A kind of tunneling and mining method of extremely thin vein ore body

A mining method and ultra-thin ore technology, which is applied in the direction of earthwork drilling, blasting, and discharge machinery, can solve the problems of ore quality decline, high mining cost, and low ore grade, so as to reduce ore dilution and improve mining efficiency. Effect of recovery rate, grade improvement and recovery rate of beneficiation and smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

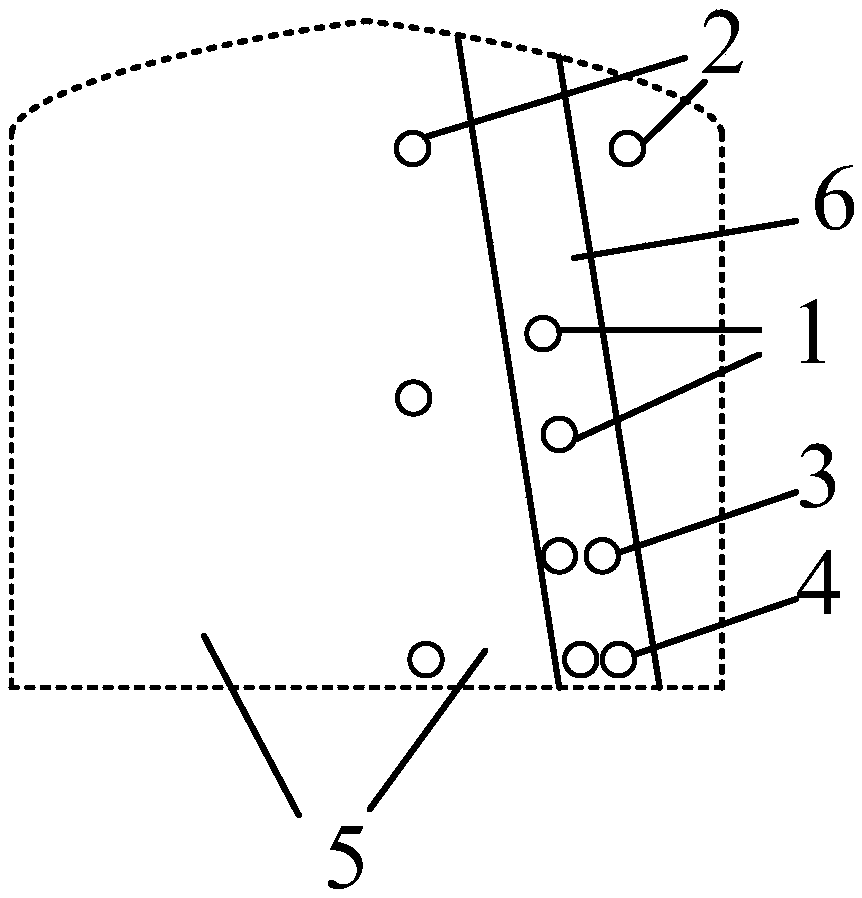

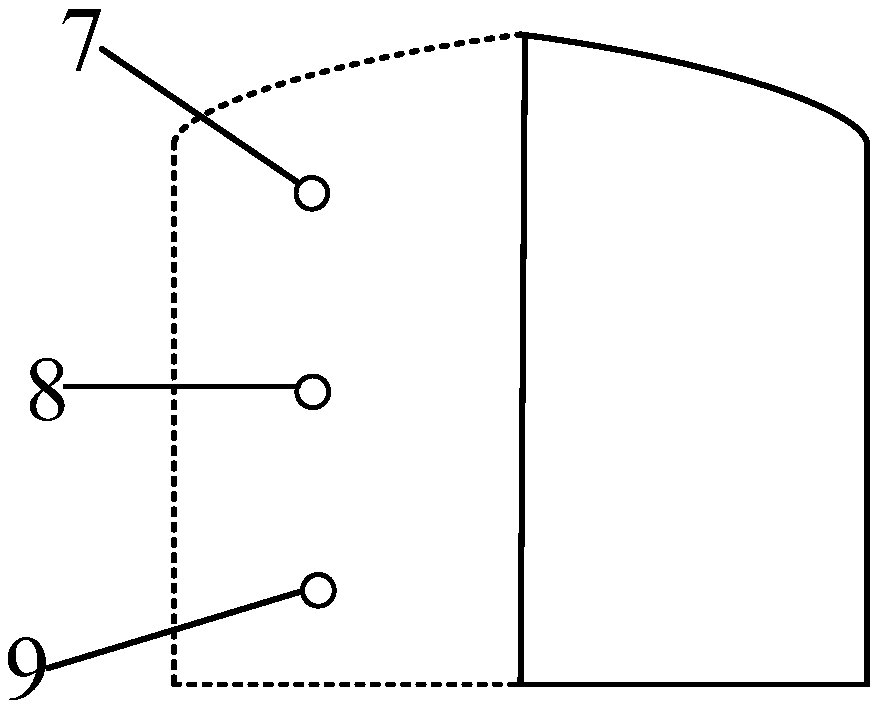

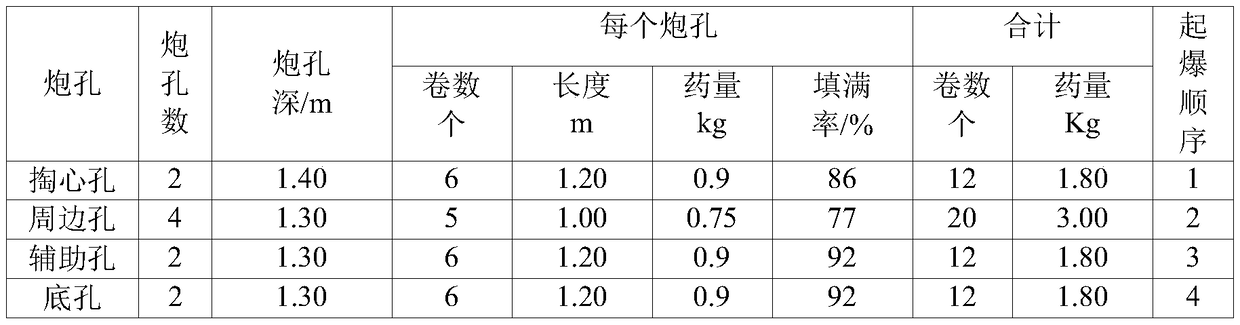

[0042] First of all, the cutting operation in the horizontal direction along the vein is carried out, and the surrounding rock is preserved to the maximum extent. The arrangement of explosive holes, charge structure and blasting sequence of the cutting operation are important basic tasks for separate excavation. Such as figure 1As shown, there are 10 first explosive holes, the depth of the core hole is 1.40-1.45m, and the depth of the auxiliary hole and the surrounding holes is 1.3m. After each blasting is completed, a blasting area section specification of 1.03m (width)×2.25m (height) is formed. The footage of 0.80-0.90m is ideal, which can meet the needs of rock drilling and by-product ore cleaning.

[0043] Under the condition that the layout of the explosive hole remains unchanged, the angle of the auxiliary hole and the structure of the charge are changed to implement throwing blasting, and 1 / 2 of the ore can be piled near the notch each time, creating conditions for mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com