Squint window structure for hot cell

A technology of peeping window and hot chamber, which is applied in the field of peeping window structure of hot chamber to achieve the effects of facilitating observation and operation, improving the accuracy and convenience of operation, and avoiding radiation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

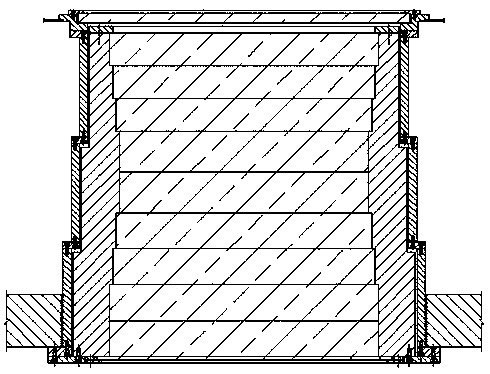

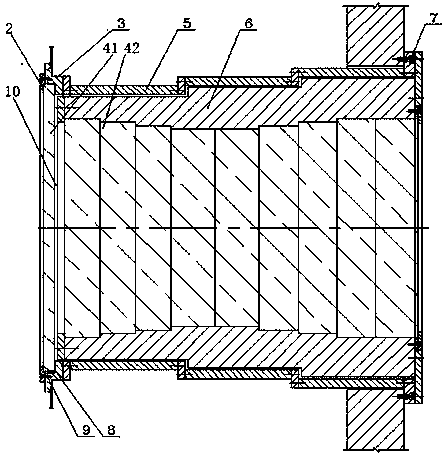

[0026] A hot cell viewing window structure, such as Figure 1-3 As shown, it includes a viewing window pressure plate 1, an inner glass pressing frame 2, a viewing window reinforcement frame 3, a first viewing window glass 41, a second viewing window glass 42 and a viewing window outer frame 5; the first viewing window glass 4 is located on the inner side Between the glass pressure frame 2 and the peep window reinforcement frame 3, the inner glass pressure frame 2 is used to fix and press the first peep window glass 4 in the peep window reinforcement frame 3; the peep window outer frame 5 is fixed on the peep window On the side of the reinforcement frame 3 opposite to the inner glass pressure frame 2 , the second peep window glass 42 is fixed in the peep window outer frame 5 . Wherein the first viewing window glass 41 and the second viewing window glass 42 are both lead glass.

[0027] The second viewing window glass 42 is a plurality of pieces, and each second viewing window...

Embodiment 3

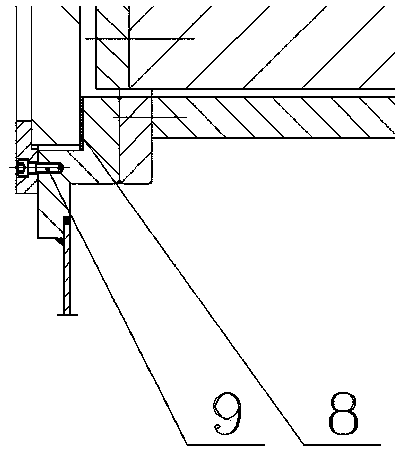

[0030] This embodiment is similar to Embodiment 1 or 2, and further, there is a gap 10 between the first peep window glass 41 and the second peep window glass 42; Gasket 8 is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com