Partial reconfiguration method of reconfigurable manufacturing system

A technology for manufacturing systems and subsystems, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as increasing reconstruction time and reconstruction cost, not involving inventory problems, complex reconstruction processes, etc., to achieve enhanced On-time delivery capability, reduced capacity loss, reduced time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0040] The present invention analyzes the reconfiguration process of the reconfigurable manufacturing system RMS, and finds that in the reconfiguration process of the RMS, under certain conditions, the front end of the configuration can maintain the production activities of semi-finished products, and the rear end of the configuration can perform reconfiguration activities to meet new needs. However, in the basic structure of traditional RMS, all structures are a continuous whole, and there is no way to realize the above demands.

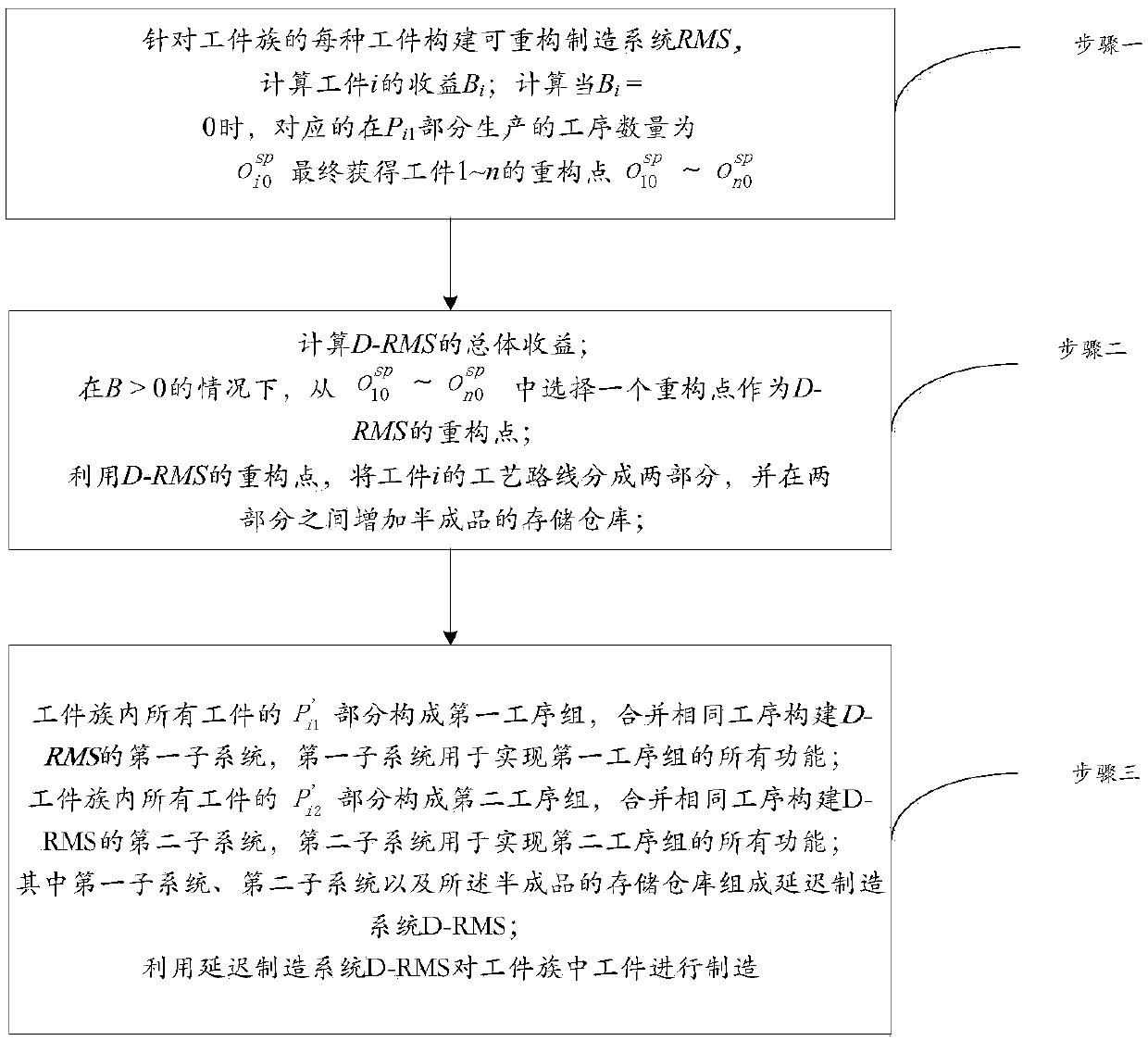

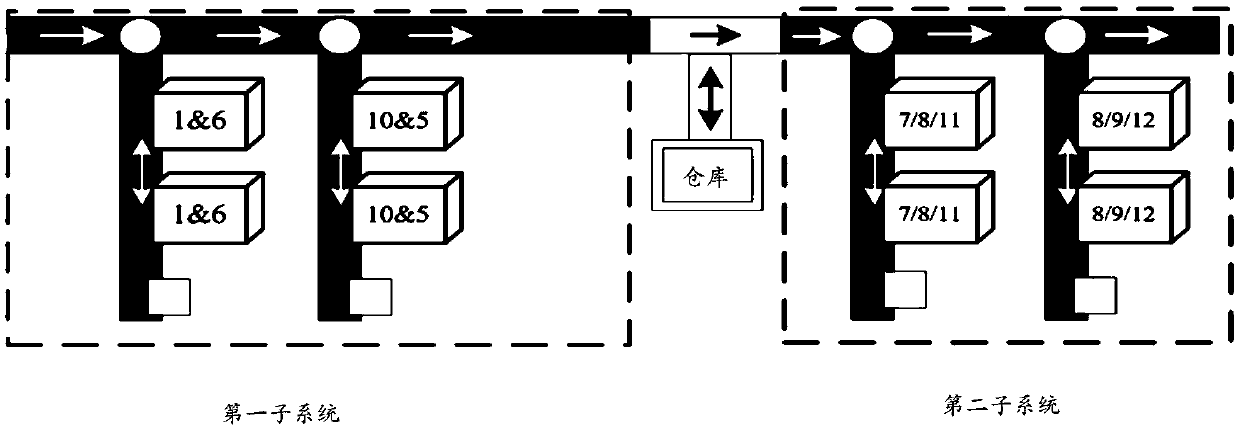

[0041] The invention provides a method for partial reconfiguration of a reconfigurable manufacturing system, the process of which is as follows figure 1 As shown, the method includes the following steps:

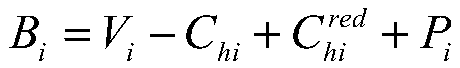

[0042] Step 1. Construct a reconfigurable manufacturing system RMS for each workpiece of the workpiece family, and the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com