Battery box concealed mounting structure for Z-shaped vehicle beam pipe

A hidden installation and battery box technology, applied in structural parts, electric power devices, battery pack components, etc., can solve the problem of the torsion resistance and deformation resistance of the beam tube, the battery box and the battery cavity size do not match, the frame is easy to Deformation and other problems occur, to achieve the effect of reasonable structural design, improved strength and anti-deformation ability, and prevention of arbitrary removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and cannot limit the protection scope of the present invention.

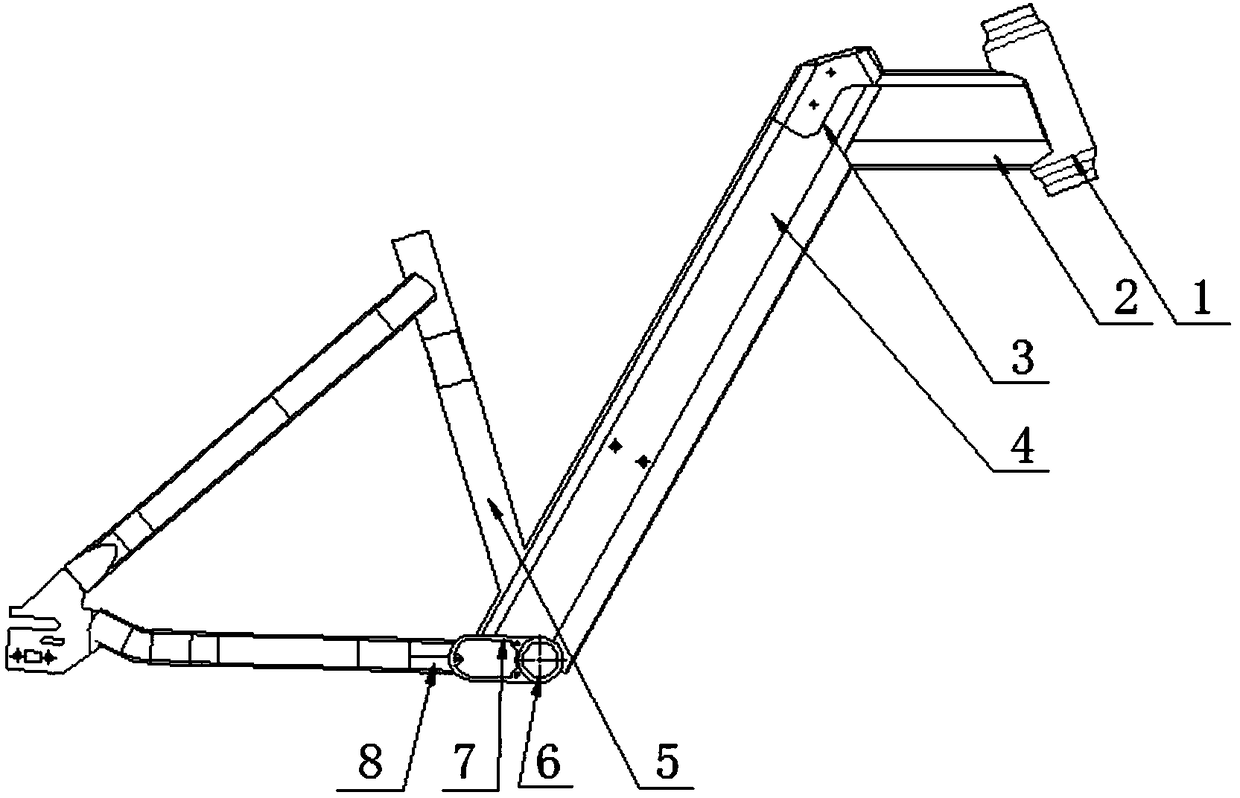

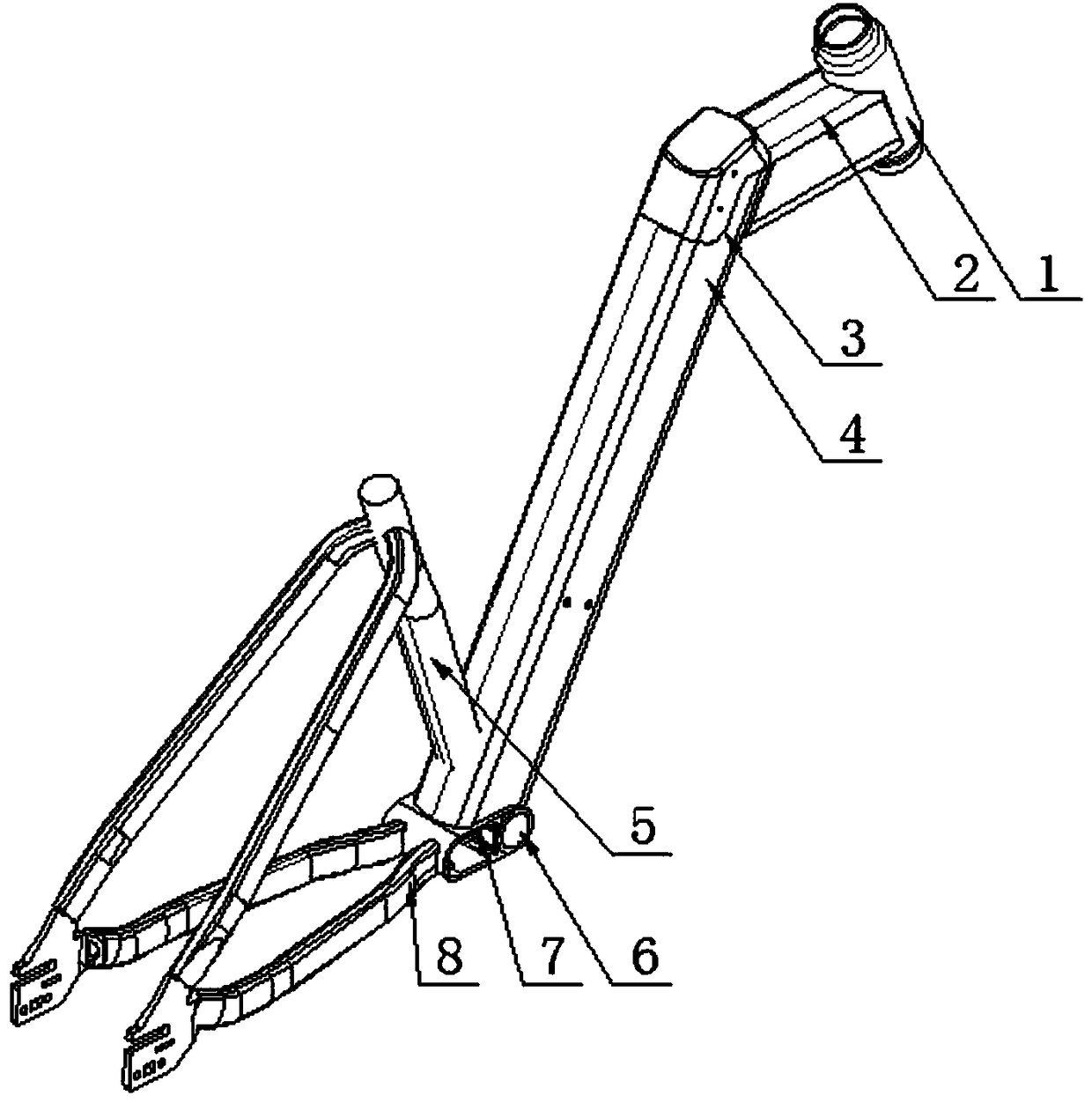

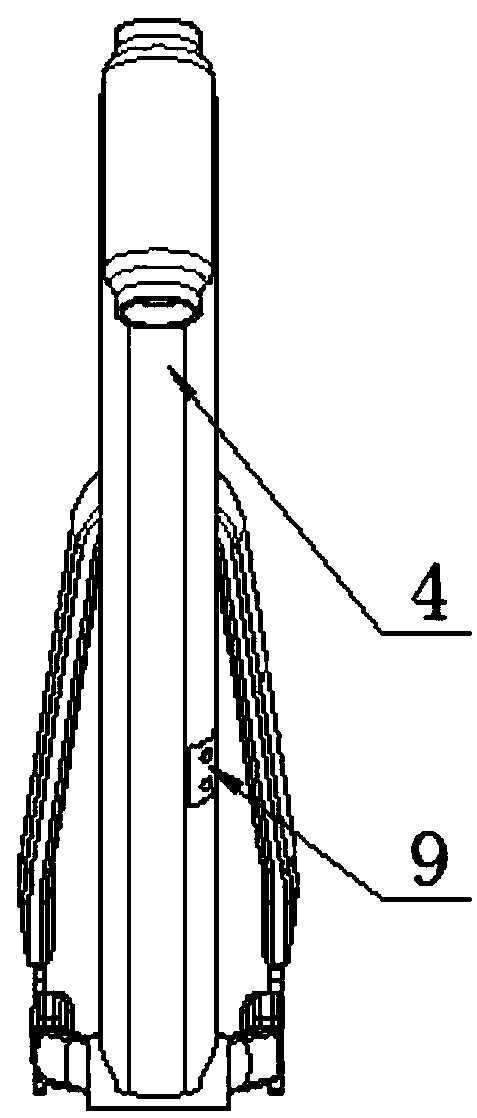

[0029] A Z-shaped car beam tube battery box hidden installation structure includes a car beam tube 4, the car beam tube is a hollow structure, and the car beam tube is made of aluminum alloy. The pipe wall at the bottom surface of the port of the vehicle beam pipe is fixedly connected with a connecting pipe 2, and the connecting pipe at the port of the vehicle beam pipe is arranged horizontally and fixedly installed with the riser pipe 1. A battery box installation entrance 3 is formed at the port of the beam tube. The battery box 12 can be inserted and removed coaxially from the battery box installation entrance at the upper end of the car beam tube without cutting and slotting on the tube body of the car beam tube, thereby effectively improving the over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com