Reversible car headrest

A car headrest and flip-up technology, applied in the field of auto parts, can solve the problems of easy damage to the matching structure, complex structure, complex unlocking structure, etc., and achieve the effect of low production cost, long service life and good operation feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

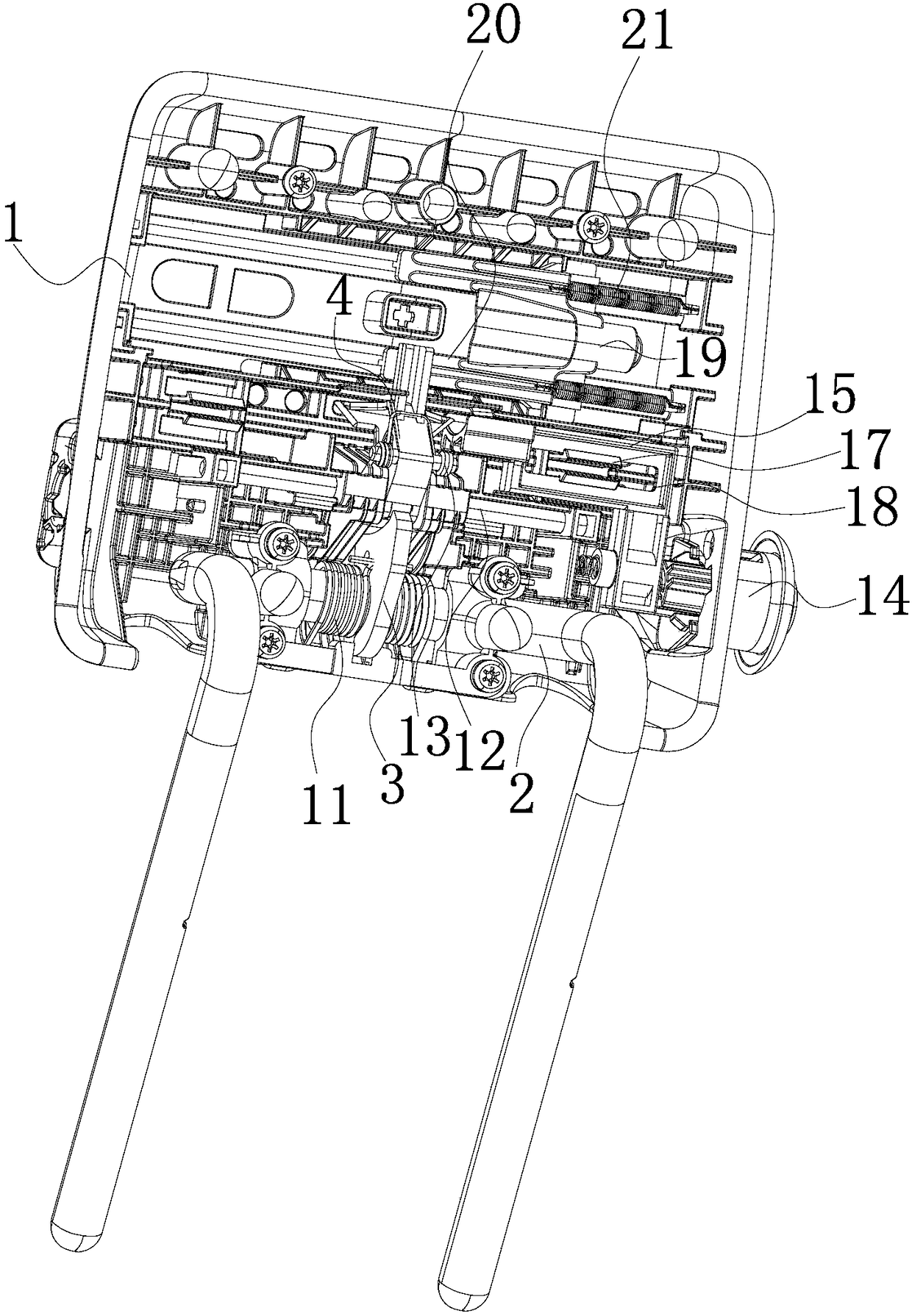

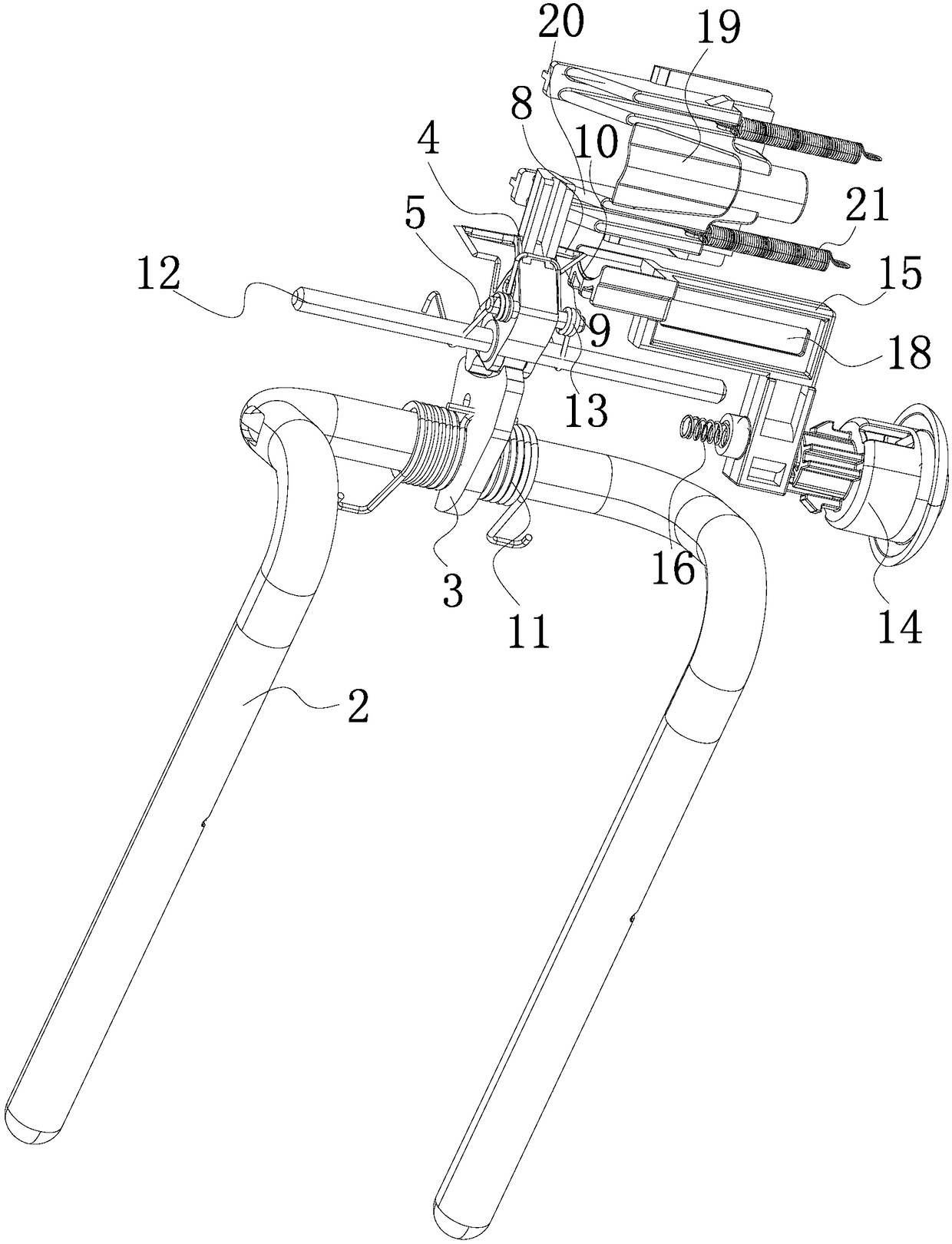

[0028] Such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown, the reversible automobile headrest 1 includes: the headrest 1, an installation space is formed inside it;

[0029] The support rod 2, the upper end of which is rotatably connected to the lower end of the headrest 1;

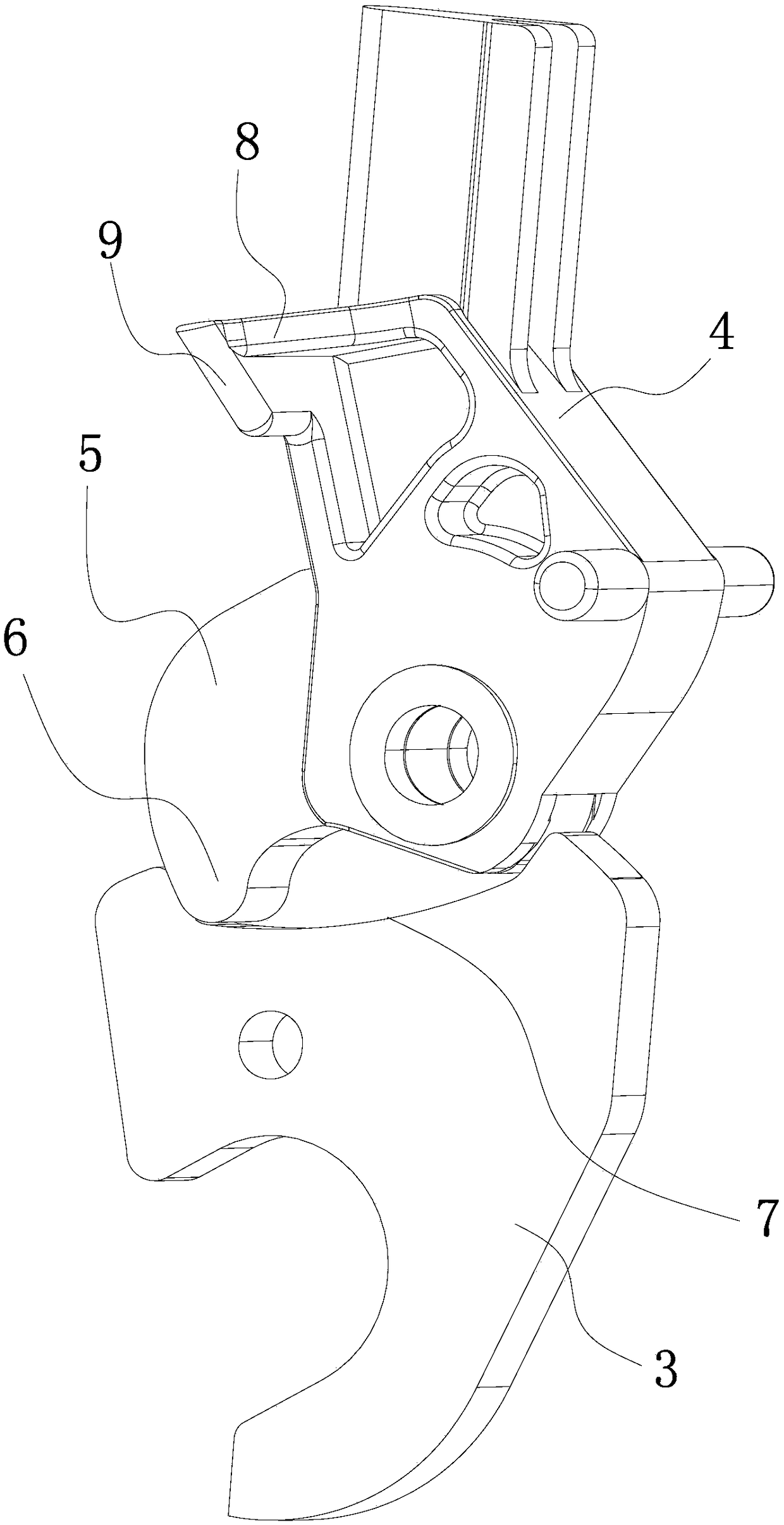

[0030] Ratchet 3, which is fixedly connected to the pole 2;

[0031] The locking component is rotatably connected to the inside of the headrest 1, and the lower end of the known component is movably clamped on the upper end of the ratchet 3;

[0032] The unlocking component is movably inserted into the headrest 1, and one end of the unlocking component abuts against the upper end of the locking component;

[0033] When the unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com