Method and device for testing vehicle body joint dynamic stiffness, storage medium

A test method and storage medium technology, applied in the automotive field, can solve the problems of high tooling cost, high overall cost, and time-consuming production, so as to reduce the test preparation time and tooling production time, reduce the amount of tooling spare parts, and be universal good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

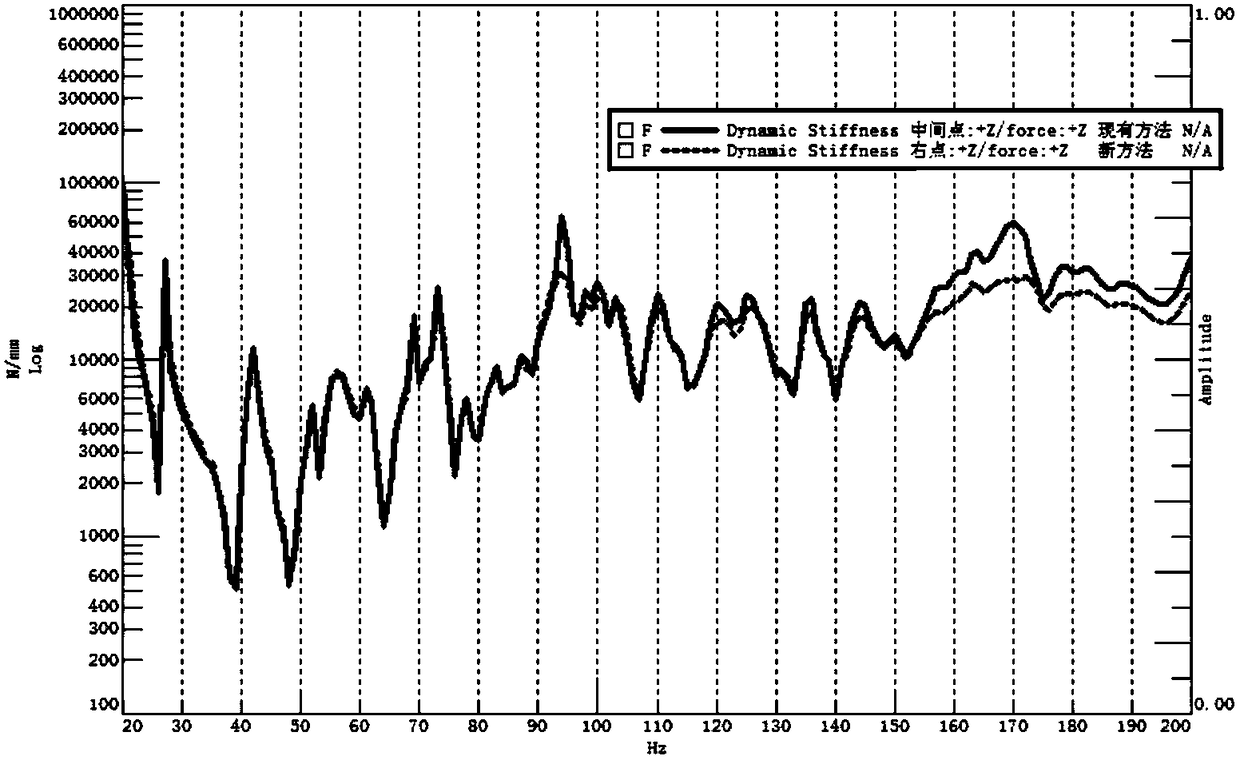

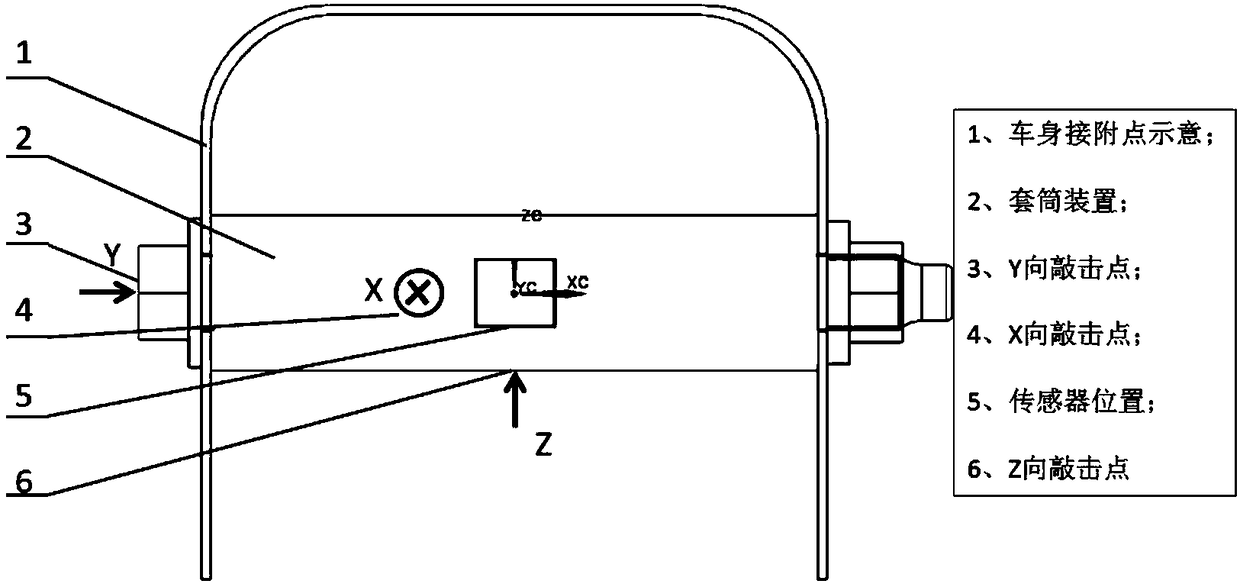

[0024] The present invention mainly calculates the origin dynamic stiffness of the center of the attachment point by measuring the dynamic stiffness of the origin on both sides of the attachment point of the two car bodies and the mutual communication, and uses mathematical formulas to calculate the origin dynamic stiffness of the center of the attachment point. The test is performed without the use of tooling to reduce the cost; accurate , Quickly test the attachment jog stiffness to improve efficiency.

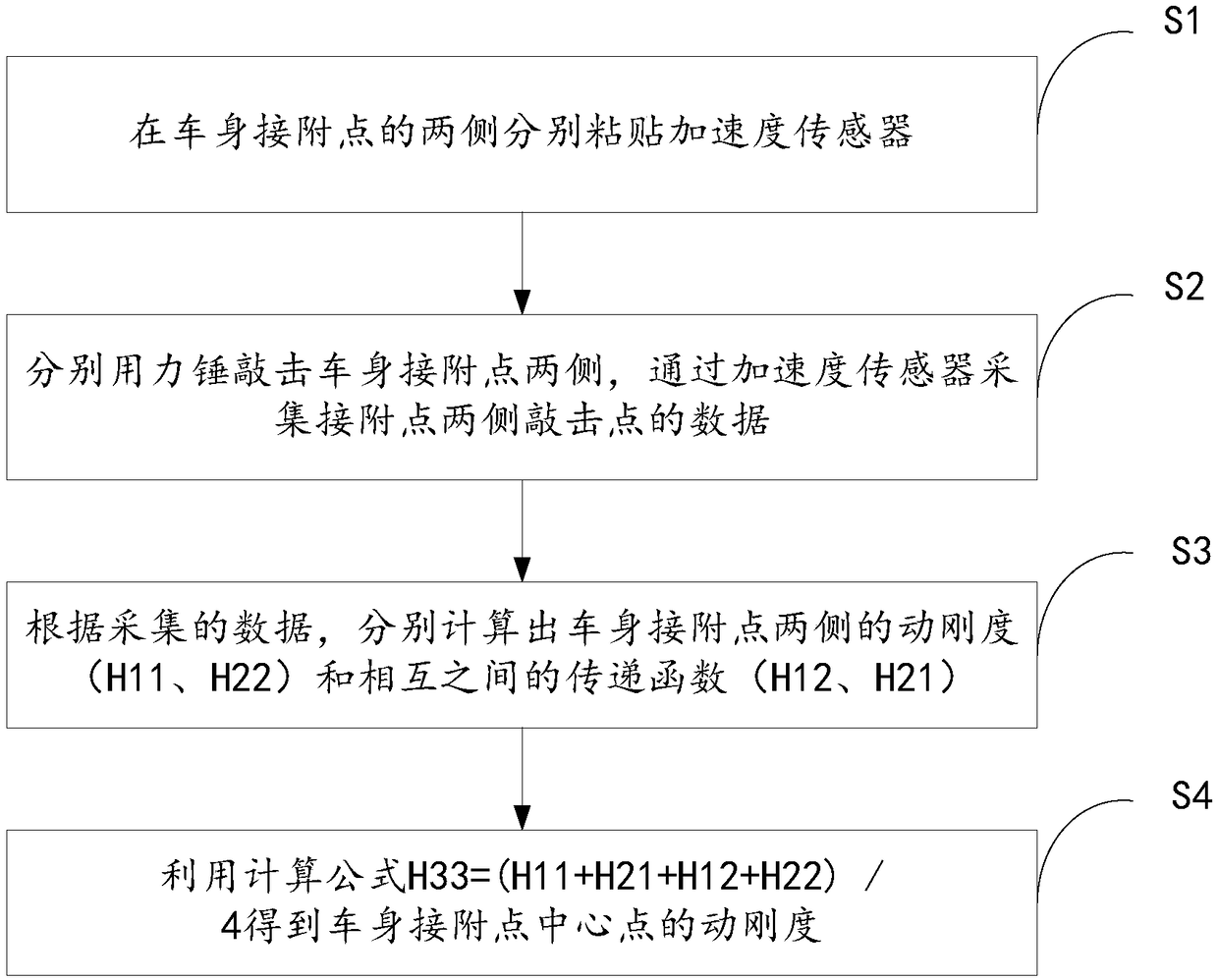

[0025] Specifically, please refer to figure 2 , figure 2 It is a schematic flowchart of a test method for body attachment inching stiffness proposed by an embodiment of the present invention.

[0026] Such as figure 2 As shown, a method for testing vehicle body attachment jog stiffness proposed in the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com