Self-adaptive joint for suction pipe

A self-adapting, pipette technology, applied in the direction of measuring tubes/pipettes, laboratory utensils, laboratory containers, etc., can solve problems such as low work efficiency, affecting accuracy, and difficult matching, and reduce labor. Strength, improved accuracy, reduced wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

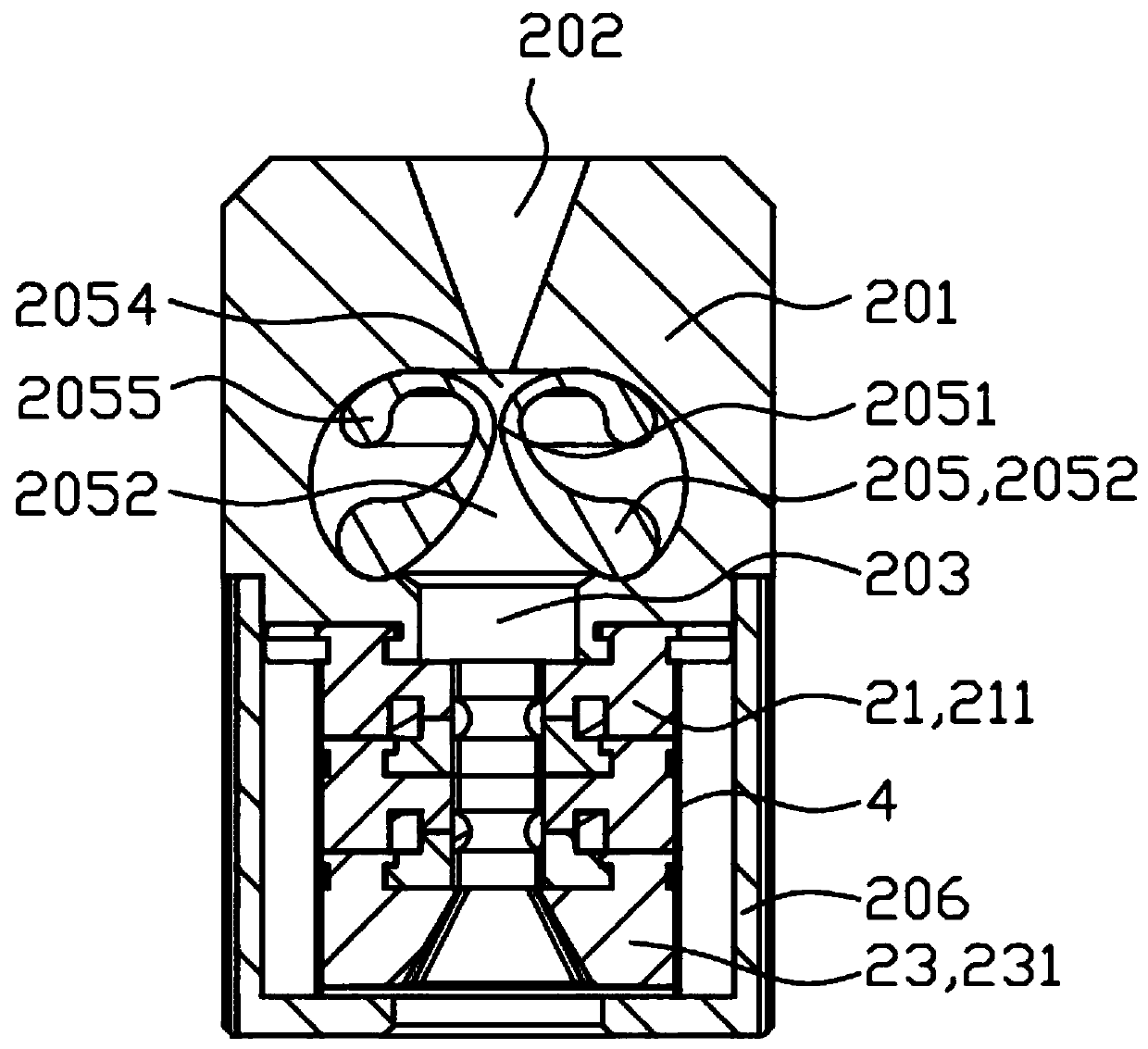

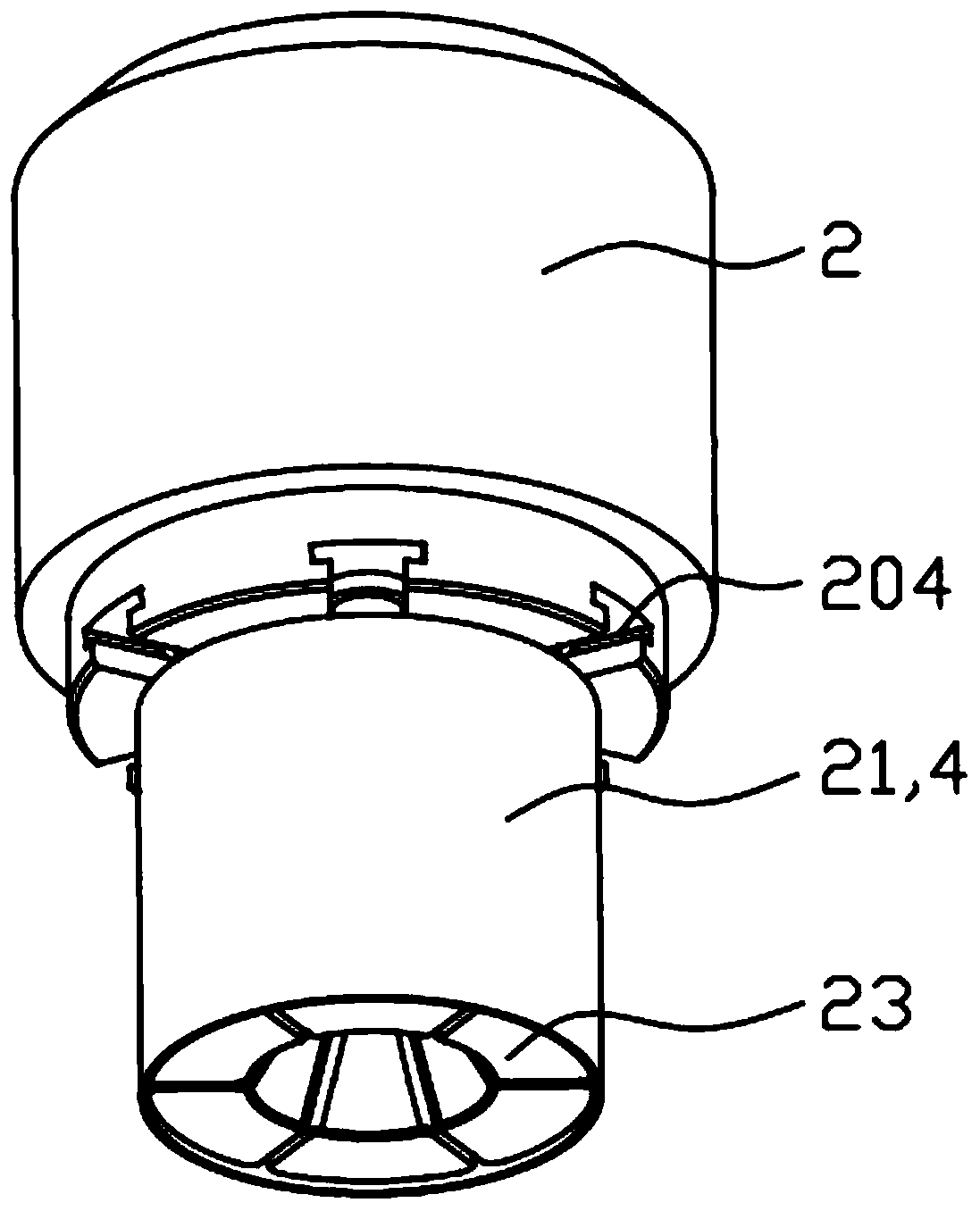

[0029] see figure 1 with figure 2 , a suction pipe self-adaptive joint, including a port assembly, a plurality of card tube assemblies 21 connected under the port assembly and a guide port assembly 23 connected under the card tube assembly 21. The port assembly includes a port body 201 with an upper port 202 and a lower port 203 and a port ferrule 205 disposed in the lower port 203 . see Figure 7 , the self-adaptive joint 2 cooperates with the ear washing ball 1 and the positioning bracket 3 to form a straw device that can be operated with one hand. The upper port 202 is in the shape of an inverted cone, and fits with the suction port 12 of the ear washing ball 1 . The lower port 203 is roughly drum-shaped. The top end of the lower port 203 is provided with a flow hole communicating with the tip of the upper port 202 . The ear cleaning ball 1 is provided with a spherical upper air bag 11 and a tapered suction port 12 extending smoothly from the air bag 11 .

[0030] se...

Embodiment 2

[0039] This embodiment is the same as the first embodiment except that the connection structure between the tube assembly 21 and the port assembly and the tube assembly 21 is different.

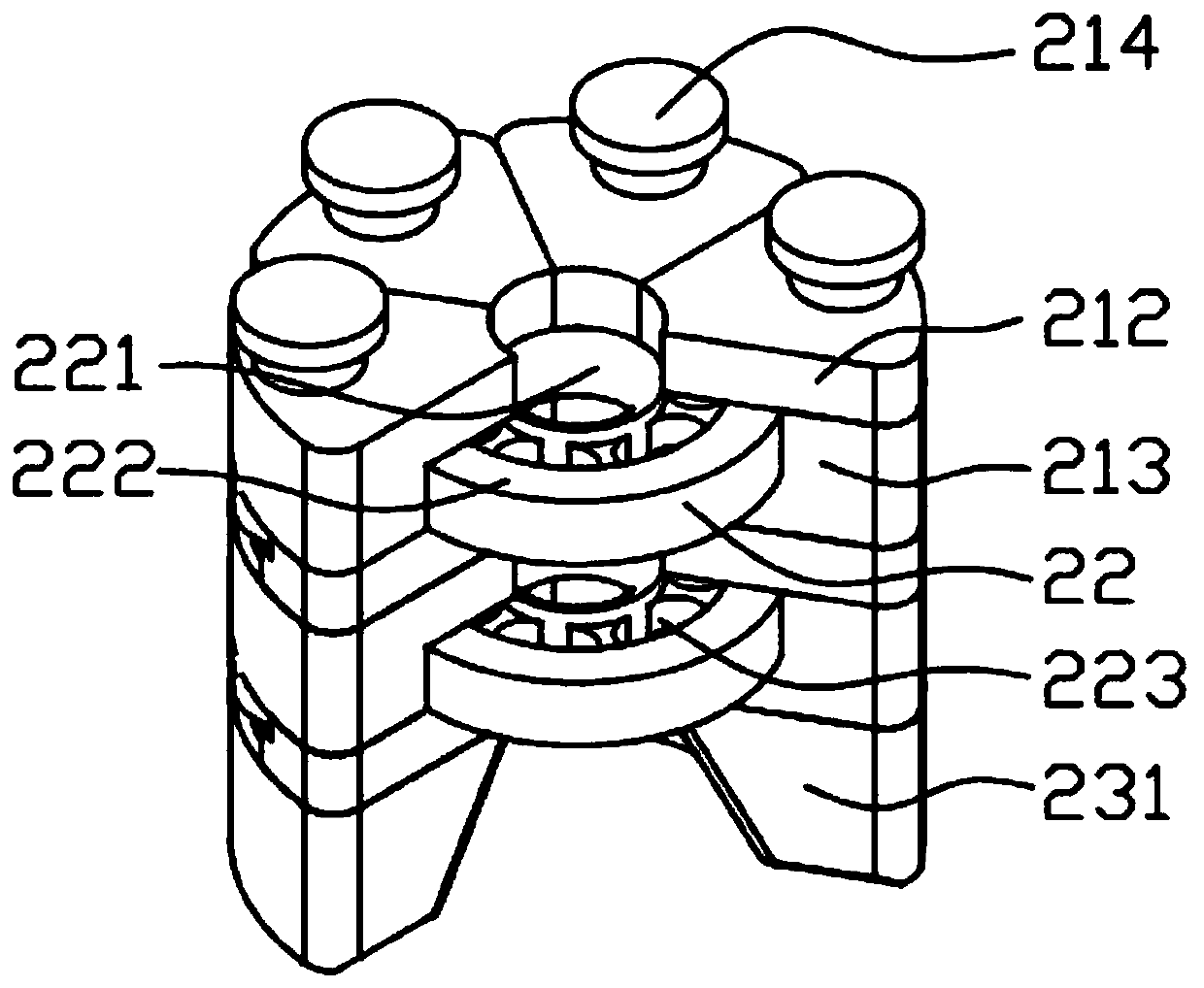

[0040] see Figure 11 , Figure 12 with Figure 13 , in this embodiment, the connection structure between the card tube assemblies 21 includes the serial connection holes 218 that pass through the upper half body 212 and the lower half body 213 on the card tube module 211 in the card tube assembly 21 and pass through The serial hole 218 is connected to the connecting rod 217 on the T-shaped slot 204 of the port assembly. Further, the self-adaptive joint 1 includes a guide port assembly 23 connected to the lower end of the tube assembly 21 . In this embodiment, the port module 231 of the port assembly 23 is also provided with a series connection hole 218, and the connecting rod 217 passes through the port assembly 23 and the series connection hole 218 of the card tube assembly 21 and then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com