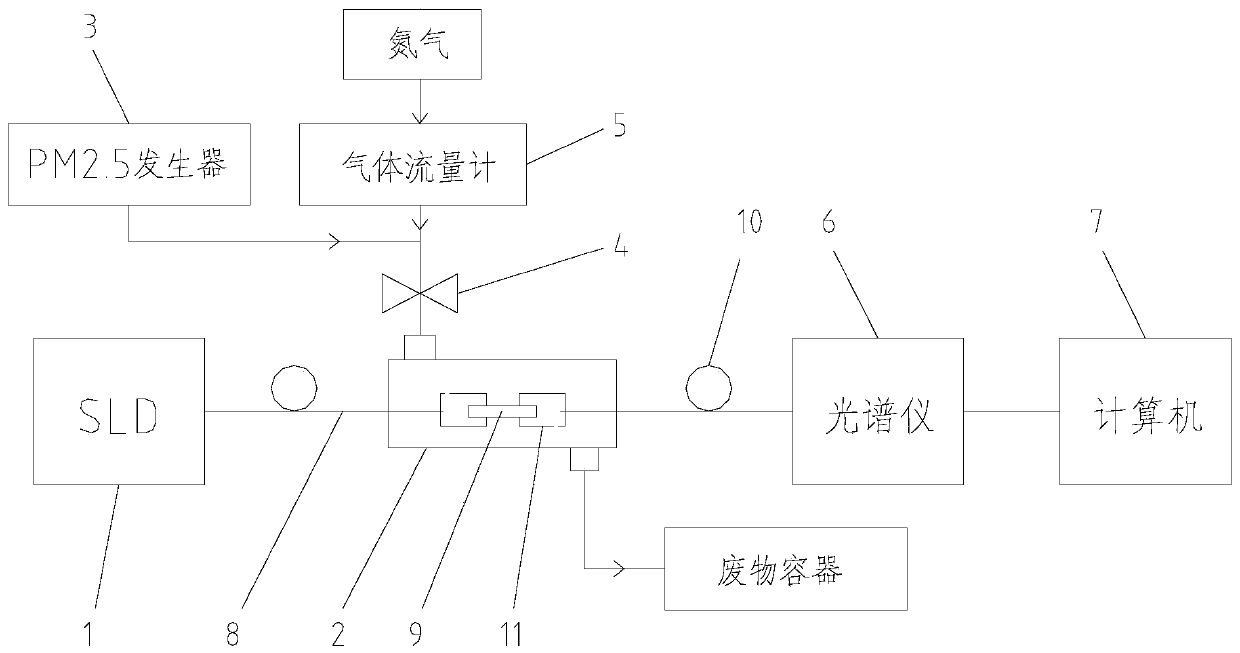

A pm based on hollow-core bragg fiber 2.5 Concentration detection device

A technology of concentration detection and optical fiber, which is applied in the field of hollow-core Bragg optical fiber fine particle concentration detection device, can solve the problems of being susceptible to environmental temperature and humidity fluctuations, and achieve the effect of simple structure, stable structure and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

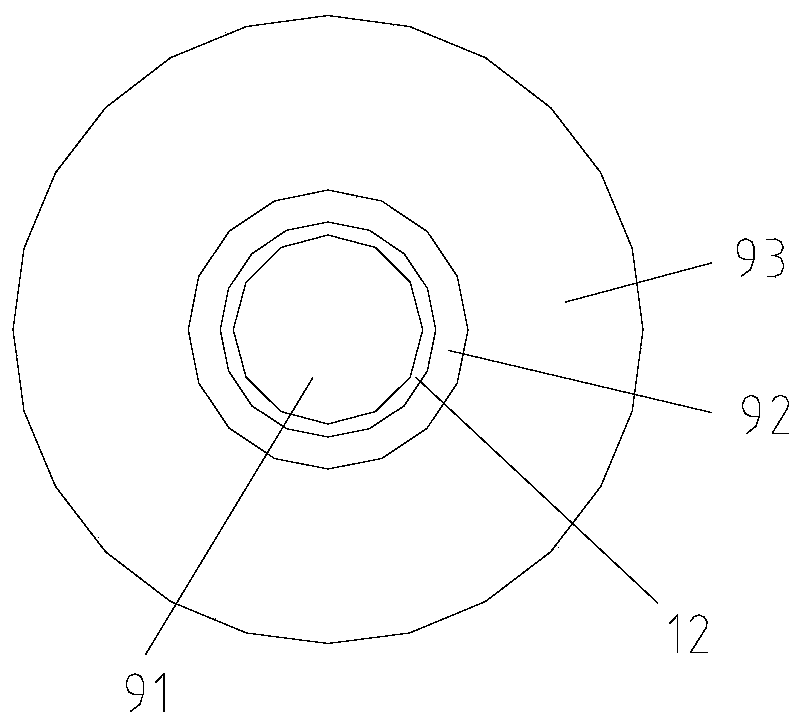

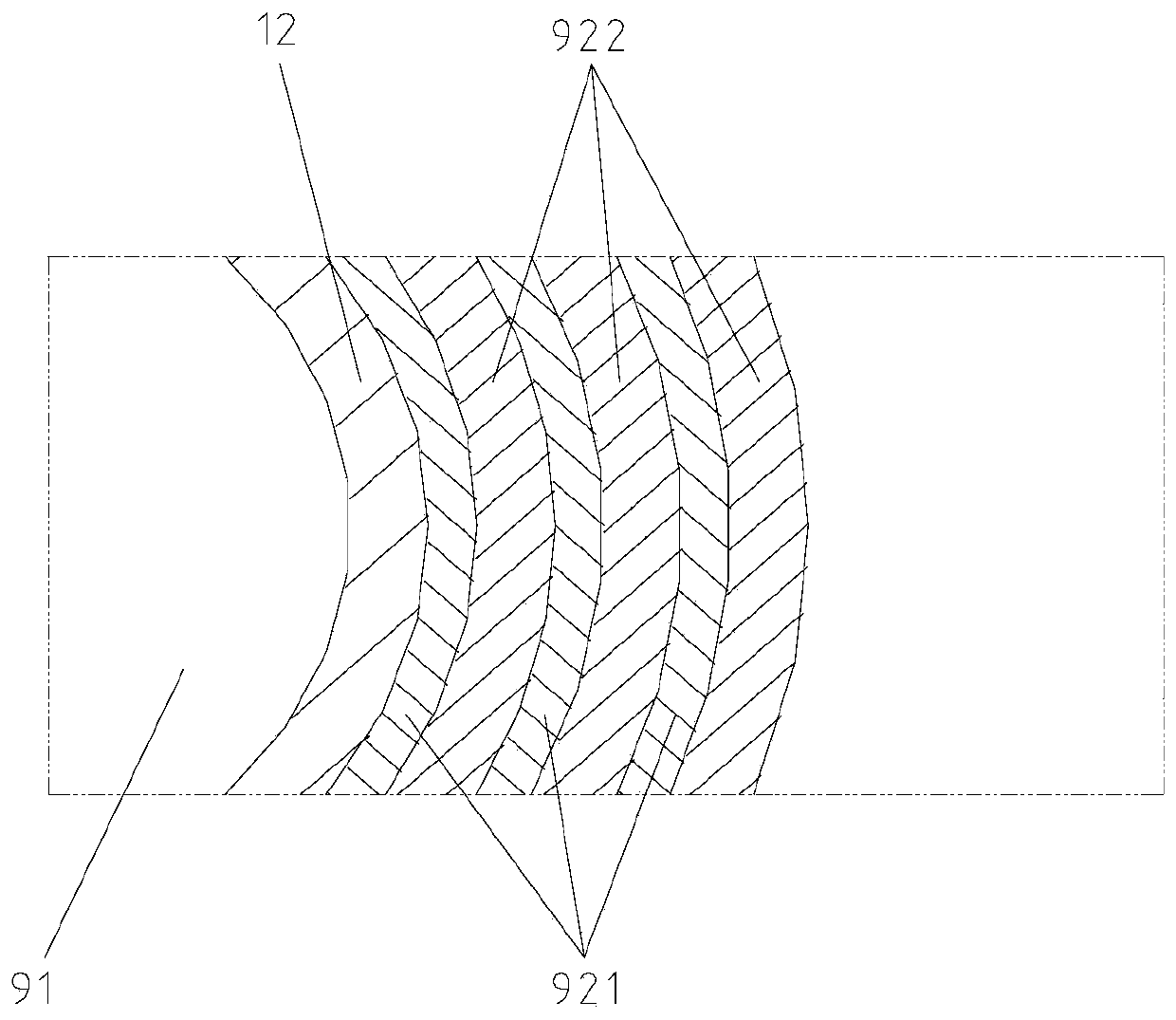

Method used

Image

Examples

experiment example 1

[0060] Experimental Example 1: The inner surface of the hollow-core Bragg fiber core is coated with iodine-doped polyacetylene film with a thickness of 100 nm and a mass concentration of 0-150 μg / m 3 PM 2.5 Nitrogen gas is used as the object, which interacts with the inner wall film of the fiber core respectively, and the resonant wavelength of the sensor transmission spectrum varies with the PM 2.5 The increase in concentration shifts towards shorter wavelengths. And the resonance wavelength shift Δλ is related to PM 2.5 There is a linear correlation between the mass concentrations c, and its linear regression equation is:

[0061] Δλ=kc+b

[0062] In the formula, c is the PM to be measured 2.5 Particle concentration, Δλ is the resonance wavelength shift of the hollow-core Bragg fiber transmission spectrum, k is the slope, and b is the intercept.

[0063] Known PM was used in the test 2.5 The mass concentration is 0, 10μg / m 3 , 20μg / m 3 , 50μg / m 3 , 80 μg / m 3, 100μg...

experiment example 2

[0065] Experimental Example 2: The inner surface of the hollow-core Bragg fiber core is coated with an iodine-doped polyacetylene film with a thickness of 150nm, and a known PM is used in the test 2.5 The mass concentration is 0, 10μg / m 3 , 20μg / m 3 , 50μg / m 3 , 80μg / m 3 , 100μg / m 3 , 150μg / m 3 The nitrogen in the sensor is detected, and the resonant wavelength of the sensor transmission spectrum varies with the PM 2.5 The increase of the concentration moves to the short wavelength direction, and the corresponding transmission spectrum resonance wavelength shifts Δλ are 0, 0.36, 0.72, 1.84, 2.34, 2.86, 3.62nm respectively, and the linear regression equation is: Δλ=0.0245c+0.2409, and the correlation coefficient is :R 2 =0.9685, that is, k and b in the linear regression equation are 0.0245 and 0.2409 respectively.

[0066] When the gas to be measured is in contact with the sensitive film on the inner surface of the hollow-core Bragg fiber core, the average shift of the r...

experiment example 3

[0067] Experimental Example 3: The inner surface of the hollow-core Bragg fiber core is coated with an iodine-doped polyacetylene film with a thickness of 170 nm, and a known PM 2.5 The mass concentration is 0, 10μg / m 3 , 20μg / m 3 , 50μg / m 3 , 80μg / m 3 , 100μg / m 3 , 150μg / m 3 The nitrogen is detected, and the resonance wavelength of the sensor transmission spectrum varies with the PM 2.5 The increase of the concentration moves to the short wavelength direction, and the corresponding transmission spectrum resonance wavelength shifts Δλ are 0, 0.34, 0.66, 1.84, 2.36, 2.82, 3.56nm respectively, and the linear regression equation is: Δλ=0.0243c+0.2293, and the correlation coefficient is :R 2 =0.9645, that is, k and b in the linear regression equation are 0.02434 and 0.2293 respectively.

[0068] When the gas to be measured is in contact with the nano-film on the inner surface of the hollow Bragg fiber core, the average shift of the resonance wavelength of the transmission s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com