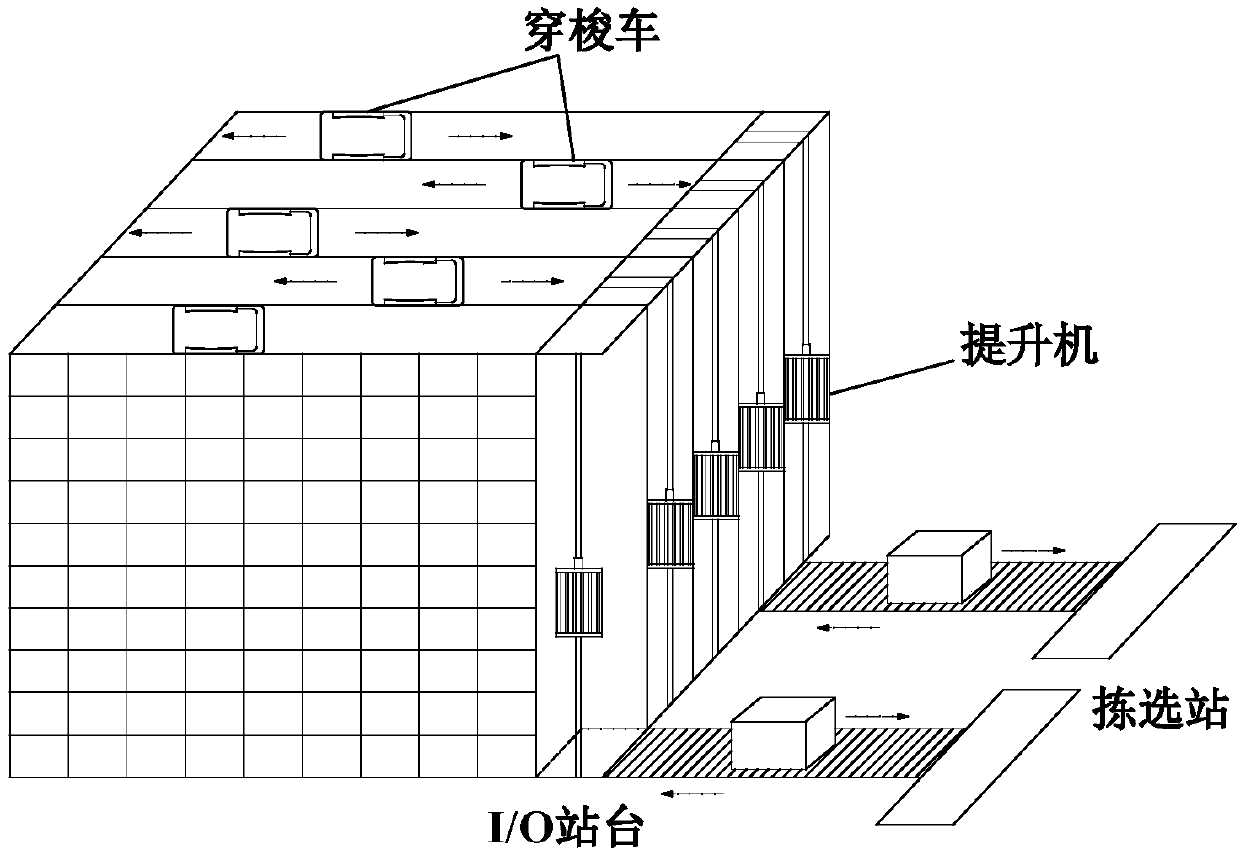

Modeling optimization method based on multi-storey shuttle car automatic storage system

A storage system and optimization method technology, which is applied in the directions of transportation, packaging, storage devices, etc., can solve the problems that the modeling method is not suitable for the automatic storage system of multi-storey shuttle vehicles, and the accuracy of the modeling method is not high, so as to save the operating cost of the system. , The effect of improving equipment usage and reducing total time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is described in detail below in conjunction with accompanying drawing:

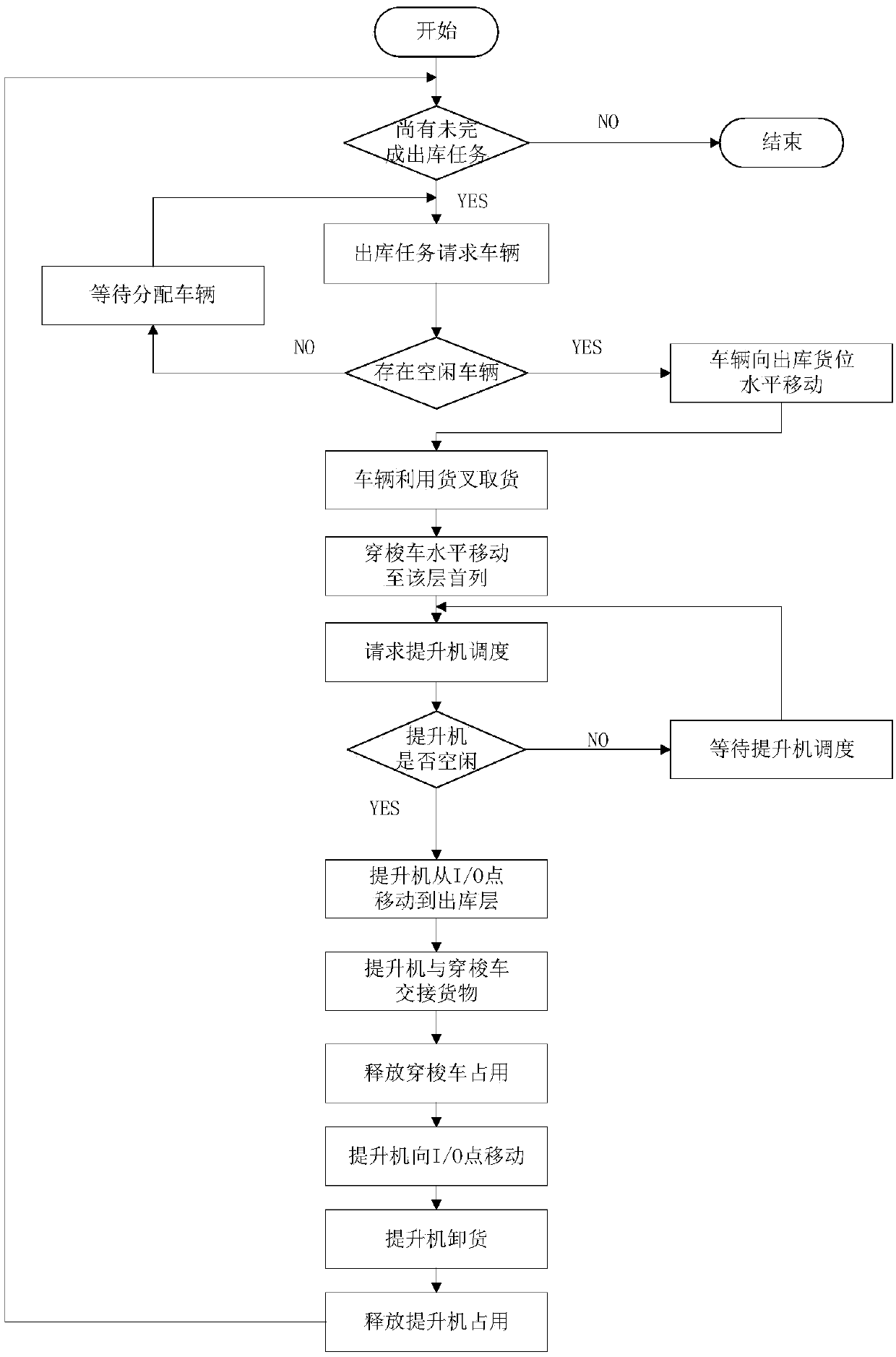

[0056] In a single outbound task, the task first requests the response of the shuttle car on the corresponding floor. According to the system scheduling, the shuttle car first moves horizontally to the delivery location assigned by the system, uses the fork to take out the goods, and then the shuttle car runs to the first column of the floor, requesting the response of the roadway hoist. Similarly, the hoist goes to the corresponding floor to complete the handover of goods with the shuttle car according to the system scheduling. The outbound task process is as follows: figure 2 shown.

[0057] Based on this, the present invention discloses a modeling optimization method based on an automatic storage system of a multi-storey shuttle, comprising the following steps:

[0058] (1) Model the multi-storey shuttle car automatic storage system, extract the number of layers, the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com