Anti-electric shock electrical connector and module socket employing same

A technology of electrical connectors and electrical connecting pieces, which is applied to the parts, connections, and two-component connecting devices of the connecting device, which can solve the problems of only benefiting the production end and cumbersome operation process, so as to avoid electric shock accidents and improve safety , the effect of preventing accidental electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

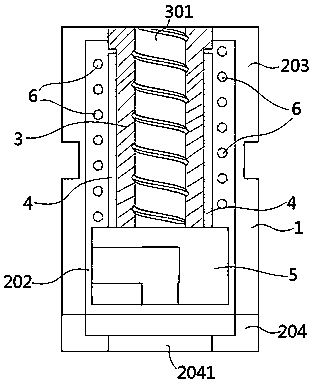

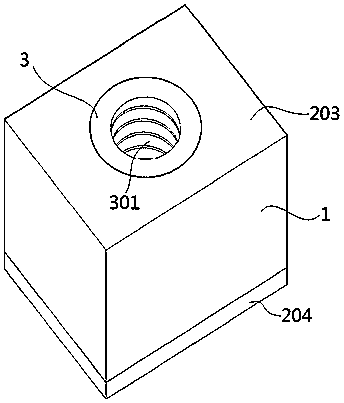

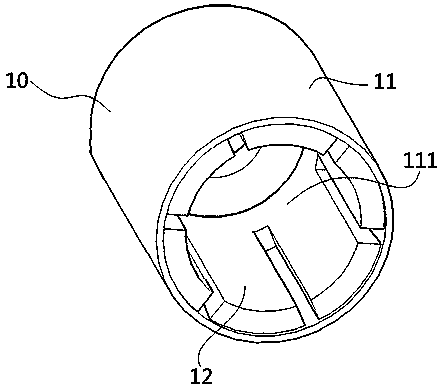

[0065] Such as Figure 1-4 As shown, an electric shock-proof connector in this embodiment includes an electrical connector male (1) and an electrical connector female (10). The electrical connector male (1) comprises a male housing (2), an insulator (3), a conductive sheet (4), a base (5) and a spring (6).

[0066] The male shell (2) includes a male upper shell (203) and a male lower shell (204). At least one of the male upper shell (203) and the male lower shell (204) has a cavity structure. The male upper shell (203) is fixedly connected to the male lower shell (204) by clamping or screws. The male upper shell (203) and the male lower shell (204) together form a limiting cavity (202). There is an action hole (201) on the top surface of the male head upper shell (203), and a wire inlet hole (2041) is arranged on the male head lower shell (204). Both the action hole (201) and the wire inlet hole (2041) communicate with the limiting cavity (202).

[0067] The outer diamete...

Embodiment 2

[0079] The main body structure of the electric shock-proof male connector of this embodiment is basically the same as that of the electrical connector male described in Embodiment 1, the difference is that: on the outer wall of the male housing (2), A locking structure (7) consisting of grooves or sheet-shaped side wings is provided, and holes may be provided on the side wings. The electrical connector male head (1) is installed on the external device by clamping the locking structure (7) on the external track, or fixedly connecting the external device with screws.

[0080] In this embodiment, on the outer wall of the male housing (2), there may be provided a clamping foot or a clamping slot for clamping with an external device.

Embodiment 3

[0082] An electric shock-proof male connector of this embodiment, the main structure is basically the same as that of the electrical connector male described in Embodiment 2, the difference is that it also includes a ferrule (8); the ferrule ( 8) It is a nut structure.

[0083] The outer wall part between the head of the male upper shell (203) or the tail of the male lower shell (204) and the locking structure (7) is a threaded column structure. The ferrule (8) can be screwed on the outer side wall of the male upper shell (203) or the male lower shell (204). The locking position of the ferrule (8) is on one side of the locking structure (7), close to the locking structure (7). When the male electrical connector (1) is clamped to the outer track, the male electrical connector (1) can be squeezed to one side of the track by twisting the ferrule (8), and finally locked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com