Shock absorption type vacuum tank for automobiles

A shock-absorbing, vacuum tank technology, which is applied to vehicle parts, reservoir layout, brakes, etc., can solve problems such as danger, vacuum tank loosening, inconvenience, etc., to improve the service life of the installation, strong storage vacuum capacity, and quick installation firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

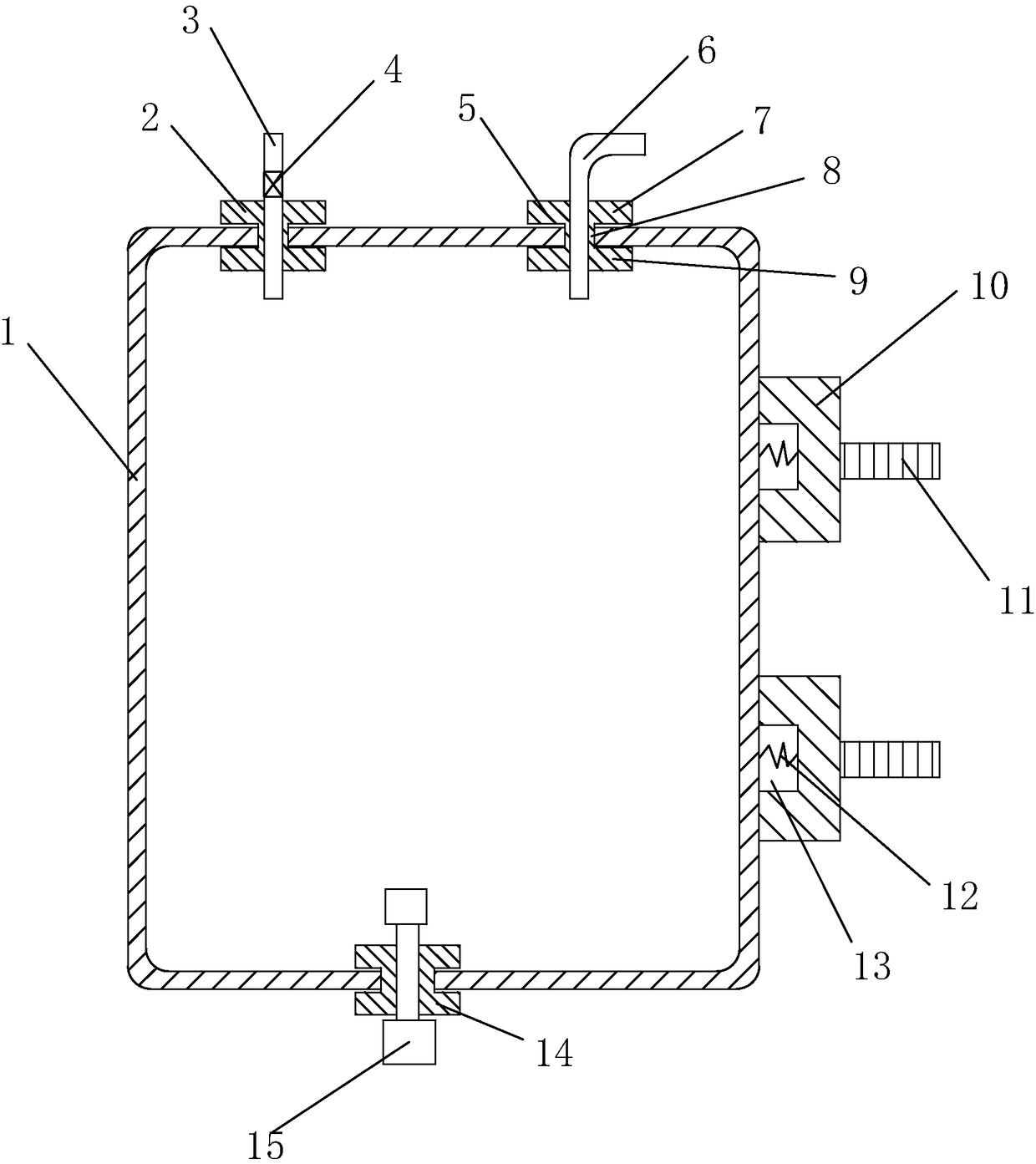

[0014] like figure 1 As shown, a shock-absorbing vacuum tank for automobiles includes a tank body 1, on which a first sealing mounting seat 2, a second sealing mounting seat 5 and a third sealing mounting seat 14 are arranged in an interference fit, the first sealing The longitudinal sections of the mounting seat, the second sealing mounting seat and the third sealing mounting seat are all I-shaped, and the setting of the first sealing mounting seat, the second sealing mounting seat and the third sealing mounting seat can effectively ensure the airtightness of the vacuum tank , the first sealing mounting seat, the second sealing mounting seat and the third sealing mounting seat are all composed of an upper plate 7, a middle section 8 and a lower plate 9, and the side of the upper plate close to the tank body is closely attached to the outer wall of the tank body, The side surface of the lower plate close to the tank body is closely attached to the inner wall of the tank body, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap