Lathe chuck fixture for stainless steel forged rail machining

A lathe chuck, stainless steel technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inaccurate processing accuracy, inability to process both ends of forged rails, and inconsistent processing dimensions, etc., to achieve guaranteed accuracy , The effect of shortening the processing time of a single piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

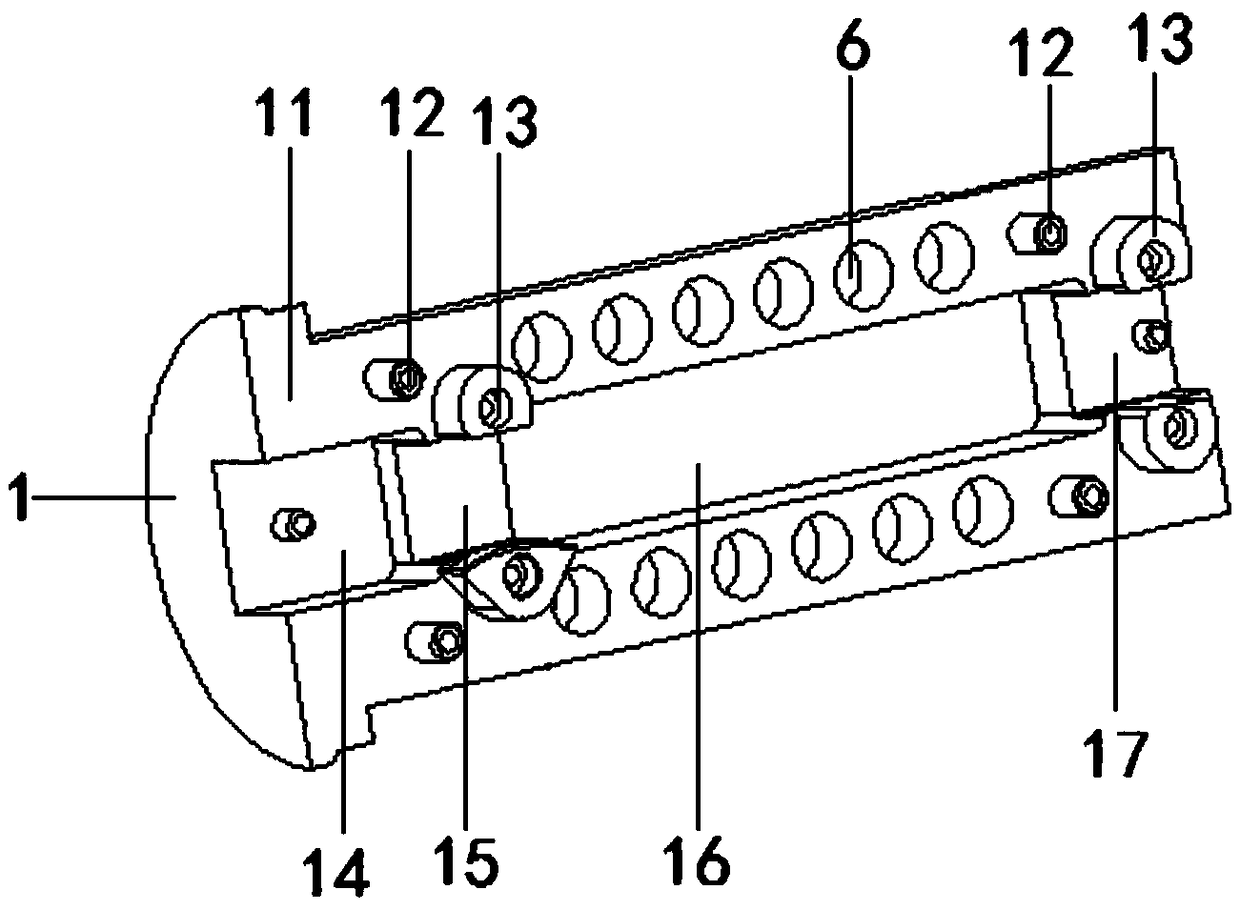

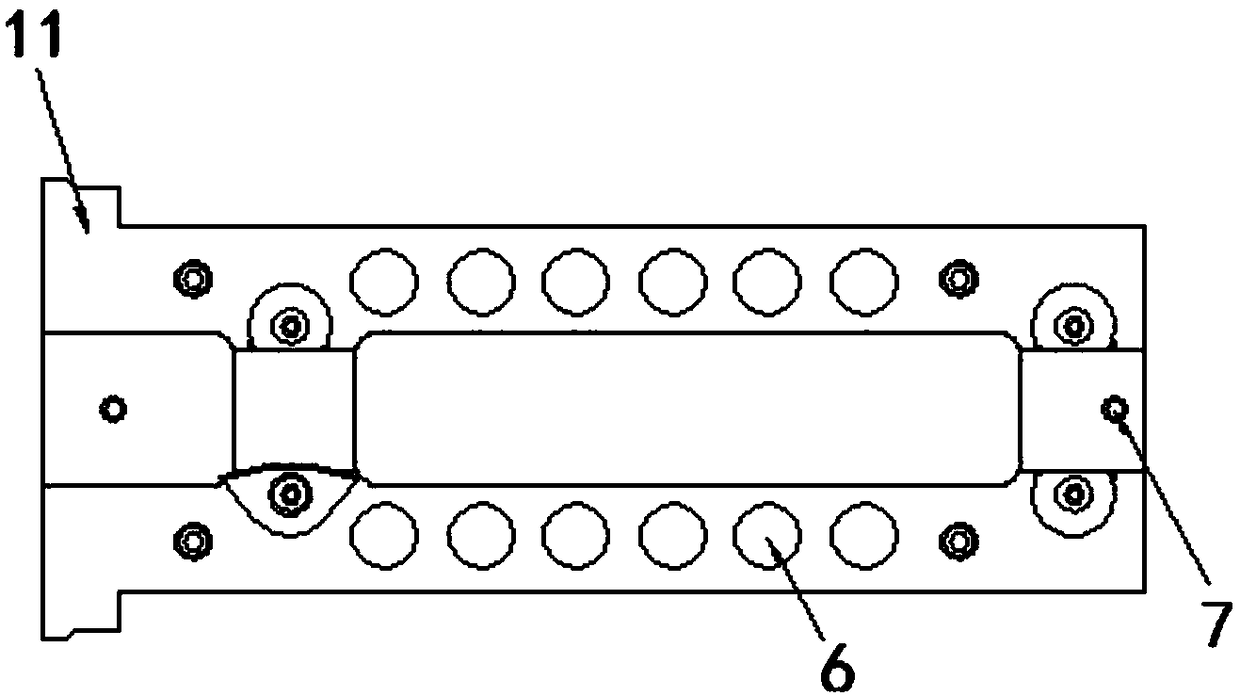

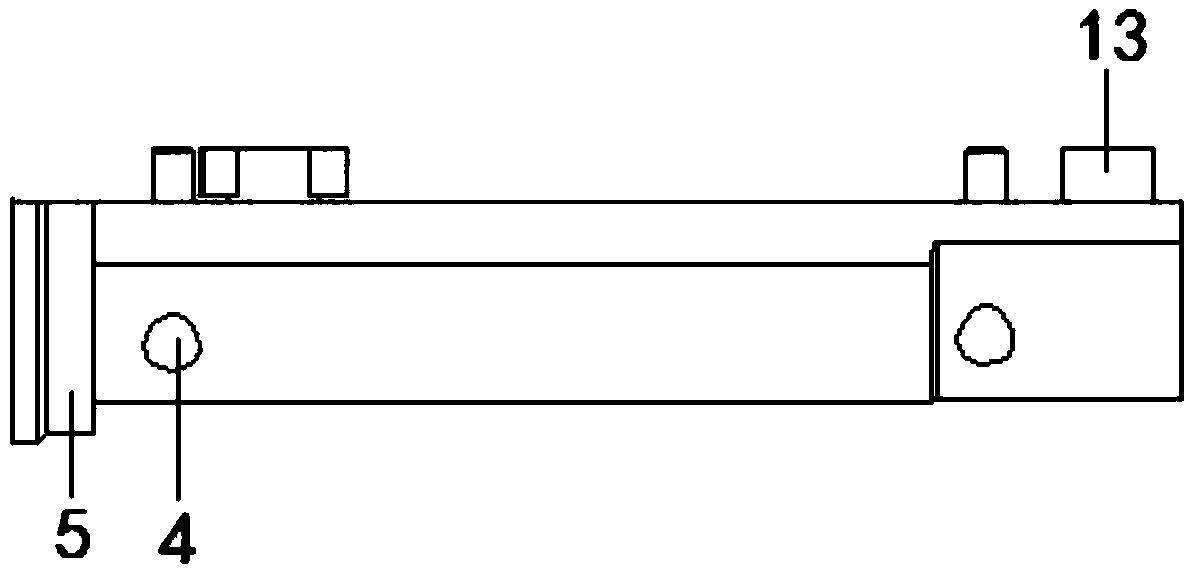

[0026] Such as Figure 1-6 , a lathe chuck fixture for processing stainless steel forged rails, including an upper die 1 and a lower die 2 cooperating with the upper die 1, both of the upper die 1 and the lower die 2 are semi-cylindrical structures, and the upper die 1 and the lower die 2 There is a cavity inside that matches the shape of the forged rail workpiece 3. The upper mold 1 and the lower mold 2 engage the forged rail workpiece 3 between them and form a cylindrical structure, wherein the upper mold 1 is aligned along the axial direction Symmetrical upper mold bosses 11 are provided on both sides of the upper mold boss, and upper mold bosses 11 are provided with positioning pins 12 and pressure plates 13, and upper mold sinking grooves 14, first square platform 15, upper mold Cavity 16, second square platform 17, the two sides of lower die 2 along the axial direction are provided with symmetrical lower die bosses 21, lower die bosses 21 are provided with positioning pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com