Obliquely horizontal moving type filter device for cleaning fluid for new material cleaning

A filter device and cleaning liquid technology, applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problems of waste of cleaning liquid, poor filtration effect, slow filtration speed, etc., and achieve improved purity, better filtration effect, and better filtration thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

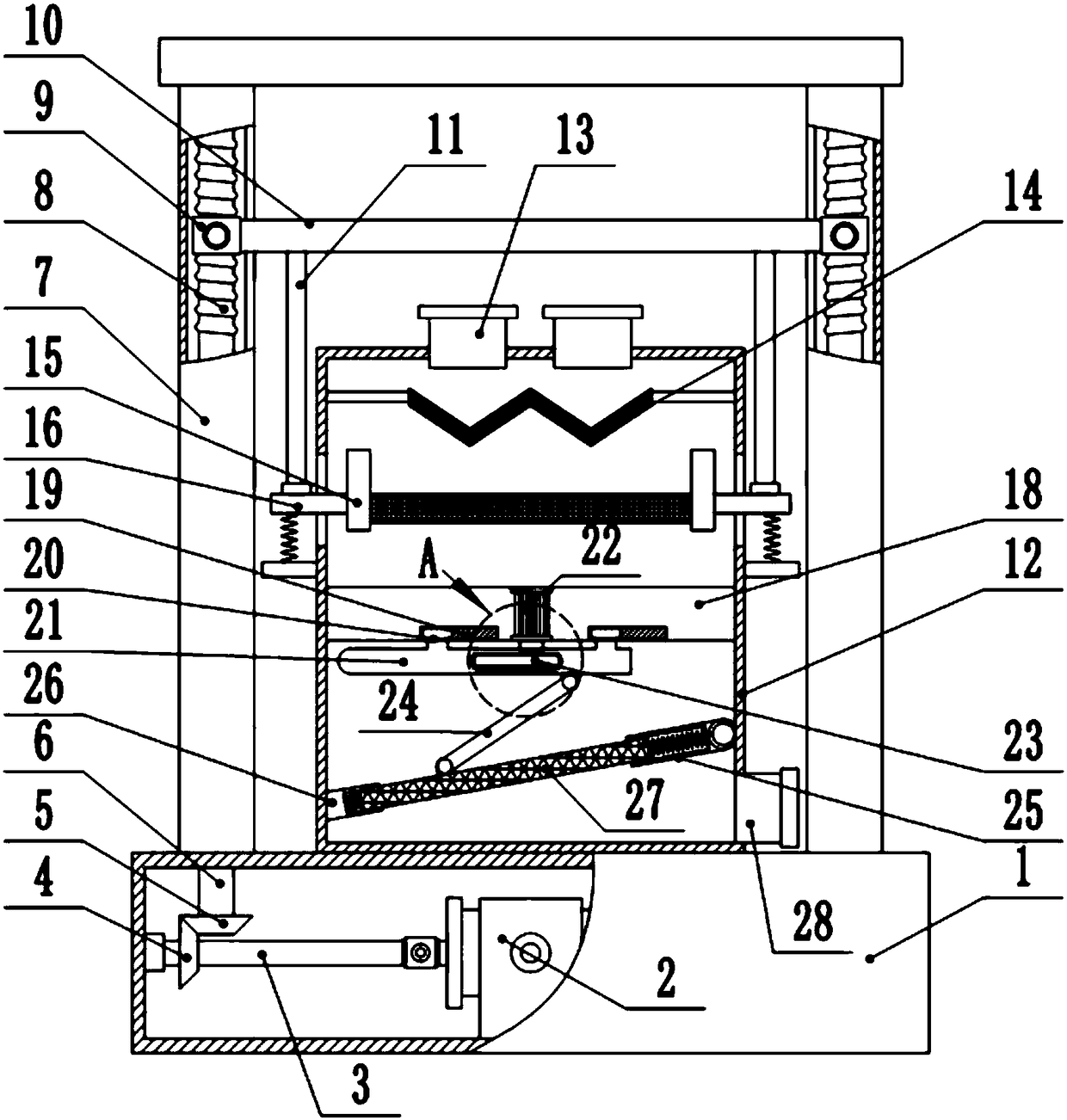

[0020] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

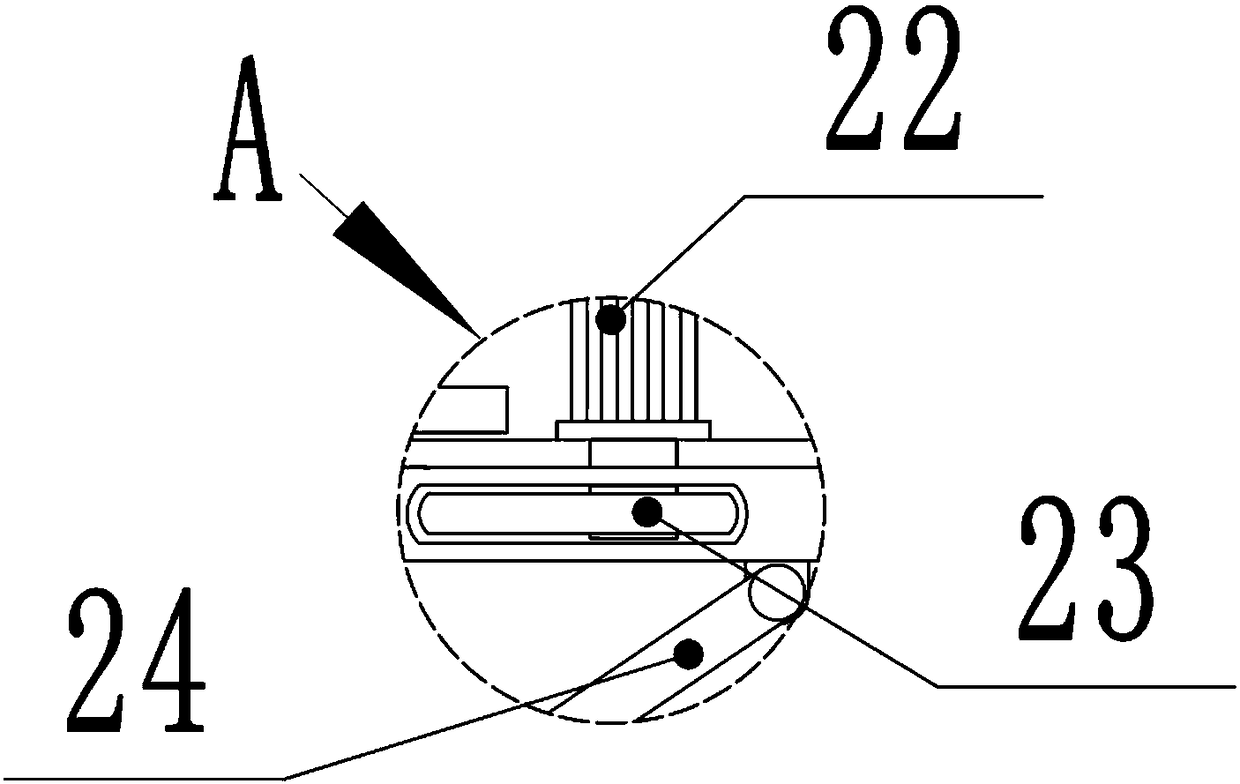

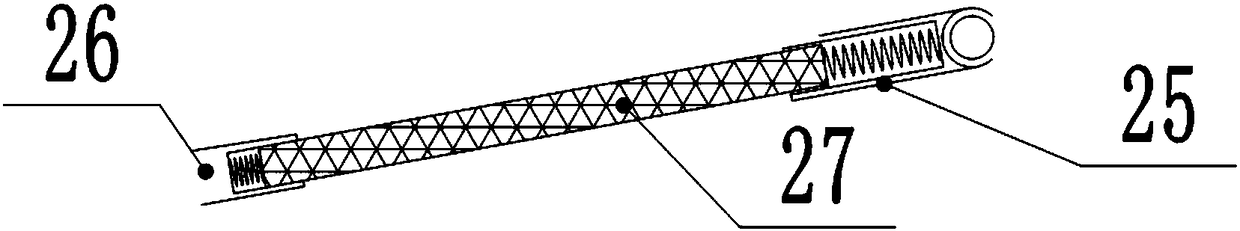

[0021] see Figure 1-3 , a new material cleaning cleaning liquid tilt-and-translation filter device, including a base 1, a filter box 12, a vibration filter box 15 and a drive motor 22, the interior of the base 1 is a hollow structure, and the inner center position of the base 1 is fixed by a bracket A biaxial motor 2 is installed, and the biaxial motor 2 is a biaxial servo motor. The output shafts at both ends of the biaxial motor 2 are fixedly connected with a connecting shaft 3 through a coupling, and the other end of the connecting shaft 3 is fixedly installed on the base through a bearing. On the inner walls of both sides of 1, a driving bevel gear 4 is installed on the connecting shaft 3 with interference fit, the upper side of the driving bevel gear 4 is meshed with a driven bevel gear 5, and the wheel core of the driven bevel gear 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com