Compensating auxiliary tooling for electroplating outside the cylinder tank

A technology for auxiliary tooling and cylinders, applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of manual replacement, production line shutdown, and increased loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

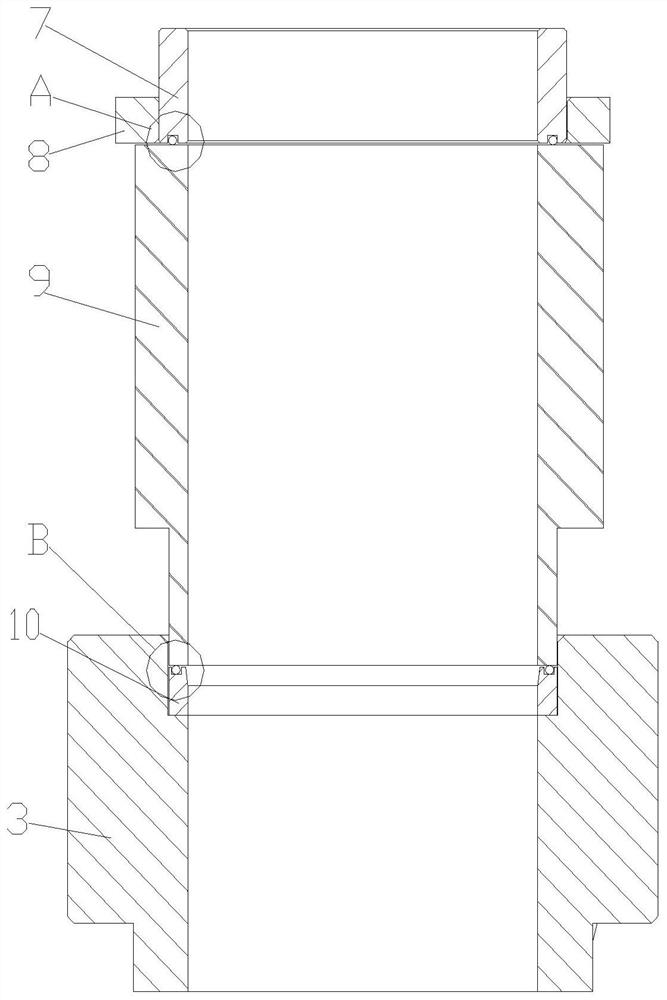

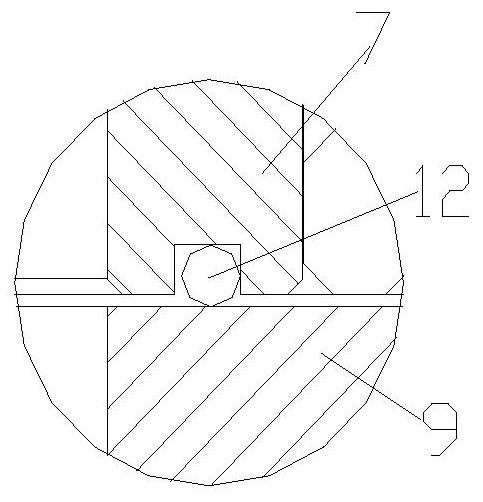

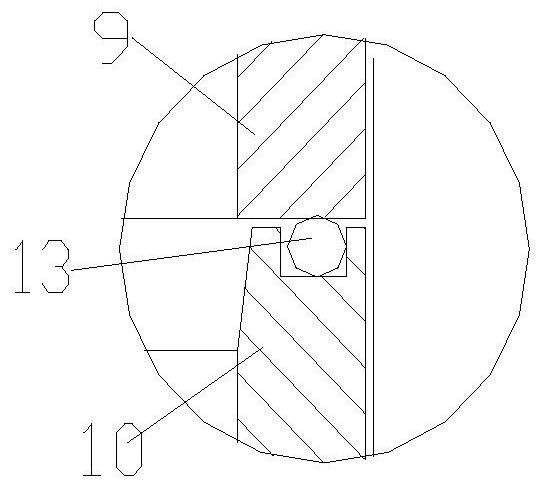

[0028] figure 1 It is a structural sectional view of the present invention, figure 2 for figure 1 Enlarged view at A, image 3 for figure 1 Enlarged view at B, Figure 4 For the present invention uses the structural sectional perspective view, Figure 5 For the present invention to use a structural perspective view, as shown in the figure: the present invention will be described in detail below with the application structure of the present invention; the compensating auxiliary tooling for electroplating outside the cylinder tank of this embodiment, the compensating auxiliary tooling is used for Install the workpiece and install and press after compensating in height and diameter, and the compensating auxiliary tooling is also used to introduce the electroplating solution into the cylinder and pass through the anode;

[0029]Of course, the present invention also needs to cooperate with the mounting frame assembly when in use, as shown in the figure, the mounting frame ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com