Raw bamboo stripping machine applicable to bending of raw bamboo

A slitting machine and bending technology, applied in mechanical equipment, sugarcane machining, etc., can solve the problems of reducing the safety of equipment slitting, the effect of raw bamboo slitting, high production and maintenance costs, and uneven slitting width. Good stripping effect, reduced production and operating costs, and improved work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

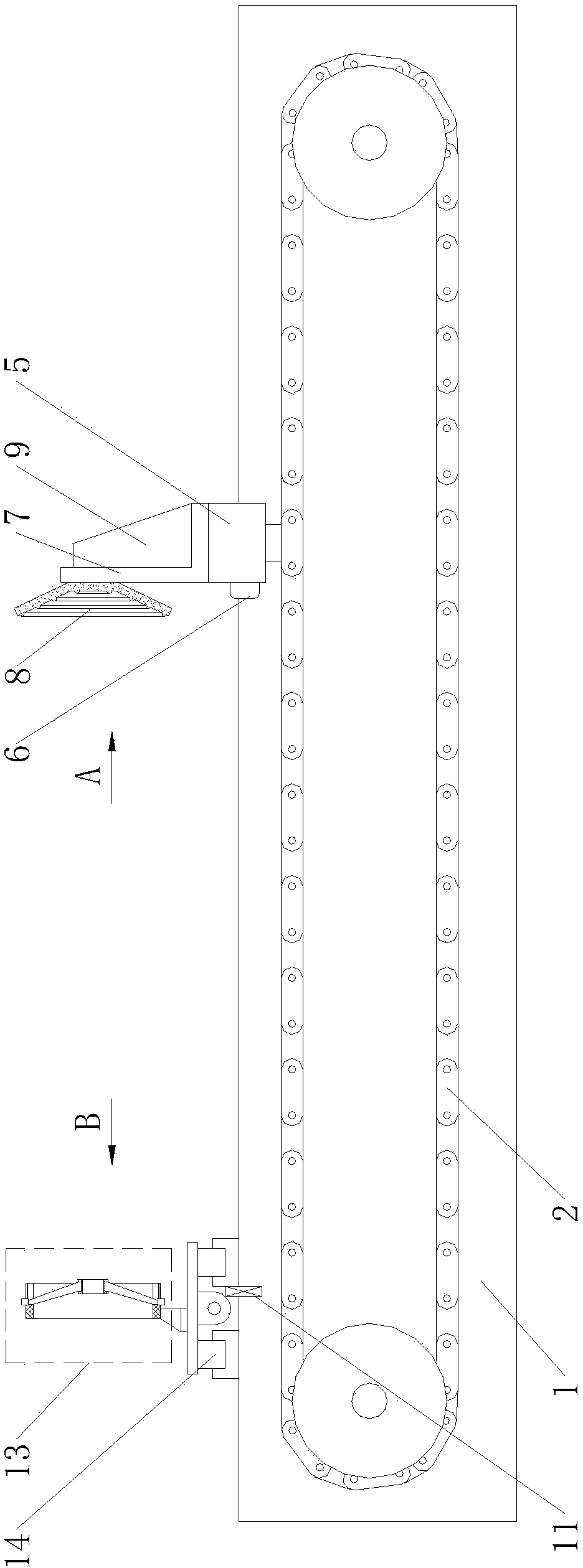

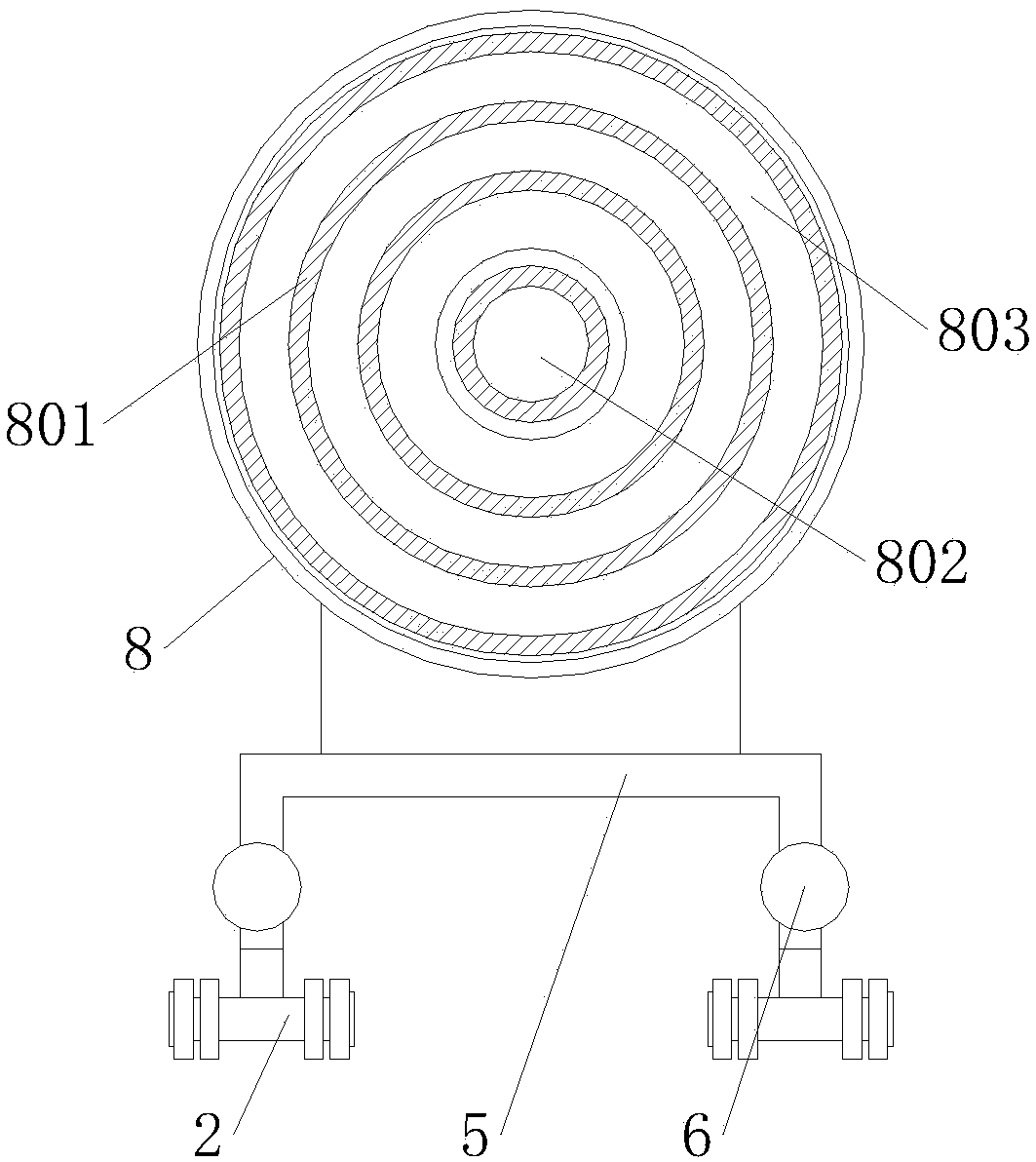

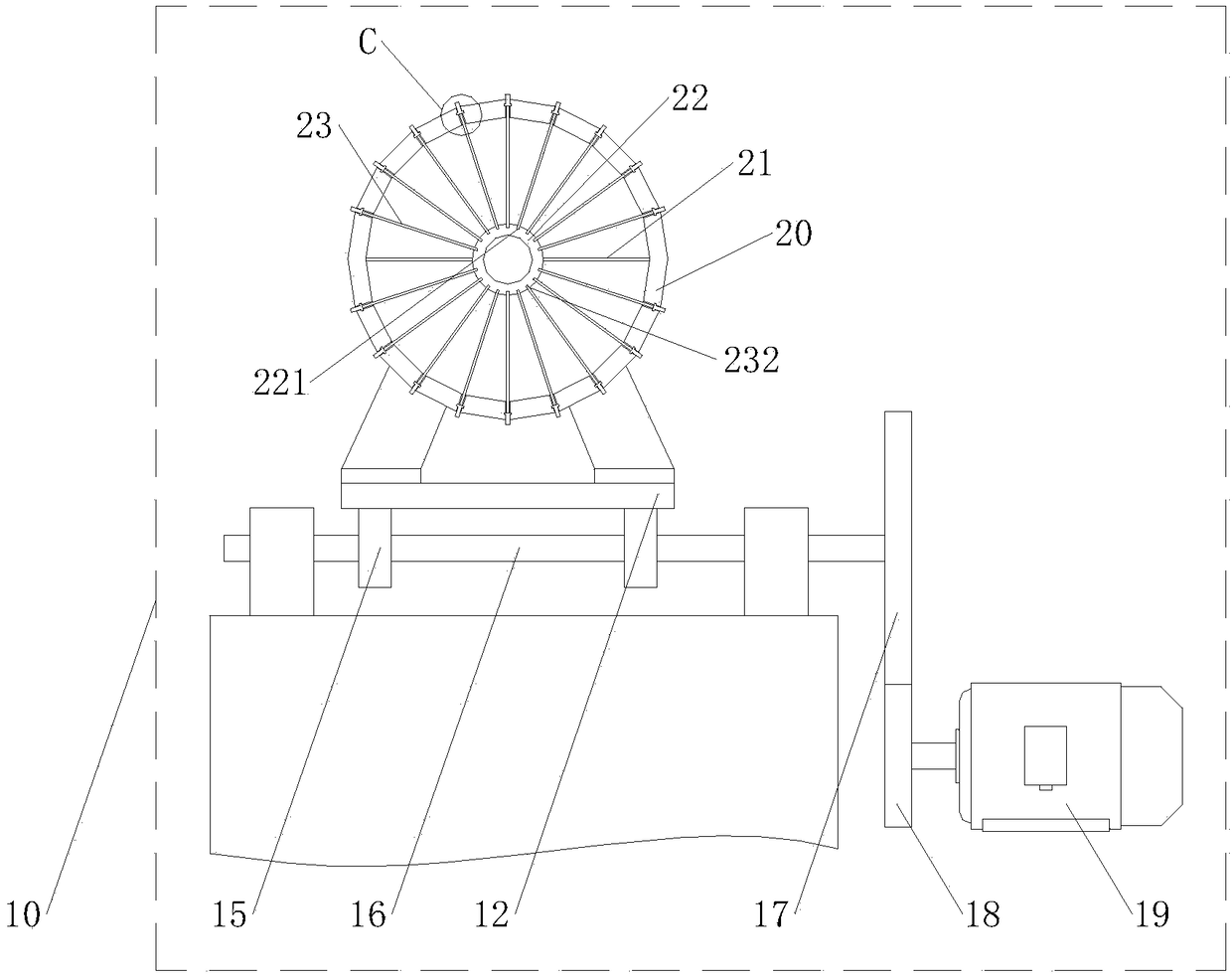

[0015] Example. Raw bamboo splitting machine suitable for bending raw bamboo, constituted as figure 1 Shown, comprise frame 1, be connected with translation support 5 through drive chain 2 on the frame, translation support 5 both sides are provided with buffer post 6, translation support 5 upper end is provided with pressing plate 8 through L-shaped push plate 7, push plate 7 is provided with a fixed rib plate 9, the side of the pressing plate 8 away from the push plate 7 is provided with a plurality of fixed rings 801 of different diameters, one end of the frame 1 is provided with a stripping device 10, and the stripping device 10 both sides are provided with a fixed The limit baffle plate 11 on the side wall of the frame 1; the strip opening device 10 includes a traverse support 12, the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com