A method of using a hot-dip galvanized sheet slag removal roll

A technology of hot-dip galvanized sheet and slag coil, which is applied in the direction of hot-dip galvanizing process, coating, metal material coating process, etc., and can solve the problem of reducing production efficiency, reducing economic benefits, and adverse effects of continuous production of hot-dip galvanizing production lines, etc. problem, achieve the effect of improving production efficiency and reducing slag roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

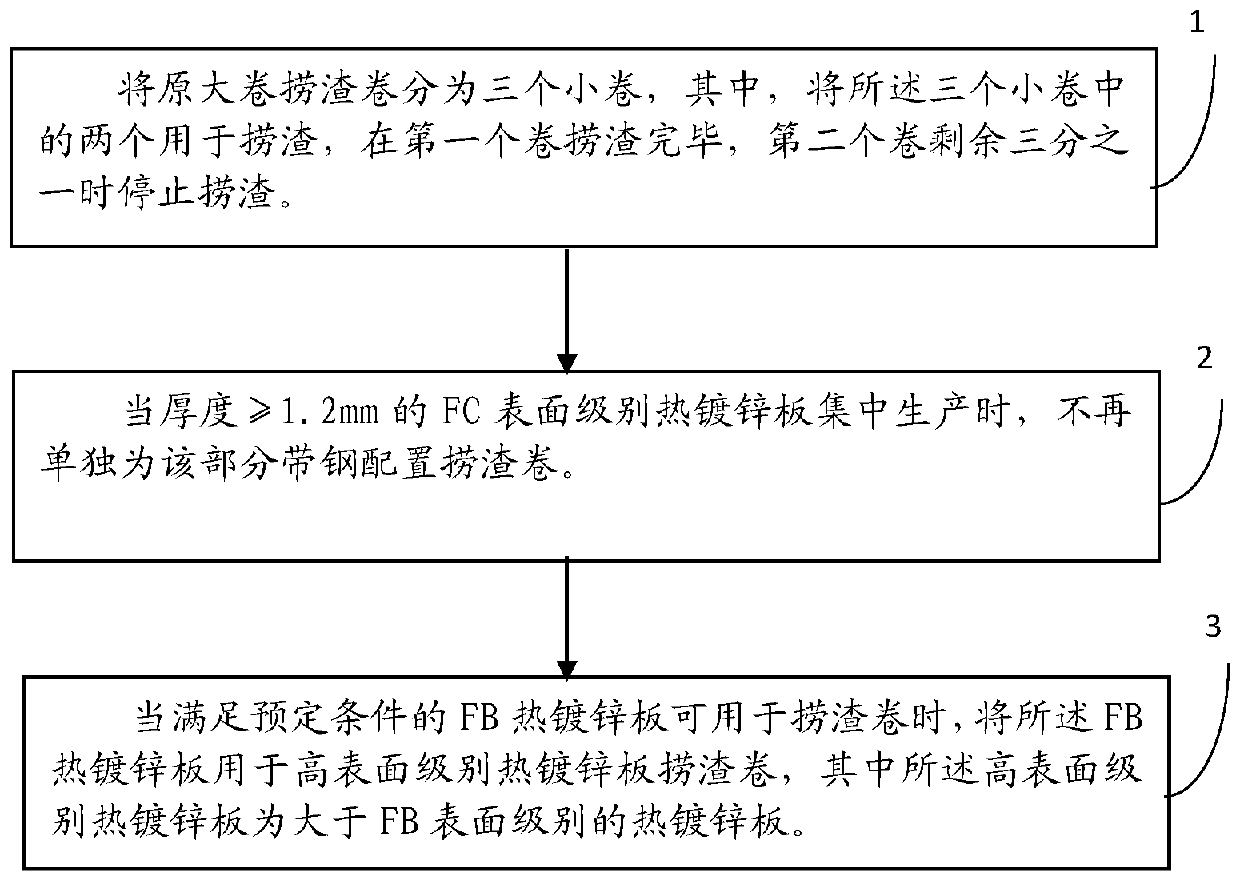

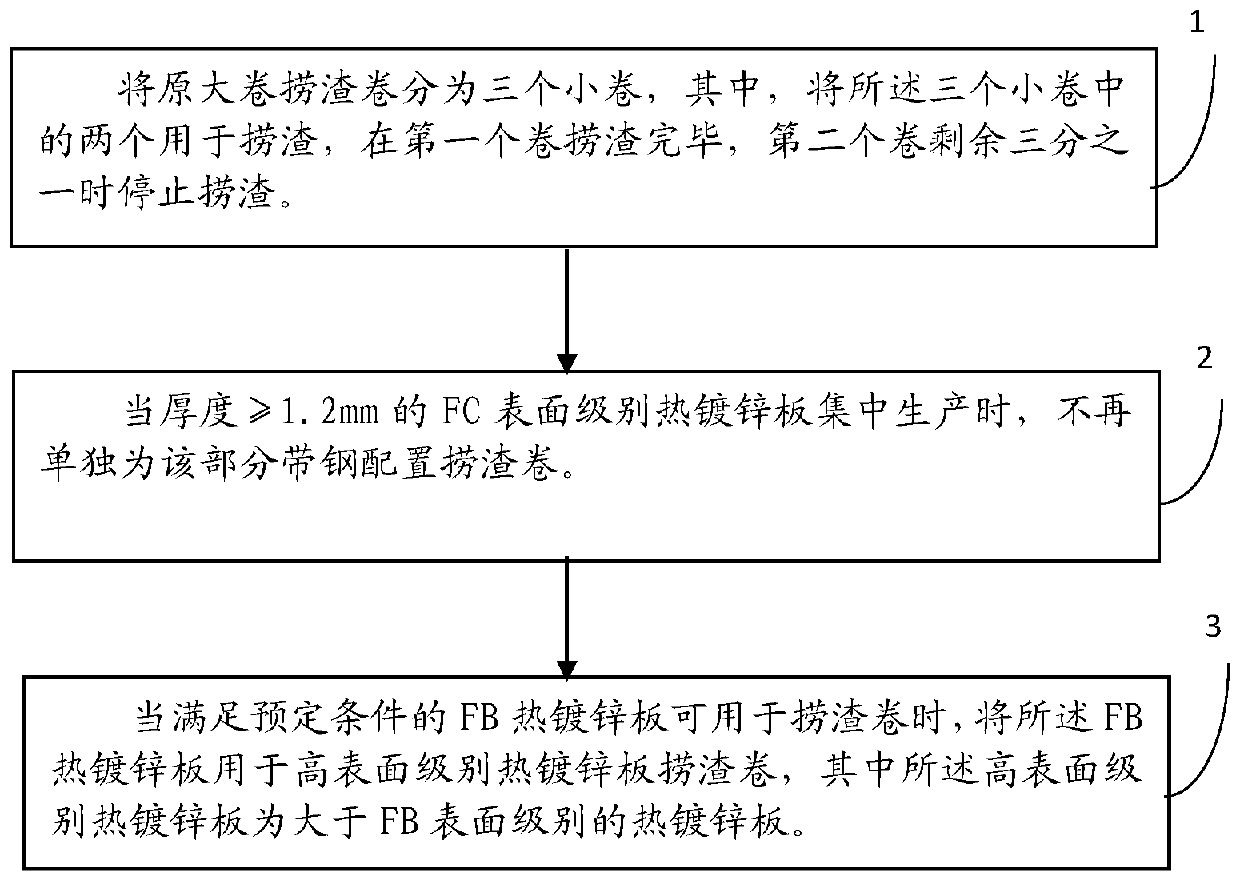

[0024] figure 1 It is a schematic flowchart of a method for using a hot-dip galvanized sheet slag removal roll in an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0025] Step 1: Divide the original large roll for slag removal into three small rolls, wherein two of the three small rolls are used for slag removal. One-third of the time stop slag removal.

[0026] Further, the weight of the original large roll of slag roll is 25-34 tons.

[0027] Specifically, the said original large coil slag coil refers to that in the prior art, when steel mills produce FC surface-grade strip steel and FD surface-grade strip steel, they need to invest in a large coil slag at a certain production interval. The slag roll is used to remove the slag. Moreover, the length of the original large roll with slag removal is 2500-3500 meters, and the weight of the roll is 25-34 tons. Therefore, the original large roll with slag removal is divided into three sm...

Embodiment 2

[0038] A method for using a hot-dip galvanized sheet slag removal roll of the present invention is described in detail below, specifically as follows:

[0039] In the embodiment of the present invention, a method of using hot-dip galvanized sheet slag rolls is provided. First, 5 rolls of the original FC surface level and FD surface level hot-dip galvanized automobile sheets are selected to count the surface slag rolls. Defect distribution, if the zinc slag defect level on the surface of the strip can reach the FD standard, it means that the slag removal is complete. When the length of the slag removal roll reaches 50%, the slag removal is more thorough. The original large slag removal roll is divided into three small rolls. Two of the three small rolls are used for slag removal, and the slag removal is stopped when the remaining third of the second small roll is left; then, when the FC surface level hot-dip galvanized with a thickness ≥ 1.2mm When the automobile sheet is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com