Multichannel electronic liquor-transferring system with standard signal interface

A standard signal, multi-channel technology, applied in the field of electronic medical devices, can solve the problems of increased mechanical structure complexity, low work efficiency, high cost, etc., and achieve the effect of easy automatic control, convenient secondary development, and high liquid absorption accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

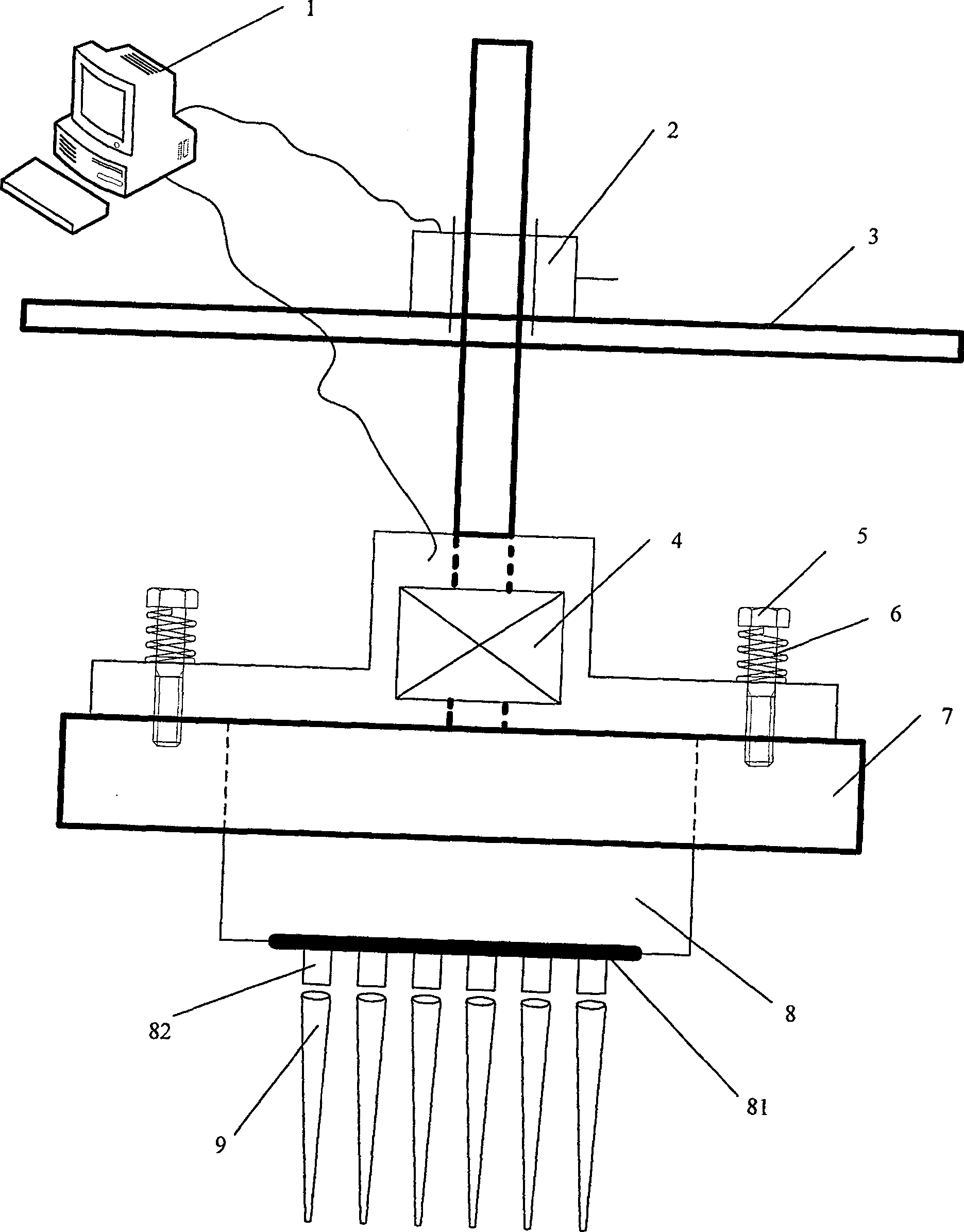

[0032] See attached figure 1 As shown, a 6-channel electronic liquid pipetting device provided by the present invention includes: a control computer 1, a carrying platform 3, a driving motor 2, a lifting platform 7, a pipette 8, an electromechanical movement unit 4 of the pipette, and a hexagonal bolt 5 , spring 6 and so on. It is characterized in that: the pipette 8 is fixed on the vertical lifting platform 7 by using the hexagonal bolt 5 and the spring 6; the computer 1 controls the drive motor 2 to make the lifting platform 7 move up and down; the carrying platform 3 can be horizontally positioned in the horizontal plane , longitudinal movement (not marked in the figure).

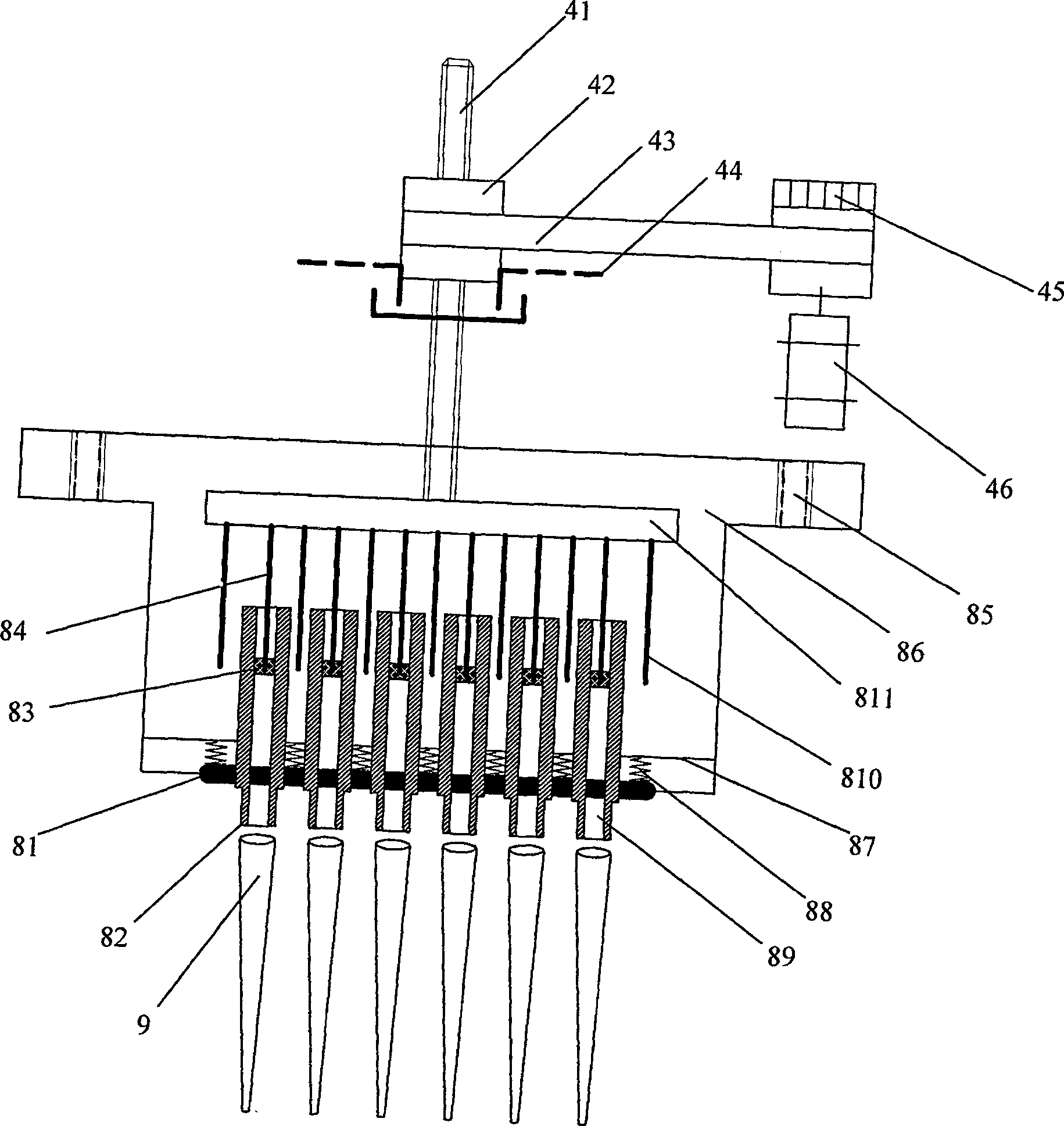

[0033] In this facility example, the pipette 8 adopts a syringe pump structure, that is, it is composed of a piston and a pump chamber. The computer 1 controls the lifting platform 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com