Vulcanized mold with enhanced seal

一种模具、模制的技术,应用在家里用具、其他家里用具、胎等方向,能够解决模具制造复杂、制造模具昂贵等问题,达到避免模制溢料、解决方案简单、节省时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

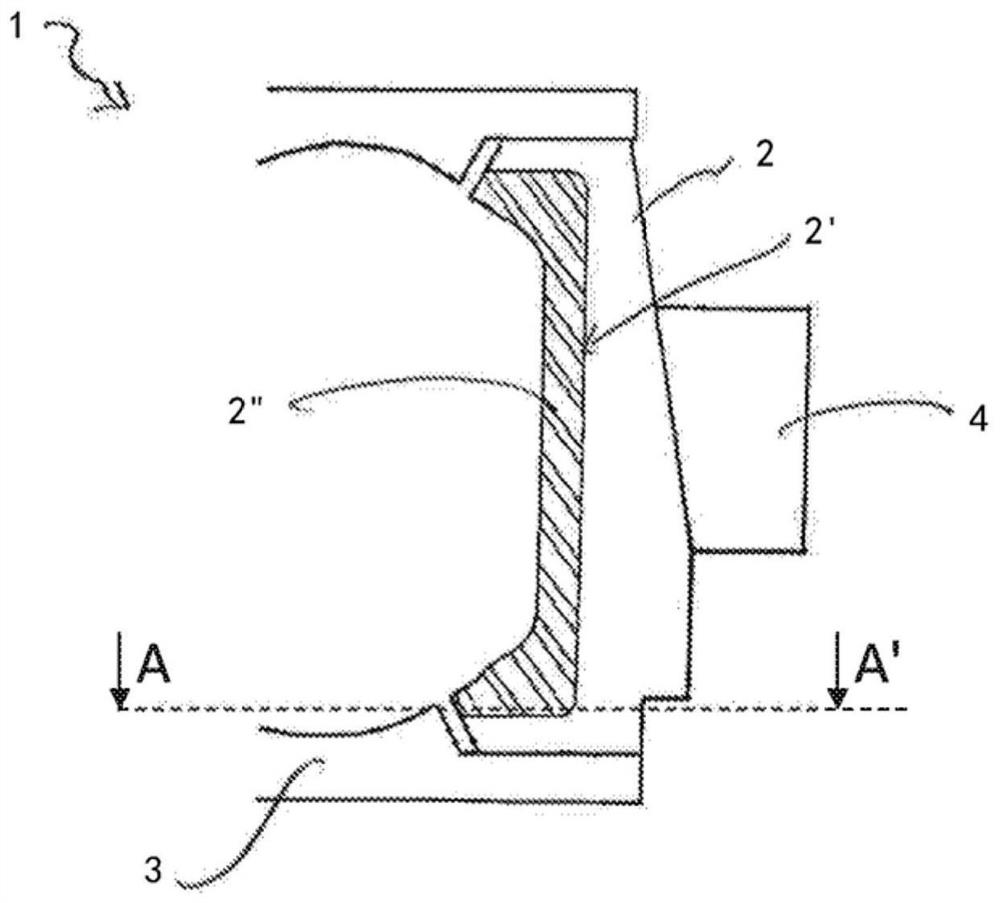

[0031] Figure 1a A partial view of a section in a meridian plane through a sector mold 1 for tires known from the prior art is shown. The mold 1 comprises a set of sectors 2 forming a ring of sectors, and two shells 3 , one being a lower shell and the other being an upper shell. Each sector 2 in the ring constituted by the sectors comprises a radially inner face 2' with a molded lining 2". The mold 1 also has a band 4 for holding the sector when the mold 1 is closed. Zone 2 stays together.

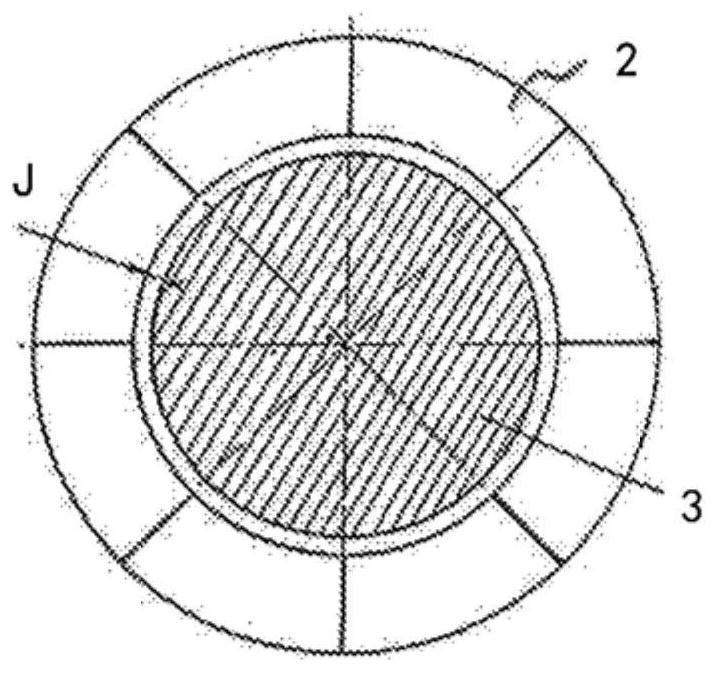

[0032] Figure 1b yes Figure 1a A section on the axis AA' shown in , which shows the first closed configuration of the mold 1, in which the closure first takes place by contact between the adjacent sectors 2, and in the ring formed by the sectors 2 and the housing 3, more specifically there is a clearance J at the interlocking circle.

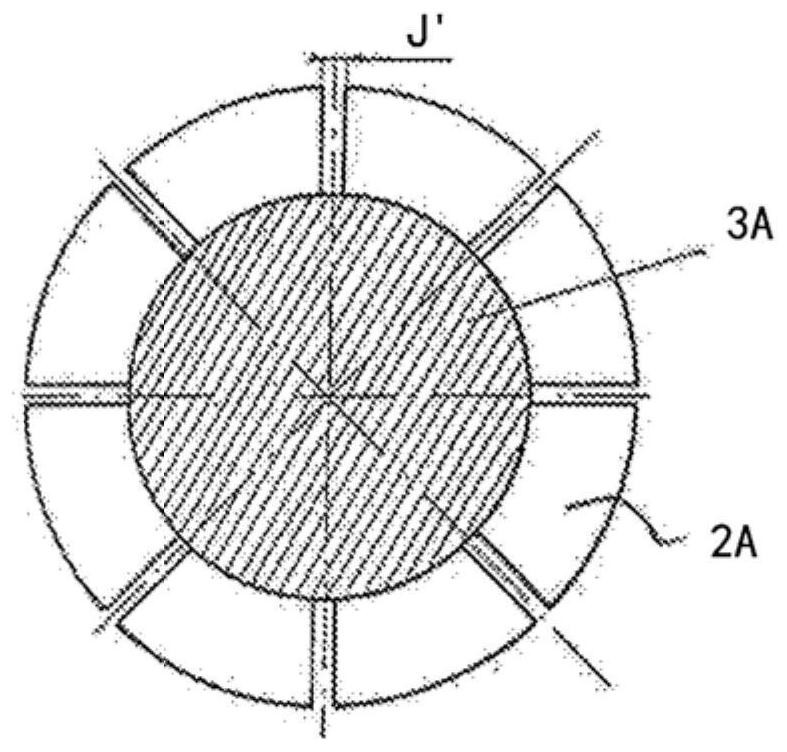

[0033] Figure 1c the same is Figure 1a Section on the axis AA' shown in , which shows the second closed configuration of the mold 1, in which the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com