Edge exposure machine and edge exposure method

An edge exposure and edge technology, which is applied in the direction of photomechanical equipment, microlithography exposure equipment, and photolithography exposure equipment, etc., can solve the problem of uneven brightness and darkness in square shapes, so as to solve uneven brightness and darkness and reduce yield loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

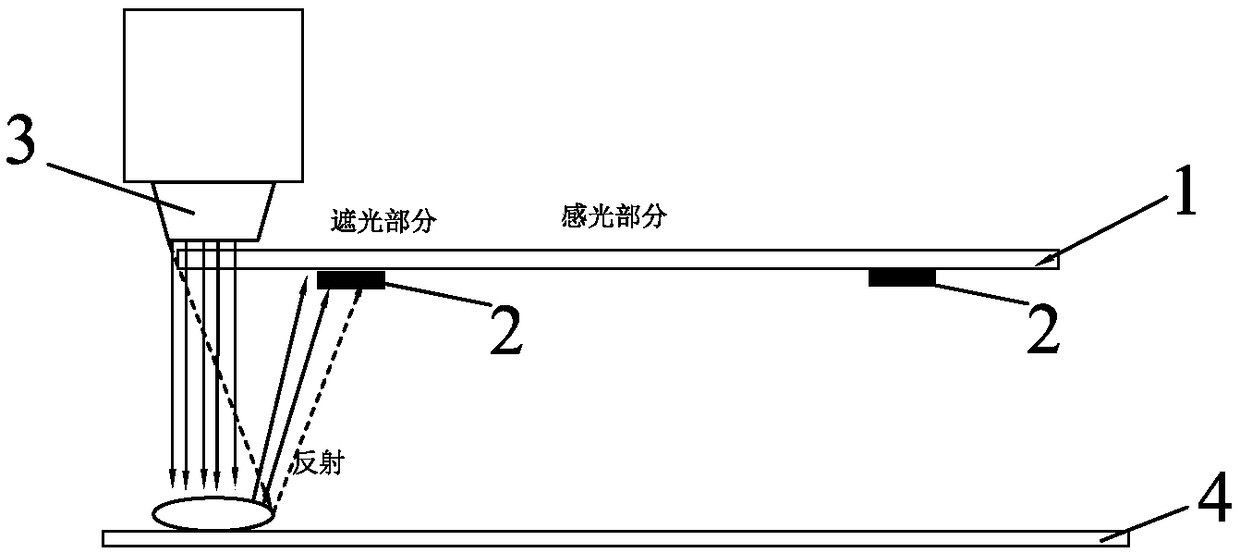

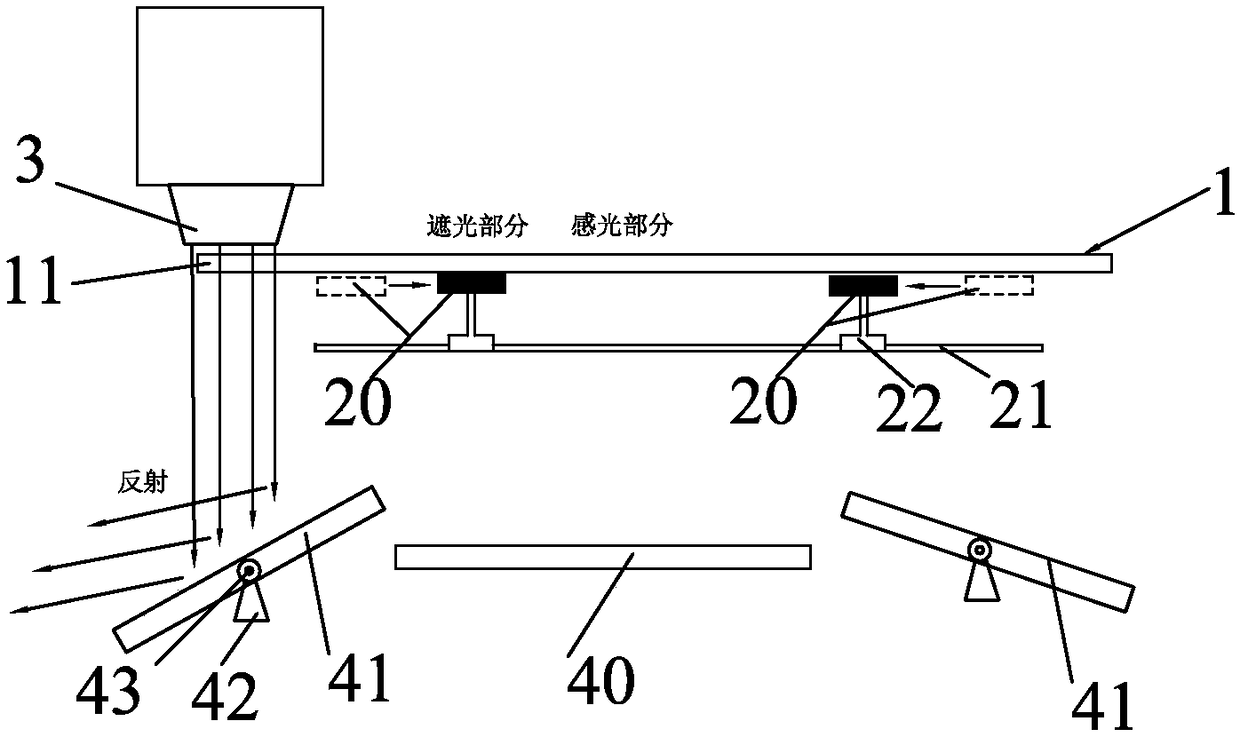

[0027] see figure 2 , which is a schematic structural diagram of a preferred embodiment of the edge exposure machine of the present invention. The edge exposure machine of the present invention mainly includes: a light source 3 for exposing the edge 11 of the substrate from above the substrate 1; a vacuum pad 20 for fixing the substrate 1 by vacuum suction from below the substrate 1 and supporting the substrate upward; a chamber located in the edge exposure machine The bottom of the chamber is used to reflect the downward light emitted by the light source 3 under the substrate 1. The reflective bottom plate may specifically include a central bottom plate 40 and an inclined bottom plate 41. When an edge exposure machine exposes a substrate edge 11, the reflective bottom plate corresponds to the substrate edge 11. A part of the reflective range is generated; it also includes a translation mechanism for adjusting the horizontal relative position between the vacuum pad 20 adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com