Prefabricated concrete-box gravity retaining wall structure and construction method thereof

A prefabricated assembly and concrete technology, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problem that the slope cannot be repaired in a short time, and achieve shortening the construction period, reducing the burden, and simple construction technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

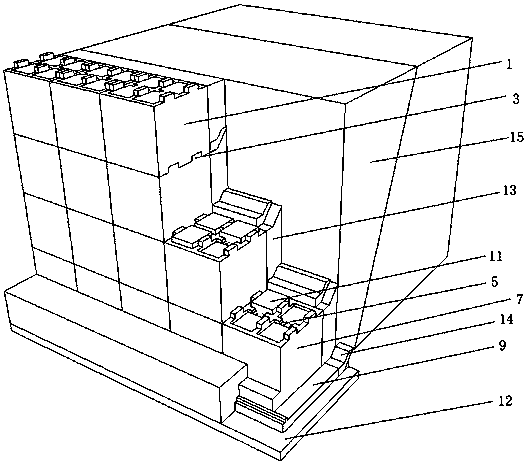

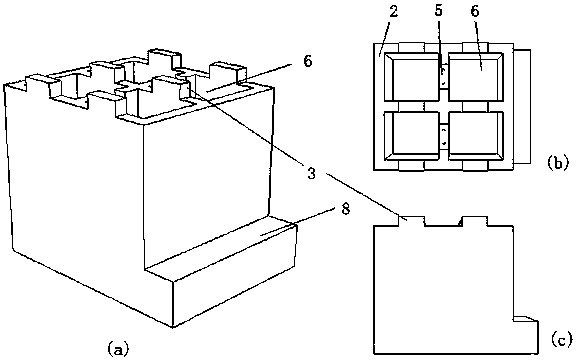

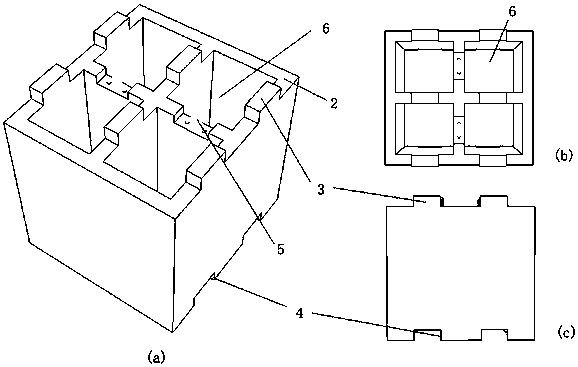

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] Such as Figure 1-4 As shown, a prefabricated concrete box-type gravity retaining wall structure, the prefabricated components that make up the prefabricated concrete box-type gravity retaining wall structure include three types: standard prefabricated components, bottom prefabricated components and prefabricated bottom slabs. Multiple standard prefabricated components are stacked and assembled, and the stacked structures are assembled side by side. The bottom standard prefabricated component is connected to the bottom prefabricated component, and the bottom prefabricated component is set on the prefabricated floor. Both the standard prefabricated component and the bottom prefabricated component are hollow box-shaped, hollow Packing is set in the box. The stacked standard prefabricated components are connected by mortise joint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com