and the uneven working surface of the traction roller boss in the working process can be repaired online; and the service life of a traction roller is prolonged, and the traction roller does not need to be disassembled for replacement, so that the productivity loss caused by long-time replacement of the traction roller is reduced.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +1

Pre-plating dust removal device for cylinder body electroplating

The invention discloses a pre-plating dust removal device for cylinder body electroplating. The pre-plating dust removal device comprises a dust removal tank and an ultrasonic generating assembly. Theultrasonic generating assembly comprises transduction heads and a driver, the transduction heads are located on the outer side of the lower portion of the dust removal tank obliquely, and the ultrasonic generating directions of the transduction heads are right opposite to the range where an inner hole of a workpiece is located when the workpiece is put in the dust removal tank. A chemical dust removal manner is avoided, and the requirements of environmental protection are met. Meanwhile, the structure that a transduction rod is put in the inner hole of the workpiece in the prior art is abandoned, the obliquely-arranged transduction heads are adopted, ultrasonic waves directly act on the inner hole of the workpiece (the dust removal tank is located on the upper portion), and the requirements of dust removal of pre-plating treatment of most current cylinder bodies can be met. The pre-plating dust removal device cooperates with a tool matched with the workpiece, a production line does not need to stop, different workpieces are replaced to be directly mounted on the device, thus, the device is suitable for existing workpieces with various sizes, seamless switching of products is achieved, capacity losses of line stop are avoided, the delivery requirements are rapidly met, the switching time of mature products is shortest, and the capacity losses are reduced to be minimal.

Owner:LONCIN MOTOR

Flexible printed circuit and detecting device, detecting method and display device thereof

ActiveUS9949367B2Extend your lifeReduced productivity lossPrinted circuit aspectsElectric connection testingContinuous useDisplay device

Disclosed are a flexible printed circuit and a detecting device, a detecting method and a display device thereof. The flexible printed circuit comprises a body and an interface structure that is connected with the body, wherein the interface structure is provided with a plurality of mark lines dividing the interface structure into a plurality of interfaces with the same structure. When a front end interface of the flexible printed circuit of the disclosure is damaged, the front end interface can be removed along the mark line, and then an exposed rear end interface can be used successively, thus preventing a situation where the flexible printed circuit cannot be used because the only interface is damaged, thereby extending the life span of the flexible printed circuit, reducing productivity loss due to frequent replacements of the flexible printed circuit and reducing production cost.

Owner:BOE TECH GRP CO LTD +1

A Partial Reconfiguration Method of Reconfigurable Manufacturing System

ActiveCN108681829BImprove practicalityShorten the timeResourcesManufacturing computing systemsReconstruction methodProcess engineering

The invention discloses a method for partial reconfiguration of a reconfigurable manufacturing system, comprising the following steps: constructing a reconfigurable manufacturing system RMS for each workpiece of the workpiece family; and dividing the process route of the workpiece i into P i1 Part and P i2 part; calculate the benefit B of workpiece i i ; calculate when B i =0, the corresponding O i sp where the routing of workpiece i is divided into P i1 Part and P i2 part, which is the reconstruction point of artifact i; then the reconstruction points of artifacts 1~n are respectively to calculate the overall income of D-RMS. In the case of B>0, select a reconstruction point as the reconstruction of D-RMS Point O 1 sp ; use O 1 sp , divide the process route of workpiece i into P’ i1 part, P' i2 Part; use P' of all workpieces in the workpiece family i1 Partially constructs the first subsystem of D‑RMS; utilizes P’ of all artifacts within the artifact family i2 The second subsystem of D-RMS is partially constructed, and the storage warehouse of semi-finished products is added between the two subsystems to construct the delayed manufacturing system D-RMS; the workpieces in the workpiece family are manufactured using D-RMS.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Universal out-of-tank plating system for cylinder blocks

ActiveCN111155155BAsh removal is completeShort switching timeElectrolysis componentsStructural engineeringCylinder block

Owner:LONCIN MOTOR

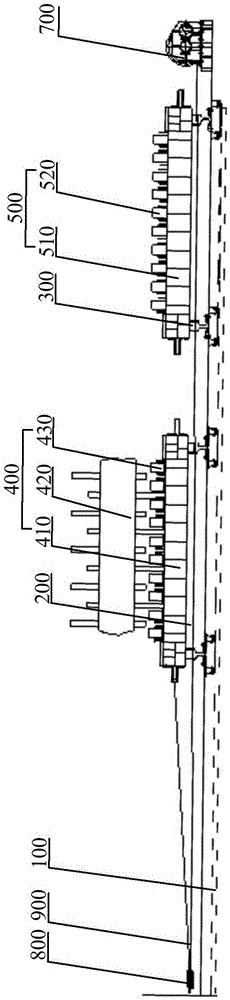

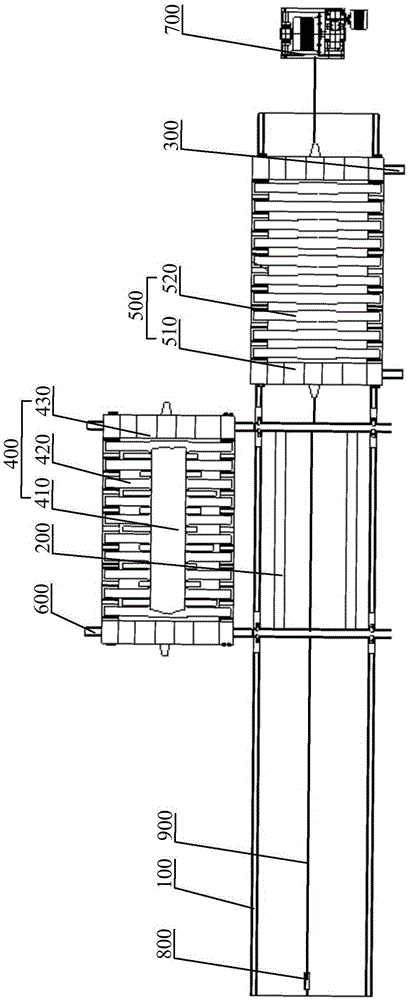

Sintering machine and single-roll grid plate replacement assisting device thereof

The invention provides a single-roll grid plate replacement assisting device of a sintering machine. The device comprises an auxiliary rail, at least two mobile trolleys and a drive device. The auxiliary rail is arranged at one ends of work rails of the sintering machine, and a set angle is formed between the auxiliary rail and the work rails and is larger than 0 degree and smaller than 180 degrees. Each mobile trolley is movably arranged on the auxiliary rail. The drive device is used for being connected with each mobile trolley and used for driving each mobile trolley to move along the auxiliary rail. Each mobile trolley is provided with a butt-joint rail in butt joint with the corresponding wok rail. In the at least two mobile trolleys, at least one mobile trolley is used for bearing a first grid plate trolley and first single-roll grid plates in a work state, and at least one mobile trolley is used for bearing a second grid plate trolley and second single-roll grid plates in a standby state. According to the scheme, the problem that the sintering work capacity is greatly influenced due to the fact that maintenance is carried out on single-roll grid plates at present can be solved. The invention further provides the sintering machine.

Owner:LAIWU IRON & STEEL GRP

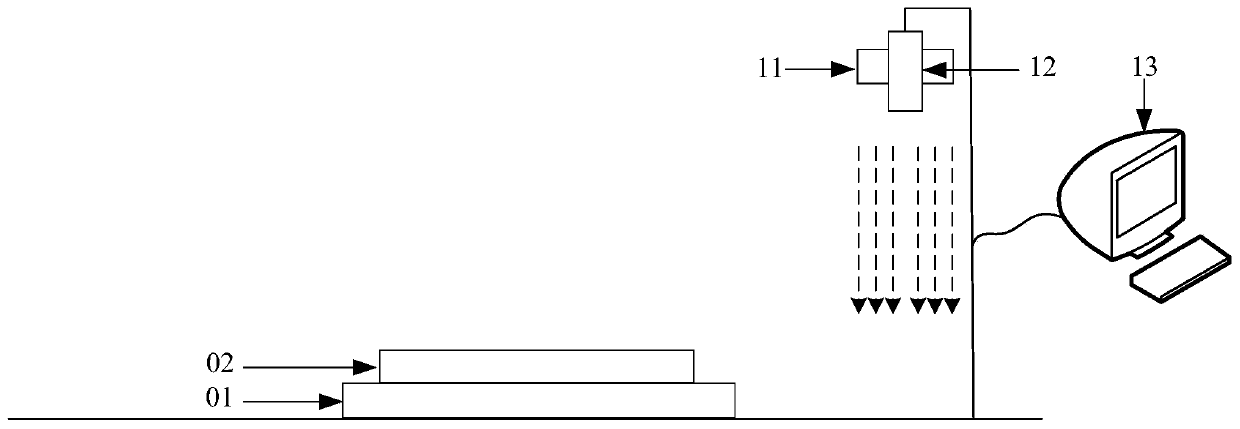

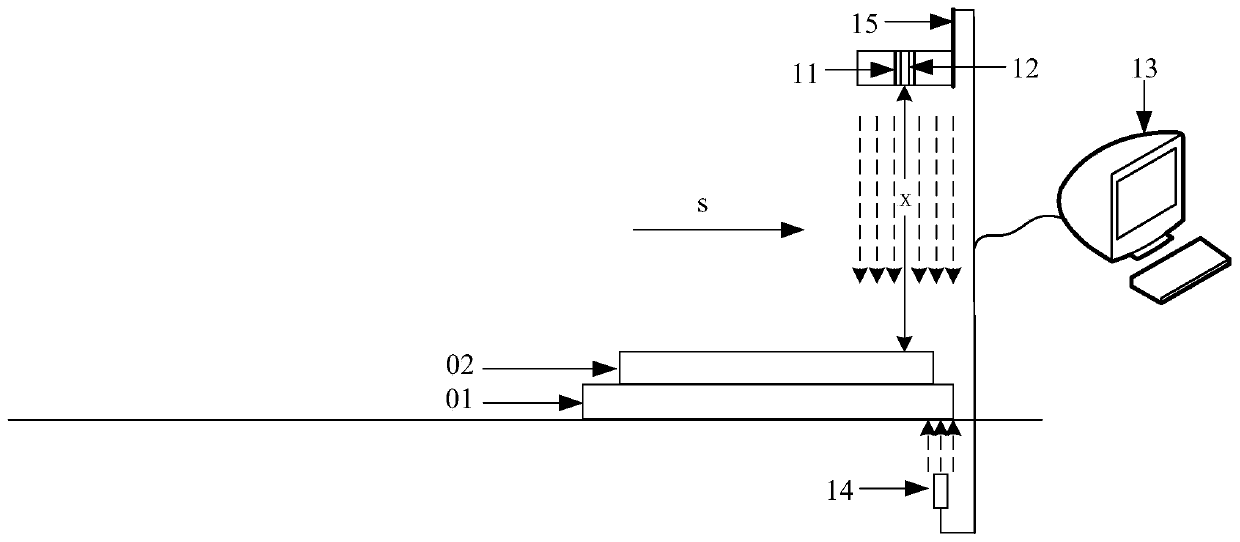

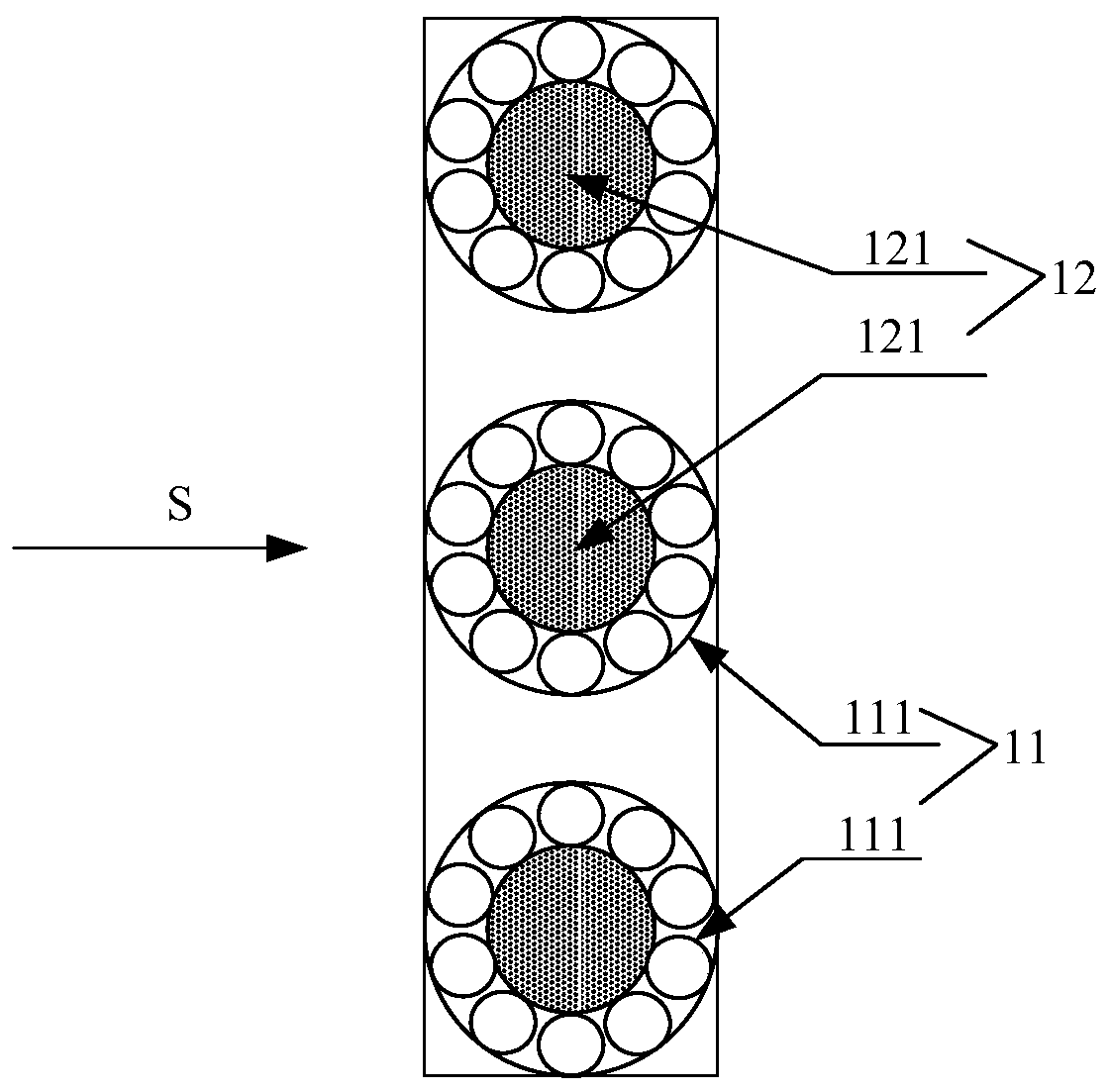

Film detection method, device and film detection system

ActiveCN107727654BAvoid scrappingAvoid downtimeMaterial analysis by optical meansOptoelectronicsLight source

Owner:MIANYANG BOE OPTOELECTRONICS TECH CO LTD +1

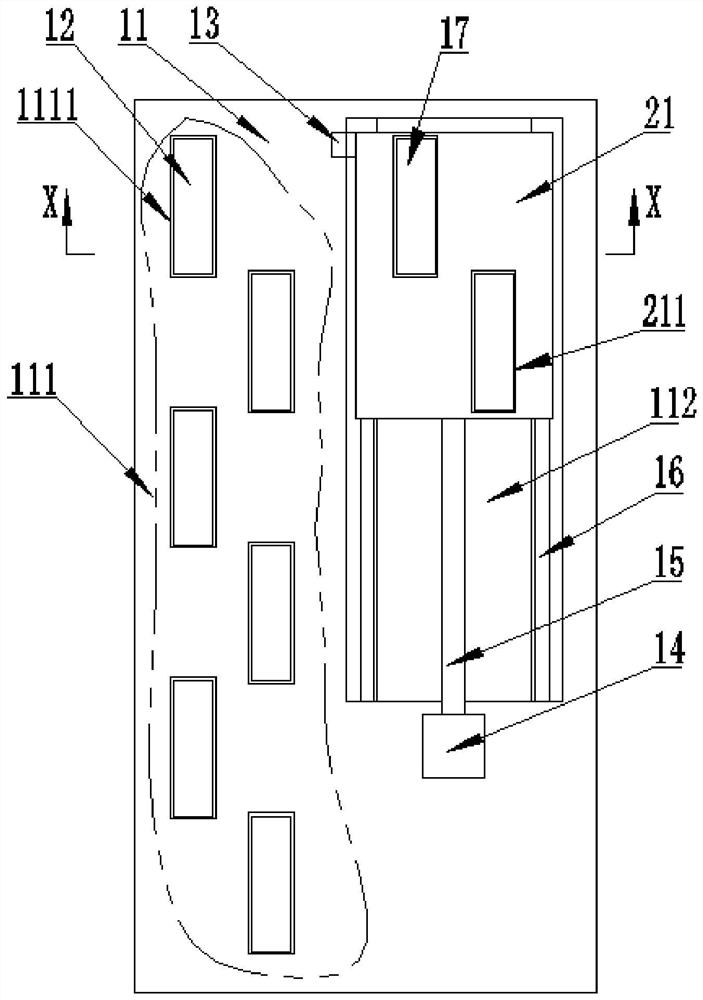

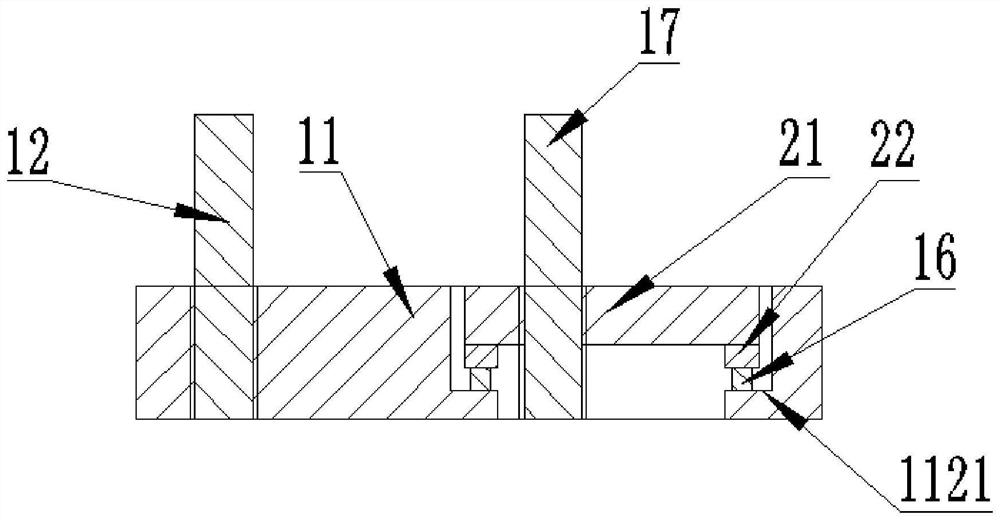

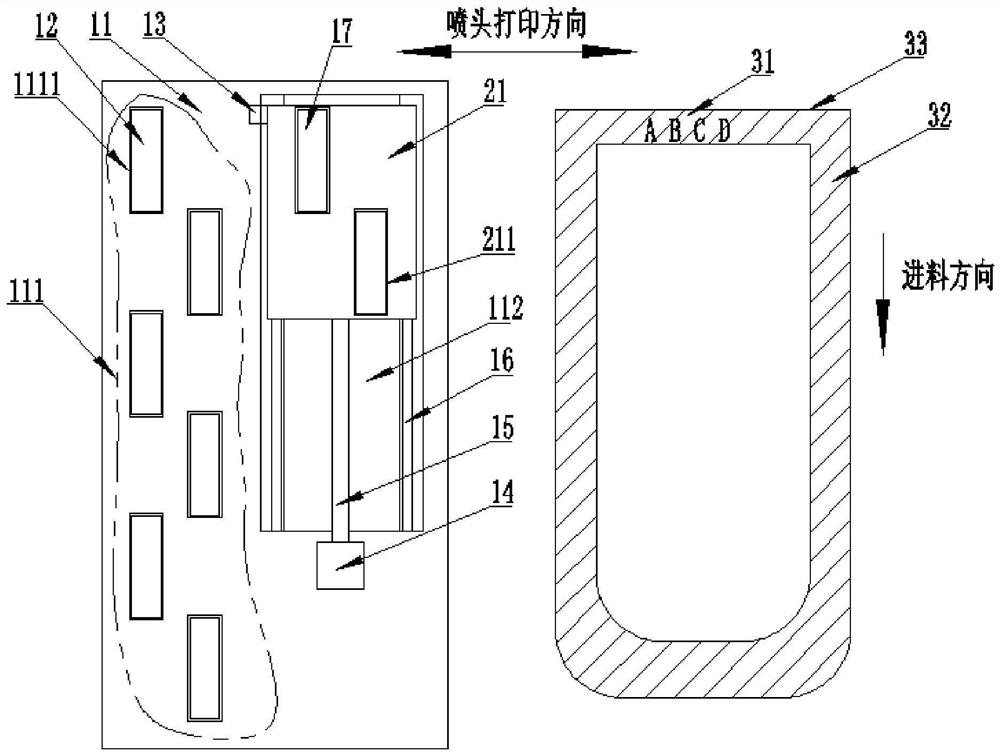

Double-color printing nozzle permutation and combination structure and printing method

The invention discloses a double-color printing nozzle arrangement and combination structure, which comprises a nozzle mounting bottom plate, a large image printing nozzle assembly arranged on the nozzle mounting bottom plate and a small image printing nozzle assembly arranged on the nozzle mounting bottom plate, and is characterized in that the large image printing nozzle assembly is used for printing a large image on a whole-surface jet printing medium, and the small image printing nozzle assembly is used for printing a small image on the whole-surface jet printing medium; and the small image printing nozzle assembly is used for printing the prominent small image on the whole surface of the jet printing medium. The nozzle mounting bottom plate is provided with a large-image nozzle assembling hole for mounting the large-image printing nozzle assembly and a small-image nozzle sliding groove for mounting the small-image printing nozzle assembly side by side, and the small-image printing nozzle assembly is slidably arranged in the small-image nozzle sliding groove. According to the invention, a large-image printing mode and a small-image printing mode are combined and arranged, the arrangement of the large-image printing nozzles can cover a whole-surface jet printing medium, the arrangement of the small-image printing nozzles only needs to cover the width of a small image needing to be highlighted, and the small-image printing nozzles can automatically move, so that the small image can be printed and highlighted at different positions of the whole-surface jet printing medium.

Owner:선전진신테크놀로지컴퍼니리미티드

Electroplating environment treatment device for electroplating outside the cylinder tank

ActiveCN110923789BShort switching timeEasy to locate and installElectrodesCylinder blockMechanical engineering

The invention discloses an electroplating environment treatment device for cylinder body out-of-groove electroplating. The electroplating environment treatment device comprises a mounting frame assembly, a mounting auxiliary assembly and a flow guide mounting assembly, wherein the mounting frame assembly comprises a fixing frame and a pressing assembly; the fixing frame comprises a bottom plate and a frame fixed on the bottom plate; the mounting auxiliary assembly is used for mounting a workpiece, is mounted on the bottom plate after being compensated in height and diameter, and is pressed bythe pressing assembly; the mounting auxiliary assembly is further used for guiding electroplating liquid into a cylinder body and is used for enabling an electroplating environment to be formed between an anode and the workpiece through the anode; and the flow guide mounting assembly is used for mounting the anode and guiding the electroplating liquid to the electroplating environment. According to the electroplating environment treatment device, the unique and simple electroplating environment is formed, the mounting and positioning are convenient, the universality is achieved when the electroplating environment treatment device is used for cylinder body out-of-groove electroplating, the electroplating environment treatment device is suitable for workpieces with various sizes, seamless switching of products is realized, the capacity loss caused by line stopping is avoided, the delivery requirement is rapidly met, the switching time of mature products is reduced to the minimum, and thecapacity loss is reduced to the minimum.

Owner:LONCIN MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com