Upper tensioner of shoe machine

A tensioning device and mechanical technology, applied to shoe lasts, footwear, applications, etc., can solve the problems of inconvenient fixation of the gripping line, easy loosening of the gripping line, inability to improve the production efficiency of the gripping process, and the like, and achieve a simple structure. , Increase the stability, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

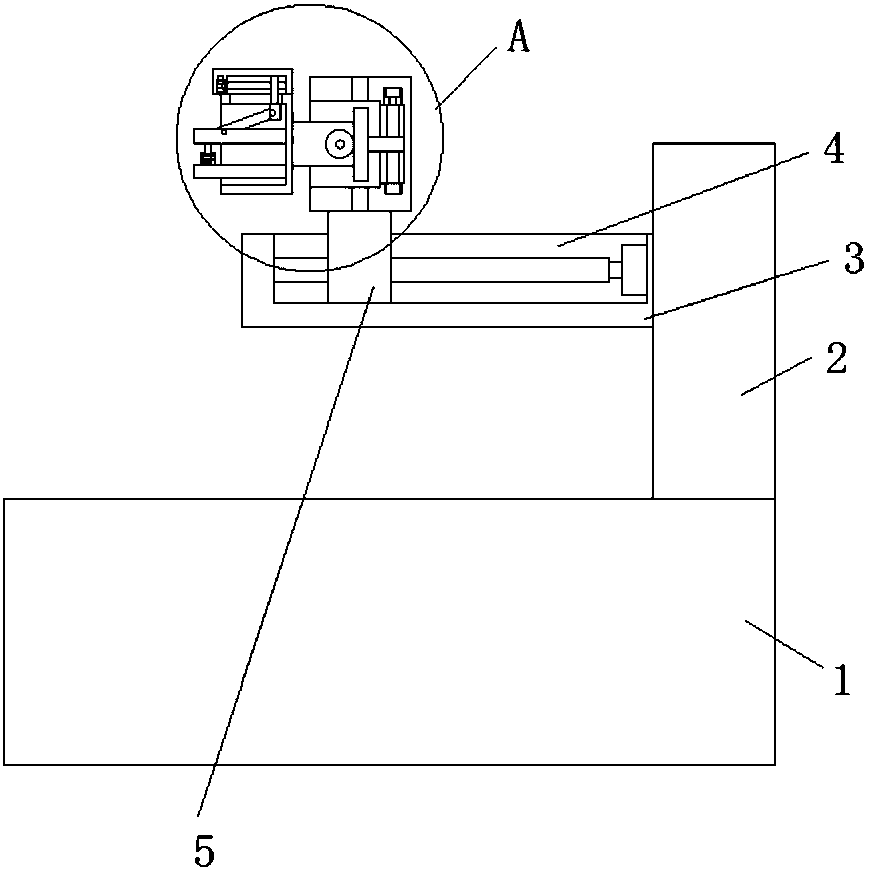

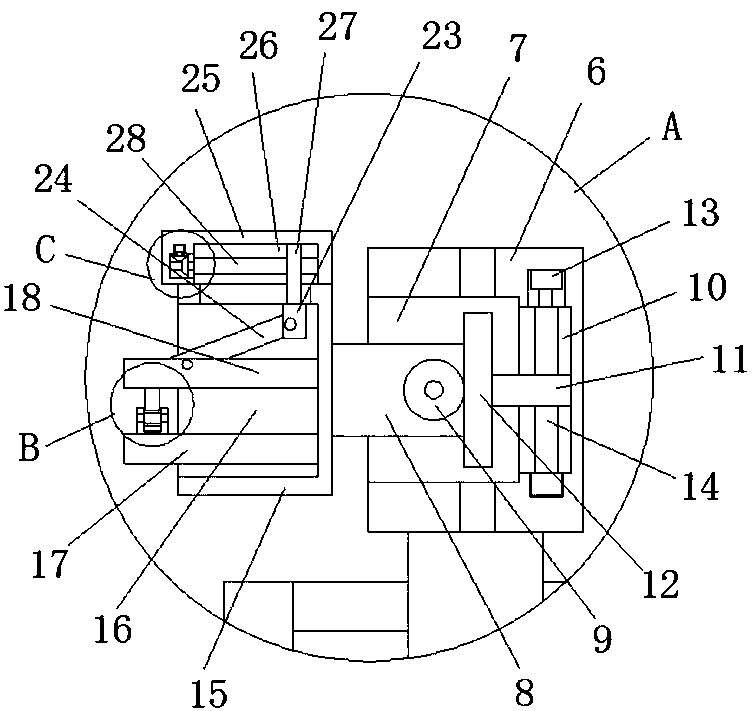

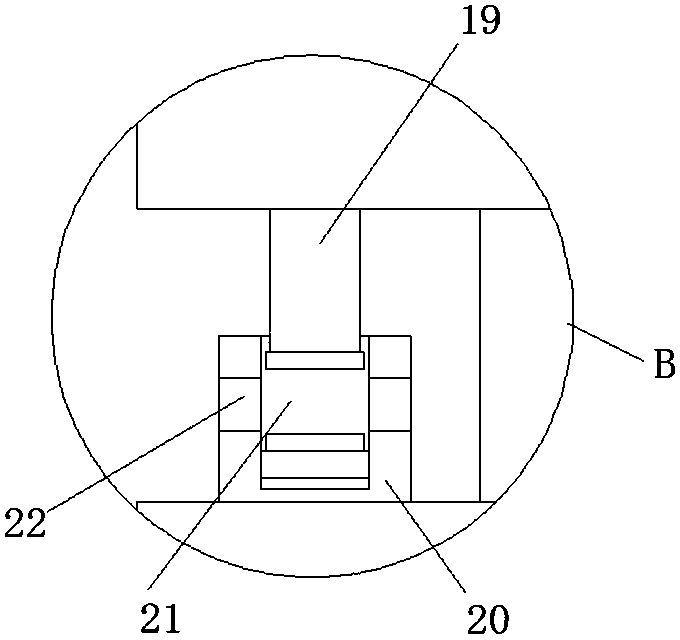

[0025] refer to Figure 1-5, in this embodiment, a shoe upper tensioning device for a shoe processing machine is proposed, comprising a base 1, a support plate 2 is fixedly installed on the top of the base 1, and a side of the support plate 2 is fixedly installed above the base 1. Seat 3, the top of the installation seat 3 is provided with a first installation slot 4, a mounting block 5 is slidably installed in the first installation slot 4, and a movable seat 6 is fixedly installed on the top of the installation block 5, and the movable seat 6 is driven by the installation block 5. Moving, the side of the moving base 6 away from the support plate 2 is provided with a rotating groove 7, and a rotating block 8 is rotated and installed in the rotating groove 7. The side of the rotating block 8 away from the support plate 2 extends to the outside of the moving base 6 and is fixedly installed The fixed table 15 is driven by the rotating block 8 to rotate. The inner wall of the rot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap