Broken material rubber plate forming machine

A molding machine and scrap technology, applied in flat products, household appliances, other household appliances, etc., can solve the problem of higher and higher requirements for plastic boards, and achieve the effect of good texture and simulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

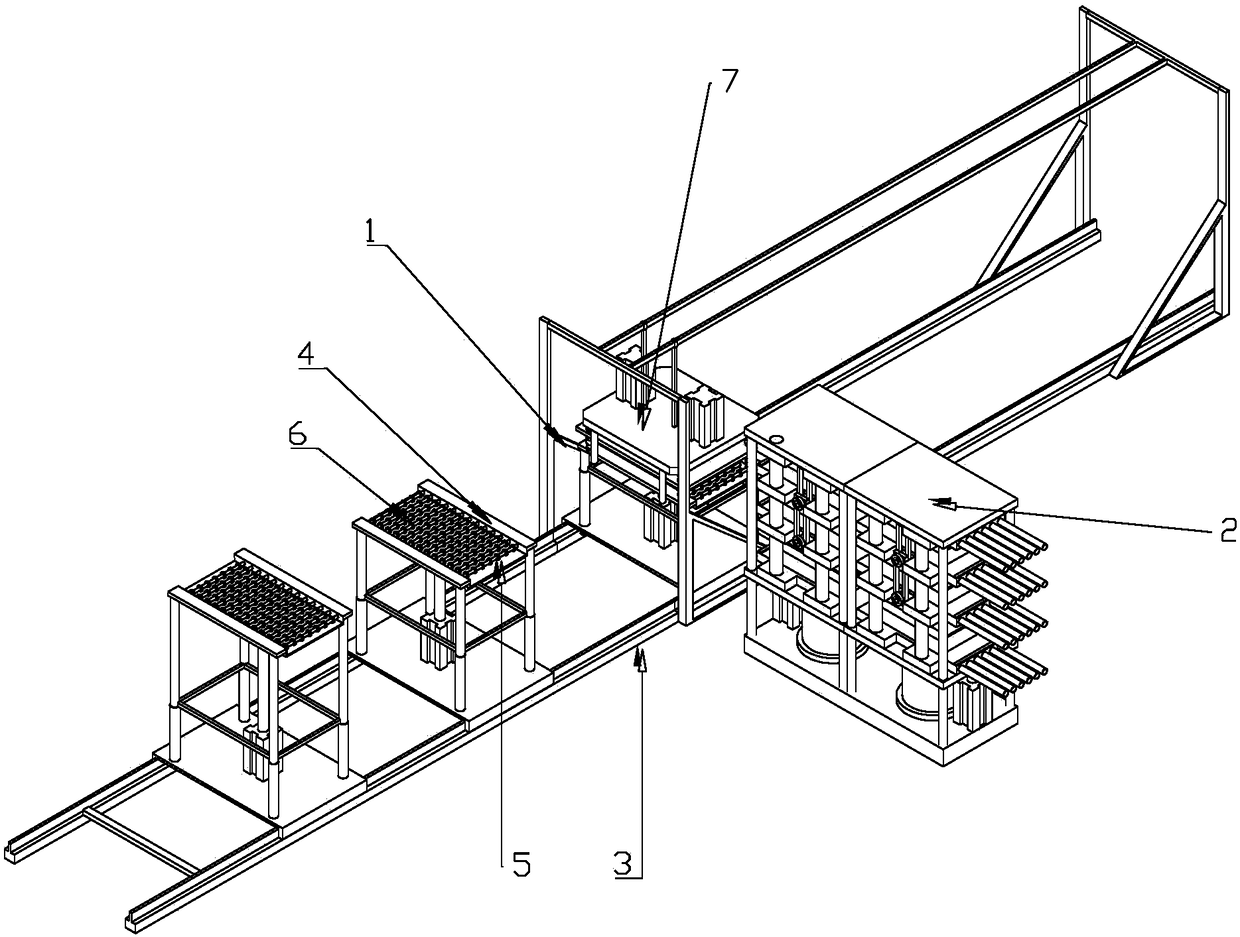

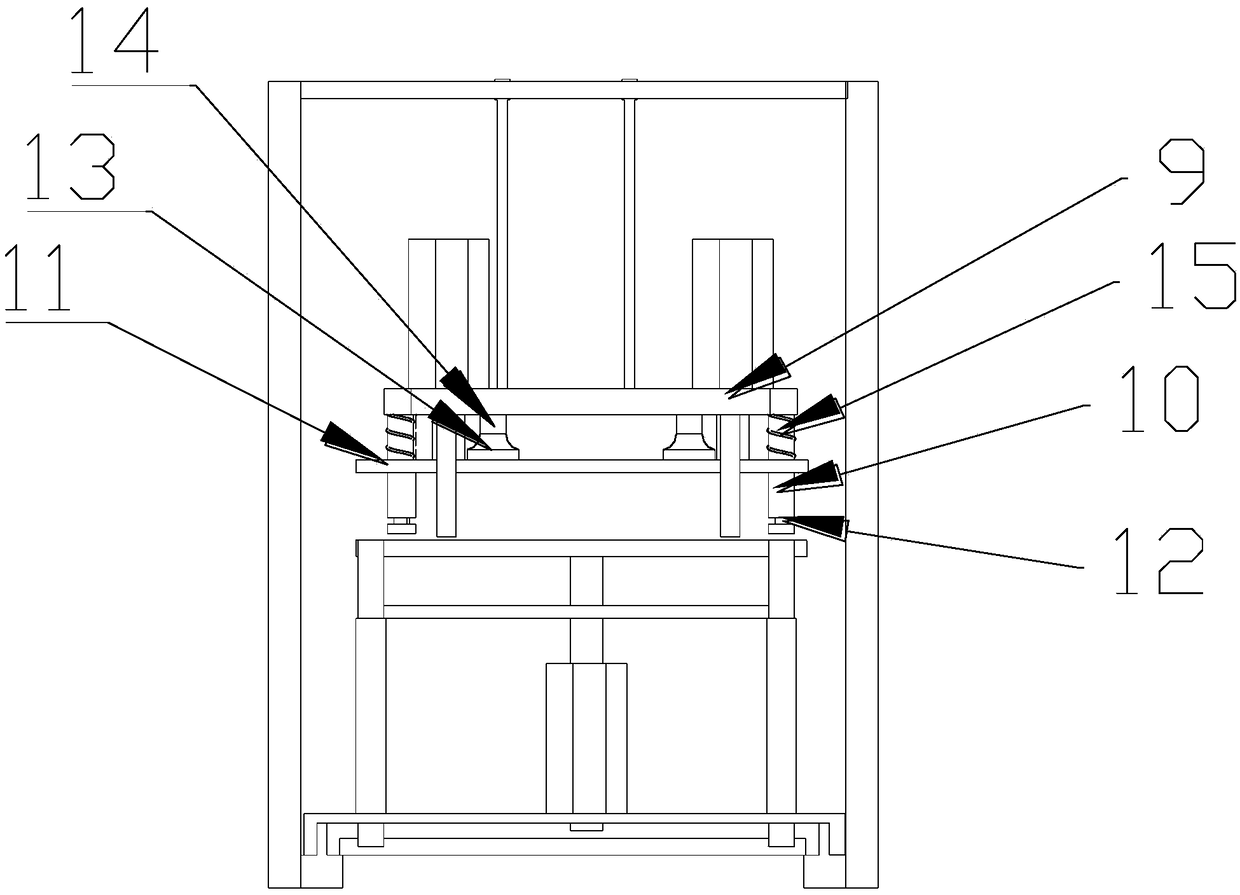

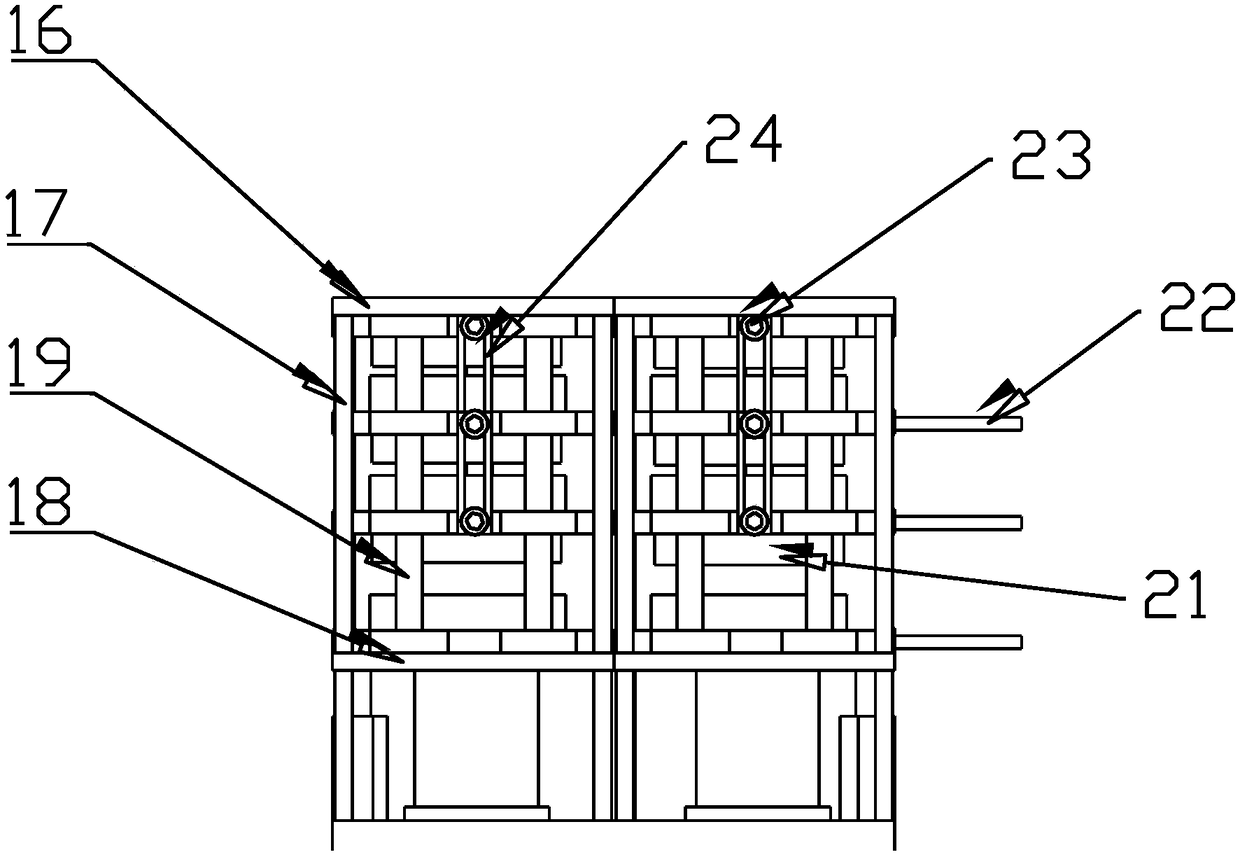

[0020] Such as Figure 1-3 As shown, a crushed rubber sheet molding machine includes a primary scrap press machine 1 and a secondary hot press 2, and the primary scrap press machine 1 is included at the feed end of the secondary hot press 2 The sliding slide rail 3 is set, and three platen frames 4 are arranged on the slide rail 3, and the three platen frames 4 are designed according to the height of the three-layer heat pressing module on the secondary heat press machine 2, the described The platen frame 4 is provided with a first notch 5 for placing the plastic sheet forming mold, and a plurality of sliding wheels 6 are arranged in the first notch 5, and the upper end of the platen frame 4 is provided with a scrap platen mechanism 7, and the crushed The material pressing plate mechanism 7 includes a pair of sliding rods 8 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com