A gas-shielded mineral powder type 314 heat-resistant stainless steel flux-cored welding wire

A technology of heat-resistant stainless steel and flux-cored welding wire, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve problems such as inability to meet service conditions, no special 314 stainless steel welding materials, and insufficient content of alloying elements. Achieve the effects of avoiding the performance degradation of welded joints, convenient and efficient mass production, and a wide range of welding current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

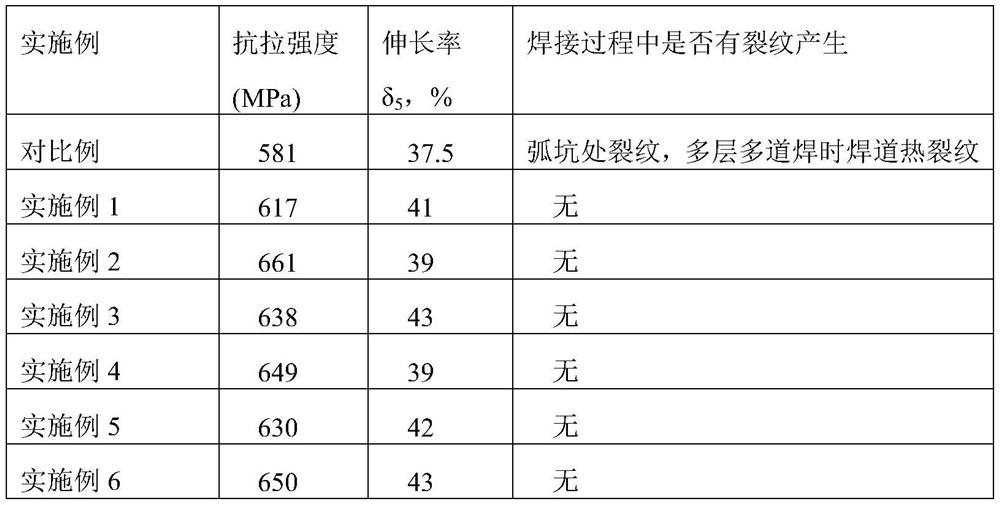

Examples

Embodiment 1

[0038] Embodiment 1. A 314 stainless steel strip of 10×0.4 (10 mm in width and 0.4 mm in thickness) is selected, and the filling rate is 24%. After drawing and reducing the diameter, a welding wire with a diameter of 1.2 mm is obtained.

[0039] The mass percent of each alloy composition in the powder core is:

[0040] The mass percentage of rutile is 18%; the mass percentage of marble is 4%; the mass percentage of feldspar is 5%; the mass percentage of fluorite is 4%; the mass percentage of quartz is 5% %; the mass percentage of bismuth oxide is 0.1%; the mass percentage of aluminum oxide is 3%; the mass percentage of magnesia is 2%. The mass percentage of metal chromium powder is 25%; the mass percentage of metal nickel is 22%; the mass percentage of electrolytic manganese metal is 3%; the mass percentage of No. 45 ferrosilicon is 2%; the mass percentage of mixed rare earth The percentage content is 3%; the mass percentage content of ferromolybdenum (same as before) is 3%; t...

Embodiment 2

[0042] Embodiment 2. A 10×0.4 (10 mm in width and 0.4 mm in thickness) 314 stainless steel strip is selected, and the filling rate is 28%. After drawing and reducing the diameter, a welding wire with a diameter of 1.6 mm is obtained.

[0043] The mass percentage of rutile is 20%; the mass percentage of marble is 3%; the mass percentage of feldspar is 5%; the mass percentage of fluorite is 6%; the mass percentage of quartz is 5% %; the mass percentage of bismuth oxide is 0.2%; the mass percentage of aluminum oxide is 3%; the mass percentage of magnesia is 3%. The mass percentage of metal chromium powder is 20%; the mass percentage of metal nickel is 20%; the mass percentage of electrolytic manganese metal is 4%; the mass percentage of No. 45 ferrosilicon is 5%; the mass percentage of mixed rare earth The percentage content is 4%; the mass percentage content of ferromolybdenum (same as before) is 1%; the balance of reduced iron powder. The composition of mixed rare earth powde...

Embodiment 3

[0045] Embodiment 3. A 314 stainless steel strip of 10×0.4 (width 10 mm, thickness 0.4 mm) is selected, and the filling rate is 26.5%. After drawing and reducing the diameter, a welding wire with a diameter of 1.6 mm is obtained.

[0046] The mass percentage of rutile is 24%; the mass percentage of marble is 3%; the mass percentage of feldspar is 4%; the mass percentage of fluorite is 4%; the mass percentage of quartz is 4% %; the mass percentage of bismuth oxide is 0.3%; the mass percentage of aluminum oxide is 3%; the mass percentage of magnesia is 3%. The mass percentage of metal chromium powder is 20%; the mass percentage of metal nickel is 18%; the mass percentage of electrolytic manganese metal is 3%; the mass percentage of No. 45 ferrosilicon is 2%; the mass percentage of mixed rare earth The percentage content is 3%; the mass percentage content of ferromolybdenum is 5%; the balance of reduced iron powder. The composition of mixed rare earth powder is: La 2 o 3 :30%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com