314 heat-resistant stainless steel metal-cored welding wire

A heat-resistant stainless steel and metal core technology, applied in the welding of 314 heat-resistant stainless steel, 314 heat-resistant stainless steel metal core welding wire, can solve the problem of high temperature resistance, oxidation resistance, high temperature creep resistance, failure to meet service conditions, Insufficient content of alloying elements, etc., to achieve excellent high temperature resistance and crack resistance, convenient and efficient mass production, and excellent wire process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

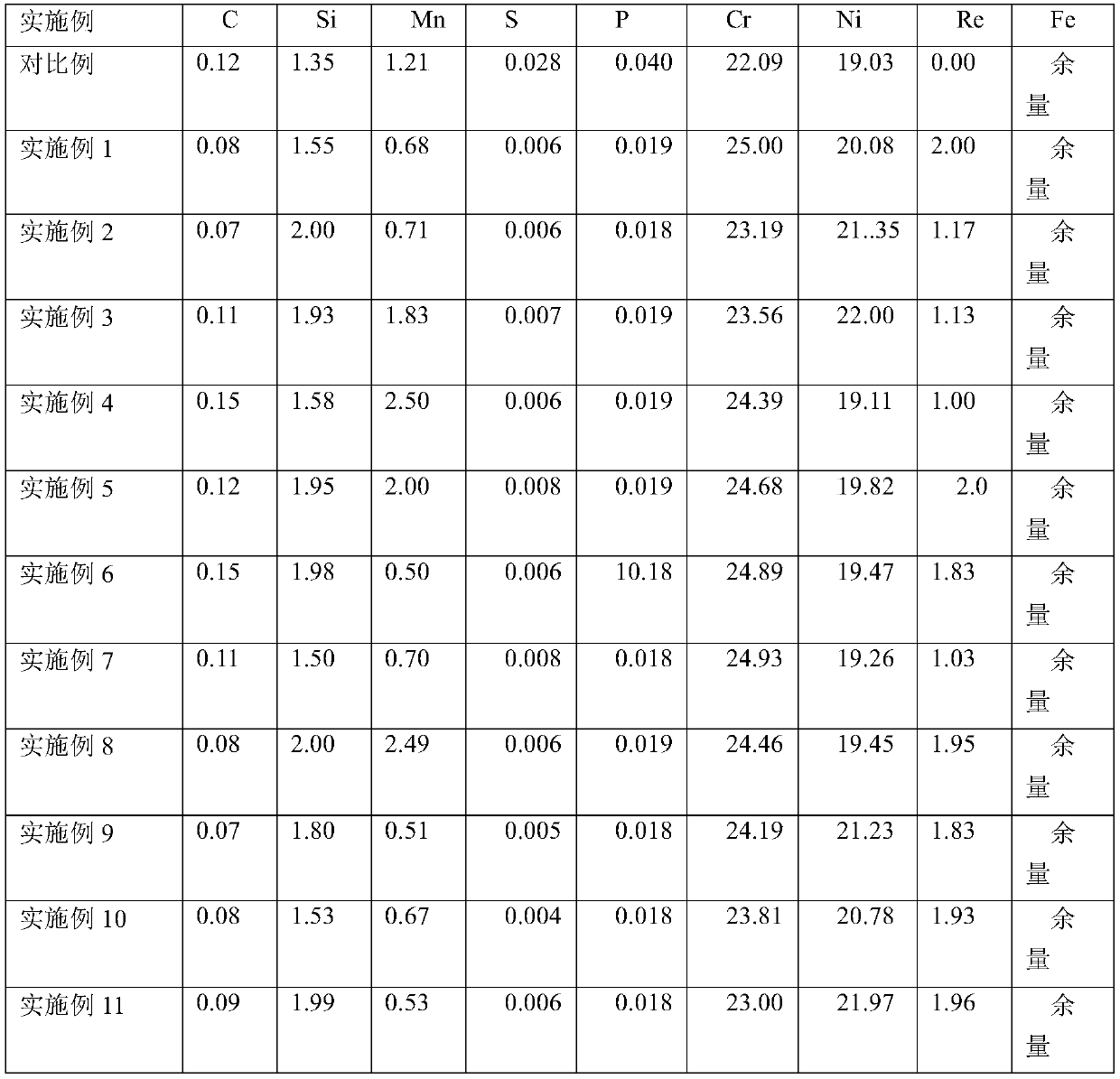

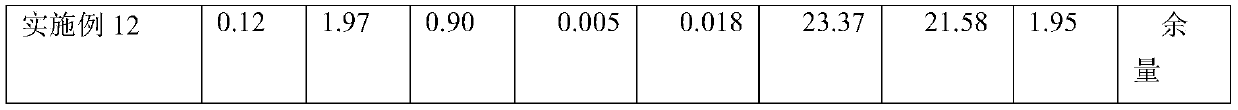

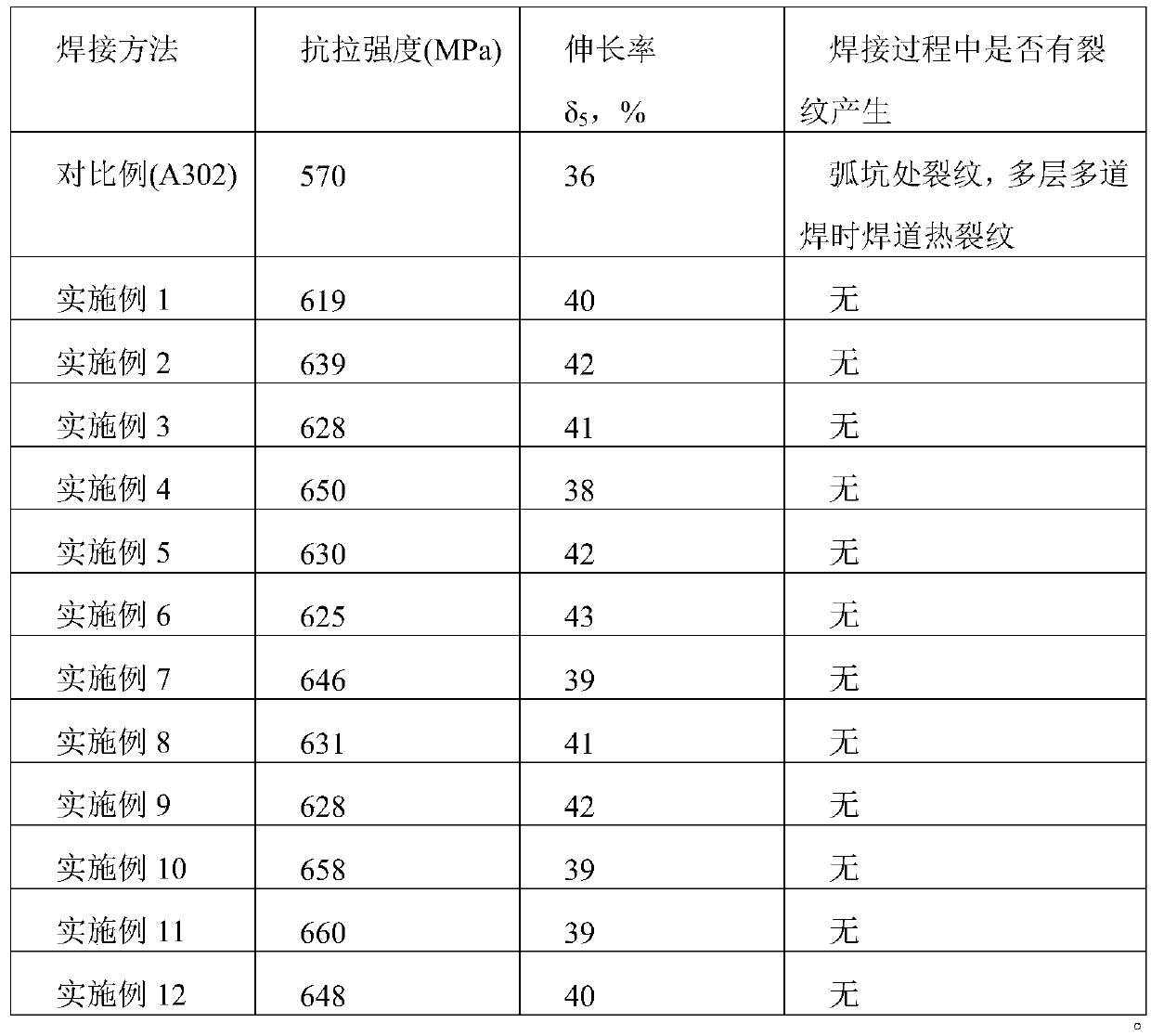

Examples

Embodiment 1

[0027] Embodiment 1. A 304 stainless steel strip of 8×0.3 (8mm in width and 0.3mm in thickness) is selected, and the filling rate is 35%. After drawing and reducing the diameter, a welding wire with a diameter of 1.2 mm is obtained.

[0028] The mass percent of each alloy composition in the powder core is: the mass percent of chromium is 44%, the mass percent of nickel is 47%, the mass percent of medium manganese is 1%, the mass percent of No. 75 ferrosilicon is 4%, mix The mass percentage of rare earth is 4%. The composition of mixed rare earth powder is: La 2 o 3 :30%, CeO 2 :48%,Pr 2 o 3 :6%,Nd 2 o 3 : 16%. The welding current used during welding is 50A, and the welding voltage is 22V. The welding shielding gas is pure argon, and the shielding gas flow rate is 10L / min.

Embodiment 2

[0029] Embodiment 2. 304 stainless steel strips of 8×0.4 (8mm in width and 0.4mm in thickness) are selected, and the filling rate is 32%. After drawing and reducing the diameter, a welding wire with a diameter of 1.6 mm is obtained.

[0030] The mass percentage of each alloy composition in the powder core is: the mass percentage of chromium is 40%, the mass percentage of nickel is 48%, the mass percentage of medium manganese is 2%, and the mass percentage of No. 75 ferrosilicon is 6%. The mass percentage of rare earth is 4%. The composition of mixed rare earth powder is: La 2 o 3:31%, CeO 2 :47%,Pr 2 o 3 :6%,Nd 2 o 3 : 16%. The welding current used during welding is 100A, and the welding voltage is 25V. The welding shielding gas is pure argon, and the shielding gas flow rate is 15L / min.

Embodiment 3

[0031] Embodiment 3. A 304 stainless steel strip of 10×0.4 (10 mm in width and 0.4 mm in thickness) is selected, and the filling rate is 32%. After drawing and reducing the diameter, a welding wire with a diameter of 2.0 mm is obtained.

[0032] The mass percent of each alloy composition in the powder core is: the mass percent of chromium is 34%, the mass percent of nickel is 53%, the mass percent of medium manganese is 4%, the mass percent of No. 75 ferrosilicon is 4%, mix The mass percentage of rare earth is 5%. The composition of mixed rare earth powder is: La 2 o 3 :31%, CeO 2 :47%,Pr 2 o 3 :5%,Nd 2 o 3 :17%. The welding current used during welding is 150A, and the welding voltage is 26V. The welding shielding gas is pure argon, and the shielding gas flow rate is 20L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com