High-strength light-weight insulating brick and preparation method thereof

An insulating brick and high-strength technology, applied in the field of new polymer building materials, can solve the problems of failing to meet the above requirements, affecting the reliability and safety of construction projects, etc., achieve light bulk density, low preparation cost, improve safety factor and use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

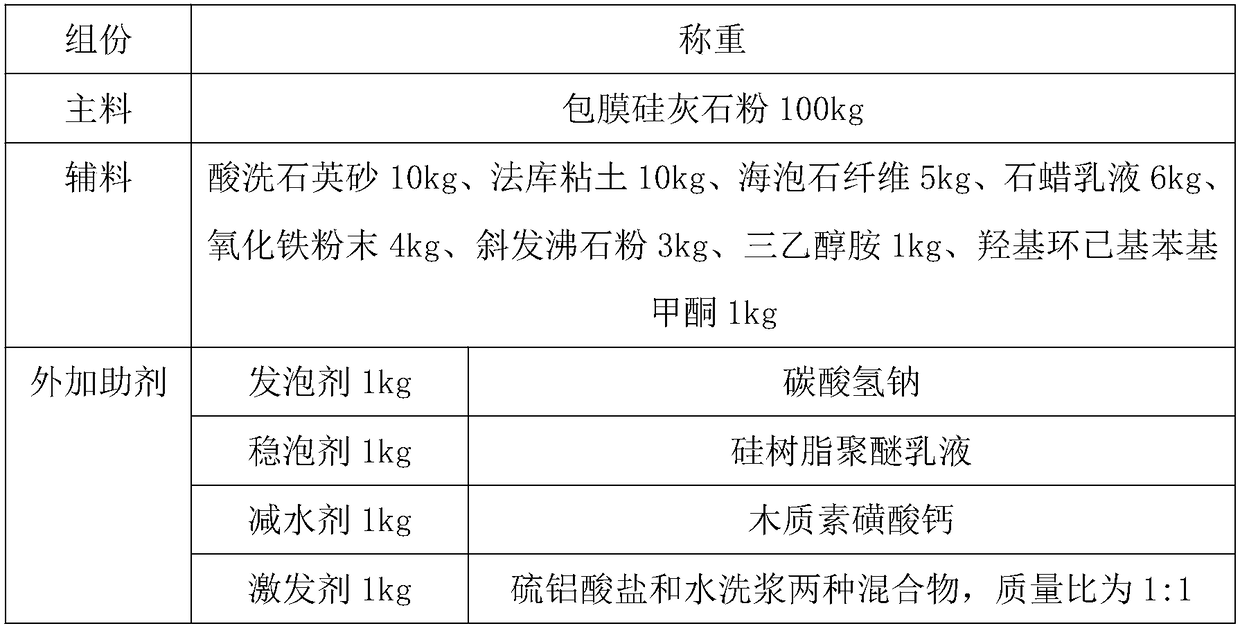

[0030] A kind of high-strength lightweight insulation brick, prepare the raw material of following table 2:

[0031] Table 2

[0032]

[0033] The above-mentioned coated wollastonite powder is prepared by the following steps: take 100kg of wollastonite powder and disperse it by ball milling with ethanol for 2 hours, dry the obtained slurry and sinter at 380°C for 1.5h, cool to 60°C, and then add Equivalent to 1% polyacrylamide by weight, 1% coconut oil fatty acid diethanolamide and 8% deionized water, ultrasonically oscillate and disperse for 30 minutes, then stir in a constant temperature water bath at 65°C for 20 minutes to obtain a modified compound mixture; In the modified compound liquid, adding the concentration equivalent to 20% of its weight is 20% Al(NO 3 ) 3 At the same time, add an appropriate amount of ammonia water to adjust the pH value to 8, stir for 30 minutes, let stand for 3 hours, filter, wash, dry, sinter at 480°C for 2 hours, and cool naturally to roo...

Embodiment 2

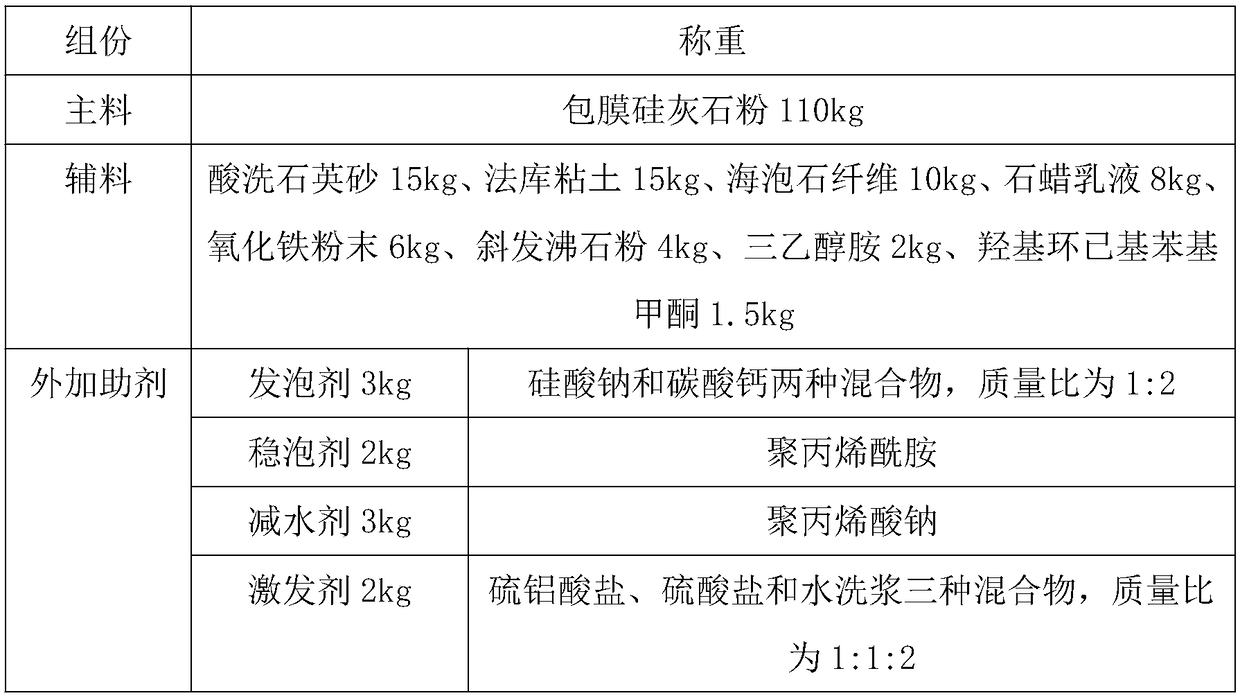

[0044] A kind of high-strength light-weight insulation brick, prepare the raw materials of following table 3:

[0045] table 3

[0046]

[0047]The above-mentioned coated wollastonite powder is prepared by the following steps: take 110kg of wollastonite powder and disperse it by ball milling with ethanol for 2.5h, dry the obtained slurry and sinter at 400°C for 2h, cool to 65°C, and add Equivalent to 2% polyacrylamide by weight, 1.5% coconut oil fatty acid diethanolamide and 10% deionized water, ultrasonically oscillate and disperse for 35 minutes, then stir in a constant temperature water bath at 70°C for 25 minutes to obtain a modified compound mixture; Adding the concentration equivalent to its weight 25% in the modified compound liquid is 20% Al(NO 3 ) 3 At the same time, add an appropriate amount of ammonia water to adjust the pH value to 9, stir for 35 minutes, let stand for 4 hours, filter, wash and dry, sinter at 500°C for 2.5 hours, and cool naturally to room tem...

Embodiment 3

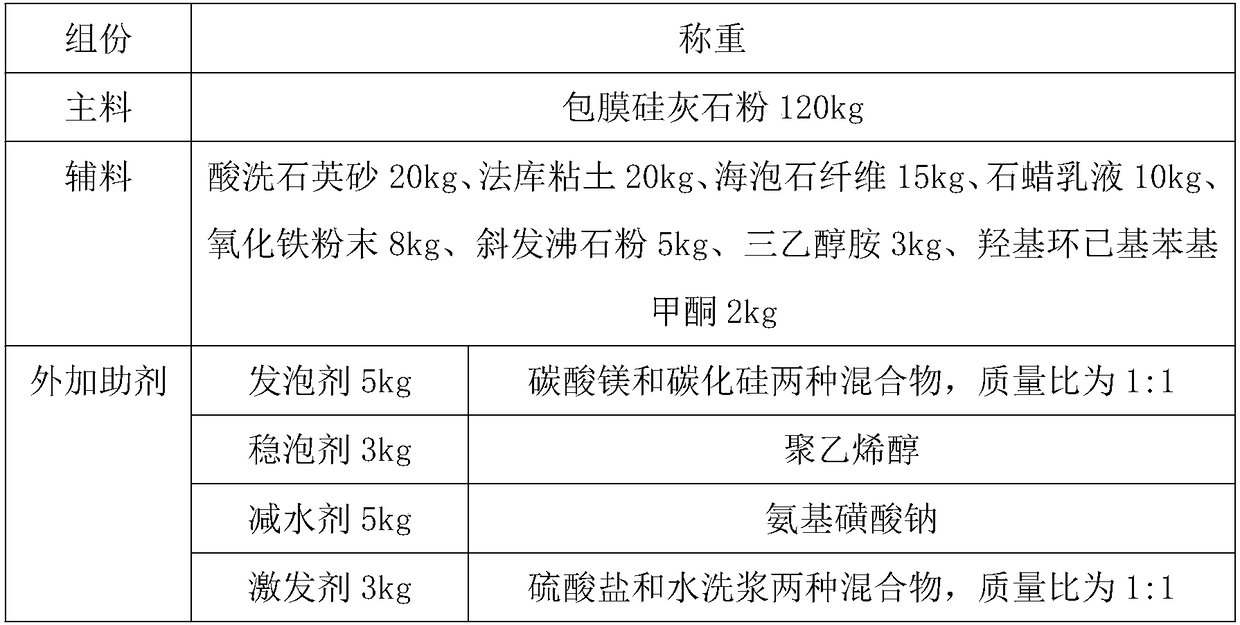

[0058] A kind of high-strength light-weight insulation brick, prepare the raw material of following table 4:

[0059] Table 4

[0060]

[0061] The above-mentioned coated wollastonite powder is prepared by the following steps: take 120kg of wollastonite powder and disperse it by ball milling with ethanol for 3 hours, dry the obtained slurry and sinter at 420°C for 2.5h, cool to 70°C, and then add Equivalent to 3% polyacrylamide by weight, 2% coconut oil fatty acid diethanolamide and 12% deionized water, ultrasonically oscillate and disperse for 40 minutes, then stir in a constant temperature water bath at 75°C for 30 minutes to obtain a modified compound mixture; In the modified compound liquid, adding the concentration equivalent to 30% of its weight is 20% Al(NO 3 ) 3 At the same time, add an appropriate amount of ammonia water to adjust the pH value to 10, stir for 40 minutes, let stand for 5 hours, filter, wash, dry, sinter at 520°C for 3 hours, and cool naturally to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap