Fully automatic shielding transfer door

A fully automatic, revolving door technology, used in shielding, reactors, nuclear engineering and other directions, can solve the problems of safety and insufficient operation automation, and achieve the effect of simple structure, space saving and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

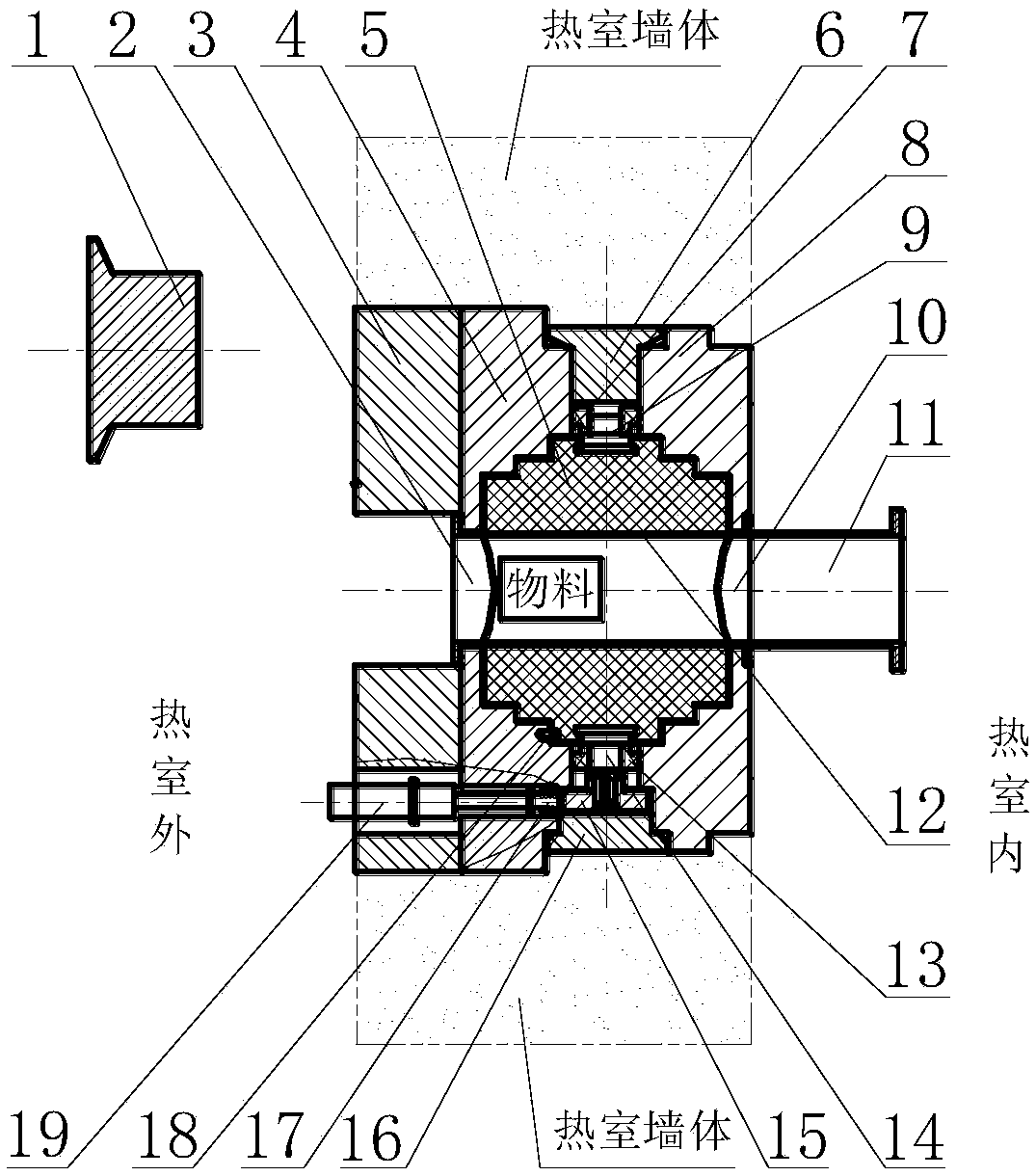

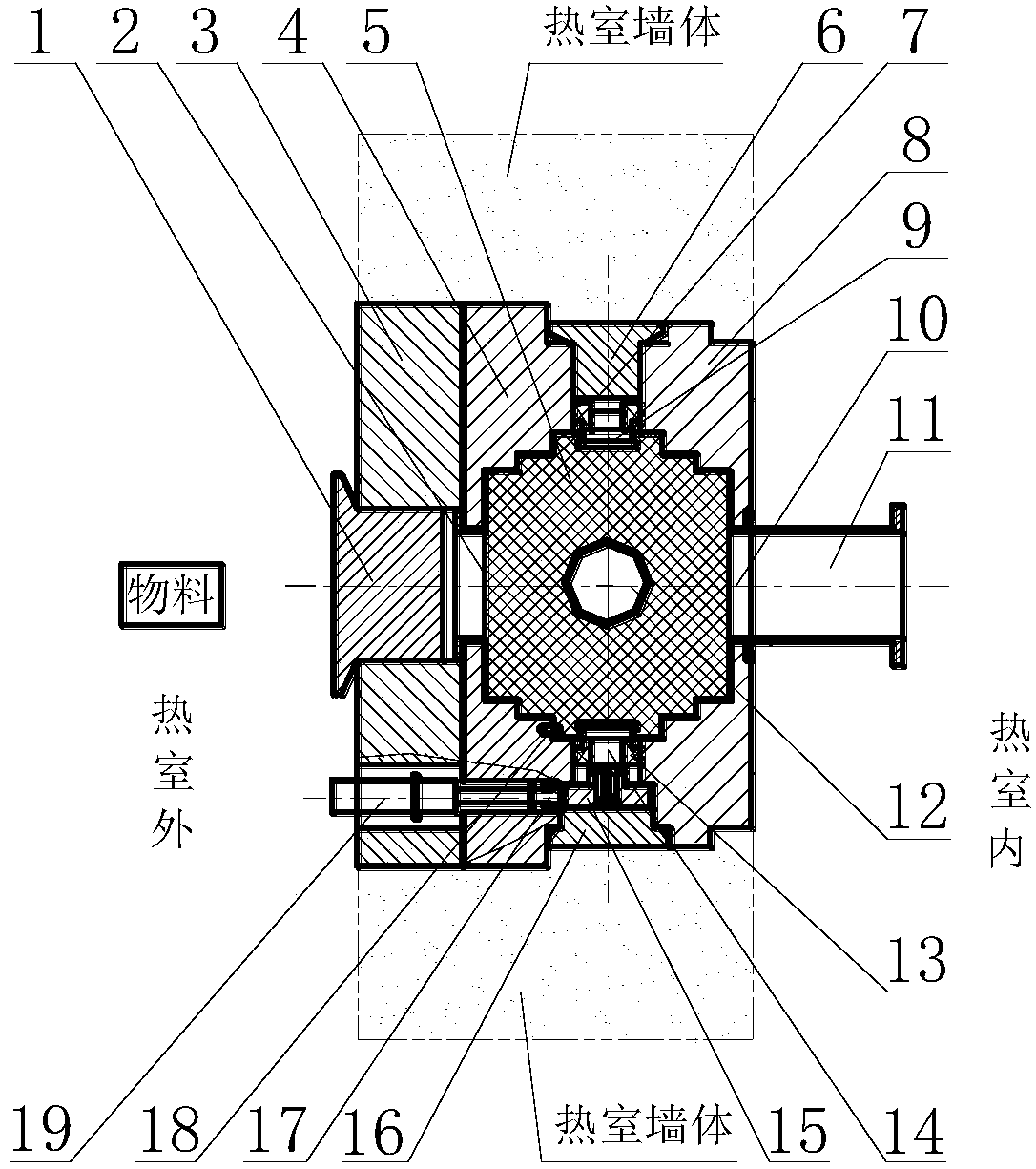

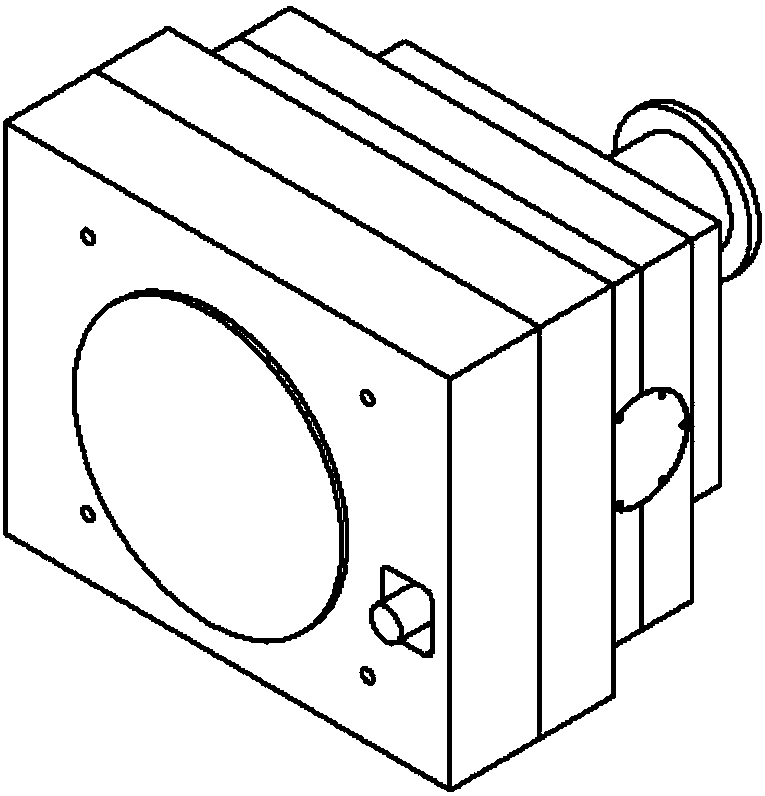

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] The present invention provides a fully automatic shielded transfer door for transporting materials, such as radioactive materials, from the outside of the heating chamber to the inside of the heating chamber. The hot chamber can be applied in the field of nuclear industry, and can also be applied in other fields that need to transfer dangerous materials.

[0030] Because the hot chamber contains a large amount of radioactive substances and has strong radiation, these particularities make the following points need to be considered when designing the hot chamber transfer door: In order to control the atmosphere in the hot chamber without polluting the external environment, the hot chamber transfer door needs to have a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com