Connecting rod automatic roll forging system

A roll forging and automatic technology, applied in the direction of forging/pressing/hammer devices, operating devices, heating/cooling equipment, etc., can solve the problems of easily damaged slide rails and hydraulic cylinders, reduce the cost of reclaiming manipulators, and high operating costs, and achieve reduction Reliance on processing accuracy, optimized structure, and effect of reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

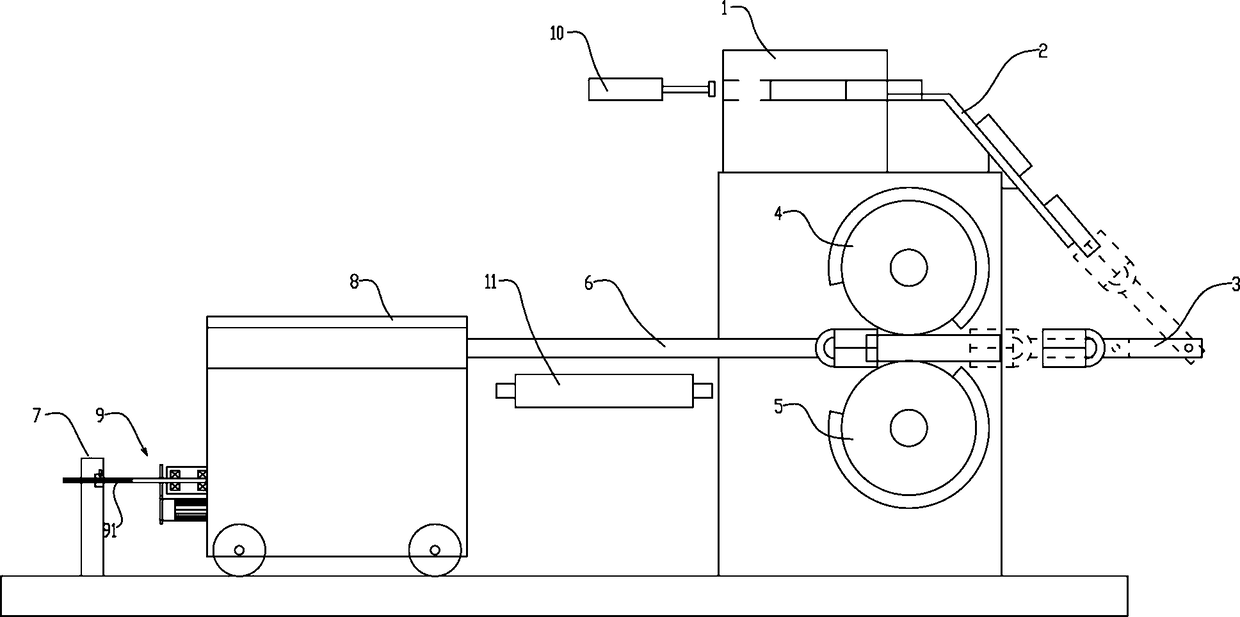

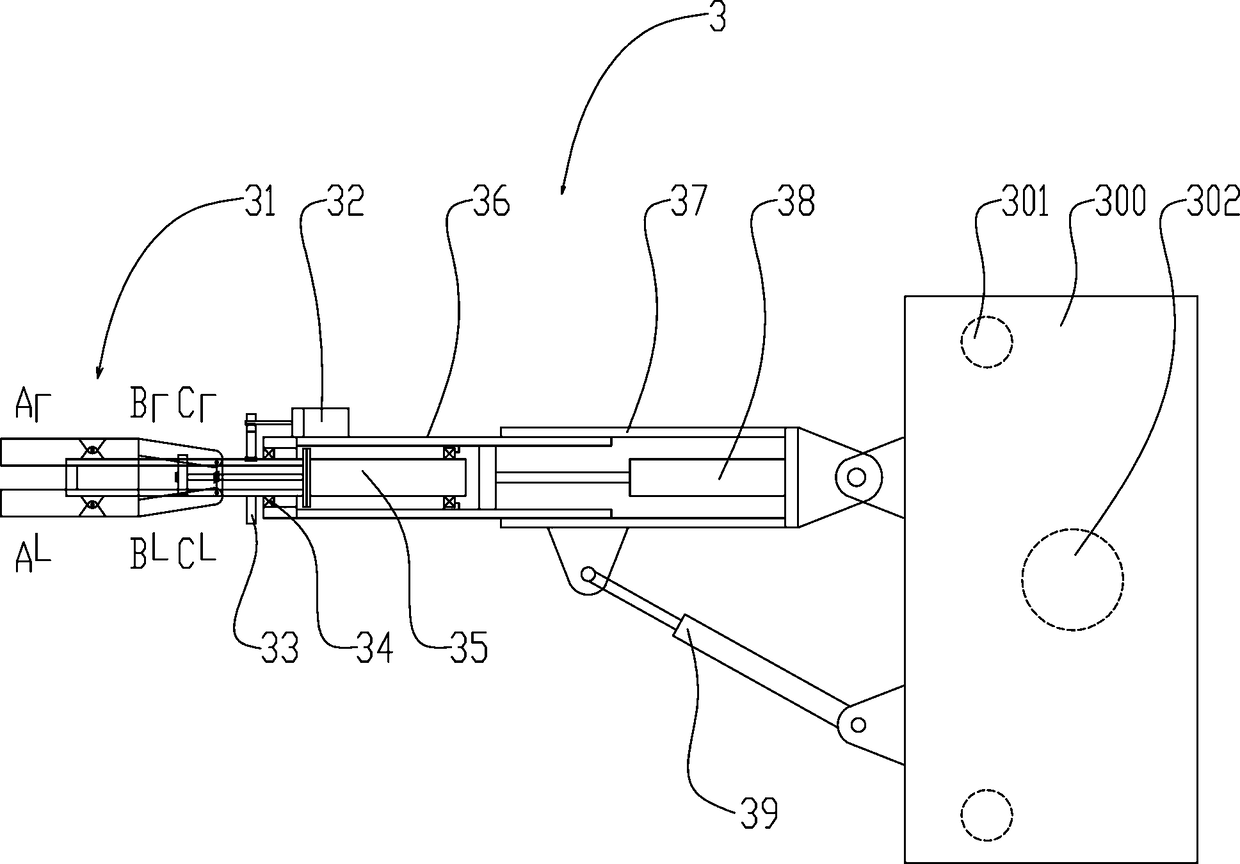

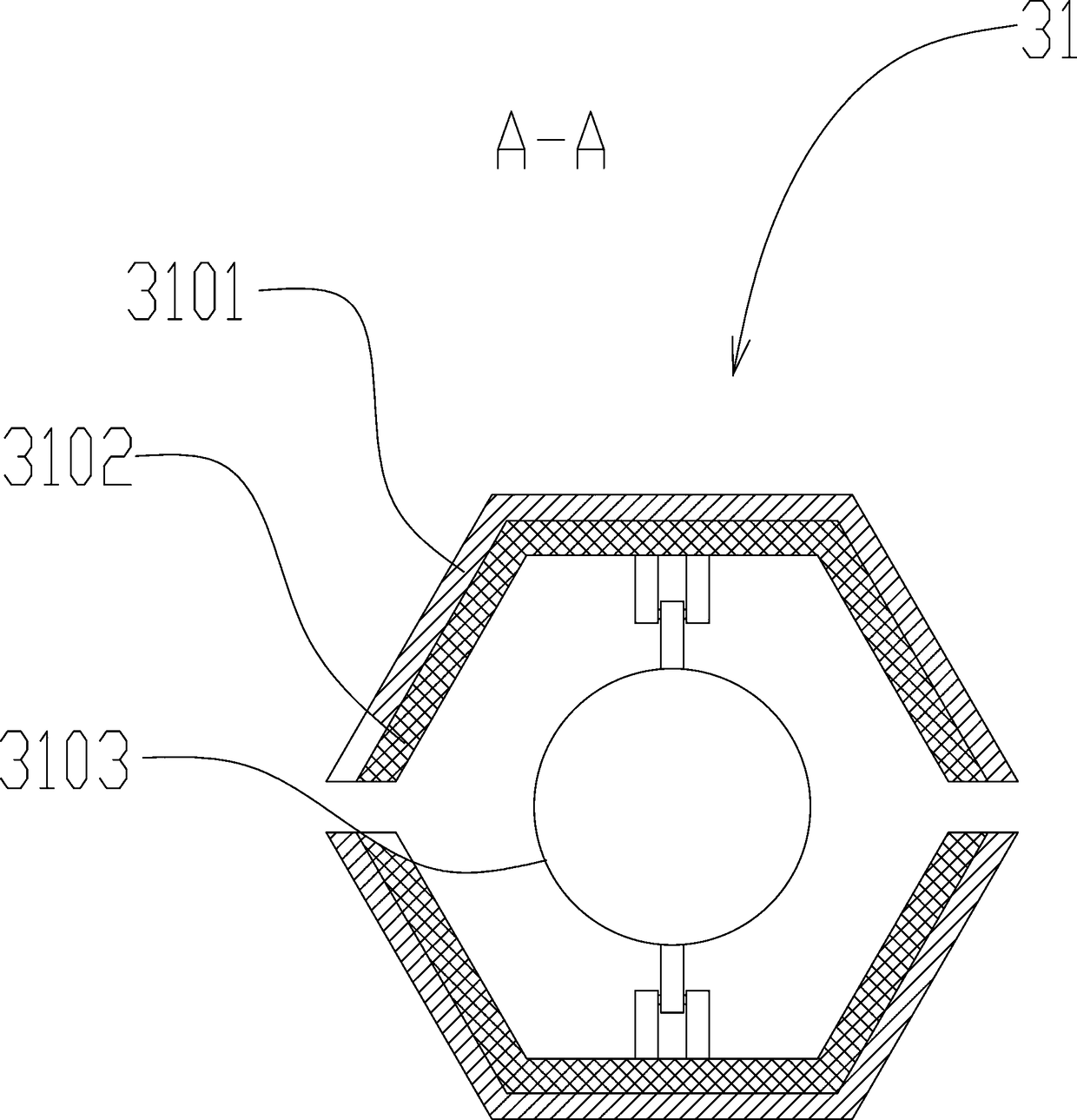

[0033] Such as figure 1 Among them, an automatic roll forging system for connecting rods, including a heating furnace 1, a roll forging device, a feeding manipulator 3 and a reclaiming manipulator 6, the heating furnace 1 is located above the roll forging device, and a slide is provided at the outlet of the heating furnace 1 Road 2, the cross section of the slideway is "V" shape, the feeding manipulator 3 is located between the bottom of the slideway 2 and the feed inlet of the roll forging device, and the reclaiming manipulator 6 is located at the other end of the roll forging device. The claw 3101 of the feeding manipulator 3 is facing the bottom of the slideway 2 after being lifted, and the heated workpiece just falls between the claws 3101 of the feeding manipulator 3, and then the feeding manipulator 3 rotates an angle, returns to the level, stretches Finally, the workpiece is sent between the upper arc-shaped extrusion die 4 and the lower arc-shaped extrusion die 5 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com