A high-weather-resistant hot-rolled h-beam with a yield strength of 450mpa and its heat treatment process

A technology of yield strength and H-shaped steel, which is applied in the field of high-weathering hot-rolled H-shaped steel with a yield strength of 450MPa and its heat treatment process, can solve the problems of unfavorable structural processing, easy brittle fracture, high strength, etc., and achieve good uniformity and comprehensive mechanics Performance, reduction of rolling difficulty and production, effect of reduction of dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

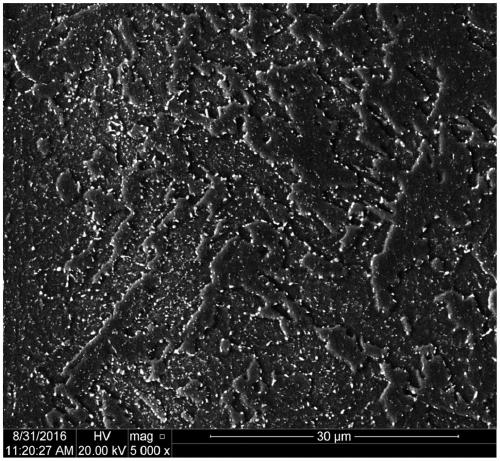

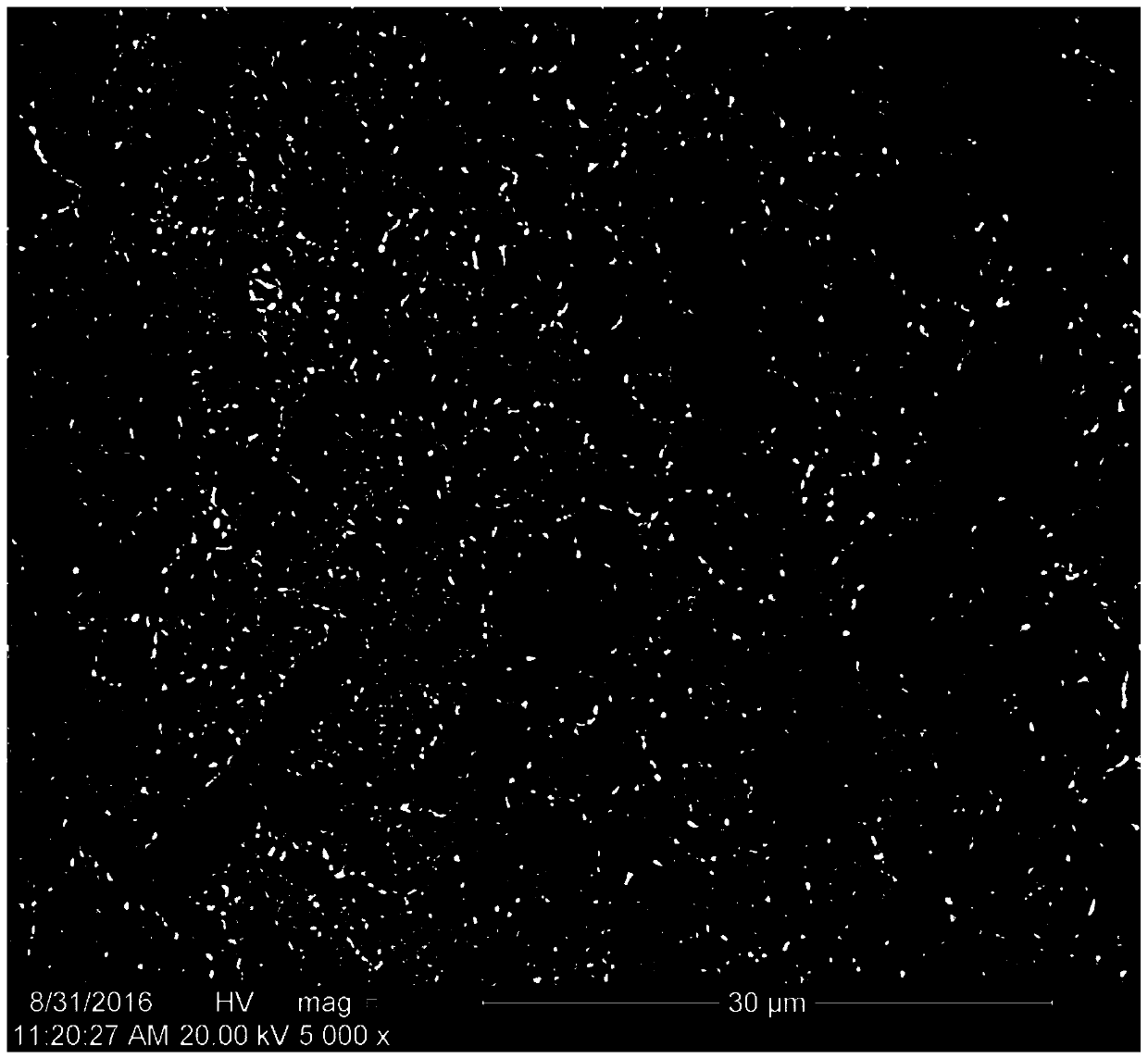

Image

Examples

Embodiment 1

[0036]A high-weather-resistant hot-rolled H-shaped steel with a yield strength of 450MPa, according to mass percentage (wt%), the melting chemical composition ratio is: C: 0.08, Si: 0.29, Mn: 0.56, P: 0.012, S: 0.009, Cr: 3.10, Ni: 0.40, Cu: 0.42, V: 0.026, Alt: 0.023, and the rest are Fe and other unavoidable impurities.

[0037] The preparation method of the high weather resistance hot-rolled H-shaped steel with a yield strength of 450MPa is as follows:

[0038] Taking the hot-rolled H-shaped steel with a flange thickness of 17mm as an example, the billet is processed by a hot-rolling process: heating temperature 1226 ° C, 2 hours in the furnace, starting rolling temperature 1093 ° C, finishing rolling temperature 907 ° C;

[0039] Then heat treatment by tempering process: heating from cold state at 10°C / s to 680°C, holding for 2h, and air cooling after being out of the furnace.

[0040] The final yield strength of the 450MPa-grade high-weather-resistant hot-rolled H-beam o...

Embodiment 2

[0042] A high-weather-resistant hot-rolled H-shaped steel with a yield strength of 450MPa, according to mass percentage (wt%), the melting chemical composition ratio is: C: 0.06, Si: 0.28, Mn: 0.42, P: 0.010, S: 0.006, Cr: 2.52, Ni: 0.33, Cu: 0.38, V: 0.019, Alt: 0.026, and the rest are Fe and other unavoidable impurities. ,

[0043] The preparation method of the high weather resistance hot-rolled H-shaped steel with a yield strength of 450MPa is as follows:

[0044] Taking the hot-rolled H-shaped steel with a flange thickness of 17mm as an example, the billet is processed by a hot-rolling process: heating temperature 1226 ° C, 2 hours in the furnace, starting rolling temperature 1093 ° C, finishing rolling temperature 907 ° C;

[0045] Then heat treatment by tempering process: heating from the cold state at 6°C / s to 615°C, holding for 2h, and air cooling after being out of the furnace.

[0046] The final yield strength of the 450MPa-grade high-weathering hot-rolled H-beam o...

Embodiment 3

[0048] A high-weather-resistant hot-rolled H-shaped steel with a yield strength of 450MPa, according to mass percentage (wt%), the melting chemical composition ratio is: C: 0.09, Si: 0.36, Mn: 0.61, P: 0.010, S: 0.009, Cr: 2.80, Ni: 0.46, Cu: 0.45, V: 0.033, Alt: 0.036, and the rest are Fe and other unavoidable impurities.

[0049] The preparation method of the high weather resistance hot-rolled H-shaped steel with a yield strength of 450MPa is as follows:

[0050] Taking the hot-rolled H-shaped steel with a flange thickness of 17mm as an example, the billet is processed by a hot-rolling process: heating temperature 1226 ° C, 2 hours in the furnace, starting rolling temperature 1093 ° C, finishing rolling temperature 907 ° C;

[0051] Then heat treatment by tempering process: heating from cold state at 18 °C / s to 700 °C, holding for 2 hours, and air cooling after being out of the furnace.

[0052] The final yield strength of the 450MPa-grade high-weather-resistant hot-rolled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com