Drive module with parallel input axes for propulsive and torque-vectoring inputs

A technology for driving modules and axes, which can be used in transportation and packaging, motor vehicles, transmissions, etc., and can solve problems such as difficulty in loading into vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

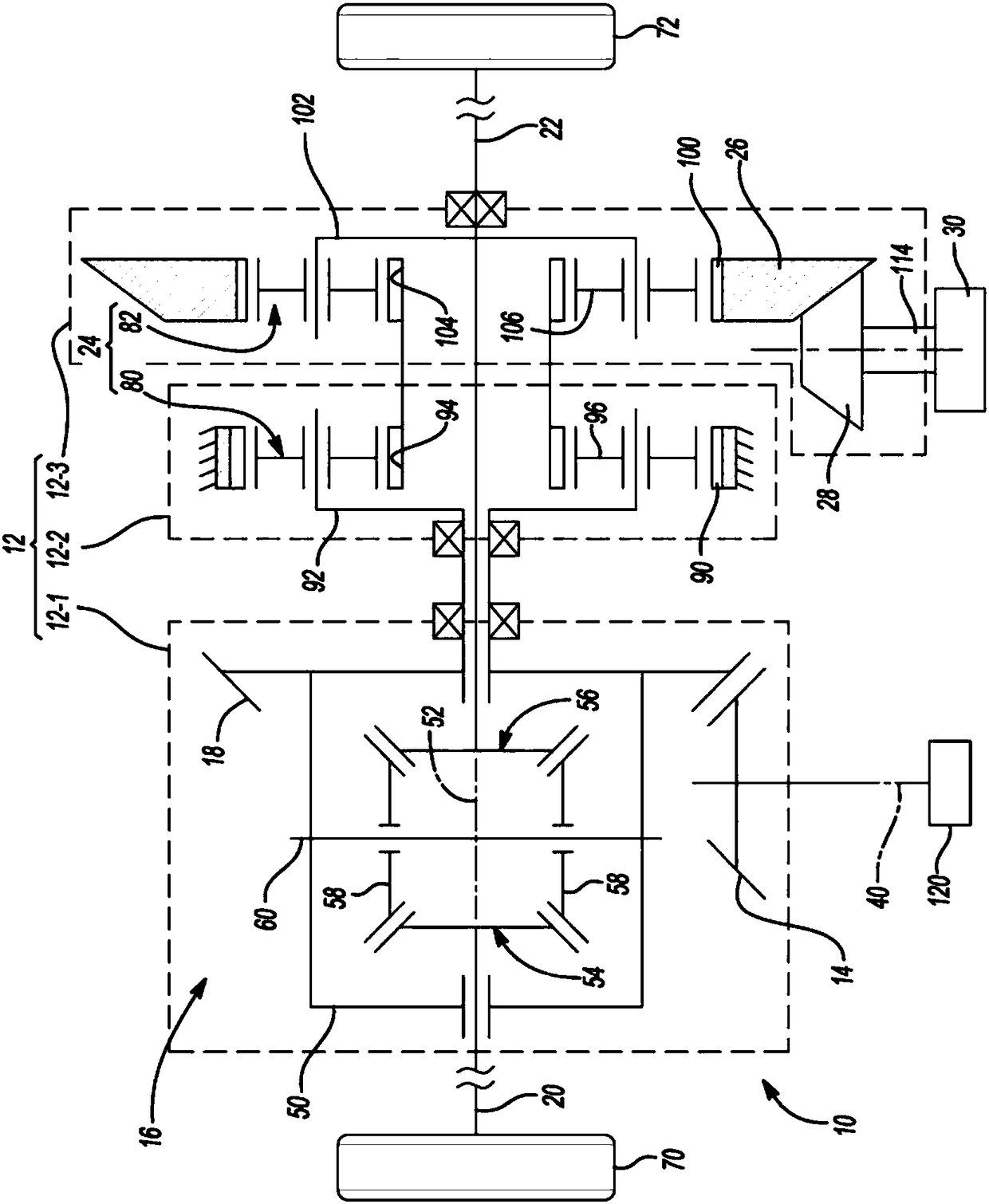

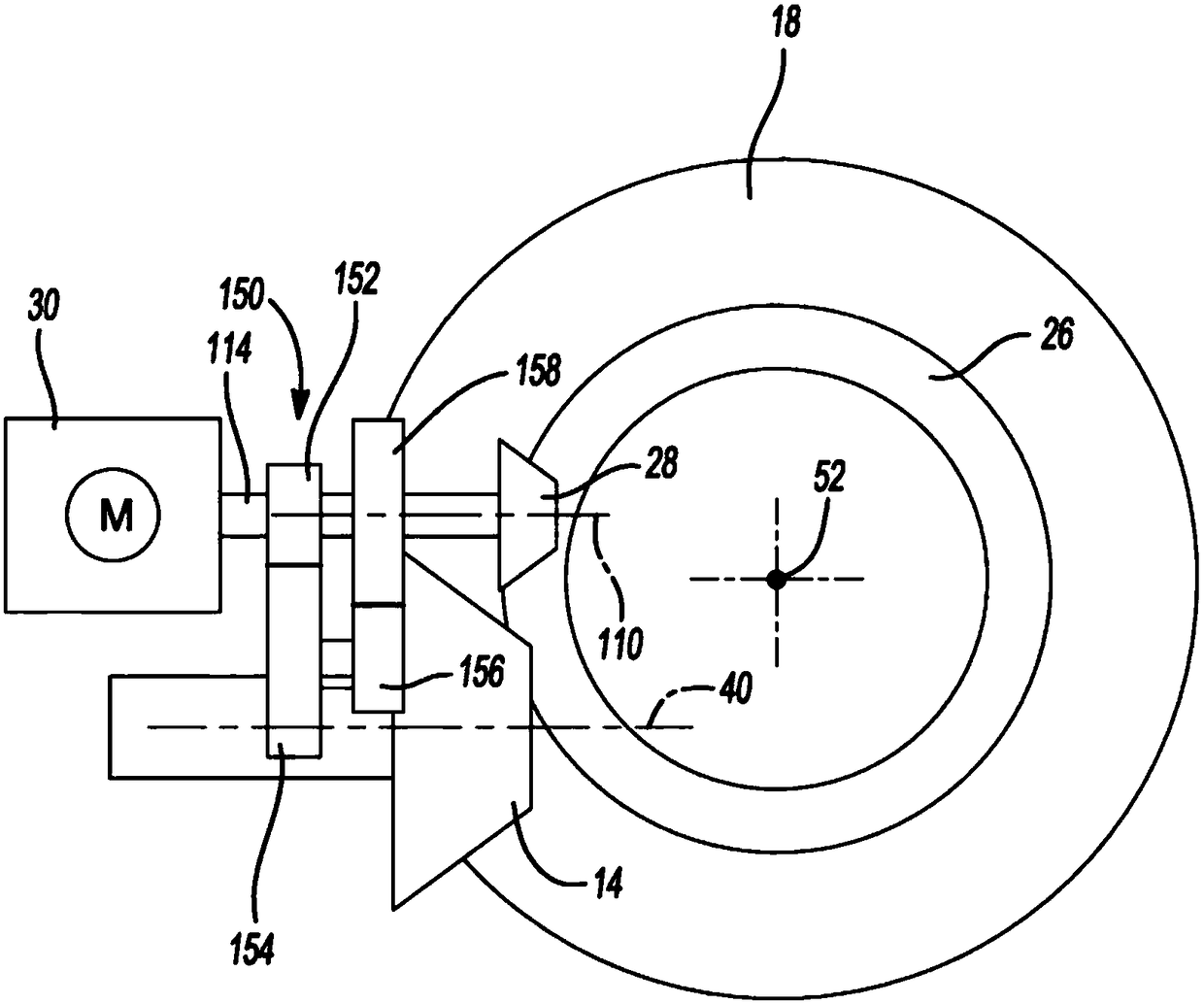

[0020] See attached figure 1 , a drive module constructed in accordance with the teachings of the present disclosure is indicated generally by the reference numeral 10 . The drive module 10 may include a housing assembly 12, an input pinion 14, a differential assembly 16, a differential ring gear 18, a first half shaft 20 and a second half shaft 22, respectively, a transmission 24, a first bevel gear 26, Second bevel gear 28 and electric motor 30 .

[0021] In the example provided, housing assembly 12 includes a plurality of discrete housing members 12-1, 12-2, and 12-3 coupled together. However, it will be appreciated that housing assembly 12 may be configured in any number of discrete housing components.

[0022] The input pinion 14 may be received in the housing assembly 12 and is rotatable about a first axis 40 .

[0023] The differential assembly 16 may be received in the housing assembly 12 and may include a differential input 50 rotatable about a second axis 52 that ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap