Printing consumable composite exhaust device

A technology of exhaust device and printing consumables, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc. It can solve problems such as surface adverse effects, generation of air bubbles, and impact on printing quality, so as to prevent the generation of air bubbles and ensure the quality of work , to ensure the effect of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

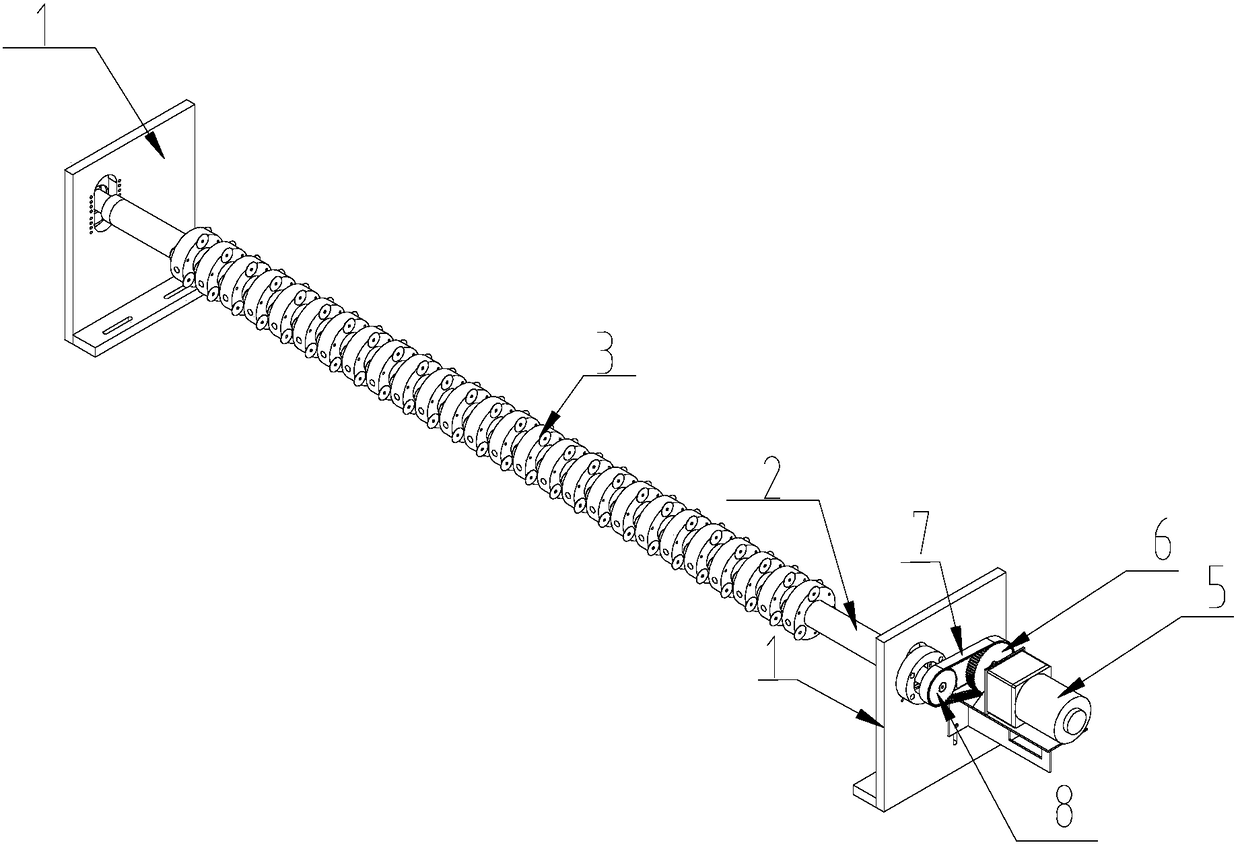

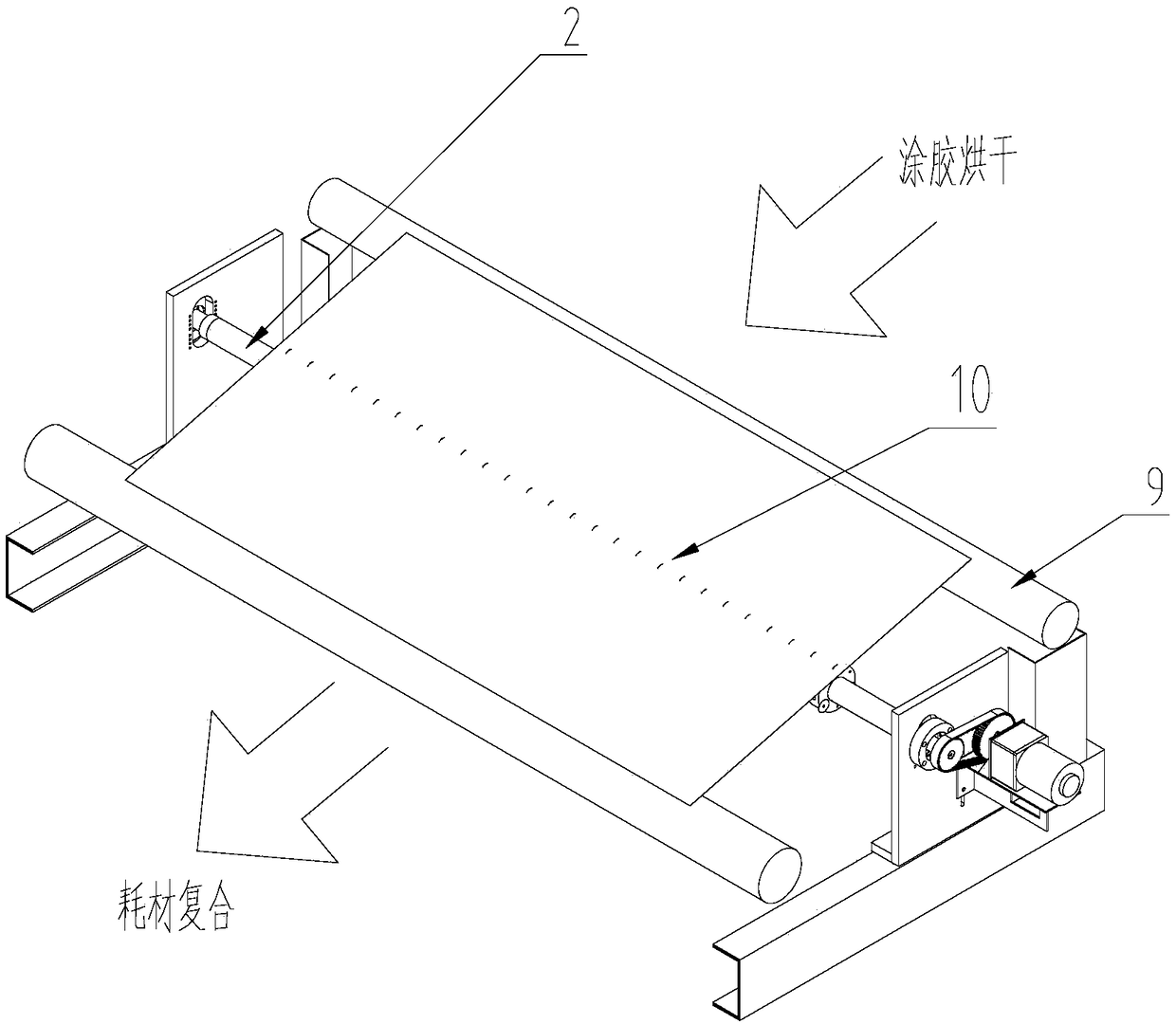

[0024] Embodiment: A compound exhaust device for printing consumables, the exhaust device is located between the gluing and drying station and the compounding station, and is facing the non-gluing of the consumables entering the compounding station from the gluing and drying station noodle.

[0025] The exhaust device includes an exhaust knife shaft 2, several sets of exhaust knife groups located on the exhaust knife shaft 2, and a driving transmission set installed at the end of the exhaust knife shaft 2 to drive the exhaust knife shaft 2 to rotate.

[0026] The arrangement direction of the exhaust knife shaft 2 is perpendicular to the forward direction of the consumables 10, and a fixed side plate 1 is arranged at both ends of the exhaust knife shaft 2, and the exhaust knife shaft 2 is fixed on the glue coating and drying station and the Between composite stations.

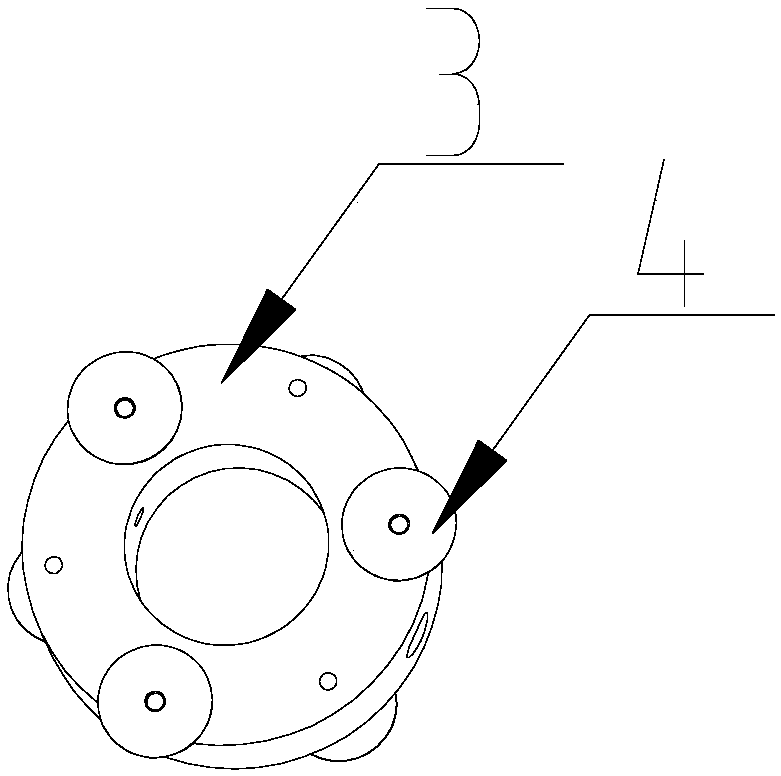

[0027] Each group of exhaust knife groups is sleeved on the exhaust knife shaft 2 at equal intervals. Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com