Azobenzene polyether ester multi-block copolymer elastomer with photo-induced deformation performance and preparation method thereof

A multi-block copolymer, azobenzene polyetherester technology, applied in the direction of one-component polyetherester rayon, etc., can solve the problem of high requirements, low molecular weight of polyetherester, difficult to obtain high-performance polymers, etc. problem, achieve good photodeformation performance, and solve the effect of small photodeformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

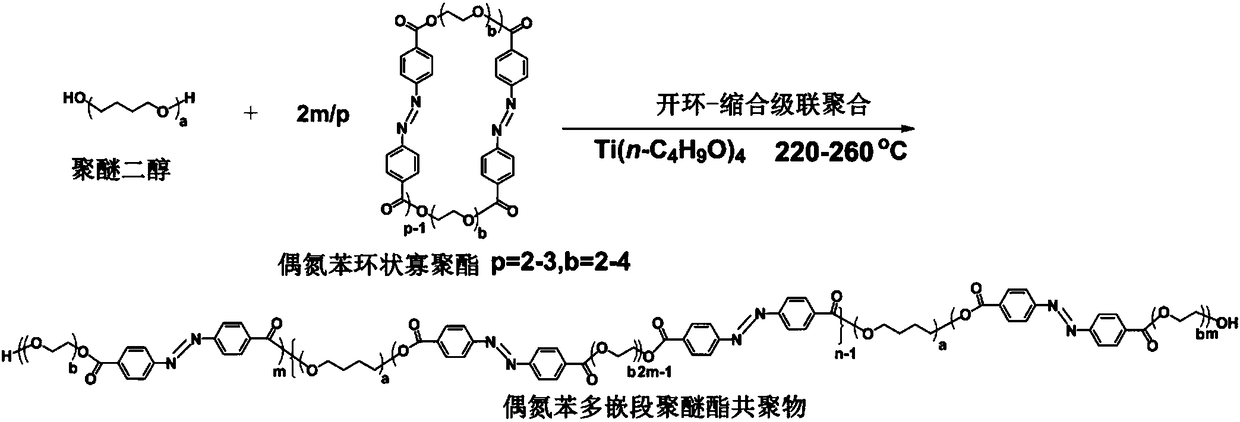

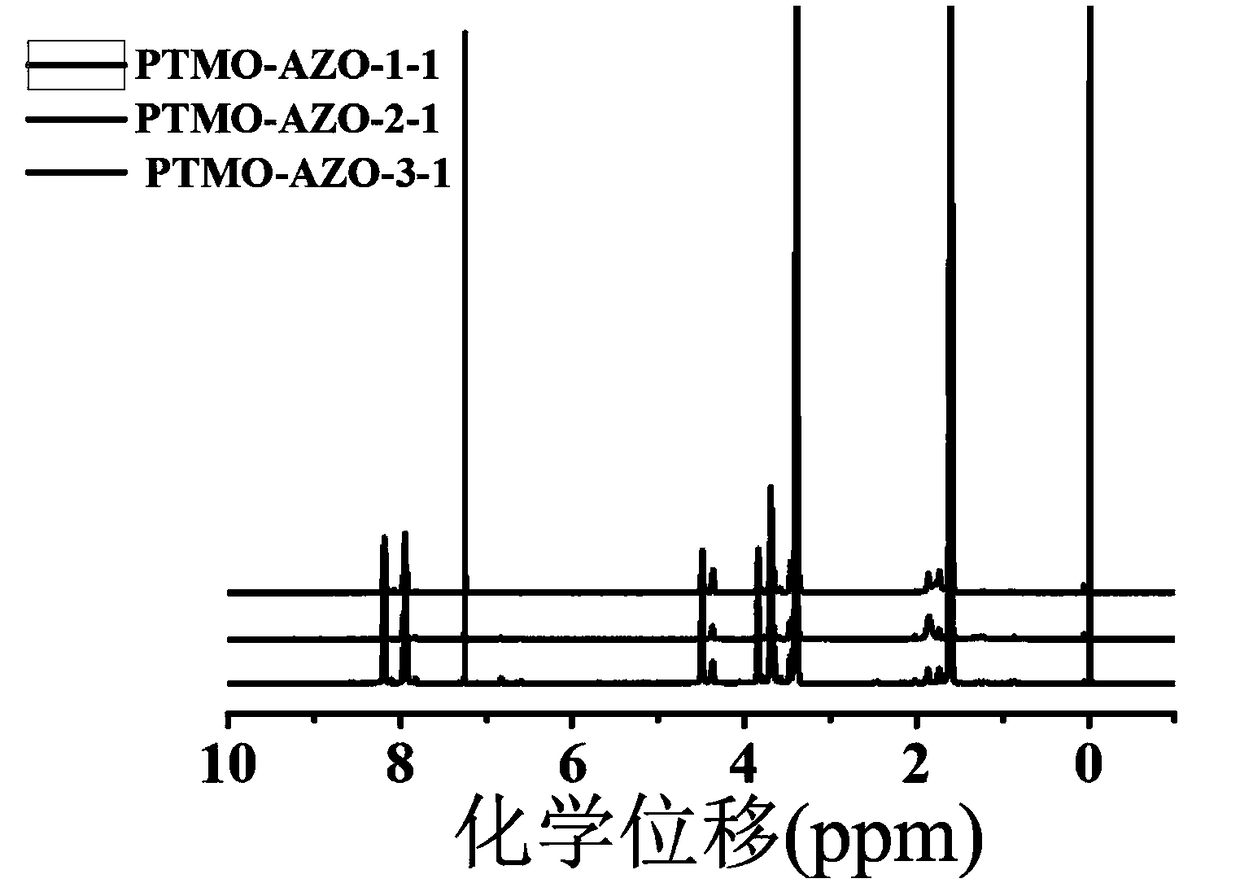

[0028] Example 1 Preparation of azophenyl polyether ester multi-block copolymer PTMO-AZO-1-1

[0029] Equipped with mechanical stirring, N 2 Into a 100 mL three-neck round-bottomed flask for the catheter, add 5 grams (g) of cyclic oligopolyazophthalate triethylene glycol, 5 g of polytetrahydrofuran diol with a molecular weight of 2900, and pass through N 2 , heated to 240°C, adding n-butyl titanate as a catalyst, 2 Stirring was continued for 3 hours to obtain the final product PTMO-AZO-1-1 as a reddish-brown solid, figure 1 A schematic diagram of the reaction equation.

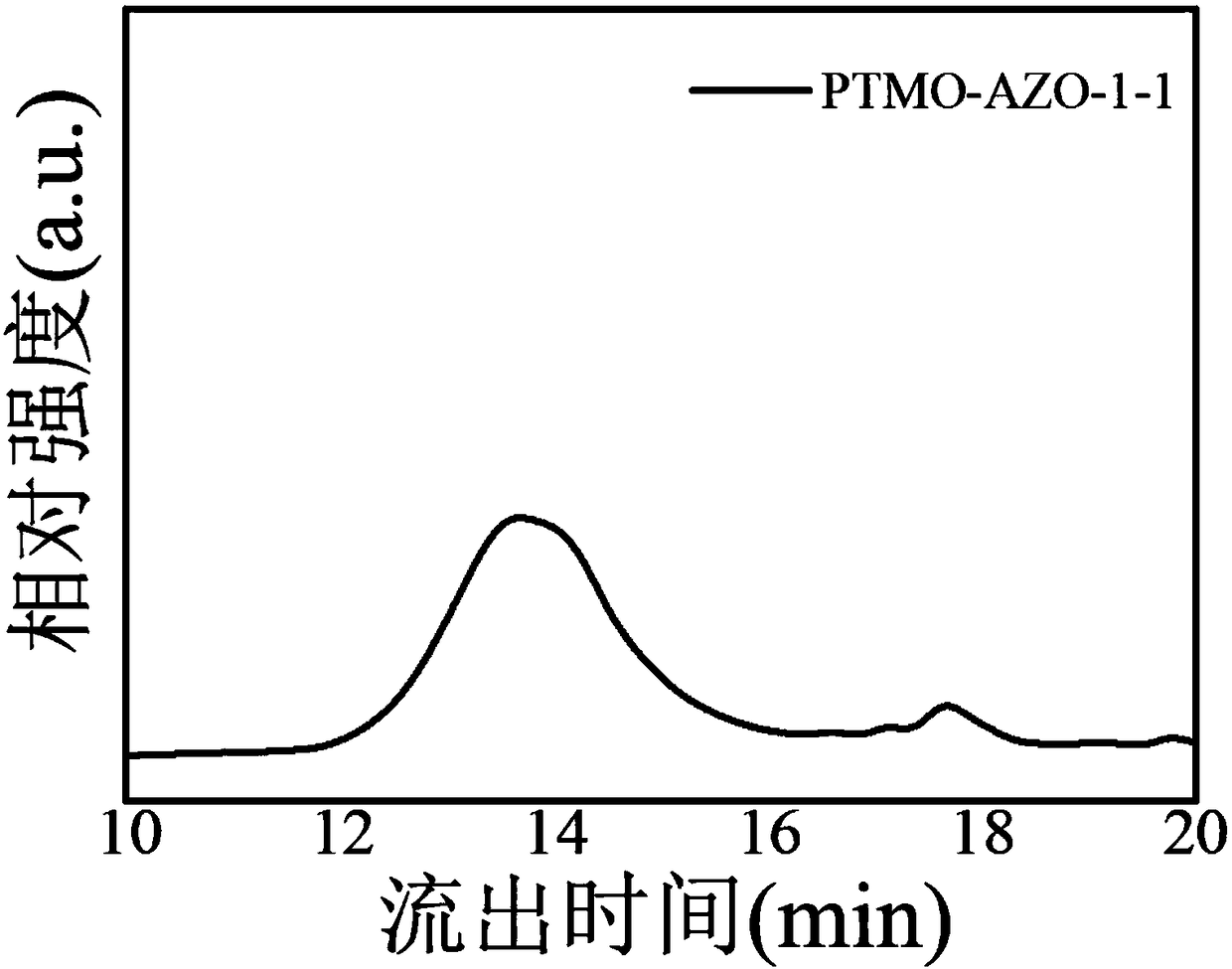

[0030] plotted by GPC ( figure 2 ) shows that the azophenyl polyether ester multi-block copolymer PTMO-AZO-1-1 with higher molecular weight was obtained.

Embodiment 2

[0031] Example 2 Preparation of azobenzene polyether ester multi-block copolymer PTMO-AZO-2-1

[0032] Equipped with mechanical stirring, N 2 Into a 100 mL three-necked round-bottomed flask with a catheter, add 3 g of cyclic oligopolyazophthalate triethylene glycol, 6 g of polytetrahydrofuran diol with a molecular weight of 2900, and pass N 2 , heated to 240°C, adding n-butyl titanate as a catalyst, 2 Stirring was continued for 3 hours under conditions to obtain the final product PTMO-AZO-2-1 as a reddish-brown solid.

Embodiment 3

[0033] Example 3 Preparation of azophenyl polyether ester multi-block copolymer PTMO-AZO-3-1

[0034] Equipped with mechanical stirring, N 2 Into a 100 mL three-necked round-bottomed flask with a catheter, add 2 g of cyclic oligopolyazophthalate triethylene glycol, 6 g of polytetrahydrofuran diol with a molecular weight of 2900, and pass N 2 , heated to 240°C, adding n-butyl titanate as a catalyst, 2 Stirring was continued for 3 hours under conditions to obtain the final product PTMO-AZO-3-1 as a reddish-brown solid.

[0035] Azophenyl polyether ester multi-block copolymers PTMO-AZO-1-1, PTMO-AZO-2-1, PTMO-AZO-3-1 with different soft and hard segment ratios were synthesized by controlling the feed ratio, molecular weight and molecular weight The distribution data are shown in Table 1, and the molecular weights are above 33,000.

[0036] Table 1 GPC molecular weight and molecular weight distribution of azobenzene polyether ester multi-block copolymer PTMO-AZO-1-1, PTMO-AZO-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com