Sludge discharge machine for sewage treatment

A technology for sewage treatment and sludge discharger, which is applied to the feeding/discharging device, chemical instrument and method, separation method, etc. of the sedimentation tank. , to improve the service life and avoid the effect of excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

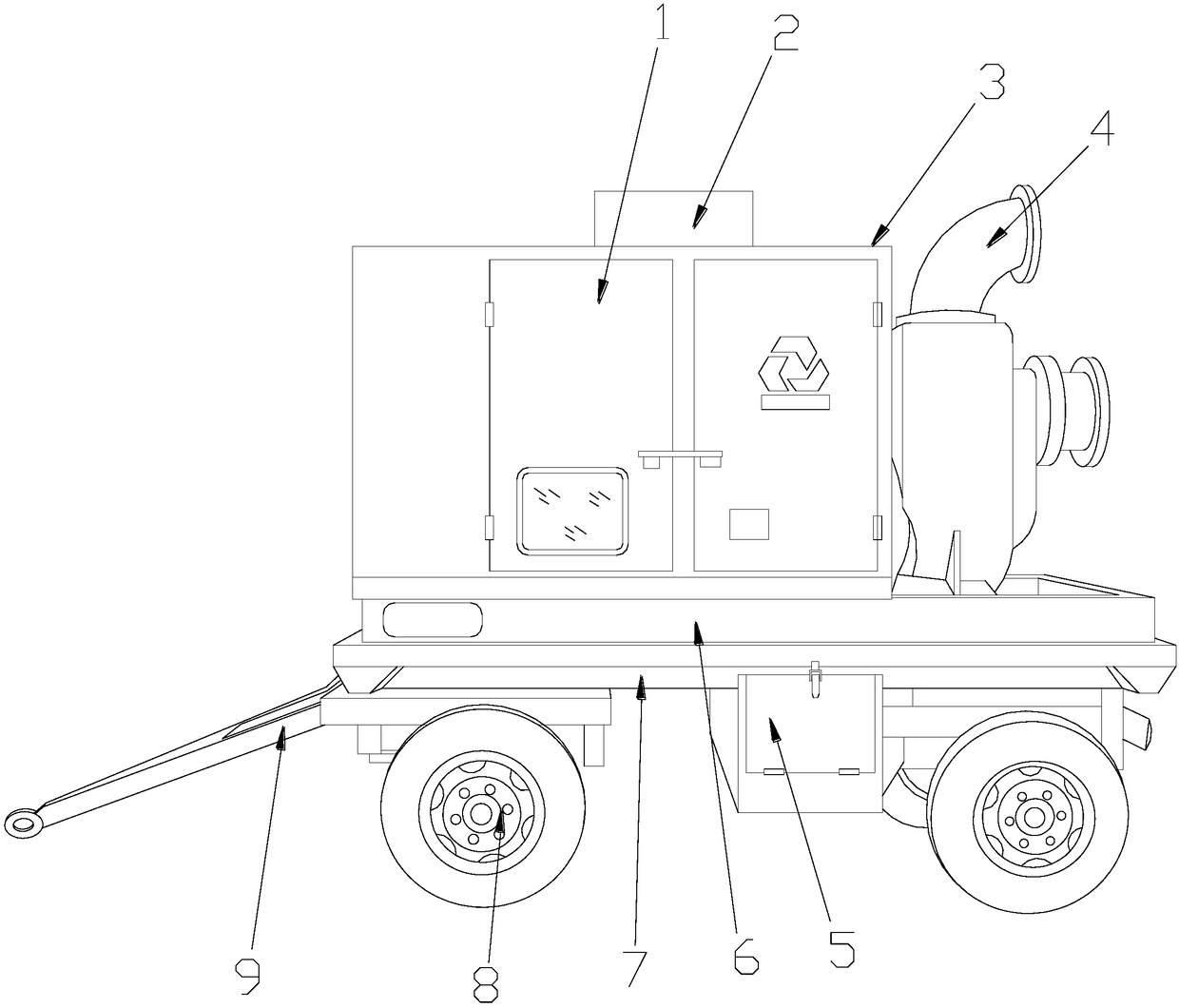

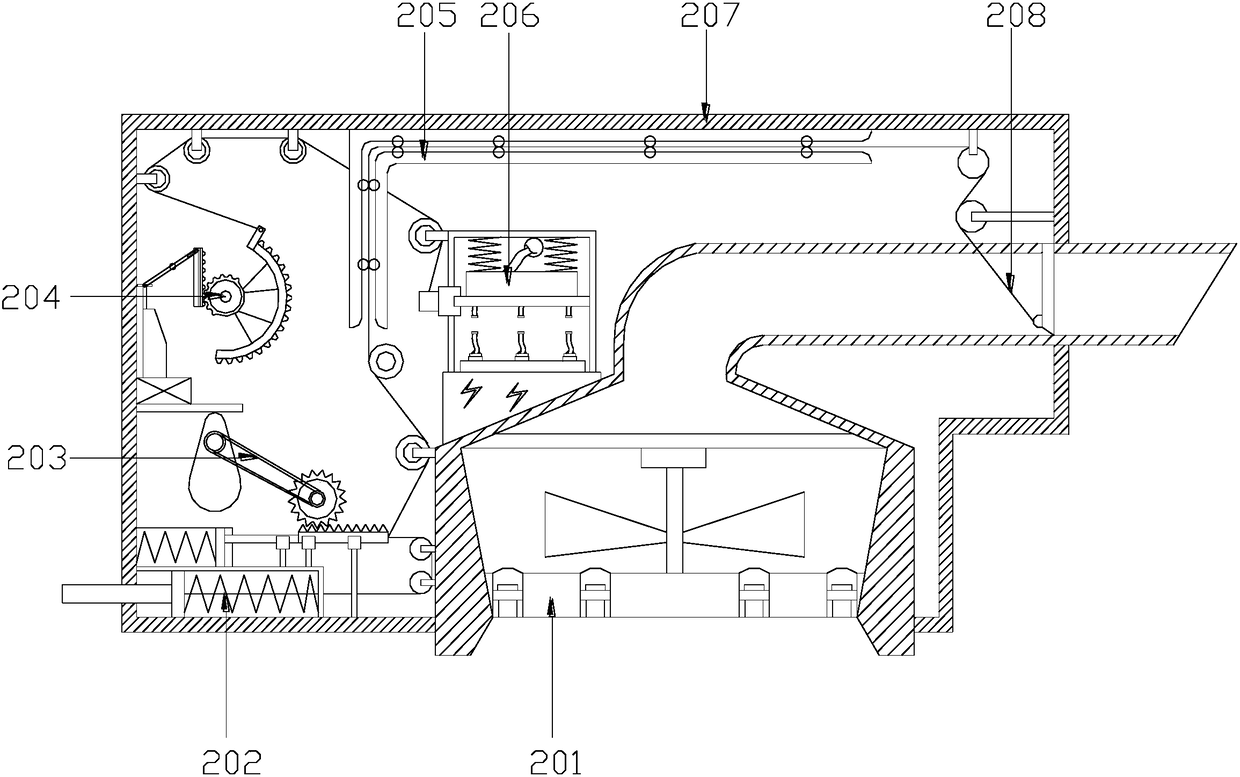

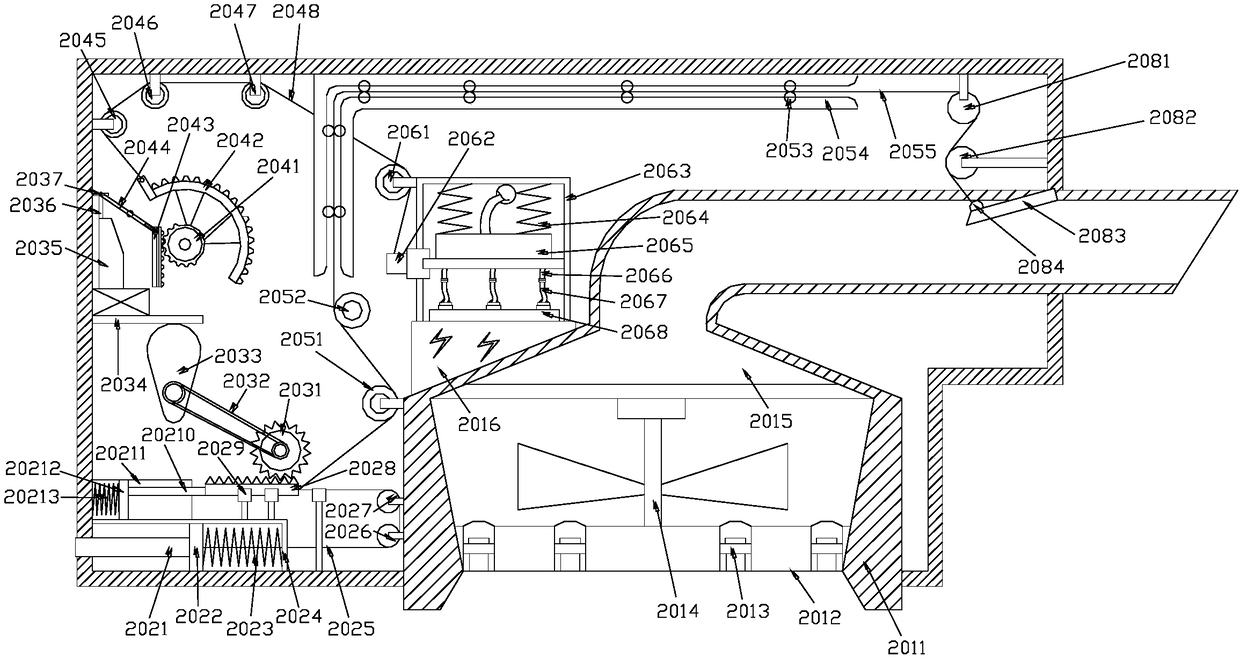

[0025] see Figure 1-Figure 5 , the present invention provides a sludge discharger for sewage treatment: its structure includes a protective door 1, a cooling device 2, a main engine 3, a dredging pump 4, a tool box 5, a main engine bottom plate 6, a mobile frame 7, wheels 8, and a portable pull rod 9. There are four wheels 8 in total, and they are installed on the front and rear sides of the mobile frame 7 by buckling. The front end of the mobile frame 7 is provided with a portable pull rod 9 and connected by a buckle. The bottom of the host chassis 6 is fastened with the upper end of the mobile frame 7. The lower end of the middle of the mobile chassis 7 is provided with a toolbox 5 and is integrally formed. The bottom of the host 3 is mounted on the chassis 6 of the host by buckling On the upper end, the top of the main machine 3 is provided with a groove for movable installation of the cooling device 2, the described dredge pump 4 is installed on the right side of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com