Pushing device of die clearing cake and aluminum profile extruding and pushing method

A push device and aluminum profile technology, applied in the field of mechanical equipment, can solve the problems of high mold cleaning temperature, high temperature, increased work intensity by manual push, etc., and achieve the effect of improving the operating environment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

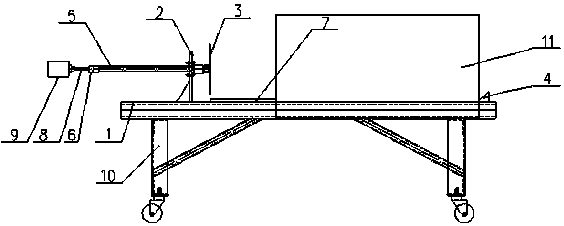

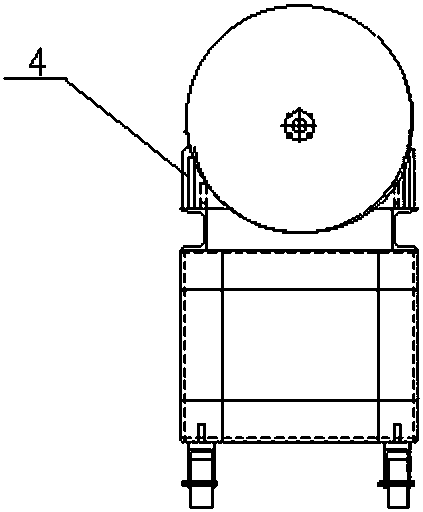

[0031] Such as figure 1 , 5 Among them, a pushing device for cleaning mold cakes includes three parts: a loading mechanism, a pushing mechanism, and a lifting mechanism.

[0032] The loading mechanism includes a power part, a transmission part and a bracket, the transmission part is connected with the power part, and the support plate 2 arranged on the guide rail bracket 1 supports the transmission mechanism;

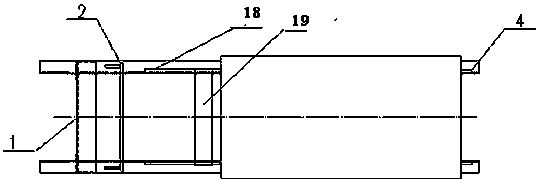

[0033] The transmission part includes a push rod 5 and a push plate 3, one end of the push rod 5 is connected with the push plate 3, and the other end is connected with the transmission part, and the push rod 5 passes through the support plate 2 through a looper. Preferably, the power part includes a hand-held motor 9, Clamp the universal flexible shaft 8, the hand-held motor 9 is connected to the coupling 6 by clamping the universal flexible shaft 8, and the push rod 5 is connected to the coupling 6. When working, the hand-held motor 9 is connected to the 1. The coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com